Beruflich Dokumente

Kultur Dokumente

CE8381-Strength of Materials and Fluid Mechanics and Machinery Laboratory

Hochgeladen von

Velmurugan CCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

CE8381-Strength of Materials and Fluid Mechanics and Machinery Laboratory

Hochgeladen von

Velmurugan CCopyright:

Verfügbare Formate

ANNA UNIVERSITY, CHENNAI

AFFILIATED INSTITUTIONS

B.E. ELECTRICAL AND ELECTRONICS ENGINEERING

REGULATIONS – 2017

CHOICE BASED CREDIT SYSTEM

CE8381 STRENGTH OF MATERIALS AND FLUID MECHANICS AND MACHINERY

LABORATORY LT PC

0 0 4 2

OBJECTIVES:

To study the mechanical properties of materials when subjected to different types of loading.

To verify the principles studied in Fluid Mechanics theory by performing experiments in lab.

STRENGTH OF MATERIALS 30

LIST OF EXPERIMENTS

1. Tension test on a mild steel rod

2. Double shear test on Mild steel and Aluminium rods

3. Torsion test on mild steel rod

4. Impact test on metal specimen

5. Hardness test on metals - Brinnell and Rockwell Hardness Number

6. Deflection test on beams

7. Compression test on helical springs

8. Strain Measurement using Rosette strain gauge

9. Effect of hardening- Improvement in hardness and impact resistance of steels.

10. Tempering- Improvement Mechanical properties Comparison

(i) Unhardened specimen

(ii) Quenched Specimen and

(iii) Quenched and tempered specimen.

11. Microscopic Examination of

(i) Hardened samples and

(ii) Hardened and tempered samples.

OUTCOME:

Ability to perform Tension, Torsion, Hardness, Compression, and Deformation test on Solid

materials.

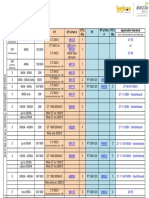

LIST OF EQUIPMENT FOR BATCH OF 30 STUDENTS

S.NO. NAME OF THE EQUIPMENT QTY.

1 Universal Tensile Testing machine with double 1 shear attachment – 40 Ton Capacity 1

2 Torsion Testing Machine (60 NM Capacity) 1

3 Impact Testing Machine (300 J Capacity) 1

4 Brinell Hardness Testing Machine 1

5 Rockwell Hardness Testing Machine 1

6 Spring Testing Machine for tensile and compressive loads (2500 N) 1

7 Metallurgical Microscopes 3

8 Muffle Furnace (800 C) 1

FLUID MECHANICS AND MACHINES LABORATORY 30

LIST OF EXPERIMENTS

1. Determination of the Coefficient of discharge of given Orifice meter.

2. Determination of the Coefficient of discharge of given Venturi meter.

3. Calculation of the rate of flow using Rota meter.

4. Determination of friction factor for a given set of pipes.

5. Conducting experiments and drawing the characteristic curves of centrifugal pump/ submergible pump

6. Conducting experiments and drawing the characteristic curves of reciprocating pump.

7. Conducting experiments and drawing the characteristic curves of Gear pump.

8. Conducting experiments and drawing the characteristic curves of Pelton wheel.

9. Conducting experiments and drawing the characteristics curves of Francis turbine.

10. Conducting experiments and drawing the characteristic curves of Kaplan turbine.

TOTAL: 60 PERIODS

OUTCOMES:

Upon completion of this course, the students will be able to:

Perform Tension, Torsion, Hardness, Compression, and Deformation test on Solid materials.

Use the measurement equipments for flow measurement.

Perform test on different fluid machinery.

LIST OF EQUIPMENT FOR A BATCH OF 30 STUDENTS

S. NO. NAME OF THE EQUIPMENT Qty.

1. Orifice meter setup 1

2. Venturi meter setup 1

3. Rotameter setup 1

4. Pipe Flow analysis setup 1

5. Centrifugal pump/submergible pump setup 1

6. Reciprocating pump setup 1

7. Gear pump setup 1

8. Pelton wheel setup 1

9. Francis turbine setup 1

10. Kaplan turbine setup 1

Das könnte Ihnen auch gefallen

- Unit 5 Cad StandardsDokument57 SeitenUnit 5 Cad StandardsArun K K100% (1)

- Dynamics Lab Manual - ME6511Dokument66 SeitenDynamics Lab Manual - ME6511vinothNoch keine Bewertungen

- Sanjivani K. B. P. Polytechnic Kopargaon: Department of MechatronicsDokument35 SeitenSanjivani K. B. P. Polytechnic Kopargaon: Department of MechatronicsChaitanya YengeNoch keine Bewertungen

- Lifeboat Engine Operation Manual 380JDokument29 SeitenLifeboat Engine Operation Manual 380JDuarte100% (2)

- Kinematics of Machine ToolsDokument28 SeitenKinematics of Machine ToolsRohit Kaushik100% (6)

- Me 8381 Computer Aided Machine Drawing III SemDokument99 SeitenMe 8381 Computer Aided Machine Drawing III Semsmguna1967% (6)

- Fea Lab Manual 18mel68 July 2021Dokument49 SeitenFea Lab Manual 18mel68 July 2021md bashirul haqueNoch keine Bewertungen

- Thread and Gear MeasurementDokument142 SeitenThread and Gear Measurementshiva100% (1)

- CAD Lab ManualDokument89 SeitenCAD Lab ManualDhamotharan S100% (1)

- 4.mechanical Measurements and MetrologyDokument6 Seiten4.mechanical Measurements and MetrologyVikram Rao100% (1)

- Physics: OxfordDokument224 SeitenPhysics: OxfordMusic Life100% (1)

- Building Services AssignmentDokument19 SeitenBuilding Services AssignmentRoushell KhanNoch keine Bewertungen

- DSM Carbon Footprint StudyDokument12 SeitenDSM Carbon Footprint StudyAbdul Rahman100% (1)

- Me8511 Kinematics and Dynamics LabDokument3 SeitenMe8511 Kinematics and Dynamics LabRatheesh VjrNoch keine Bewertungen

- Ce3481 Set1Dokument3 SeitenCe3481 Set1THIRUMALAINoch keine Bewertungen

- ME8511-Kinematics and Dynamics Laboratory: Fifth SemesterDokument2 SeitenME8511-Kinematics and Dynamics Laboratory: Fifth SemesterSiva RamanNoch keine Bewertungen

- Assigment 1 - SWIPEDokument2 SeitenAssigment 1 - SWIPEMr-Mk MughalNoch keine Bewertungen

- Machine Drawing Two Mark QuestionsDokument13 SeitenMachine Drawing Two Mark QuestionsHimanshuSisodiyaNoch keine Bewertungen

- On Line Test MCQ Aim, Procedure and Tabulation ResultDokument2 SeitenOn Line Test MCQ Aim, Procedure and Tabulation ResultMech RepresentativeNoch keine Bewertungen

- Dynamics Lab ManualDokument51 SeitenDynamics Lab ManualRavindiran ChinnasamyNoch keine Bewertungen

- Ce 8381som Lab ManualDokument31 SeitenCe 8381som Lab ManualAERO JPR50% (2)

- Engineering Practices Lab Regulation 2017 AU Sample Question PaperDokument4 SeitenEngineering Practices Lab Regulation 2017 AU Sample Question Papergoldencomet100% (3)

- UNIT-IV Question BankDokument3 SeitenUNIT-IV Question BankParamasivam VeerappanNoch keine Bewertungen

- Dynamics of Machines Study MaterialDokument20 SeitenDynamics of Machines Study Materialsara vanaNoch keine Bewertungen

- MEB 532 - Modern Machining Processes GuideDokument2 SeitenMEB 532 - Modern Machining Processes GuideHoe Bhaji100% (1)

- Machine Design-II Question BankDokument9 SeitenMachine Design-II Question BankProf. Avinash MahaleNoch keine Bewertungen

- LVDT Lab ManualDokument3 SeitenLVDT Lab Manualguruabhay100% (2)

- 1 Design of Machine Tool DrivesDokument23 Seiten1 Design of Machine Tool DrivesFurkan AhmadNoch keine Bewertungen

- Design of Transmission System Question BankDokument18 SeitenDesign of Transmission System Question BankAravind50% (2)

- AIP Lab Manual - 012110050524 - 1Dokument11 SeitenAIP Lab Manual - 012110050524 - 1Martin De Boras PragashNoch keine Bewertungen

- Selection Criteria For CNC Machining ToolsDokument16 SeitenSelection Criteria For CNC Machining ToolsGbm RajNoch keine Bewertungen

- CAD-CAM University QPDokument1 SeiteCAD-CAM University QPDaniel DasNoch keine Bewertungen

- Me 8594 Dynamics of Machinery Unit 1 Online Video LectureDokument42 SeitenMe 8594 Dynamics of Machinery Unit 1 Online Video LecturesankarNoch keine Bewertungen

- Shaper Tool Head AssemblyDokument6 SeitenShaper Tool Head AssemblykamelsuxNoch keine Bewertungen

- Design of Machine Elements Hand Written Notes PDFDokument17 SeitenDesign of Machine Elements Hand Written Notes PDFrockmanmaxNoch keine Bewertungen

- Cotter Joint Design GuideDokument15 SeitenCotter Joint Design GuidenkchandruNoch keine Bewertungen

- Thermal Engineering Lab ManualDokument64 SeitenThermal Engineering Lab ManualERKATHIR86% (7)

- Dynamics of Machinery 2 Marks All 5 UnitsDokument14 SeitenDynamics of Machinery 2 Marks All 5 UnitsDHINAKARANVEEMAN100% (2)

- ME8781 Mechatronics Lab Manual - Experiments on Hydraulic and Pneumatic CircuitsDokument49 SeitenME8781 Mechatronics Lab Manual - Experiments on Hydraulic and Pneumatic Circuitsusiaf007100% (1)

- Cad Cam Lab Manual AnDokument54 SeitenCad Cam Lab Manual AnPranjal SrivastavaNoch keine Bewertungen

- MT II LAB MANUAL NewDokument51 SeitenMT II LAB MANUAL NewSiva RamanNoch keine Bewertungen

- ACD Lab Manual Spur Gear DesignDokument4 SeitenACD Lab Manual Spur Gear Designbalaguru780% (1)

- Me8691-Computer Aided Design and ManufacturingDokument2 SeitenMe8691-Computer Aided Design and ManufacturingGeorge Oliver100% (3)

- Me 8511 K&D Lab ManualDokument126 SeitenMe 8511 K&D Lab ManualBharathi K 2018100% (2)

- Question Bank 3D PrintingDokument2 SeitenQuestion Bank 3D PrintingSujit MuleNoch keine Bewertungen

- Automats and Tool LayoutsDokument20 SeitenAutomats and Tool LayoutsAyesha IshuNoch keine Bewertungen

- Automated InspectionDokument31 SeitenAutomated InspectionVijay Kumar100% (8)

- Design of Transmission System 2 MarksDokument3 SeitenDesign of Transmission System 2 MarksMANOJ M100% (1)

- ME83691-Computer Aided Design and ManufacturingDokument15 SeitenME83691-Computer Aided Design and Manufacturingraman thiru55Noch keine Bewertungen

- CAD CAM Question BankDokument2 SeitenCAD CAM Question BankrsdeshmukhNoch keine Bewertungen

- ME I - Experiment No 2 Spinning ProcessDokument3 SeitenME I - Experiment No 2 Spinning Processmansukh0% (1)

- Tom Lab ManualDokument24 SeitenTom Lab Manualm_er100Noch keine Bewertungen

- Me6712 Mechatronics Lab Manual PDFDokument46 SeitenMe6712 Mechatronics Lab Manual PDFAhmed M H Al-Yousif50% (2)

- Casting and Pattern Making ProcessesDokument11 SeitenCasting and Pattern Making ProcessesAshok PradhanNoch keine Bewertungen

- Unconventional Machining ProcessesDokument2 SeitenUnconventional Machining ProcessesP.N. MohankumarNoch keine Bewertungen

- ME6711 Simulation and Analysis Lab PDFDokument40 SeitenME6711 Simulation and Analysis Lab PDFrajNoch keine Bewertungen

- SomDokument2 SeitenSomAshlin AarthiNoch keine Bewertungen

- Fluid Mechanics and Machinery LaboratoryDokument65 SeitenFluid Mechanics and Machinery LaboratoryRavi RaneNoch keine Bewertungen

- Mechanical Lab DetilaDokument6 SeitenMechanical Lab Detilasudhir1983Noch keine Bewertungen

- Ancoragem em RochaDokument11 SeitenAncoragem em RochaJ.GuerhardNoch keine Bewertungen

- Civil Engineering Department Lab ManualDokument47 SeitenCivil Engineering Department Lab Manualubaid quaziNoch keine Bewertungen

- Dynamics and Metrology LaboratoryDokument99 SeitenDynamics and Metrology LaboratoryEdison PandianNoch keine Bewertungen

- Som Lab Manual Nnce PDFDokument39 SeitenSom Lab Manual Nnce PDFObakoma JosiahNoch keine Bewertungen

- Ce 8381 - Question PaperDokument2 SeitenCe 8381 - Question PaperculvertsNoch keine Bewertungen

- ME8791 - Mechatronics U-I QPDokument3 SeitenME8791 - Mechatronics U-I QPVelmurugan CNoch keine Bewertungen

- ME8791 - Mechatronics U-I QPDokument3 SeitenME8791 - Mechatronics U-I QPVelmurugan CNoch keine Bewertungen

- PMC/UT-I/3.5.3/MECH Reg. No: Unit Test-I ME8501- Metrology and MeasurementsDokument3 SeitenPMC/UT-I/3.5.3/MECH Reg. No: Unit Test-I ME8501- Metrology and MeasurementsVelmurugan CNoch keine Bewertungen

- ME8501 Metrology and Measurements U-I QPDokument3 SeitenME8501 Metrology and Measurements U-I QPVelmurugan CNoch keine Bewertungen

- Renewable Energy Sources Course OverviewDokument5 SeitenRenewable Energy Sources Course OverviewVelmurugan CNoch keine Bewertungen

- ME8791 - Mechatronics UT-I QPDokument3 SeitenME8791 - Mechatronics UT-I QPVelmurugan CNoch keine Bewertungen

- Concept Note For Wind ParkDokument7 SeitenConcept Note For Wind ParkArun MehtaNoch keine Bewertungen

- Paraloid km-334Dokument5 SeitenParaloid km-334Naseer MianNoch keine Bewertungen

- Luminous PDFDokument1 SeiteLuminous PDFKushal AkbariNoch keine Bewertungen

- The Kinetics of Hydrogen Absorption in Palladium (A - and P-Phase) and Palladium-Silver-AlloysDokument10 SeitenThe Kinetics of Hydrogen Absorption in Palladium (A - and P-Phase) and Palladium-Silver-AlloysJose Fernandez AdellNoch keine Bewertungen

- 02 - Chemical Equilibrium (Theory) Module-3-1Dokument18 Seiten02 - Chemical Equilibrium (Theory) Module-3-1Raju SinghNoch keine Bewertungen

- Project Report - TarunDokument5 SeitenProject Report - TarunrajuNoch keine Bewertungen

- Miroljub Todorović - ApeironDokument25 SeitenMiroljub Todorović - Apeiron"Mycelium" samizdat publishersNoch keine Bewertungen

- Solar Project REPORTDokument15 SeitenSolar Project REPORTismailNoch keine Bewertungen

- Downstream - Processing - Lecture 5rnjDokument8 SeitenDownstream - Processing - Lecture 5rnjqwertyuNoch keine Bewertungen

- Heat Exchangers of PolypropyleneDokument2 SeitenHeat Exchangers of PolypropyleneTan So100% (1)

- Bachelor of Engineering (Hons) Chemical Course OutlineDokument2 SeitenBachelor of Engineering (Hons) Chemical Course OutlineWan Mohammad Faris FahmiNoch keine Bewertungen

- Altronics DD Annunciator BLLTN 07-1996 PDFDokument4 SeitenAltronics DD Annunciator BLLTN 07-1996 PDFSMcNoch keine Bewertungen

- Planar Linkages Mechanism GuideDokument8 SeitenPlanar Linkages Mechanism GuideAlbert ArominNoch keine Bewertungen

- Parts Crane Hitachi FK600 - PRDokument2 SeitenParts Crane Hitachi FK600 - PRDefly Gusti100% (1)

- V-3111-002-A-711 - 2 Method Statement For Water Well WorkDokument14 SeitenV-3111-002-A-711 - 2 Method Statement For Water Well WorkWidya PrasetyaNoch keine Bewertungen

- Enigma Motors: Mobility Company That Sticks To GrassrootsDokument14 SeitenEnigma Motors: Mobility Company That Sticks To GrassrootsUmangNoch keine Bewertungen

- Marine Propulsion Engines GuideDokument20 SeitenMarine Propulsion Engines GuideyoungfpNoch keine Bewertungen

- 66 KV Design Parameters in GujaratDokument1 Seite66 KV Design Parameters in GujaratAkhilesh SolankiNoch keine Bewertungen

- HexaneDokument3 SeitenHexaneIan RidzuanNoch keine Bewertungen

- Hypercell 1994 Engl by Hans HassDokument126 SeitenHypercell 1994 Engl by Hans HassClaimDestinyNoch keine Bewertungen

- Master Plan For Delhi: Dr. Mayank MathurDokument40 SeitenMaster Plan For Delhi: Dr. Mayank MathurJay PrakashNoch keine Bewertungen

- Engineering Physics - G. AruldhasDokument100 SeitenEngineering Physics - G. AruldhasJaya sankarNoch keine Bewertungen

- Eco NicalDokument13 SeitenEco Nicalluizfellipe95Noch keine Bewertungen

- CT/PT Selection Chart: Applicable Standard (A) (V) CT's Qty PT PT's Part # PT's Qty Service Size CT CT's Part # PhaseDokument1 SeiteCT/PT Selection Chart: Applicable Standard (A) (V) CT's Qty PT PT's Part # PT's Qty Service Size CT CT's Part # PhasePrabakar PNoch keine Bewertungen

- Alfa Laval Koltek MH Valve enDokument8 SeitenAlfa Laval Koltek MH Valve enjpsingh75Noch keine Bewertungen

- Rrsport 160 en INTDokument94 SeitenRrsport 160 en INTstrateguo1Noch keine Bewertungen