Beruflich Dokumente

Kultur Dokumente

Poku 2006

Hochgeladen von

sudeviOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Poku 2006

Hochgeladen von

sudeviCopyright:

Verfügbare Formate

Construction Scheduling and Progress Control Using

Geographical Information Systems

Stephen E. Poku1 and David Arditi, M.ASCE2

Abstract: Traditional scheduling and progress control techniques such as bar charts and the critical path method 共CPM兲 fail to provide

information pertaining to the spatial aspects of a construction project. A system called PMS-GIS 共Progress Monitoring System with

Geographical Information Systems兲 was developed to represent construction progress not only in terms of a CPM schedule but also in

terms of a graphical representation of the construction that is synchronized with the work schedule. In PMS-GIS, the architectural design

is executed using a computer-aided drafting 共CAD兲 program 共AutoCAD兲, the work schedule is generated using a project management

software 共P3兲, the design and schedule information 共including percent complete information兲 are plugged into a GIS package

共ArcViewGIS兲, and for every update, the system produces a CPM-generated bar chart alongside a 3D rendering of the project marked for

progress. The GIS-based system developed in this study helps to effectively communicate the schedule/progress information to the parties

involved in the project, because they will be able to see in detail the spatial aspects of the project alongside the schedule.

DOI: 10.1061/共ASCE兲0887-3801共2006兲20:5共351兲

CE Database subject headings: Scheduling; Geographic information systems; Project management; Computer aided drafting 共CAD兲;

Construction management; Information systems.

Introduction of the schedule can be extended to monitoring not only the con-

struction process itself, but also all the auxiliary activities, includ-

Growing pressure to shorten project delivery times, new procure- ing onsite plant and equipment 共Adjei-Kumi et al. 1996兲. In

ment practices, and the increasing complexity of today’s construc- addition, the practical and educational benefits of being able to

tion projects have resulted in an increase in the number of visualize construction at a fine level of detail are significant

commercially available computerized planning and scheduling 共Kamat and Martinez 2002兲.

tools 共Retik 1997兲. But the construction industry has acknowl- Several research efforts in construction visualization have

edged that its current scheduling and progress reporting practices been conducted relative to scheduling. They involve linking

are in need of substantial improvements in quality and efficiency activity-based construction schedules and 3D computer-aided

共Retik 1997兲. Visualization was recognized as one of the most drafting 共CAD兲 models of facilities to describe discretely evolv-

important tools for achieving this goal 共Research 1997兲. ing construction product visualization, called 4D CAD 共Kamat

Research efforts to incorporate visualization into project and Martinez 2002兲. Research work has suggested that the project

scheduling and progress control have been motivated by the fail- managers that use 4D simulation are more likely to allocate re-

ure of traditional techniques such as bar charts and the critical sources more effectively than those who do not 共Fischer 2000兲.

path method 共CPM兲 to provide information pertaining to the spa- The use of 4D planning also assists the planner in avoiding sched-

tial aspects of a construction project 共Koo and Fischer 2000兲. uling conflicts, analyzing constraints, and evaluating alternative

Retik 共1997兲 notes that visual simulation of a construction process construction methods 共Vaugn 1996兲. Given the prototypes pre-

might assist a planner in a better perception of a project as well as sented in the literature, the closest tool that shows a CPM-

in the integration of other parties’ activities in the planning pro- generated bar-chart in synchrony with actual progress is the

cess. Furthermore, in large-scale projects, a visual representation system generated by Abeid et al. 共Abeid and Arditi 2002a,b, 2003;

Abeid et al. 2003兲, which displays a time-lapse movie of the

1

Graduate Student, Illinois Institute of Technology, Dept. of Civil and construction site alongside a CPM-generated bar-chart.

Architectural Engineering, Construction Engineering and Management Visualizing construction progress in three dimensions along-

Program, 3201 S. Dearborn St., Chicago, IL 60616-3793. E-mail: side a CPM-generated bar-chart provides the construction project

pokuste@iit.edu manager with a more intuitive view of the construction sequence.

2

Professor, Illinois Institute of Technology, Dept. of Civil and Archi- Three-dimensional visualization allows the construction manager

tectural Engineering, Construction Engineering and Management Pro- to view the construction activities during any stage of the con-

gram, 3201 S. Dearborn St., Chicago, IL 60616-3793. E-mail: struction process. The objective of this research was to demon-

arditi@iit.edu strate that geographical information systems 共GIS兲 can be utilized

Note. Discussion open until February 1, 2007. Separate discussions

for construction progress visualization in three dimensions along-

must be submitted for individual papers. To extend the closing date by

side a synchronized CPM-generated work schedule.

one month, a written request must be filed with the ASCE Managing

Editor. The manuscript for this paper was submitted for review and pos-

sible publication on December 13, 2004; approved on February 13, 2006. 4D CAD Applications

This paper is part of the Journal of Computing in Civil Engineering,

Vol. 20, No. 5, September 1, 2006. ©ASCE, ISSN 0887-3801/2006/5- Computer-aided drafting 共CAD兲 is widely used during the engi-

351–360/$25.00. neering design stage of construction projects. CAD generally con-

JOURNAL OF COMPUTING IN CIVIL ENGINEERING © ASCE / SEPTEMBER/OCTOBER 2006 / 351

tains a wealth of information about the facility to be constructed; Heesom and Mahdjoubi 共2004兲兴. Common Point 4D 共CP4D兲 is a

this information can be effectively used for construction decision tool that emerged from research activities undertaken at the Cen-

making. Construction planners typically rely on CAD to develop ter for Integrated Facility Engineering 共CIFE兲 at Stanford Univer-

CPM-based systems to schedule and coordinate the work of mul- sity. This tool uses 3D Industry Foundation Classes 共IFC兲

tiple disciplines on a project. Traditional design and construction compliant models that can be generated by using AutoCAD dwg

planning tools, such as 2D drawings and CPM diagrams, do not or DXF formats. Schedule information is read from Primavera

support the timely and integrated decision making necessary to Project Planner 共P3兲 or MS Project file formats. The linking of

move projects forward quickly. They do not provide the informa- products to processes is undertaken manually. Objects can be

tion modeling, visualization, and analysis environment necessary manually grouped together and attached to one or multiple tasks.

to support the rapid and integrated design and construction of Annotations can be added to each 4D product group to provide an

facilities. Synthesis of construction schedules from design de- explanation of the 3D objects during the simulation. CP4D was

scriptions and integrated evaluation of design and schedule alter- used successfully in two major commercial applications, a hospi-

natives are still mainly manual tasks. Furthermore, the underlying tal expansion project and a large amusement park construction

representations of a design and a construction schedule are too 共Fischer 2003兲. Kamat and Martinez’s 共2002兲 4D CAD system

abstract to allow the multiple stakeholders to visualize and under- provides a visualization of the interaction between the continu-

stand the cross-disciplinary impacts of design and construction ously evolving construction and the involved resources, such as

decisions. machines, labor groups, and material. Retik and Shapira 共1999兲

4D CAD is a concept that combines an object-oriented 3D developed a system for virtual planning and monitoring of the

CAD model with time. 4D CAD is a kind of information visual- construction process, including the building, cranes, other equip-

ization that is easier to understand than traditional methods, such ment, and temporary structures.

as the 2D drawings and time schedules that are used to manage 4D CAD models have their limitations 共Heesom and

construction projects. 4D CAD is a logical way of imagining a Mahdjoubi 2004兲. For example, the few 4D-modeling tools that

construction. The utilization of 4D visualization allows a more allow a user to link a 3D model with a construction schedule to

intuitive comprehension of the construction process than tradi- visualize construction over time on a computer screen are based

tional 2D drawings and schedule information 共Bergsten 2001兲. on object-oriented concepts and can be queried by the user about

A number of 4D CAD applications have been developed since their content and relationships. But the resulting 4D model is

1987 for use in the construction industry 共Fischer and Kam 2001兲. purely a visualization tool, rather than a tool that can be used for

Barrett 共2000兲 perceived this technological development as hav- analytical purposes 共Heesom and Mahdjoubi 2004兲. The use of

ing the potential to provide an improved relationship between 4D CAD models has been primarily for planning, design phase

construction designers and constructors. Also, 4D CAD was seen analysis, and postmortem or appraisal types of analysis, with only

as a natural progression to 3D CAD models, as it adds a further a few that have been used for construction phase decision making

dimension 共Phair 2000兲. It provides the ability to represent con- and administration 共Martinez and Halpin 1999兲. Most of these

struction plans in three dimensions while adding the temporal tools have an ad-hoc modeling approach that makes updating and

dimension to schedules. It can even be used as a training tool for maintaining these systems cumbersome by anybody but the origi-

inexperienced planners 共Heesom and Mahdjoubi 2004兲. nal creator 共“4D Modeling” 2004兲. Furthermore, 4D CAD models

Heesom and Mahdjoubi 共2004兲 evaluated the characteristics of have a single level of detail, which hinders the collaboration of

six commercially available 4D CAD packages. The following general contractors and subcontractors, because they work to-

examples include the six systems reported by Heesom and wards the same goal, but at different levels of detail. Also, most

Mahdjoubi 共2004兲 as well as other systems reported in the litera- 4D CAD applications do not support computer-based analyses

ture. A system developed by Koo and Fischer 共2000兲 was used on of cost, safety, and other performance metrics 共Heesom and

a commercial construction project that involved three identical Mahdjoubi 2004兲. Finally, some of the 4D CAD models are avail-

two-story office buildings; Koo and Fischer 共2000兲 were able to able only for single-user desktop environments, whereas many

detect problems by analyzing the 4D model of the first building project participants need to participate in building and critiquing a

that was completed and provide recommendations to improve 4D model.

constructability for the two remaining buildings. Another example

is the Bentley Schedule Simulator developed by Jacobus Technol-

ogy. This system dynamically links 3D design data imported from Geographical Information Systems

various CAD-based design packages and schedule data obtained

from either Primavera Project Planner or MS Project 关reported by Geographic information science is the discipline that tries to un-

Heesom and Mahdjoubi 共2004兲兴. The SmartPlant Review devel- derstand the world by describing and explaining human relation-

oped by Telegraph links information from a project schedule to ships with the Earth. Geographic information science goes

objects in a CAD display 关reported by Heesom and Mahdjoubi beyond description; it also includes analysis, modeling, and pre-

共2004兲兴. diction 共Huxhold 1991兲. According to the Environmental Systems

Balfour Technologies’ FourDviz technology involves virtual Research Institute 共Introduction 1995兲, a GIS is defined as “an

reality objects that are generated to create the visual scene; tem- organized collection of computer hardware, application software,

poral characteristics are attributed to these objects by external geographic data, and personnel designed to efficiently capture,

programs that perform CPM analysis, but there are no dynamic store, update, manipulate, analyze, and display all forms of geo-

links between the CPM-based package and the visualization graphic referenced information.” Estes defines a GIS as “an in-

关Sheppard 共2004兲, also reported by Heesom and Mahdjoubi formation system that is designed to work with data referenced by

共2004兲兴. Visual Project Scheduler 共VPS兲 imports 3D DXF files spatial or geographic coordinates” 共Huxhold 1991兲. Thus, a GIS

into a common database, creates objects, creates schedule and is both a database system with specific capabilities for spatially

cost models, and associates the objects with the schedule through referenced data, as well as a set of operations for working with

different color schemes 关Sheppard 共2004兲, also reported by the data.

352 / JOURNAL OF COMPUTING IN CIVIL ENGINEERING © ASCE / SEPTEMBER/OCTOBER 2006

time basis. The system developed by Integral GIS Inc. 共1997兲

used GIS for logistics planning during the construction of the

New Pacific Northeast Baseball Park in Seattle. The objective of

Wright et al.’s 共1993兲 GIS-based system was the efficient plan-

ning of road network maintenance routes and snow and ice

control routes for the Indiana Department of Transportation.

Udo-Inyang and Uzoije 共1997兲 developed a GIS-based highway

construction, inspection, and management system to provide con-

struction personnel with easy access to construction data and in-

formation with graphical enhancement.

The collection and management of various types of informa-

tion efficiently and on demand is seen as the key to successful

management of construction projects. GIS has helped in the com-

munication of information, particularly because the information is

always referenced to a geographical location such as a location on

a construction site or along a highway network.

Fig. 1. Data relationships in GIS

Progress Monitoring System with GIS „PMS-GIS…

GIS makes use of two types of databases. One is an attribute The intent of the study presented in this paper is to demonstrate

table including geographic data that is contained in a shape file. the benefits of using GIS in construction project management,

The shape file constructs maps with lines, points, polygons, and which is a field of study not ordinarily associated with GIS. In

elevations in a view 共Fig. 1兲. These are known as features. Point this study, a system called PMS-GIS 共Progress Monitoring Sys-

features such as an elevation benchmark have only one location. tem with GIS兲 is developed using ArcViewGIS, Primavera Project

Line features have several locations strung out along the line in Planner 共P3兲, and AutoCAD to assist construction managers in

sequence, an example being a river. Area features consist of one controlling and monitoring construction progress. Successful

or more lines that form a loop, such as the shoreline of a lake. All project control is a challenging responsibility for all construction

these features represented in a view are known as a theme. managers. Visualization of information is an important benefit of

The other type of database file may be numeric, string, or date PMS-GIS.

information. This is imported from data sources and/or made in The objective of this study is to display the progress and se-

the GIS application. Usually it is linked with the former file so quence of the construction work in CAD format with different

that the data will be shown in the view 共Fig. 1兲. Thus, GIS can use colors and labels and in three dimensions while synchronizing

information from many different sources, in many different this information with a formal CPM work schedule. This form of

forms, and can link data sets together by common location data. presentation is expected to help all parties involved in a construc-

GIS can also make it possible to link information that is difficult tion project to visualize the progress in a natural way, hence mini-

to associate through other means. mizing delays and cost overruns. In addition to monitoring the

In recent years, three-dimensional GIS display and analysis schedule, the system can also be extended to monitor quantities of

tools have become more widely accessible to mainstream practi- materials, costs, and resources.

tioners. These 3D GIS tools allow users to generate fly-through of Fig. 2 shows the information flow among the various applica-

high-resolution scenes for presentations and collaborative work. tions in the system. It also shows the procedure that needs to be

In addition, 3D GIS enables users to visualize the results of volu- followed in using the system. A typical single-family house con-

metric analyses in great detail. struction is selected as a case study. The steps that were per-

formed to generate PMS-GIS progress reports are described in the

following sections.

GIS Applications in Construction

GIS applications have proliferated in the construction industry in

Step 1: Creating Architectural Design

recent years. This fact is illustrated by the growing number of

articles finding their way into civil engineering and construction The design of the single-family house was created using

journals and conference proceedings, in addition to the handful of AutoCAD, a widely used software package in architectural design

special publications devoted to GIS 共Oloufa et al. 1994兲. practice. Fig. 3 shows the floor plan and front elevation of the

GIS was used by Oloufa et al. 共1994兲 to create a database for house used in the case study.

storage of descriptive soil data pertaining to boreholes and linked

the descriptive data to the corresponding geographic locations of

Step 2: Creating Work Breakdown Structure

the boreholes. Cheng and O’Connor 共1996兲 developed an auto-

mated site layout system called ArcSite that assists designers in Fig. 4 shows the four parts of the project. This was done to make

identifying suitable areas to locate temporary facilities, whereas project control effective and manageable. The first part involves

Cheng and Yang’s 共2001兲 site layout system, called MaterialPlan, groundwork, i.e., activities related to trench excavation, founda-

assisted construction managers in identifying suitable areas in a tion concrete, foundation walls, backfilling, compaction of soil

construction site to locate materials. Cheng and Chen 共2000兲 and gravel, and concrete floor slab. The second part involves the

developed an automated schedule monitoring system called superstructure, i.e., activities related to exterior walls, interior par-

ArcShed for precast building construction that integrated bar- tition walls, doors and windows, floor finishes, plumbing, and

codes and GIS for monitoring construction progress on a real- kitchen appliances. Part three involves activities pertaining to roof

JOURNAL OF COMPUTING IN CIVIL ENGINEERING © ASCE / SEPTEMBER/OCTOBER 2006 / 353

Fig. 4. Work breakdown structure

Step 3: Initiating Scheduling Process

Primavera Project Planner 共P3兲 was used as the scheduling tool.

The project was scheduled based on the activities identified in the

work breakdown structure described in Step 2. P3 was used to

schedule the project, showing the start and completion dates, lo-

cating the critical path共s兲 and float times of activities, and also

showing the sequence and interrelationships between the activi-

ties. Fig. 6 shows the bar-chart schedule generated by P3 for the

house whose floor plan and elevation are presented in Fig. 3.

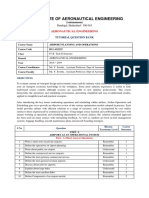

Table 1. Activity Information in House Project

Duration

Fig. 2. Design and information flow chart Activity Activity description 共days兲 Work packages

SM 20 Foundation trench excavation 5

SM 30 Foundation formwork 3

construction, and part four involves electrical, plumbing, and SM 40 Foundation reinforcement 2

HVAC. Each of these parts is monitored as a different view in SM 50 Foundation footing concrete 3

ArcViewGIS. SM 60 Foundation wall concrete 5

The design created in AutoCAD was used as a basis for defin- SM 90 Backfilling and compaction 4

ing the various activities that make up the project, such as exca- SM 110 Floor slab concrete 3

vation, exterior walls, and roof assembly. A list of the activities in SM 130 Exterior walls 20 SM 130⫻ 01

the house project is presented in Table 1. Activities were then SM 130⫻ 02

broken down into smaller work packages. Each work package has

SM 130⫻ 03

a different location. For example, the activity “Exterior Walls”

SM 130⫻ 04

was divided into work packages, such as the ones specified in Fig.

SM 130⫻ 05

5 and Table 1.

SM 130⫻ 06

SM 140 Interior walls 15

SM 150 Exterior brick wall 10

SM 170 Roof construction 10

SM 180 Install ceiling 10

SM 190 Install electrical conduits 7

SM 200 Install ventilation ducts 10

SM 210 Install plumbing pipes 7

SM 220 Install doors and windows 10

SM 230 Painting 10

SM 240 Floor finishes 10

SM 250 Electrical fixtures 8

SM 270 Kitchen furniture and appliances 5

SM 280 Landscape 10

Fig. 3. Floor plan and front elevation of single family house project SM 300 Touch up and clean 10

354 / JOURNAL OF COMPUTING IN CIVIL ENGINEERING © ASCE / SEPTEMBER/OCTOBER 2006

Fig. 5. Various work packages in exterior walls

Step 4: Transferring Drawings into ArcViewGIS Step 5: Creating “Merged Themes” for Activities

After creating the design in AutoCAD, the DXF files were trans- The themes 共polygons, lines, or points兲 created for the work pack-

ferred to ArcViewGIS. The topologic data structure of the basic ages were merged together into activities defined earlier in the P3

design layers was created as “themes” based on the work pack- schedule. Thus, the work packages that belong to the same activ-

ages identified in the AutoCAD drawings. ity but are located at different positions were joined together as

Fig. 6. CPM-generated bar chart schedule of house project

JOURNAL OF COMPUTING IN CIVIL ENGINEERING © ASCE / SEPTEMBER/OCTOBER 2006 / 355

Fig. 7. Typical database features

one “merged theme.” For example, the work packages denoting n

the various parts of the exterior wall in Fig. 5 were merged into 兺

j=1

PCij ⫻ Qij

one merged theme called the “Exterior Walls” activity. PCi = n

Step 6: Creating Database

兺

j=1

Qij

The attributes needed for each layer were created in a database.

The database includes at a minimum information about identifi- where PCi = percent complete for activity 共i兲; PCij = percent com-

cation, quantity, and percentage complete for each work package. plete for work package 共j兲 of activity 共i兲; Qij = quantity associated

In addition, the database may include information such as activity with work package 共j兲 of activity 共i兲; and n = number of work

costs, dimensions, types of material, etc. It is possible to prepare packages in activity 共i兲.

all this information as an independent database and later import it The percent complete information for each work package was

to ArcViewGIS. Fig. 7 shows the typical database features. manually input into the database. But the percent complete infor-

mation for each activity is calculated by PCS-GIS automatically.

Step 7: Adjusting Database to Include Activity

Information Step 8: Importing “Activity Percent Complete”

Information from ArcViewGIS to P3 and Creating

The percent complete information on the work packages are en-

Updates of P3 Schedule

tered into the database by the user in Step 5. This information is

used in Step 7 to calculate the percent complete for each activity, The percent complete information calculated in Step 7 was manu-

which is obtained by calculating the weighted average of the per- ally transferred to P3 every time a progress evaluation was made

cent complete of the work packages. The weighted average is 共e.g., every month兲. P3 was run to generate the updated schedule

calculated as follows: network. The updated schedule shows the progress for all the

356 / JOURNAL OF COMPUTING IN CIVIL ENGINEERING © ASCE / SEPTEMBER/OCTOBER 2006

Fig. 8. 3D view of superstructure section of project with as-planned CPM-generated schedule

activities as of the new date of the update 共e.g., at the end of every terior Walls” activity. Progress information can be viewed for an

month兲 and the percent complete information. The format is the individual activity as well as for a number of selected activities

same as in Fig. 6. 共or all activities兲 at the same time.

Step 9: Creating 3D View of Project in ArcViewGIS

Benefits and Limitations of System

The project’s 3D view was created in ArcViewGIS. The activity

themes created in Step 5 were converted into 3D themes in

ArcViewGIS. The new themes are shown in the 3D view created. Traditionally, the CPM schedule does not provide any informa-

Mathematical expressions are set in the 3D theme properties dia- tion pertaining to the spatial aspects or context and complexities

log box to monitor progress. of the various components of a construction project. Therefore, to

interpret progress information, users normally look at 2D draw-

ings and conceptually associate components with related

Step 10: Showing Synchronized Progress in 3D activities. Different project members may develop inconsistent

Drawings and P3 Network Schedule interpretations of the schedule when viewing only the CPM

The progress of work was shown in graphical format and in dif- schedule. This causes confusion on many occasions and usually

ferent colors. The amount of work done on the various work makes effective communication among project participants diffi-

packages could be seen in the 3D view. The project was updated cult. PMS-GIS allows project planners and managers to see in

as progress information became available 共e.g., monthly兲 and the detail the spatial characteristics of the project by showing on the

corresponding P3 schedule was sent to ArcViewGIS. This was same screen a bar-chart schedule and a 3D rendering of the

done through the hotlink window in ArcViewGIS. project marked for progress. With PMS-GIS, all project members

The example project described hereafter was run using this should be able to visually observe the progress, which will help in

system. Fig. 8 shows the final 3D view of the superstructure sec- effective communication of the schedule. The system is run peri-

tion along with the as-planned schedule, and Figs. 9 and 10 show odically 共e.g., every month兲 over the duration of the project.

progress at the end of the second and third months for the “Ex- When the limitations of the 4D CAD models briefly described

JOURNAL OF COMPUTING IN CIVIL ENGINEERING © ASCE / SEPTEMBER/OCTOBER 2006 / 357

Fig. 9. 3D view of superstructure section 共progress in “Exterior walls” activity, second month兲 with CPM-generated updated schedule

earlier are considered, it is observed that PMS-GIS compares fa- use by different parties; for example, it is possible for a masonry

vorably to most of them. For example, while most 4D models are subcontractor to view not only the progress of the project in its

designed purely as a visualization tool primarily used for plan- entirety, but also the progress of only masonry walls. In other

ning, design phase analysis, and post mortem analysis, PMS-GIS words, each party can view the progress of the entire project or, if

is designed for decision making in the construction phase. they so desire, only in the portions associated with their own

Progress in the project, in individual activities, and in smaller activities. Furthermore, information stored in P3 may indicate that

work packages can be clearly observed during construction by the construction of the exterior walls is 50% complete, while in

means of a CPM-derived bar-chart and a 3D model of the struc- reality, not all the walls at different locations are 50% done. PMS-

ture. Decisions are made based on this visual picture in order to GIS is able to show the amount of work done on each portion of

keep the project on schedule. The system can of course be used the “Exterior Walls” activity 共e.g., Figs. 9 and 10兲. The project

for planning, design phase analysis, and post mortem analysis too. manager will be able to see whether work has started on an indi-

While the updating and maintaining of most 4D systems are vidual wall portion and the amount of work done on it.

cumbersome 共typically done by the developer兲, PMS-GIS can be While most 4D CAD applications do not support analyses of

handled by the user as long as the user is familiar with cost, safety, and other relevant information, PMS-GIS has the

ArcViewGIS. The current version of PMS-GIS requires that some capability of storing in different databases all sorts of information

updating tasks, such as transferring information from P3 and 共e.g., percent complete, cost, safety, materials, labor resources,

AutoCAD to ArcViewGIS, be performed manually. However, it equipment, etc.兲 associated with the work packages identified in

should be possible for P3, AutoCAD, and ArcViewGIS to com- the model. This information can be analyzed by making use of the

municate automatically with each other seamlessly, and work is capabilities of the database system and can yield performance

underway to automate this process. But the user will have to metrics that can be used in decision making during construction.

generate the drawings in AutoCAD, define the work breakdown Only one database was developed in the first version of PMS-

structure in terms of activities and smaller work packages, and GIS, it includes percent complete information. The addition of

populate the database with information 共e.g., percent complete, other databases could enlarge the scope of the system and en-

number and extent of accidents, cost, resources used, etc.兲. hance its benefits.

While most 4D CAD models have a single level of detail, Finally, while some of the 4D CAD models are available only

PMS-GIS can be formulated to offer different levels of detail for for single-user desktop environments, PMS-GIS can be developed

358 / JOURNAL OF COMPUTING IN CIVIL ENGINEERING © ASCE / SEPTEMBER/OCTOBER 2006

Fig. 10. 3D view of superstructure section 共progress in “Exterior Walls” activity, third month兲 with CPM-generated updated schedule

into a web-based multiuser system. Indeed, many project partici- used in all phases of the construction process, including planning,

pants need to use a 4D model. While the first version of PMS-GIS design, post mortem, and most importantly day-to-day decision

was not developed for a multiuser environment, it should be pos- making during construction; 共3兲 it can provide specific and local-

sible to expand it. ized information about equipment, labor, cost, accidents, etc., that

is necessary to run an efficient construction project; and 共4兲 it

allows different parties involved in the project to view not only

Conclusion the general picture but also the portion of the project directly

related to them in great detail.

This research discussed the development of PMS-GIS as a tool Because of the limitations of the first version of PMS-GIS, the

for visualizing construction progress in three dimensions, side by interfaces between ArcViewGIS, AutoCad, and P3 need to be

side with a CPM-generated work schedule. In comparison with done manually, only one database is available and that is the one

current methods, PMS-GIS has created a new way of representing that is essential to the operation of the system 共i.e., percent com-

construction progress in graphical terms using GIS, CAD, and plete information兲, and the system is designed for use in single-

project management software. user desktop environments. The development of seamless

It has become apparent that construction organizations wel- communication between the three programs is possible and is

come any support that will help in the planning, scheduling, and currently being pursued. Additional databases for safety, costs,

overall management of construction projects. Yet CPM schedules resources, and any other information deemed necessary for the

do not effectively convey thought processes and the assumptions efficient management of a project can be developed based on

made in generating them. Users must conceptualize the associa- demand. The development of a web-based multiuser application

tion between components and related activities to understand the is earmarked for future research.

construction process 共Fischer 2000兲. The model presented in this

study reduces the need for this conceptualization, as it also con-

veys the spatial aspects of the planning information. Thus, it has References

integrated the locational and thematic information into a single

environment, by showing what physical components are built

“4D modeling.” 共2004兲. Emerging construction technologies, Construc-

where and in which time frame.

tion Industry Institute, 具http://www.new-technologies.org典 共Mar. 1,

PMS-GIS compares favorably to other systems developed so 2004兲.

far and helps to effectively communicate the schedule/progress Abeid, J., Allouche, E., Arditi, D., and Hayman, M. 共2003兲. “Photo-Net

information to all the parties involved in the project. PMS-GIS II: A computer based monitoring system applied to project manage-

has several advantages: 共1兲 it can be used by anyone who is ment.” Autom. Constr., 12共5兲, 603–616.

familiar with ArcViewGIS; 共2兲 it is a management tool that can be Abeid, J., and Arditi, D. 共2002a兲. “Time-lapse digital photography ap-

JOURNAL OF COMPUTING IN CIVIL ENGINEERING © ASCE / SEPTEMBER/OCTOBER 2006 / 359

plied to project management.” J. Constr. Eng. Manage., 128共6兲, 530– Integral GIS Inc. 共1997兲. “Building a baseball stadium using GIS.” Inte-

535. gral GIS White Paper, Seattle.

Abeid, J., and Arditi, D. 共2002b兲. “Linking time-lapse digital photogra- Introduction to ArcView. 共1995兲. Environmental Systems Research Insti-

phy and dynamic scheduling of construction operations.” J. Comput. tute, Redlands, Calif.

Civ. Eng., 16共4兲, 269–279. Kamat, V. R., and Martinez, J. C. 共2002兲. “Comparison of simulation-

Abeid, J., and Arditi, D. 共2003兲. “Photo-Net: An integrated system for

driven construction operations visualization and 4D CAD.” Exploring

controlling construction progress.” Eng., Constr., Archit. Manage.,

10共3兲, 162–171. New Frontiers: Proc., 2002 Winter Simulation Conf., E. Yucesan, C.

Adjei-Kumi, T., Retik, A., and Shapira, A. 共1996兲. “Integrating on-site H. Chen, J. L. Snowdon, and J. M. Charnes, eds., Institute of Electri-

tasks into planning and scheduling of construction projects.” Proc., cal and Electronics Engineers, New York, 1765–1770.

Shaping Theory and Practice, Managing the Construction Project and Koo, B., and Fischer, M. 共2000兲. “Feasibility study of 4D CAD in com-

Managing Risk: Int. Symp. on Organization and Management of Con- mercial construction.” J. Constr. Eng. Manage., 126共4兲, 251–260.

struction, D. A. Langford and A. Retik, eds., E&FN Spon, Glasgow, Martinez, L. H., and Halpin, D. W. 共1999兲. “Real world applications of

U.K., 283–292. construction process simulation.” Proc., 1999 Winter Simulation

Barrett, P. 共2000兲. “Construction management pull for four-dimensional Conf., P. A. Farrington, H. B. Nembhard, D. T. Sturrock, and G. W.

computer-aided design 共4D CAD兲.” Proc., Construction Congress VI, Evans, eds., WSC Foundation, Phoenix, 956–962.

K. D. Walsh, ed., ASCE, Reston, Va., 977–983. Oloufa, A. R., Ethan, A., and Papacostas, C. S. 共1994兲. “Integrated GIS

Bergsten, S. 共2001兲. “4D CAD—An efficient tool to improve the produc- for construction site investigation.” J. Constr. Eng. Manage., 120共1兲,

tion method for integration of apartments into existing buildings.” 211–222.

Proc., CIB W78 Conf.: IT in Construction in Africa, CSIR Building Phair, M. 共2000兲. “Software model builders add an extra dimension to 3D

and Technology, Mpumalanga, South Africa. CAD.” ENR, 244共9兲, 16.

Cheng, M. Y., and Chen, J. C. 共2000兲. “Integrating barcode and GIS for Research futures: Academic responses to industry challenges. 共1997兲.

monitoring construction progress.” Autom. Constr., 11共1兲, 23–33. Construct IT Center of Excellence, Salford, U.K.

Cheng, M. Y., and O’Connor, J. T. 共1996兲. “ArcSite: Enhanced GIS for Retik, A. 共1997兲. “Planning and monitoring of construction projects using

construction site layout.” J. Constr. Eng. Manage., 122共4兲, 329–336. virtual reality.” Proj. Manage. J., 97共1兲, 28–31.

Cheng, M. Y., and Yang, S. C. 共2001兲. “GIS-based cost estimates inte- Retik, A., and Shapira, A. 共1999兲. “VR based planning of construction

grating with material layout planning.” J. Constr. Eng. Manage., site activities.” Autom. Constr., 8共6兲, 671–680.

127共4兲, 291–299.

Sheppard, L. M. 共2004兲. “Virtual building for construction projects.”

Fischer, M. 共2000兲. “Benefits of four-dimensional 共4D兲 models for facil-

IEEE Comput. Graphics Appl., 24共1兲, 6–12.

ity owners and AEC service providers.” Proc., 6th Construction Con-

Udo-Inyang, D., and Uzoije, C. H. 共1997兲. “HICIMS: An integrated GIS

gress, D. K. Walsh, ed., ASCE, Reston, Va., 990–995.

and DBMS application.” Computing in Civil Engineering: Proc., 4th

Fischer, M. 共2003兲. “The benefits of virtual building tools.” Civ. Eng.

Mag., 73共8兲, 60–67. Computing in Civil Engineering Congress, T. M. Adams, ed., ASCE,

Fischer, M., and Kam, C. 共2001兲. “4D modeling: Technologies and re- New York, 240–247.

search.” Proc., Workshop on 4D Modelling: Experiences in UK and Vaugn, F. 共1996兲. “3D & 4D CAD modeling on commercial design-build

Overseas, The Network on Information Standardization, Milton Key- projects.” Computing in Civil Engineering: Proc., 3rd Computing in

nes, U.K., 具http://www.research.scpm.salford.ac.uk/siene/典 Civil Engineering Congress, J. Vanegas and P. Chinowsky, eds.,

Heesom, D., and Mahdjoubi, L. 共2004兲. “Trends of 4D CAD applications ASCE, New York, 390–396.

for construction planning.” Constr. Manage. Econom., 22共2兲, 171– Wright, R. J., Wang, J. Y., and Haslem, E. 共1993兲. “A spatial decision

182. support system for vehicle routing.” Computing in Civil and Building

Huxhold, W. E. 共1991兲. An introduction to urban geographic information Engineering: Proc., 5th Int. Conf., L. F. Cohn, ed., ASCE, New York,

systems, Oxford University Press, New York. 726–729.

360 / JOURNAL OF COMPUTING IN CIVIL ENGINEERING © ASCE / SEPTEMBER/OCTOBER 2006

Das könnte Ihnen auch gefallen

- 1 s2.0 S0378778814003570 MainDokument13 Seiten1 s2.0 S0378778814003570 MainsudeviNoch keine Bewertungen

- 1 s2.0 S0378778818306224 MainDokument10 Seiten1 s2.0 S0378778818306224 MainsudeviNoch keine Bewertungen

- SD 308Dokument13 SeitenSD 308sudeviNoch keine Bewertungen

- 1 s2.0 S0301421513003935 MainDokument8 Seiten1 s2.0 S0301421513003935 MainsudeviNoch keine Bewertungen

- Radio Mentions: An Analysis of Radio Personalities and Ethical BehaviorDokument22 SeitenRadio Mentions: An Analysis of Radio Personalities and Ethical BehaviorsudeviNoch keine Bewertungen

- Assessment of Lean Construction Principles A CaseDokument11 SeitenAssessment of Lean Construction Principles A CasesudeviNoch keine Bewertungen

- EQ2 Earthquake EffectsDokument23 SeitenEQ2 Earthquake EffectssudeviNoch keine Bewertungen

- Aluminium Design Manual 2010 - The Aluminium AssociationDokument440 SeitenAluminium Design Manual 2010 - The Aluminium AssociationQuang Hoành Lê100% (15)

- 7) Thermal Processing of WasteDokument44 Seiten7) Thermal Processing of WastesudeviNoch keine Bewertungen

- 7) Thermal Processing of WasteDokument44 Seiten7) Thermal Processing of WastesudeviNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Congratulations! Your Booking Is Now ConfirmedDokument6 SeitenCongratulations! Your Booking Is Now ConfirmedTufail AibaniNoch keine Bewertungen

- Letter of TransmittalDokument6 SeitenLetter of TransmittalEngr. Shahidul IslamNoch keine Bewertungen

- Assighment 1 Ma Thu Hương GCD201620Dokument65 SeitenAssighment 1 Ma Thu Hương GCD201620Bao Trang TrangNoch keine Bewertungen

- Autocad Daywise - SyllabusDokument1 SeiteAutocad Daywise - SyllabusAmal_YaguNoch keine Bewertungen

- Data Aire DAP III Modbus Integration Instructions: Data Aire, Inc. 230 West Blueridge Avenue Orange, California 92865Dokument12 SeitenData Aire DAP III Modbus Integration Instructions: Data Aire, Inc. 230 West Blueridge Avenue Orange, California 92865magoo1234Noch keine Bewertungen

- Chris Welman MSCDokument84 SeitenChris Welman MSCPablo Angel ToiaNoch keine Bewertungen

- MGT382-2 Coursework Specification (Individual Report) 2022-2023Dokument4 SeitenMGT382-2 Coursework Specification (Individual Report) 2022-2023Darshil D ShethiaNoch keine Bewertungen

- 6 Matrix Chain M UltiplicationDokument19 Seiten6 Matrix Chain M UltiplicationArslan Ahmed DanishNoch keine Bewertungen

- Equipment Brochure AdorDokument84 SeitenEquipment Brochure AdorHum Hum0% (1)

- Computer Science Syllabus Third Year - Semester 6Dokument14 SeitenComputer Science Syllabus Third Year - Semester 6shudhir chaudhariNoch keine Bewertungen

- Resume TumurDokument1 SeiteResume TumurTumur BazarragchaaNoch keine Bewertungen

- Circuit Analysis I UpdatedDokument116 SeitenCircuit Analysis I UpdatedSumaiya AslamNoch keine Bewertungen

- Notebook Power System Introduction TroubleshootingDokument44 SeitenNotebook Power System Introduction TroubleshootingJosé Santos100% (5)

- Master of Engineering Programme: Revised Study and Evaluation SchemeDokument31 SeitenMaster of Engineering Programme: Revised Study and Evaluation SchemeabcdNoch keine Bewertungen

- Map Reduce Tutorial-1Dokument7 SeitenMap Reduce Tutorial-1jefferyleclercNoch keine Bewertungen

- Full-Spectrum Sensor: SeriesDokument24 SeitenFull-Spectrum Sensor: SeriesAhya Al AnshoriiNoch keine Bewertungen

- 2020 McosmosDokument12 Seiten2020 McosmosRaquel RochaNoch keine Bewertungen

- Depth in DepthDokument10 SeitenDepth in DepthblahNoch keine Bewertungen

- Business Analytics and Big Data OutlineDokument4 SeitenBusiness Analytics and Big Data OutlineCream FamilyNoch keine Bewertungen

- Global Sourcing OptionsDokument25 SeitenGlobal Sourcing OptionsKazi ZamanNoch keine Bewertungen

- APlate Washer StatFax 2600 OM Rev I.2Dokument42 SeitenAPlate Washer StatFax 2600 OM Rev I.2Omar Mesta0% (1)

- B12 - Motor Management Systems - EN (Web) PDFDokument41 SeitenB12 - Motor Management Systems - EN (Web) PDFtongaiNoch keine Bewertungen

- Ac 160Dokument12 SeitenAc 160kanbouchNoch keine Bewertungen

- Iare Apo Question Bank 0 PDFDokument7 SeitenIare Apo Question Bank 0 PDFBharat TejNoch keine Bewertungen

- MAN11641-10 Installation Manual For RDI08-001A Remote Data InterfaceDokument35 SeitenMAN11641-10 Installation Manual For RDI08-001A Remote Data InterfaceMehmet TaşçıNoch keine Bewertungen

- DSA ProjectDokument3 SeitenDSA ProjectTARUN SAINoch keine Bewertungen

- Signal Multiplier Icc312Dokument2 SeitenSignal Multiplier Icc312supermannonNoch keine Bewertungen

- Manual Do Usuário Aurora Audio GTP8Dokument3 SeitenManual Do Usuário Aurora Audio GTP8Santos RobsonNoch keine Bewertungen

- LG 55UH615 Chassis UA65RDokument99 SeitenLG 55UH615 Chassis UA65RBreno Ortega Fernandez100% (1)

- Logcat Prev CSC LogDokument278 SeitenLogcat Prev CSC LogDarkzin ProNoch keine Bewertungen