Beruflich Dokumente

Kultur Dokumente

MBBR Product Information Materials

Hochgeladen von

Avinash kandhare0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

89 Ansichten2 Seitendetail understaning

Originaltitel

Mbbr Product Information Materials

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldendetail understaning

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

89 Ansichten2 SeitenMBBR Product Information Materials

Hochgeladen von

Avinash kandharedetail understaning

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

Moving Bed Biofilm Reactor (MBBR)

The Ecologix MBBR is a highly effec ve bio-

logical treatment process based on a combi-

na on of conven onal ac vated sludge pro-

cess and biofilm media. The MBBR process

u lizes floa ng High Capacity BioChips media

within the aera on and anoxic tanks. The mi-

croorganisms consume organic material. The

media provides increased surface area for the

biological microorganisms to a)ach and grow.

The increased surface area reduces the foot-

print of the tanks required to treat the

wastewater. The treatment process can be

aerobic and/or anaerobic and operates at

high volume loads. MBBR Advantages

• Compact units with small footprint

• Increased treatment capacity

• Complete solids removal

• Improved se)ling characteris cs

• Higher suspended biomass concentra ons

• Long sludge reten on mes

• Enhanced process stability

• Low head loss

• No filter channeling

• No need of periodic backwashing

• Reduced sludge produc on

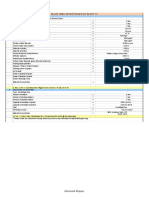

MBBR - SHIPPING CONTAINER PLATFORM

FLOWRATE Skids

MODEL

GPD GPM m3/day m3/hr ISO 40' ISO 20'

Great for Industrial Wastewater MBBR 040120 - AC 25000 17 95 3.9 0 1

MBBR 040120 - C 32000 22 121 5.0 0 1

• Dairy processing (milk, cheese, yogurt) MBBR 040120 37500 26 142 5.9 0 1

55000 38 208 8.7 1 0

• Beverage factories (breweries, juice, soda) MBBR 140020 - AC

MBBR 140020 - C 64000 44 242 10.1 1 0

• Automo ve industry MBBR 140020

MBBR 240120 - AC

75000

128000

52

89

284

484

11.8

20.2

1

2

0

1

• Paper and pulp industry MBBR 540020 - AC 256000 178 969 40.4 5 0

MBBR 440120 - C 300000 208 1136 47.3 4 1

• Metal pla ng and finishing MBBR 540120 - AC 320000 222 1211 50.5 5 1

Ecologix Mutag BioChips (MBC)

• Small in size with high capacity

• Largest Surface Area > 3,000 m²/m³

• Used worldwide since 2008

• Flat, curvy and with 3D rough surface to maximize Bacte-

ria’s Biofilm growth area

• Special Protec on Ring with material combina on

• Flexible and Free from Breakage

• No abrasion due to aerodynamic shape

• Best Diffusion of Substrate and Oxygen with a diffusion

depth of 0.5mm

• Can be mixed and pumped without damage

• Low energy requirements for mixing

MBC Applica ons:

• Denitrification

• Nitrification

• COD removal

• Anammox

> 3,000 m²/m³ • IFAS

Diffusion of O2 into the Cell Cluster

Das könnte Ihnen auch gefallen

- Municipal Wastewater Treatment: Evaluating Improvements in National Water QualityVon EverandMunicipal Wastewater Treatment: Evaluating Improvements in National Water QualityNoch keine Bewertungen

- Textile Effluent TreatmentDokument6 SeitenTextile Effluent TreatmentvenkatharunNoch keine Bewertungen

- Summary Report: RO System Flow DiagramDokument3 SeitenSummary Report: RO System Flow Diagramjugal ranaNoch keine Bewertungen

- Soil Pollution: Presented byDokument37 SeitenSoil Pollution: Presented byHakim Asif Haider50% (4)

- Past Exam Administrative LawDokument6 SeitenPast Exam Administrative LawMaybach MurtazaNoch keine Bewertungen

- The Environment Will Change Dramatically in The Next 50 YearsDokument7 SeitenThe Environment Will Change Dramatically in The Next 50 Yearspatty09750% (2)

- SHELL AND TUBE HEAT EXCHANGER DESIGNDokument16 SeitenSHELL AND TUBE HEAT EXCHANGER DESIGNSarvagyaNoch keine Bewertungen

- Determine BOD using dilution methodDokument3 SeitenDetermine BOD using dilution methodrockingtwo07Noch keine Bewertungen

- Design of Ammonia StripperDokument1 SeiteDesign of Ammonia StripperthirumuruganNoch keine Bewertungen

- What Is Water PollutionDokument13 SeitenWhat Is Water PollutionYudeimy Vargas NiñoNoch keine Bewertungen

- 2014 Berghof Membrane TechnologyDokument53 Seiten2014 Berghof Membrane TechnologyVictor DominguezNoch keine Bewertungen

- Hyd - Cal. WTP BaggiDokument27 SeitenHyd - Cal. WTP BaggiChief Engineer PMUNoch keine Bewertungen

- L6 Activated Sludge SystemDokument38 SeitenL6 Activated Sludge SystemNurul Aliza100% (2)

- Biomod: Packaged Moving Bed Biofilm ReactorDokument4 SeitenBiomod: Packaged Moving Bed Biofilm ReactorAlvaro Huete100% (1)

- T MBBR and MBR PDFDokument117 SeitenT MBBR and MBR PDFSwaminathan ThayumanavanNoch keine Bewertungen

- ATV Wastewater Filtration StandardDokument18 SeitenATV Wastewater Filtration StandardLaurentiu GheorghitaNoch keine Bewertungen

- Faecal Sludge Treatment Technologies in IndiaDokument44 SeitenFaecal Sludge Treatment Technologies in Indianeeraj sharmaNoch keine Bewertungen

- Intermittent Aeration and Biological Phosphorous Removal According To ATV/DWA StandardsDokument3 SeitenIntermittent Aeration and Biological Phosphorous Removal According To ATV/DWA Standardsunconformist100% (1)

- Nitrogen RemovalDokument96 SeitenNitrogen RemovalnusageniNoch keine Bewertungen

- EcoMix PDFDokument1 SeiteEcoMix PDFMarllon Boamorte LobatoNoch keine Bewertungen

- KEE MBBR BrochureDokument6 SeitenKEE MBBR Brochureseragak100% (1)

- Barangay Pandan Beca 2023Dokument70 SeitenBarangay Pandan Beca 2023Charina MiclatNoch keine Bewertungen

- Trickling Filters: Biological Wastewater Treatment Using Porous MediaDokument7 SeitenTrickling Filters: Biological Wastewater Treatment Using Porous MediaTasirmistNoch keine Bewertungen

- Simple Activated Sludge Design With Septic Tank 3000Dokument4 SeitenSimple Activated Sludge Design With Septic Tank 3000AlyannaKatePalasNoch keine Bewertungen

- Activated Sludge Waste Water Treatment Calculations - S.I. UnitsDokument2 SeitenActivated Sludge Waste Water Treatment Calculations - S.I. Unitsnsr2t100% (1)

- Waste Management Practices-Sample QuestionnaireDokument9 SeitenWaste Management Practices-Sample QuestionnaireKaine Bolton71% (7)

- What A Waste - A Global Review of Solid Waste ManagementDokument116 SeitenWhat A Waste - A Global Review of Solid Waste ManagementrenodfbNoch keine Bewertungen

- KUBOTA Submerged Membrane Unit Optional Parts: Lifting Tool Guide SetDokument1 SeiteKUBOTA Submerged Membrane Unit Optional Parts: Lifting Tool Guide SetmutazsalihNoch keine Bewertungen

- MBR Design SheetDokument9 SeitenMBR Design SheetVenkatesh SivaramanNoch keine Bewertungen

- Chlorine DosingDokument1 SeiteChlorine DosingkailashNoch keine Bewertungen

- Design & Sizing WWTPDokument30 SeitenDesign & Sizing WWTPRavishankar ANoch keine Bewertungen

- Suspended growth treatment systemsDokument45 SeitenSuspended growth treatment systemsNoureddine MerahNoch keine Bewertungen

- MBBR Vs Othe STPsDokument22 SeitenMBBR Vs Othe STPsNeelam Sharma67% (3)

- Disinfection: University Curriculum Development For Decentralized Wastewater ManagementDokument35 SeitenDisinfection: University Curriculum Development For Decentralized Wastewater ManagementLTE002Noch keine Bewertungen

- ACWA MBR presents Submerged Membrane Bioreactors using the Kubota MembraneDokument48 SeitenACWA MBR presents Submerged Membrane Bioreactors using the Kubota Membranecharles samsonNoch keine Bewertungen

- Optimizing Water Treatment ProcessDokument30 SeitenOptimizing Water Treatment ProcessEri VirnandoNoch keine Bewertungen

- Dimension wastewater treatment tanksDokument23 SeitenDimension wastewater treatment tanksmothman22Noch keine Bewertungen

- MBBR enDokument4 SeitenMBBR enRoland LumpasNoch keine Bewertungen

- 8 Sutari Aeration Mixing SystemsDokument43 Seiten8 Sutari Aeration Mixing SystemsTech ManagerNoch keine Bewertungen

- EWT Carrousel Systems: UNR SeriesDokument8 SeitenEWT Carrousel Systems: UNR SeriesKhang TrầnNoch keine Bewertungen

- Friction Factor CalculationsDokument2 SeitenFriction Factor CalculationsHu Hin AngNoch keine Bewertungen

- MBBR Design CalculationDokument5 SeitenMBBR Design CalculationPANDIARAJ KARUPPATHEVARNoch keine Bewertungen

- Bab IX OrificeDokument40 SeitenBab IX OrificeDark Specialist DNoch keine Bewertungen

- 150 KLD fecal sludge treatment plant design basisDokument56 Seiten150 KLD fecal sludge treatment plant design basissharan kommi100% (1)

- Optimization of A2O BNR Processes Using PDFDokument16 SeitenOptimization of A2O BNR Processes Using PDFPhạm LinhNoch keine Bewertungen

- AWW December 2017Dokument68 SeitenAWW December 2017prabal rayNoch keine Bewertungen

- Solution: Introduction To Solutions Group 5 Cornelia Espiritu Lumasag Mejorada OmbleroDokument12 SeitenSolution: Introduction To Solutions Group 5 Cornelia Espiritu Lumasag Mejorada OmbleroGezem GigantoNoch keine Bewertungen

- Self-Aerated Flow On Corps of Engineers SpillwaysDokument112 SeitenSelf-Aerated Flow On Corps of Engineers SpillwaysdjajadjajaNoch keine Bewertungen

- ACO Passavant - Technical Handbook and Product CatalogueDokument24 SeitenACO Passavant - Technical Handbook and Product CatalogueACO PassavantNoch keine Bewertungen

- Trickling Filter and Trickling Filter-Suspended Growth Process Design and OperationDokument19 SeitenTrickling Filter and Trickling Filter-Suspended Growth Process Design and OperationMichał KisielewskiNoch keine Bewertungen

- 1295 - Offer 50 KLD Package Type STP 27.08.2022 - RemovedDokument11 Seiten1295 - Offer 50 KLD Package Type STP 27.08.2022 - RemovedsanjeevNoch keine Bewertungen

- Adapatation of WWTP Warm Climates CH WalderDokument8 SeitenAdapatation of WWTP Warm Climates CH WalderChokri ChakiirNoch keine Bewertungen

- AnoxKaldnesBrochure2016Dokument6 SeitenAnoxKaldnesBrochure2016n_zeinounNoch keine Bewertungen

- Air CalculationsDokument4 SeitenAir CalculationsSerkan YukselNoch keine Bewertungen

- Appendix 7 (1) .1. UNITANK Process &technical Proposal 13Dokument77 SeitenAppendix 7 (1) .1. UNITANK Process &technical Proposal 13Huonghuynh Truongthi100% (1)

- Pipeline Systems OptimizationDokument29 SeitenPipeline Systems OptimizationVeena NageshNoch keine Bewertungen

- Kuliah MBR ITB 14 Nov 2022 - For PrintDokument31 SeitenKuliah MBR ITB 14 Nov 2022 - For PrintEni RohkayatiNoch keine Bewertungen

- SEKO Solenoid Dosing Pumps Kompact SeriesDokument3 SeitenSEKO Solenoid Dosing Pumps Kompact SeriesmauiraNoch keine Bewertungen

- Teknofanghi Monoscrew Pump - CatalougeDokument4 SeitenTeknofanghi Monoscrew Pump - CatalougeKarim ShamashergyNoch keine Bewertungen

- Trikling FiltersDokument16 SeitenTrikling Filtersmosaad khadrNoch keine Bewertungen

- WWTP Budgeting SaddamDokument11 SeitenWWTP Budgeting SaddamAQUAMART INDONESIANoch keine Bewertungen

- 1) (15 PTS) A 10 Inch Diameter Sanitary Sewer Is Designed Such That ItDokument13 Seiten1) (15 PTS) A 10 Inch Diameter Sanitary Sewer Is Designed Such That ItZeyad Tareq Al Sarori100% (1)

- Non-Uniform Open Channel Flow - Surface Profile Calculations - S.I. UnitsDokument32 SeitenNon-Uniform Open Channel Flow - Surface Profile Calculations - S.I. UnitsdiegoNoch keine Bewertungen

- Hospital Waste Water TreatmentDokument5 SeitenHospital Waste Water TreatmentNP100% (1)

- Drinking Water Treatment Residuals - A Review of Recent UsesDokument12 SeitenDrinking Water Treatment Residuals - A Review of Recent Usesgabriel oliveiraNoch keine Bewertungen

- Calculation of Sludge Production From Aerobic ASP JanusDokument8 SeitenCalculation of Sludge Production From Aerobic ASP Janusكرم عمرو100% (1)

- Trickling Filter Performance at Different TemperaturesDokument10 SeitenTrickling Filter Performance at Different Temperaturesanita pratiwiNoch keine Bewertungen

- Presentation On Biscuit SegmentDokument13 SeitenPresentation On Biscuit SegmentSachin KothariNoch keine Bewertungen

- 13 - Chapter 4 Final PDFDokument28 Seiten13 - Chapter 4 Final PDFNARINDERNoch keine Bewertungen

- ISE I Sample Paper 2 - HC Corrections + AnswersDokument5 SeitenISE I Sample Paper 2 - HC Corrections + AnswersNatalie Jaén Cartwright50% (2)

- Waste Water Treatment Lecture Notes 01Dokument4 SeitenWaste Water Treatment Lecture Notes 01eddy currentNoch keine Bewertungen

- ECC Condition-Industrial GroupDokument2 SeitenECC Condition-Industrial GroupKim Howard CastilloNoch keine Bewertungen

- Unit 2 - Touchstone 2.1 Evaluate A Source - Tri BurtonDokument5 SeitenUnit 2 - Touchstone 2.1 Evaluate A Source - Tri BurtontristylistNoch keine Bewertungen

- Multifunctional Urban Greeen InfrastructureDokument356 SeitenMultifunctional Urban Greeen InfrastructureDanna Marcela ÁvilaNoch keine Bewertungen

- Noise Doc Unit 11Dokument2 SeitenNoise Doc Unit 11Javaid Hussain100% (1)

- Waste DisporsalDokument28 SeitenWaste DisporsalOsmanNoch keine Bewertungen

- Visit To A Local Polluted SiteDokument5 SeitenVisit To A Local Polluted SiteShaunak De100% (2)

- Unit 4 - Week 3: Assignment 3Dokument5 SeitenUnit 4 - Week 3: Assignment 3Aniket shendeNoch keine Bewertungen

- Autonomous Garbage Segregator MachineDokument10 SeitenAutonomous Garbage Segregator MachineCP Pineda ArolNoch keine Bewertungen

- FGD & ESP Tobe Installed in India Power PlantsDokument87 SeitenFGD & ESP Tobe Installed in India Power Plantstsrinivasan5083Noch keine Bewertungen

- Legal and Regulatory Framework For Management of Health Care Waste in South Africa - M KgoleDokument9 SeitenLegal and Regulatory Framework For Management of Health Care Waste in South Africa - M KgoleAnafi MatakaNoch keine Bewertungen

- Water PolutionDokument4 SeitenWater PolutionsilualNoch keine Bewertungen

- Health Econ BibDokument262 SeitenHealth Econ BibAhmed HassanNoch keine Bewertungen

- Silvertown Tunnel: Document TitleDokument12 SeitenSilvertown Tunnel: Document TitlemeskiNoch keine Bewertungen

- Be It Enacted by The Senate and House of Representative of The Philippines in Congress AssembledDokument36 SeitenBe It Enacted by The Senate and House of Representative of The Philippines in Congress AssembledGina Portuguese GawonNoch keine Bewertungen

- Arsenic Contamination in Groundwater 2.0Dokument12 SeitenArsenic Contamination in Groundwater 2.0Thao LyNoch keine Bewertungen

- 3M - Proteccion AuditivaDokument2 Seiten3M - Proteccion AuditivaMAEBNoch keine Bewertungen

- Interpretation of Law and RegulationsDokument21 SeitenInterpretation of Law and Regulationslucian munyaradziNoch keine Bewertungen

- Aplikasi Teknologi Pengolahan Air Sederhana Untuk Masyarakat PedesaanDokument10 SeitenAplikasi Teknologi Pengolahan Air Sederhana Untuk Masyarakat PedesaanEcha FaraNoch keine Bewertungen