Beruflich Dokumente

Kultur Dokumente

Us3177771 PDF

Hochgeladen von

ashis0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

22 Ansichten3 SeitenOriginaltitel

US3177771.pdf

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

22 Ansichten3 SeitenUs3177771 PDF

Hochgeladen von

ashisCopyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 3

United States Patent Office 3,177,771

Patented Apr. 13, 1965

2

cylindrical casing 10 of suitable metal such as, for example,

3,177,771 a high strength aluminum alloy or steel tubing. End discs

COUNTER-RECOL MECHANISMFOR FREARMS 11 and 12 are fitted one in each end of the casing 10, and

Carrol D. McKim, 791 34th Ave., San Francisco, Calif. are strongly and fixedly secured in place therein in any

Fied Dec. 3, 1963, Ser. No. 327,628 suitable manner, as by welding, or, in the case of brass or

7 Claims. (Cl. 89-14)

steel, silver soldering. The inner end disc 11 is provided

The present invention relates to a recoil mechanism for with a threaded hole 13 therethrough of a size to permit

firearms, and pertains more particularly to such a mecha the threaded muzzle end portion 14a of a gun barrel 14

nism which is of extremely light weight and simple con to be screwed firmly and co-axially therein. The disc 12

struction. 0. in the other end of the casing tube 10 has a hole 17 there

In the past, numerous attempts have been made to pro through axially aligned with the threaded hole 13, and of

vide a mechanism which would reduce the recoil, and also a diameter to permit a projectile, not shown, fired from

the muzzle blast and flash, incidental to the firing of a high the gun barrel 14, to pass therethrough without contact

power rifle. Some of such prior devices have been quite with the surrounding disc 2.

heavy and cumbersome, and some thereof involve moving 15 A plurality of tubes 18 of an external diameter sub

parts, which are subject to rapid deterioration or damage stantially smaller than the casing tube 10, but larger than

by the high velocity, hot gases discharged from the muzzle the bore 19 of the gun barrel 14, are mounted transversely

upon the firing of a firearm upon which such a device is of the casing tube 10 with their axes substantially inter

mounted. Others thereof have provided less than satis secting the common axis of the barrel bore 19 and the

factory recoil reduction, while many of them have actual 20 holes 13 and 17 when the mechanism A is mounted on a

ly added to the noise effect on the shooter, being worse gun barrel 4 as shown in FIG. 2. Each of the trans

than with the bare muzzle. verse tubes 18 is fitted into a pair of holes 22 and 23

An object of the present invention is to provide an im provided in opposite sides of the casing tube 10, and has

proved and simplified muzzle-mounted counter-recoil a pair of co-axial holes 20 and 2 diametrically there

mechanism for firearms. 25 through. The tubes 3 are so positioned that the axes of

Another object is to provide a light weight muzzle all of the holes 20 and 21 therethrough are coincident with

mounted counter-recoil and noise reducing mechanism for each other and with the common axis of the holes 13

firearms. and 17 in the end discs 11 and 2 respectively. Each of

Another object of the invention is to provide a muzzle the transverse tube holes 20 and 21 is of diameter slightly

mounted counter-recoil mechanism comprising a tubular larger than the bore 19 of a gun barrel 14 for which the

casing having a plurality of open end smaller tubes counter-recoil mechanism A is intended, so as to permit

mounted transversely therein, each of the transverse tubes a bullet fired from the gun barrel to pass centrally there

having an opening diametrically therethrough of a size, through without contacting any of the tubes 8.

and so located, as to permit a bullet fired from the rifle While the drawings show the tubes 18 arranged with

barrel upon which the mechanism is mounted to pass their axes in a common plane, and diametrically of the

through these holes, whereby propellant gases following casing tube 10, which may be preferable in some in

such bullet expand throughout the interior of the casing to stances, it is obvious, however, that this arrangement can

thereby exert a forwardly directed force on the opposite be varied without departing from the present invention

end of the casing and on the transverse tubes in a direction as long as the holes in the tubes 18 are so aligned as to

opposite to that of the recoil caused by the firing of the permit a projectile from a gun barrel upon which the

projectile. mechanism is mounted to pass freely therethrough. The

A further object of the invention is to provide a muzzle tubes 18 as shown in FIGS. 1 and 2 terminate flush with

mounted counter-recoil and noise reducing mechanism for the outer surface of the casing 10, and the ends of all

firearms wherein a tubular casing is mounted in axially of the tubes 18 except the rearmost one are open. Disks

parallel relation on the muzzle end of a gun barrel, a 16 are affixed in sealing relation in the ends of the rear

plurality of smaller tubes being mounted transversely with most tube 18, since it has been found that the sound effect

in the casing and with their axes intersecting the bore axis of the report on the shooter is greatly reduced when this

of a gun barrel upon which the mechanism is mounted, first tube is so closed off, while the recoil reduction is

holes being provided in the transverse tubes to permit not adversely affected by such closing.

a bullet to pass therethrough, a plurality of the transverse 50 The operation of the form of the invention shown in

tubes communicating at their ends with the atmosphere, FIGS. 1 and 2 is as follows: When a projectile (not

whereby the gases propelling a bullet fired from such gun shown) is fired from a gun barrel 14 upon which a mech

barrel and passing through the casing and through the anism. A embodying the invention is mounted as shown

holes in the transverse tubes exert a counter-recoil force in FIGS. 1 and 2, the projectile passes successively

on the mechanism, and escape to the atmosphere through through the holes 20 and 21 in all of the transverse tubes

some or all of the tubes and the outer end of the casing 18, and through the hole 17 in the forward disc 2 with

after expansion into the tubular casing, thereby also great out contacting any portion of the mechanism A. Since

ly reducing the muzzle blast. all of the holes through which the projectile thus passes

These, and other objects and advantages of the inven are concentric with the cross sectional configuration of

tion, will be apparent from the following description and 60 such projectile, no force is exerted on the projectile by

the accompanying drawings, wherein: such passage which would tend to divert it from its normal

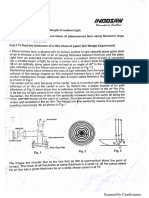

FIG. 1 is a perspective view of one form of counter trajectory. The propellant gases from the explosion

recoil mechanism embodying the invention, a portion of which propel the projectile enter the casing 10, where

the muzzle end of a rifle barrel upon which the mecha they immediately expand, and in their violent forward

nism is mounted being shown in broken lines. travel they encounter the transverse tubes 18 and the for

FIG. 2 is an enlarged, diametrical, sectional view of the ward end disc 12, exerting a powerful forwardly directed

mechanism shown in FIG. 1, the muzzle end portion of force thereon which tends to nullify the usual recoil

the gun barrel also being shown sectionally. resulting from the firing of a high power rifle.

FEG. 3 is a sectional view generally similar to FIG. 2, Also, these expanding gases build up a tremendous

but showing a modified form of the invention. 70 pressure within the casing 10, and this pressure forces the

The illustrated embodiment of the invention comprises gases into each of the tubes 18 through the holes 28 and

a muzzle mounted counter-recoil mechanism A, having a 21 therein, and also out the end hole 17. As the gases

3,177,771

f

t 4.

enter the tubes 18 through the holes 20 and 21 from open to the atmosphere exteriorly of the casing,

opposite sides, the shock waves of the oppositely directed (f) means for mounting the casing co-extensively on

incoming gases tend to cancel each other out, while the the muzzle end of a rifle barrel with the opening in

gases, issuing from the several orifices provided by the the outer end of the casing and the holes diametri

open ends of the tubes 18 and the end opening 17 pro 5 cally through the transverse tubes co-axial with the

duce, in effect, a number of small explosions, the sharp bore of such barrel, and with the inner end of the

ness and intensity of which is greatly reduced by the ex casing Sealed to such barrel.

pansion of the gases within the casing 10. 2. An arrangement according to claim 1 wherein the

In addition to a reduction of recoil and report noise, ends of the transverse tube nearest the muzzle end of

the present invention results in a marked reduction in O the casing are sealed off and the ends of the remaining

muzzle flash, since the propellant gases are trapped transverse tubes are open to the atmosphere.

momentarily within the casing 10, and even this momen 3. An arrangement according to claim 2 wherein each

tary delay permits at least some of the burning particles transverse tube is fitted into a pair of holes provided

of the propellant charge to be consumed in the casing 10. therefor in the casing, and is fixedly secured therein.

While the casing 10 is shown in FIGS. 1 and 2 as being 5 4. A counter-recoil mechanism for a rifle, comprising:

mounted co-axially of the bore 19 of a rifle barrel 14 (a) a tubular casing having an interior diameter a

upon which the mechanism A is mounted, and this ar plurality of times that of the bore of a rifle upon

rangement is presently preferred, particularly for use which it is to be mounted,

with telescopic sights, this arrangement is not essential (b) each end of the casing being closed except for

to the invention and the holes in the end discs i? and 12, an opening therein of a diameter greater than the

and the holes 21 and 22 in the tubes 18 may be located bore of such rifle, the openings in the casing ends

with their common axis adjacent the upper side of the being co-axial,

casing 0 as shown in FIG. 3, which arrangement may (c) the opening in the inner end of the casing being

be preferable where ordinary or iron sights are employed. threaded for screwing co-axially onto the correspond

The arrangement shown in FIG. 3 is generally similar ingly threaded muzzle of a rifle barrel,

to that shown in FIGS. 1 and 2, and corresponding parts (d) a plurality of tubes of an external diameter,

thereof are designated by the same reference numerals Smaller than the internal diameter of the casing and

as those employed in FIGS. 1 and 2 with the prime (') larger than the bore of such barrel, and mounted

added thereto. Aside from the lateral offsetting of the transversely of the casing, each transverse tube hav

common axis of the holes 13, 17, 20' and 21 from the 3. ing aligned holes in opposite walls thereof diametri

axis of the casing 10', and the elongation of the trans cally therethrough, the holes diametrically of the

verse tubes 18 to provide the extensions 18'a, the modi transverse tubes being of slightly larger diameter

fied form A of FIG. 3 is substantially the same as that than the bore of such barrel,

shown in FIGS. 1 and 2. Its operation will, therefore, (e) the transverse tubes being mounted with the holes

be obvious to one having an understanding of the struc diametrically therethrough co-axial with each other

ture and operation of the form A of FIGS. 1 and 2, and and with the openings in the ends of the casing.

will not, therefore, be described in further detail herein. 5. An arrangement according to claim 4 wherein the

The invention provides a simple, light weight, inexpen ends of the transverse tubes terminate substantially flush

sive and highly effective counter-recoil mechanism for 40

with the outer surface of the casing.

firearms, with little or no adverse effect on the trajectory 6. An arrangement according to claim 4 wherein the

of a projectile fired from a firearm, such as a rifle, upon transverse tubes are of a length to project radially beyond

which the invention is mounted, and with the additional the casing.

advantage of reducing both report noise and muzzle flash. 7. A counter-recoil mechanism for a rifle, comprising:

While I have illustrated and described a preferred em (a) an elongated casing having an interior diameter

bodiment of the present invention and one modified form a plurality of times that of the bore of a rifle upon

thereof, it will be understood, however, that various which it is to be mounted, and having aligned open

changes and modifications may be made in the details ings in opposite ends thereof of a diameter greater

thereof without departing from the scope of the invention than the bore of such rifle,

as set forth in the appended claims. (b) a plurality of tubes of an external diameter sub

Having thus described the invention, what I claim as stantially smaller than the casing and larger than

new and desire to protect by Letters Patent is defined the bore of such barrel mounted transversely across

in the following claims. the interior of the casing, each transverse tube hav

1. A counter-recoil mechanism for a rifle, comprising: ing a hole diametrically therethrough of slightly

(a) a tubular casing having an interior diameter 55 greater diameter than the bore of such barrel,

several times that of the bore of a rifle upon which (c) the transverse tubes being mounted with the holes

it is to be mounted, diametrically therethrough aligned with each other

(b) the outer end of the casing being closed except and with the openings in the ends of the casing,

for an opening therein of a diameter slightly greater (d) and means for mounting the mechanism on the

than the bore of such rifle, 60

muzzle of a rifle barrel with the openings in the

(c) a plurality of tubes of an external diameter sub casing ends and the holes diametrically through the

stantially smaller than the internal diameter of the transverse tubes aligned with the bore of such barrel

casing and larger than the bore of such barrel to permit a projectile fired through said bore to pass

mounted transversely of the casing, each transverse freely through said mechanism.

tube having aligned holes in opposite walls thereof References Cited by the Examiner

diametrically therethrough, the latter holes being of UNITED STATES PATENTS

slightly larger diameter than the bore of such barrel,

(d) the transverse tubes being mounted with the holes 2,453,121 11/48 Cutts ---------------- 89-14.3

diametrically therethrough co-axial with each other

and with the hole in the outer end of the casing, 70 BENJAMIN A. BORCHELT, Primary Examiner.

(e) the ends of some of the transverse tubes being FRED C. MATTERN, JR., Examiner.

Das könnte Ihnen auch gefallen

- Thermodynamics Enthalpy Entropy Mollier and Steam TablesDokument44 SeitenThermodynamics Enthalpy Entropy Mollier and Steam TablesashisNoch keine Bewertungen

- Air Cycle RefrigerationDokument10 SeitenAir Cycle RefrigerationashisNoch keine Bewertungen

- InternalBallistics 10262675 PDFDokument280 SeitenInternalBallistics 10262675 PDFashisNoch keine Bewertungen

- MathIlluminated 02 TXT PDFDokument57 SeitenMathIlluminated 02 TXT PDFashisNoch keine Bewertungen

- Newtons RingsDokument8 SeitenNewtons RingsashisNoch keine Bewertungen

- Final Ps - Static.01 EquliDokument4 SeitenFinal Ps - Static.01 EquliashisNoch keine Bewertungen

- LatheDokument8 SeitenLatheashisNoch keine Bewertungen

- The Manhattan Project-A Part of Physics History: Ann-Marie M Artensson-PendrillDokument9 SeitenThe Manhattan Project-A Part of Physics History: Ann-Marie M Artensson-PendrillashisNoch keine Bewertungen

- Particle Property of Wave: PH-1201 Unit 8 Lecture-17 (Two Classes)Dokument11 SeitenParticle Property of Wave: PH-1201 Unit 8 Lecture-17 (Two Classes)ashisNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Label OutnerDokument90 SeitenLabel OutnerSaktiNoch keine Bewertungen

- Daily Monitoring Defect SheetDokument15 SeitenDaily Monitoring Defect Sheetmanju nathNoch keine Bewertungen

- 541, 551, and 552 Hydraulic System Track Feller Buncher: DD EEDokument8 Seiten541, 551, and 552 Hydraulic System Track Feller Buncher: DD EEPinheiro WelintonNoch keine Bewertungen

- Raychem IM INST216 ATTS13 ML PDFDokument12 SeitenRaychem IM INST216 ATTS13 ML PDFey0oxNoch keine Bewertungen

- 793D SERV1817-01 - SLIDE - Aug2006Dokument233 Seiten793D SERV1817-01 - SLIDE - Aug2006Ishan IqbalNoch keine Bewertungen

- CNC Programming Tapping With g32 g84 Tapping Cycle Tapping On CNC Lathe - YouTubeDokument1 SeiteCNC Programming Tapping With g32 g84 Tapping Cycle Tapping On CNC Lathe - YouTubejaisankar94Noch keine Bewertungen

- Equipment Encyclopedia v2.0.5Dokument16 SeitenEquipment Encyclopedia v2.0.5Asen0% (1)

- Prelim Lesson 1.3 Historical Background of BallisticsDokument3 SeitenPrelim Lesson 1.3 Historical Background of BallisticsTIPAY, EMELIE L.Noch keine Bewertungen

- Spisok Zapasnyih Chastey 8 MPVDokument22 SeitenSpisok Zapasnyih Chastey 8 MPVCyril DepalomaNoch keine Bewertungen

- MSRP-S3 IndexDokument4 SeitenMSRP-S3 Indexdi jinNoch keine Bewertungen

- Angle Measurement PDFDokument85 SeitenAngle Measurement PDFSnigdhaNoch keine Bewertungen

- User Servicing Manual: EnglishDokument182 SeitenUser Servicing Manual: EnglishHadi BitarNoch keine Bewertungen

- Bosch Dishwasher Multi-Model Test ProgramsDokument10 SeitenBosch Dishwasher Multi-Model Test ProgramsSamurai Appliance Repair Man75% (4)

- Industrial Case Study Report atDokument14 SeitenIndustrial Case Study Report atamitdhakateNoch keine Bewertungen

- Plumbing Max FajardoDokument175 SeitenPlumbing Max FajardoKeannosuke SabusapNoch keine Bewertungen

- Mortise & Tenon Template InstDokument2 SeitenMortise & Tenon Template InstRamon CoelhoNoch keine Bewertungen

- Weapon Lights and Targeting LasersDokument3 SeitenWeapon Lights and Targeting LasersバラモスまさゆきNoch keine Bewertungen

- HEYM Express Catalog 2017Dokument1 SeiteHEYM Express Catalog 2017risang akrima fikriNoch keine Bewertungen

- Plan de Maintenance Atlas Copco ORX12 - GEMEXDokument3 SeitenPlan de Maintenance Atlas Copco ORX12 - GEMEXPhilippe Dumont100% (1)

- 36-6020 20series 20table 20saw 20parts 20list 20 20rev 204Dokument5 Seiten36-6020 20series 20table 20saw 20parts 20list 20 20rev 204Jose Daniel RosarioNoch keine Bewertungen

- Extec Jaw QJ340 Spare Parts CatalogueDokument117 SeitenExtec Jaw QJ340 Spare Parts CatalogueS Sathish KumarNoch keine Bewertungen

- 210 Dial Bore GaugeDokument1 Seite210 Dial Bore Gaugeajay upadhyayNoch keine Bewertungen

- Safe Handling of Flammable Refrigerants June 01, 2023 (Thursday)Dokument18 SeitenSafe Handling of Flammable Refrigerants June 01, 2023 (Thursday)kaleem siddiquiNoch keine Bewertungen

- Brazed Tool ArDokument5 SeitenBrazed Tool ArRoni MustafiqNoch keine Bewertungen

- Cavities DimensionsDokument10 SeitenCavities DimensionsLuis Carlos Gomez MontoyaNoch keine Bewertungen

- Direct Type Manual of PRI-SAFETY FM200 Novec1230 Fire SystemsDokument8 SeitenDirect Type Manual of PRI-SAFETY FM200 Novec1230 Fire Systemsshadi elhagNoch keine Bewertungen

- RCOM C02-2220-4 SD - Raw Water Piping Pump Skid Gen Arr R4Dokument3 SeitenRCOM C02-2220-4 SD - Raw Water Piping Pump Skid Gen Arr R4Charles SaingNoch keine Bewertungen

- Installation Mantainance ManualFan CoilYEKN YGKNDokument19 SeitenInstallation Mantainance ManualFan CoilYEKN YGKNJavier SosaNoch keine Bewertungen

- WFL m120 Tool ListDokument2 SeitenWFL m120 Tool ListSreenivass SegaranNoch keine Bewertungen

- BSP Threaded EN1092 DIN2566 FlangeDokument4 SeitenBSP Threaded EN1092 DIN2566 FlangeChowKC03Noch keine Bewertungen