Beruflich Dokumente

Kultur Dokumente

5-ETAP - User Defined Dynamic Models

Hochgeladen von

Manohar PotnuruOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

5-ETAP - User Defined Dynamic Models

Hochgeladen von

Manohar PotnuruCopyright:

Verfügbare Formate

Chapter 25

User-Defined Dynamic Models (UDM)

The ETAP User-Defined Dynamic Models (UDM) program is a graphic logic editor (GLE)

interpreter tool for the creation of user-defined governor, exciter, and power system stabilizer

models for synchronous machines, generic load and wind turbine generator models. This module

allows the models to be linked to ETAP’s transient stability program. The models can be built in

the ETAP UDM Graphic Logic Editor or can be imported from Matlab Simulink files. ETAP

uses these dynamic models at run time when conducting Transient Stability Studies. This tool is

fully integrated into ETAP to allow the creation of dynamic models.

The main application of the UDM module is to create and tune (validate) dynamic control

elements which are not part of the standard ETAP dynamic model library (built-in models). The

following types of controllers / dynamic models can be created with UDM:

1) Synchronous Motors Exciter / AVR models

2) Synchronous Generator Exciter / AVR models

3) Synchronous Generator Turbine, Engine / Speed Control models

4) Synchronous Generator PSS (Power System Stabilizer) models

5) Wind Turbine Generator Models

6) Generic Load Models (Lumped Load Element Dynamic Models)

7) Generic Controller Models (plant-level controls)

8) Energy-Storage Devices

The UDM interface also has the capability to assist in the selection of parameters or settings for

each of the controllers or dynamic models listed above. This capability is called, “Dynamic

Parameter Estimation and Tuning,” or DPET for short. DPET can be used to estimate the values

of the parameters which make the controllers respond as similar as possible to a field-measured

response (i.e. measurements from a staged test or field-recorded disturbance). The tuning of the

UDM model response is accomplished by using an iterative approach, which automatically adjusts

the tunable settings/parameters in the model to make the controller response match that of field-

recorded data. This process may also be known as, “automatic model validation parameter tuning.”

Combined with the UDM variable parameter capability, DPET adds a lot of time-saving

capabilities which can literally save hundreds of engineering man-hours previously spent on the

tedious process of model validation parameter tuning. Furthermore, a section on how to best use

DPET is included in this chapter.

This chapter also covers the basics of how to model, simplify, debug and configure initialization

routines required to make the models work properly for Transient Stability Studies.

ETAP 25-1 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Graphic Logic Editor

UDM Graphic Logic Editor

This section describes how to open the UDM interface and how to use all of its related general

toolbars and functionalities.

25.1.1 Accessing the UDM Interface

There are two ways to access the UDM Editor. The first method is from the system toolbar. The

second method to access the UDM Editor is from the synchronous generator editor individual

pages (Governor, Exciter & PSS pages), synchronous motor exciter page, dynamic page of the

lumped load editor and the Info page of the wind turbine generator editor. Please note that the

model type is inherited from the editor from which the UDM interface was accessed.

If you open the UDM Editor from the Individual Editors:

If the UDM Editor is opened from the synchronous generator, synchronous motor, lumped load

or wind turbine editor, any content that is not related to the individual element is filtered out.

This means that only the models created specifically for the given machine will be listed in the

model selection drop list. If there is no model created, then the UDM model selection drop list is

blank. Clicking on the UDM Editor Button opens the UDM Interface. At this time, a new model

can be created. When the model is saved, it will be associated with the element from which the

editor was accessed. The model can be associated with other elements or added to the model

library later on if required.

Once the UDM editor is opened from the generator element, the default directory for the file

“save” and “open” is the current project directory.

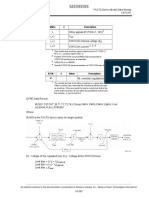

The following image illustrates the process of opening a UDM model for the first time from the

generator editor:

Once the model is saved, the model will be linked to the element for which it was created using

the following naming convention:

<Element ID>_<Type>_<Model Name>.

ETAP 25-2 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Graphic Logic Editor

More on the naming convention is included under the file saving section of this chapter.

If you open the UDM Editor from the System Toolbar:

Opening the UDM Editor from the system toolbar allows you to modify all model files including

the ones in the current project directory or the ones from the library. The program file open and

file save directory are defaulted to the UDM library directory (\\ETAP Installation

Directory\UDM). However, it is possible to save and link to an element as long as the model is

saved in the project directory with the proper naming convention. If this is done, the model

would be linked exclusively to an element and can be accessed from the element itself.

The following image show how to access the UDM GLE Interface from the system toolbar by

clicking on the UDM Interface Icon:

ETAP 25-3 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Saving UDM Model Files

The UDM Interface saves the models using a *.udm extension. The files will be stored in two

locations. The first will be the project directory. The other will be the UDM library directory (i.e.

template directory).

If the models are saved to the library, then they will be saved in the following directories inside

of the ETAP installation director:

Governor Models \UDM\Gov

Exciter Models \UDM\Exc

PSS Models \UDM\PSS

Generic Load \UDM\Generic

Wind Turbine \UDM\WTG

Please note that the UDM directory is located inside of the ETAP installation directory such as

C:\ETAP7.5.1\UDM

Note: When naming the device and the UDM file, do not include period, forward slash or colon

in the name: “.”, “/”, or “:”.

Please note that you can also place Simulink files to be imported or converted to a *.udm

format by placing them in the same locations as described above.

Note: A*.mdl file can only be imported into the UDM editor. These files will only be visible to

the UDM Interface if the user selects the import or export function. The UDM import function

has been disabled for ETAP 16.0.0. It will be enabled in future versions of the UDM tool.

ETAP 25-4 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

File Naming convention for UDM Models (files with extensions *.udm, *.bin & *.doc):

The files which are purposely saved as specific models for certain generators need to have the

following naming convention.

<Element ID>_<Type>_<Model Name>.UDM

Element ID-> Where the Element ID is the Element ID from ETAP Element. This could be the

synchronous generator or synchronous motor ID.

Model Name-> IEEE1, IEEEAC7B, GELM2500, etc, etc. This is the actual model name as

shown in the element editor UDM model selection drop list.

The types available are:

Type->EXC

Type->GOV

Type->PSS

Type->Generic

Type->WTG

For example: if an exciter from the library (i.e. IEEE1.UDM) is to be associated with Generator

1, then the file should be named:

“Gen1_EXC_IEEE1.UDM”

Other Examples would be:

“GeneratorXYZ_GOV_DT.UDM”

“EmergencyDiesel_EXC_IEEEAC7B.UDM”

“Gen1_PSS_STAB2A.UDM”

“SynchMotor_EXC_IEEE1.UDM”

“Lump1_GENERIC_CONV1.UDM”

“Lump2_GENERIC_SEQ1.UDM”,

Etc, etc.

This naming convention achieves the following:

If the Type is EXC, then this file is only visible from the Exciter pages of the Synchronous

Generator and Motor. If the Type is GOV, then the model is only visible from the Governor page

of the synch generator and finally, if the type is PSS, then it would only be visible from the PSS

page. If the Type is GENERIC, then this file is only visible from the Dynamic Page of the

Lumped Load. If the type is “WTG” then the models are only visible from the WTG editors.

ETAP 25-5 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

The following file types are also generated by the UDM GLE Interface after the model is

compiled:

*.DOC, *.BIN, *.LK, *.SC

The *.bin files generated by the compiler have the following naming convention:

<Element ID>_<Type>_<Model Name>.bin

The *.doc files generated by the compiler have the following naming convention:

<Element ID>_<Type>_<Model Name>_data.doc

The *.LK files generated by the compiler have the following naming convention:

<Element ID>_<Type>_<Model Name>.lk

This file is created when the models include lookup table elements with significant amount of

imported data.

The *.SC files are generated by the compiler have the following naming convention:

<Element ID>_<Type>_<Model Name>.sc

The *.sc files are created when the models include any DPET study cases.

This naming convention has the same purpose and it is to associate the models with their

respective elements.

ETAP 25-6 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

25.2.1 UDM Editor Presentation

This section describes the toolbars, menu items and all the capabilities of the UDM graphic logic

editor interface. The image below shows the UDM Graphic Logic Editor Interface with a

governor model open. The interface also shows the Simulation (test mode) and the DPET mode

toolbar.

File Menu Items:

The file menu items allow the user to open, save and import information into the UDM Editor.

The following are the options available through this drop down menu:

ETAP 25-7 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

New

This menu item allows the user to create a new UDM model.

Open

The “open” option allows the user to open a UDM model. The open function opens a dialog

which has a default directory. The default is the project directory. The file open dialog opens

only the files with extension *.udm.

Open from Library

This option is used to open the UDM models stored in the UDM model library directories for

Exc, Gov, Pss, Generic and WTG models. The location or path for this is always the ETAP

project in the UDM directory (i.e. C:\ETAP 800\UDM\). Once in the library directory, the user

can browse inside each directory and choose which file to open.

Close

Close the currently selected model.

Save

This option saves the UDM file into the current project directory unless the user specifies a

different location. Depending from where the file was opened, the save button will also link a

model to an element and type.

If the UDM model was opened from the generator editor, then upon saving, the program would

name the model as:

<Element ID>_<Type>_<Model Name>.UDM

If the UDM model was opened from the system toolbar, then the UDM modeled will be saved

based on the user given name. The program would not rename the model.

Save as

Saves the *.udm file as specified and where specified by the user. The remaining options to save

as EMF, GIF, PNG, BMP, JPEG, TIFF, SVG file are allowed and save the UDM model as a

graphical image.

Save to library

This function allows the user to save the current model as part of the library items. When saved

in the library, the user is free to specify the name and the interface does not follow the naming

convention since the model is meant to be a generic library model.

Import (from *.mdl Simulink files)

This function allows the user to import models into the UDM editor which were created in

Simulink . The following mapping table is used in order to map the inputs and outputs from

Simulink into the ETAP UDM Graphic Logic Editor format.

This feature has been temporarily disabled for ETAP 16.0.0 and will be enabled in future

releases.

ETAP 25-8 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

If the type of the model is a GOV, PSS, Generic or WTG then the mapping table adjusts to show

the input and output ports for those elements only. Please note that any unmapped input and

output ports are removed, since they would not be supported by the ETAP compiler.

The blocks supported from Simulink which are recognized by the UDM compiler are shown

below:

ETAP 25-9 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Please note that any block which is imported into the UDM editor which is not supported is

automatically deleted in the imported UDM model. The import program supports imported

Simulink models up to version 7.11.0.584 (R2010b).

The models which can be imported into ETAP should follow the model design rules of previous

versions of the UDM compiler. If those model design rules are not followed, the model may not

compile properly in the new UDM compiler. Those rules are summarized below:

The maximum order of a transfer function (Transfer Fcn) block is a third order function.

The function types that can be used in an Fcn block consist of: sin, cos, tan, atan, abs, exp, sqrt, and

log.

The input/output variable names in Simulink can be specified arbitrarily and then mapped to ETAP

input/output variable names using the System Variable Selection Editor. This was true up to version

7.5.3. However, In ETAP11 we recommend using the following key words for the input/output

variable names. The appropriate key words reserved for ETAP UDM Turbine/Governor,

Exciter/AVR, and PSS models, are provided in the following tables:

Turbine/Governor Model

Key Word Description

Pe Generator Real Electrical Power

Input

W Generator Speed

Output Pm Turbine Output Mechanical Power

Exciter/AVR Models

Key Word Description

Vt Machine Terminal Voltage

CVt Machine Terminal Voltage in complex form

It Machine Terminal Current

CIt Machine Terminal Current in complex form

Pe Machine Real Power

Input

Qe Machine Reactive Power

Vs PSS Signal

Ifd Machine Field Current

Fre Machine Terminal Voltage Frequency

PF Machine Power Factor

Output Efd Exciter Output Voltage

ETAP 25-10 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

PSS Model

Key Word Description

Vt Generator Terminal Voltage

W Shaft Speed

f Generator Terminal Voltage Frequency

Input

Pe Generator Real Power

Pm Generator Mechanical Power

Ang Generator Rotor Angle

Output Vs PSS Output Signal

Using these input/output variable names will simplify the import process significantly since in

ETAP11, those inputs and output names are fixed block types.

The check box “Save the imported UDM model into library” allows the user to automatically

same the imported model into the corresponding library of UDM models. This is done according

to the model type.

Export

This function allows the user to export the *.udm file into a *.mdl file. The export function

supports up to version 7.11.0.584 (R2010b) of Simulink.

The export function has been disabled in ETAP 16.0.0. It will be enabled in future releases.

Note: Default settings are used for the parameters not included in the *.udm model file.

Page Setup

Regular page setup function (landscape, portrait, page size, etc).

Print Preview

Regular print preview tool.

Print

Regular printing utility

Exit

Exit the project. Prompts if the file has not been saved or has been modified since the last save.

ETAP 25-11 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Edit Menu Items:

This menu list contains following functions:

Undo

Undo a certain action such as hiding or moving an element. You may also undo adding or

deleting a connection. The Undo feature can revert back up to 20 actions.

Redo

This option allows you to ‘Redo” up to 20 actions. The following image shows an example of the

“Undo” and “Redo” functions.

Delete Study Case

This menu item allows the deletion of dynamic parameter estimation and tuning (DPET) study

cases. The image below shows the delete window.

ETAP 25-12 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Cut

The Cut command on the Edit menu will delete selected elements from the workspace and place

them in memory. You can also cut selected elements by right-clicking and selecting the cut

command from the pop-up menu. To select a group of elements, click and hold the left mouse

button down while dragging the pointer across the elements you want to select.

Copy

The Copy command from the Edit Menu copies selected elements from the workspace. You can

also copy multiple elements selecting them (press and hold the left mouse button down while

dragging the pointer across the elements you want to select) and then right-clicking and pressing

the Copy command from the pop-up menu.

Paste

To paste an element or a group of elements from the memory, select the Paste command from the

Edit menu or you can right-click and select the Paste command from the pop-up menu.

Format

This option includes Fill and Shadow to set the inside color and shadow of the selected objects.

Basically, you can change color and format of the selected blocks in this section.

ETAP 25-13 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Fill

Under Edit menu go to Format then click on Fill. The “FillStyle Dialog” allows you to change

the background and fore color of the selected blocks. Also, different brush styles can be selected.

Shadow

Under Edit menu go to Format then click on Shadow. The “ShadowStyle Dialog” allows you to

configure the shadow for a particular element block. The shadow style is shown in the “Preview”

section.

ETAP 25-14 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

View Menu Items:

The “View” menu contains the following functions:

Rulers

The horizontal and vertical rulers in the UDM Graphical Grapical Logic editor are often used to

align text, graphics, tables, and other elements in the workspace.

ETAP 25-15 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Symbol Palette

This option activates the Control Element Symbol Palette (shown on the left-hand side of the

workspace by default)

Properties

This command shows the properties window (shown on the right-hand side of the workspace by

default)

ETAP 25-16 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

When copying and pasting elements from one model to another, the diagram size should be set to

a size appropriate to hold all the pasted elements. If this is not the case, the copy/paste action will

not take effect until the size is modified accordingly. The image below shows the location of the

diagram size dialog.

ETAP 25-17 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Pan Zoom Window

This window can be used to preview a panoramic view of the elements in the workspace. The

panoramic view can be modified by dragging the panoramic box around the workspace preview

window. This tool is useful to zoom in and out and to navigate through very complex and large

models.

There is a pin icon on top of the toolbox shown as . By clicking this pin you can Hide/Show

the toolbox in UDM.

ETAP 25-18 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Before:

After:

ETAP 25-19 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Document Explorer

This window provides good information about the elements in the selected model. It lists all the

elements by type. This tool can be used to navigate through the model elements and make

changes to the individual properties without having to find the block graphically in the

workspace.

Layers (will be available in future)

To add a block to a layer you need to make the layer active

while you are dragging the block to your workspace. If two

layers are active at the same time, the created block will

belong to both layers, and if you hide one of the layers, all

the blocks which belong to the layer will be invisible.

Element changes are applicable to all active layers. If an

element or connection is to appear only in one layer, then all

the remaining layers must be de-activated. Only the desired

layer should be active when the element block is added or the

connection is made.

The image below illustrates the end result of associating

some elements and connections to different layers. Elements

not active during simulation will not be considered active in

the mathematical calculations. This tool will not be active in

the first release of the UDM Graphic Logic Editor.

ETAP 25-20 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Model 1 Model 2

Layer 1 is Visible

Layer 2 is Visible

Layer 1 is Visible

Layer 2 is Invisible

Layer 1 is Invisible

Layer 2 is Visible

ETAP 25-21 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Header

With thisFooter

option you can add your desired header and footer to your model. The header and

footer contents can be customized by applying different font styles and colors.

ETAP 25-22 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Page Borders

You can select different borders, weight, and style. Also by changing the color and transparency,

you have the option to choose your desired color for borders.

ETAP 25-23 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Model Parameters

The model parameter section lists all the parameters used in the UDM model.

Please refer to section 25.4.2 for more details.

Actions Menu Items

After you select some functions block from Actions toolbar, the “Align” option can perform the

actions as described below:

Action Result

Align Left moves all blocks to the most left side of the reference block

Align Center moves center of all blocks to the center of the reference block

Align Right moves all blocks to the most right side of the reference block

Align Top moves all blocks to the top side of the reference block

Align Middle moves all blocks to the middle line of the reference block

Align Bottom moves all blocks to the bottom line of the reference block

Please note that the first block created is the reference block

ETAP 25-24 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Before After

Align Left Align Center Align Right

Before

Align Top

After Align Middle

Align Bottom

ETAP 25-25 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Flip

The flip option causes a reflection of the selected block. The blocks can be flipped horizontally

or vertically. The following image illustrates the result of flipping some blocks horizontally:

ETAP 25-26 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Rotate

This function helps to rotate selected object 90 degree clockwise or counter-clockwise. You can

activate the rotation by clicking the right mouse button and selecting the different rotate

commands from the menu.

Figure 17- Rotate Toolbar

Mouse right click

Figure 18- Using Rotate option from Mouse Right Click popup menu

Figure 19- Rotate Toolbar

ETAP 25-27 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Window Menu Item

Tabbed MDI

This is a control that allows you to use tabbed document interface and change the project

windows view as shown below:

ETAP 25-28 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Hot Keys/ Shortcut keys

These hotkeys work at the “model” level, not at the UDM editor window level. That is, you

must be inside the model tab to activate these keys.

• Ctrl+G = compiles model

• Ctrl+T = runs model test

• Ctrl+W = closes all plots

• Ctrl+U = open UDM library

• Ctrl+O = open project directory

• Ctrl+N = open new diagram

• Ctrl+S = save UDM file

• Ctrl+A = select all the blocks

• Ctrl+D = delete DPET study case

• Ctrl+Z = undo

• Ctrl+X = cut

• Ctrl+Y = redo

• Ctrl+C = copy

• Ctrl+V = paste

• Alt+F = open file option

• Alt+E = open Edit option

• Alt+V = open view option

• Alt+A = open actions option

• Alt+W = open window option

• Alt+H = open help option

ETAP 25-29 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Mode Toolbar

The mode toolbar selects which simulation mode is to be used for the controller or dynamic

model. The first option is “Simulation” or “Test” mode. The purpose of this mode is to allow the

running of simple test simulation routines on the models to check their performance. The second

mode is the DPET mode. The dynamic parameter estimation and tuning mode can be used to run

the model validation or tuning simulations. The mode toolbar is displayed below (both docked

and undocked).

ETAP 25-30 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

25.2.2 Simulation (Test) Mode

This mode includes several simulation test routines, which can be used to check the performance

of the model after it has been created. The mode contains a specific compiler toolbar and test

routines which can be accessed through the parameters editor.

Translator (Compiler) Toolbar:

The translator / compiler toolbar is used to save, link and compile the UDM models in

preparation for their use in ETAP’s transient stability calculations. The following image shows

the toolbar and its location:

Compile UDM Model Icon

The “Compile UDM Model” icon is used to compile (translate) the model once it has been

created. While the compiling takes place, a progress bar (located on the lower right-hand side of

the interface) and a message is displayed when the compiling is complete.

ETAP 25-31 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Compile all Models

The “Compile all Models” icon on this toolbar can translate all models, or all uncompiled or

untranslated models in the user-specified directory. When this icon is clicked, the following

dialog opens:

The option “All Models” compiles all UDM models within the specified directory. The option

“Uncompiled Models Only” compiles only the models which do not have an up-to-date

translation file (file with extension *.bin). An out-of-date or uncompiled UDM model is one

which does not have a corresponding *.bin file last saved within a minute of the save time of the

*.udm file (within a one-minute period).

The following message informs about the results of the compilation process:

ETAP 25-32 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

The information shows how many models compiled successfully and how many models failed

compilation. For information on failed compilation issues, please refer to the advanced topics

section of this chapter.

Open Plots Icon

The “Open Plot” icon opens previous test output plots for all the scopes within the model.

Close Plots Icon

The “Close Plots” icon closes the active plots for the UDM model.

Warning or compiler error messages may be displayed during the compiler process. These

message windows will indicate certain conditions such as missing required parameters or illegal

block combinations or connections. An example of a warning message is shown below:

Run Test Simulation

When clicking on the “run test simulation” icon, the program launches a test simulation which is

geared to test the exciter, governor, power system stabilizer models, etc, etc. by simulating

certain disturbances like faults, load acceptance and load rejection (shed). The test settings and

initialization settings must be configured prior to running any test routines.

The progress bar is also displayed during the time the simulation test is running. When the test is

complete, a plot of the test results will appear.

ETAP 25-33 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Note: as soon as the test simulation is launched, the model must be initialized by the compiler.

The initialization may take a considerable amount of time depending on the initialization method

selected or the time constant values used in the model. If the model is not configured properly for

initialization, a message or warning will appear and the test will not start. It may take several

minutes in extreme cases for a model to initialize. The progress bar will only start to advance

until once the model has been initialized.

Prior to running the test simulation, the Initialization, test settings and system reference setting

must be configured. The image below shows the location of the model parameters property sheet

where these settings are stored:

The image below shows an enhanced view of the system parameters property sheet:

ETAP 25-34 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

View Test Simulation Results

When clicking on the “view test simulation” results icon, the program displays a plot showing

the results of the simulation. If the test simulation was a fault, then the test results might look like

the ones shown below:

ETAP 25-35 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Plot of Test Results for a Load Shed Simulation

Plot of Test Results for a Load Acceptance Simulation

ETAP 25-36 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Plot of Test Results for a Fault Simulation

Plot of Test Results for a None Simulation (steady-state condition)

ETAP 25-37 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

25.2.3 Dynamic Parameter Estimation and Tuning (DPET) Mode

This mode has the DPET toolbar, which has the study cases, output plots and DPET result

analyzer. This model of analysis can be used to launch the iterative parameter estimation and

tuning process, based on comparisons against field-measured results.

DPET Toolbar

The DPET toolbar contains the following controls:

1. Duplicate DPET study case

2. DPET study case dropdown list

3. DPET study case editor

4. DPET output report dropdown list

5. Open DPET reports

6. DPET Analyzer

1 2 3 4 5 6

Duplicate DPET Study Case

This option allows the creation of DPET study case duplicates, which can be modified for

different analysis scenarios. To delete the study cases, go to the “Edit” menu and select “Delete

Study Case.”

DPET Study Case Dropdown List

This tool lists all existing DPET study cases. The DPET study cases are only applicable for a

single model. This list only contains DPET study cases for the active model.

DPET Output Report Dropdown List

This list contains the names of all the output reports from the DPET simulations. Please note that

the DPET simulations are filtered from other DPET output reports (i.e. from a different model

within the same ETAP project) by the use of a special naming convention in the project

directory. A directory with the same name as the model is created to store all the outputs related

to the active model. For example, if the names of the models are, “GENLOADST” and

“GENLOADSTFinal” then the DPET program would create two output report directories with

the same model names inside of a general output report directory. Both of these directories are

placed inside of the active ETAP project directory. In this case, the active ETAP project

directory is “TCS-UDM-046” (see below):

ETAP 25-38 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Please note that the output reports are stored in *.xlsx format.

Open DPET Output Reports

This button simply opens the active DPET output report from the DPET report dropdown list.

DPET Analyzer

Pressing this icon will launch the DPET report analyzer. The analyzer is discussed later in this

section.

DPET Study Case Editor

The DPET study case is the main interface editor for configuring the DPET simulations. The

input field-measured parameters like voltage, current, electrical power, frequency, etc. need to be

specified from this editor. The parameters, which will be considered in the simulation, are also

specified along with the iterative method solution precision and iteration time. The image below

shows the DPET study case:

ETAP 25-39 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Data Loading Page

Study Case ID

This field holds the alphanumeric identifier or study case name. The study case name can have as

many characters as needed (125 characters or more) to have unique study case names.

Field Recorded Data

This section holds the input field-measured results. The field-measured results can come from

staged tests such as exciter reference voltage bump tests, load bank step tests, Q-axis response

tests, etc. The measured results can also be from actual recorded disturbances like faults, system

disconnections, etc. The recorded data needs to be entered in Microsoft Excel format (*.xls or

*.xlsx). Future versions will allow direct import of recorded events from comtrade or PMU

formats.

ETAP 25-40 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Name

This field shows the names of the inputs and outputs in the model for which field-measured

results will be assigned. For SISO (single input single output) models, only a pair of inputs will

be listed. In the case of an exciter with SISO, only the Vt (terminal voltage in pu) and Efd

(exciter field voltage in pu) will be listed. All the names are pre-determined based on the type of

inputs and outputs present in the model.

Location

This shows the directory where the Excel file containing the field measurements are stored.

Browse

Allows the specification of the directory where the field measurements are stored.

Plot

This icon opens plot(s) of the selected field-measured data. The plot shows the data tabulated

against time (x-axis). It is recommended to check the data by means of this plot button before

running DPET study.

Start T. (s)

This field can be used to specify the starting point of the input data to be used for the DPET

simulation. In the majority of cases, the starting time should be the same for all the input field-

measured results. For synchronization, the smallest common time span selected will be used for

the DPET simulation.

End T. (s)

This field can be used to specify the ending point of the input data to be used for the DPET

simulation. In the majority of cases, the ending time should be the same for all the input field-

measured results. For synchronization, the smallest common time span selected will be used for

the DPET simulation.

ETAP 25-41 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

The following data shows the exciter field current with a starting time at 120 seconds. The end

time is 125.5 seconds. The total data collected covers a span of 420 seconds. The net simulation

time span is only 5.5 seconds, but this time is sufficient to capture the transient period. The

transient period is what is used to perform the exciter parameter estimation in this case.

S. Rate (s)

This is the sampling rate that the program will use when reading the field measurements. The

sampling rate is the same as the time step of the first few steps in the input data. There is no

requirement for the sampling rate to be fixed (constant); however, it is preferred. The sampling

rate can be increased or decreased depending on the situation and the amount of data points

collected in the measured data.

The following images show input signals with a sampling rate of 1.0 millisecond. The image also

shows two different input signals. The first image (on the left) is a scalar input signal and the

ETAP 25-42 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

first column is the time with a time step of 1.0 millisecond. The second image is a complex (on

the right) signal. Again, the first column is always the time and the remaining columns are the

magnitude and angle (p.u. magnitude and radians):

In some cases, it may be necessary to increase the sampling time to reduce the amount of

measured data points that are used in the DPET simulation.

Case 1: The time step of the measured field disturbance is 0.000333 or around 0.33 milliseconds.

However, the simulation time is 1.0 milliseconds. In this case using a sampling rate of 0.33

millisecond will only slow down the simulation and not provide any more resolution or catch any

transient behavior that can be captured by the DPET or eventual transient stability simulation. In

this case, the sampling rate can be decreased.

Case 2: The sampling rate can be decreased as well, if the smallest value of the time constant

parameters is known. Time constants will not capture or pass any values with a sampling rate

smaller than the time constant value. For example, assume again that the time step of the field

measurement is 0.33 milliseconds and that the minimum value of any time constant in the control

system is 0.010 seconds. Then, in this case, it is recommended to decrease the sampling rate to

0.005 seconds. This will collect less data in the simulation and speed up the DPET simulation.

Note: Decreasing the sampling rate can be a good way to speed up the DPET simulation;

however, the sampling rate should not be decreased to the point where it would cause the loss of

the actual transients required in the parameter estimation. An example of this is shown below.

The first plot was generated based on a sampling rate of 33 milliseconds (left). The second plot

was generated with a sampling rate of 0.5 sec.

ETAP 25-43 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

As can be seen above, there is a loss of the lower voltage dip of the input voltage measurement.

This portion of the signal would be needed to be able to match the calculated results against the

field measurements.

Format for the Input Field-Measured Data

The field measurements must be provided in MS Excel format. The interface accepts files with

extension *.xls (Excel 97-2003) and *.xlsx (Excel 2007 and later versions). The following

considerations should be taken when preparing the input data for the simulations:

1) Each excel file for a scalar input/output has two columns- first column is for time in

second and second column is for value in per unit (pu).

2) Each excel file for a complex input-output has three columns- first column is for time in

second, second column is for magnitude in pu and third column is for angle in radian.

3) The data must be sequential (i.e. t=0+ to t=end time).

4) The excel data must not contain any text or time data in hour:min:sec format. No strings

are accepted. Only number formats are accepted.

5) It is preferred if all the input field measurements have a common time span or recording

duration. For example, one signal could have been measured for 100 seconds and another

one for only 80 seconds. It would be preferred if both measurements are trimmed to the

common time span of 80 seconds. If this is not done, then at least the starting time should

be common to both measurements so that there is correlation between the different

measurements.

ETAP 25-44 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

6) Do not include the column or plot data headers in the excel files. The inputs should only

be numbers. The program will automatically label the data plots depending on the type of

input or output ports to which the data is assigned.

Parameter Estimation List

The parameter estimation list is probably the most important portion of the study case. The

information available in this section will be used to define the range of estimation and the

number of parameters available for the tuning. The process of parameter estimation and tuning

can be quite complex, extensive and time-consuming. The selection of parameters and their

ranges should be carefully considered, based on the physical limits and practical implementation

of the actual range of the hardware controls.

Fixed

This check box is a simple indicator to the DPET program that the parameter should not be

considered for tuning. As simple as this seems, the selection of which parameters should be fixed

(checked box) and which ones should be variable (unchecked) can make all the difference for a

realistic result in terms of parameter estimation. The following rules of thumb should be applied

when selecting the application of the fixed parameter checkbox:

1) Physical limits of the controller (i.e. Pmax, Efdmax, Pmin, Vrmax, Vrmin) are generally kept

fixed in the parameter estimation. These limits should be included only in situations

where extreme transients are used which may result in clipping or saturation limits to be

engaged. The difference between the estimated and field measurement should provide

some insight as to how the range of the parameter should be set once a limit is included in

the simulation by unchecking its fixed condition.

2) Time constants for actuators, valves, fuel system, combustion system, regulators (for

most electromechanical or mechanical control mechanisms) typically should not be

included in the estimation process. Most of the time, these time constants represent the

time delay of the actual control system mechanism to take action based on the input error

or control signal. However, if the actual values are unknown, then they can be included

but their range of estimation should be limited to a range reasonable for the type of

element being modeled. Examples of these are transducers. Their time constants can

ETAP 25-45 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

range between 0.002 seconds to 0.010 seconds for most applications. If the actual value is

not known then the transducer time constant can be included (fixed box unchecked) and

its range can be set from 0.002 to 0.010 with an initial value of 0.005 sec.

3) Time constants and gains in PID controllers, AVRs and/or Speed controllers or any other

type of control portion (typically elements right after the error signal difference summing

point) can be included in the estimation and tuning process (fixed box unchecked). These

parameters are tunable be means of electronic controls or adjustable electromechanical

potentiometer or other types of control systems. For example, in a PID control you may

encounter KI, KP, KD, KF, TF etc. The range for KP can be set to 0.2 to 10 with an initial

value of 5. Tf can be set as 0.005 to 0.1 with an initial value of 0.06 seconds. Please note

that the manufacturer documentation should be consulted when selecting the range and

initial value, and that each application may require different ranges.

4) Typically relative operators or boolean logic operators or signal-switching control

parameters should not be included in the estimation. Examples of these are threshold

values inside of signal-routing switch elements. Other examples are relative values to set

boolean logic implementation.

5) Reference signals are typically not tunable although they can be varied to adjust the

estimation process. More details on this will be provided in a later section, which

explains how to setup dynamic reference control signals in the parameter estimation tool.

In general, the fixed check box can be summarized as an indicator of whether a parameter is

included or not in the estimation process.

Note: When a parameter is fixed, its initial value is used by the DPET program as a known

constant parameter.

Block

This field shows corresponding block name, which contains the parameter. The list of parameters

can be sorted by block name. This field is read-only. Of course, the block name can be changed

from the individual block property editor.

Name

This field displays the parameter name. The parameters can be sorted by their name. This field is

display only. The parameter name can be changed by accessing it from the variable where the

parameter is contained.

Base

This shows base values of all parameters. The base value can be defined as the “current”

parameter value in the model. In most cases, the base values can be described as the

manufacturer or vendor provided parameters for the model. The base values are the parameters

which will be used in any kind of transient stability simulation in the UDM model. It is important

to note that the estimated parameters can replace the base values in the model. This should be

done only after the model validation and estimation is complete. It is recommended to create a

ETAP 25-46 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

new model that uses the estimated parameters from the DPET simulation. With this technique, it

is possible to compare the performance of the model before and after the parameter estimation

process.

The parameters can be sorted by the base value. This field is read-only. However, their values

can be edited from the Model Parameters section/window. In most cases, the base value is used

as the initial value in the DPET simulation.

Initial

The initial value as described under the “Fixed” section above is used to set the first iteration

value of the parameter in the DPET simulation. The initial value should be set to the value,

which is considered to be the best expectation of the actual parameter value. In most cases, the

initial value is the base value unless a better “guess” or estimate can be provided to the program.

The DPET simulation will reach a solution faster if the initial value is close (good guess

guestimate?) and the range of the parameter variation is smaller.

A parameter takes its initial value and keeps it constant during DPET optimization process if the

parameter is fixed. If a parameter is not fixed, DPET optimization starts with random values

from an initial value to lower or upper values (limits).

The relation between the initial, lower and upper limit is:

Lower Initial Upper.

If this relation is not followed, then an error message will appear. See image below. The

relational condition must be satisfied before the error message disappears.

Lower

It is lower limit of a parameter value.

Upper

It is upper limit of a parameter value.

ETAP 25-47 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Update Initial with Base

Updates all initial values with the current model base values for all parameters.

Study Remarks

You can enter up to 120 alphanumeric characters in the Remarks box. The purpose of this

information text area is to provide information specific to the conditions for each study case.

DPET Simulation Parameter Page

Simulation Data

Iterations

The number of iterations for DPET should be set according to the expected duration of the

estimation process. The optimization process stops after the specified number of iterations. If the

expected deviation is too small for the specified number of iterations, increasing the number of

iterations and running it again may be needed until the desired average deviation is reached.

Default value is 10 and max is 9,999.

Agents

Enter the number of agents. Agents interact with each other and share their information at each

iteration. The recommended and default value is 10; however, max is 999. Higher numbers of

ETAP 25-48 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

agents will make the optimization process slow. Note: For five iterations and ten agents, total

number of optimization calculations will be (5X10=) 50.

Time Step(s)

This is the time step for running the DPET optimization simulations. The range of the time step

is from 0.0001 sec to 10 sec. The time step is also used to initialize the model after each iteration.

However, the DPET time step should be smaller than the time step or sampling rate of the input

measured data. The following considerations should be applied when selecting the time step for

the DPET optimization process:

1) The time step should be smaller than the smallest sampling rate of all the signals.

2) The time step should be smaller than the smallest possible minimum time constant of all

blocks. However, setting the simulation time step as a very small value will make the

simulation slow down significantly.

Ex. Time(s)

This time determines the execution time in seconds. The optimization process will stop after that

execution time has been reached. The execution time should be selected based on the model

complexity, number of parameters being considered, and their range. Longer execution times

may be needed in order for the optimization process to converge (reach the desired average

deviation). If the desired deviation is not small enough for the specified execution time limit,

increasing the execution time can help the simulation to converge. The default execution time

value is 500 seconds.

Deviation Avg.

Enter desired average deviation of measured and calculated outputs in p.u. The default value is

0.01 pu.

Max. Ind. Point

Enter maximum deviation of measured and calculated outputs in p.u. at any point of time that

should be achieved. The default value is 0.01 pu.

Simulation Time Step Multiplier

Enter time step multiplier. The multiplier is an integer value which can be used to speed up the

optimization process; however, using multiplier values higher than 1 may increase the overall

deviation. The recommended and default value is 1. However, a value as high as 10 or more can

be used, in some cases.

Running DPET

Executing the DPET simulation is simple. The following steps are required to launch the

simulation:

ETAP 25-49 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

1) Setup the DPET study case by entering the input measured results and setting up all the

parameters to be considered.

2) Compile the model.

3) Launch the DPET simulation by clicking on the “start simulation” icon on the toolbar.

4) During simulation the plots will open and display the current optimization iteration and

the current results in graphs.

5) The DPET can be stopped at any time to get the current estimated parameters. Please note

that the simulation will stop after the “stop simulation” icon is clicked and the current

iteration is completed (i.e. the DPET optimization engine will stop only after completing

the simulation for the current iteration and thus may not stop right away).

6) The DPET results can be viewed by means of the reports or the DPET report analyzer.

Compile

The compile button is the same as the UDM compile button described in section 25.2.2. The

model needs to be re-compiled after any changes have been made to the model. Failure to

compile will cause the latest changes (since last successful compilation) to be neglected in the

current UDM test or DPET simulation. Changes in the DPET study cases do not require re-

compiling the model. However, the DPET start simulation icon is only activated the first time

after the model has been compiled.

Run

This icon allows the DPET process to start (if the model has been properly compiled). The study

case must be configured as mentioned before running DPET. During the DPET process, a group

ETAP 25-50 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

of plots are opened and refreshed after each iteration. These plots provide a visual indicator of

where the current convergence state and deviation between the measured and calculated results.

The following images show the estimation results at iteration 12/100 (12th iteration out of total

100) and at iteration 96/100.

Stop

During the DPET optimization process, users can stop running DPET any time. The DPET

process can be stopped if the current iteration shows satisfactory results, even if the desired

overall deviation has not been reached. If DPET is stopped, the results reported for the

parameters correspond to those of the current iteration (please note that these results may not

necessarily be those that provided the least deviation). The best set of estimated parameters is

only reported if the simulation stops automatically after reaching the desired average deviation.

Plot

This button brings up all the available plots (graphs). It has zooming capability to see specific

parts of the graphs clearly.

ETAP 25-51 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Model Initialization

The initialization process is the same as that described in the test simulation section. However,

the main difference is that the initial input and output values used for the initialization come from

the first set of data points from the field-measured parameters. In the test routine, the initial

conditions are specified from the model properties section.

The initialization process may be slow and sometimes even impossible to reach. If that is the

case, it will take a long time for each DPET iteration to complete. In general, using the direct

initialization process is not preferred. The iterative process should work in all cases, except those

where a solution is not possible, because the states are outside the possible solution range. It is

recommended to use the iterative method of initialization for all possible situations.

Please see the Advanced Topics section for more tips on how to configure the model

initialization for UDM and DPET.

Note: The simulation time from the Simulation Parameter page is used as the initialization time

for all models in DPET. This means that the test routines take the initialization time from the

model properties section, and the DPET simulation takes the initialization simulation time from

the DPET study case’s Simulation Parameters page.

ETAP 25-52 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

25.2.4 DPET Analyzer

The DPET analyzer is a power tool, which can be used to view and compare the results of

multiple DPET simulation results. The DPET analyzer will only show simulation results for

DPET simulations which were executed in the current model.

Study Reports

Report

The report section shows all available reports for the active model. Users can select report(s) to

show initial and estimated parameter values for selected report(s). It has sorting capability by

report name. This field is display only.

Max Dev

This shows achieved maximum deviation of the corresponding report. The User can compare

different reports and pick the best one. It has sorting capability by maximum deviation. This field

is ‘display only.’ Note: Achieved maximum deviation and average deviation are written in the

report.

Parameter Results

Block

This shows block names. If the block name is empty for a parameter, the parameter was deleted

from the project. It has sorting capability by block name. This field is display only.

Name

This shows parameter names. If a parameter has no block name, in that case, the parameter was

deleted. It has sorting capability by parameter name. This field is display only.

ETAP 25-53 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Base

This shows base values of all the parameters. It has sorting capability by base value. This field is

display only.

Initial

This shows initial values of all the parameters for the optimization process when the report was

generated. It has sorting capability by initial value. This field is display only.

Estimated

This shows estimated values of all the parameters using DPET optimization. It has sorting

capability by estimated value. This field is display only.

Active Model

This shows the active model name. This field is display only.

Update Base

This updates base values of all parameters by estimated values of corresponding parameters of a

selected report. This button is active once any report is selected from "Parameter Results."

section.

Create New Model

This button is active once any report is selected from "Parameter Results" section. It creates a

new model with estimated parameter values of the selected report as base values.

Plot

This button is active once any report is selected from "Parameter Results" section. It plots all

calculated, measured and deviation graphs for the estimated parameter values including input

graphs. It has zooming capability to see specific parts of the graphs clearly.

ETAP 25-54 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

25.2.5 DPET Excel Report

Info

This tab shows UDM model name, file name, DPET study data and study case name. It also

includes average and maximum deviations of measured and calculated data.

Model Parameter Results

This tab reports UDM block names, parameter names and base values. It also includes initial

guesswork of all the parameters used in DPET optimization process and their final estimated

values.

Plot Data

This reports all measured data for inputs and outputs, calculated data for outputs, and deviation

of measured and calculated data for outputs. Users can make plots from those data.

ETAP 25-55 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

ETAP 25-56 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

25.2.6 Model Global Properties

The model property sheet is used to configure the global model parameters, which are used for

compiling the model so that it can be used in a transient stability calculation. The property sheet

includes sections for setting the model type, initialization and testing.

Parameters

Name

This field is used to enter the model name.

Appearance

Background Color

Change the background color.

Diagram Size

Modify the document size and orientation such as landscape or portrait.

System Model Parameters

The following table describes the System Model Parameters in detail for an exciter model.

ETAP 25-57 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

ETAP 25-58 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Logic for the System Reference (i.e. Qref, Pref, Vref, etc)

These fields are used to tell the program which blocks are used for specific signal references

required by each type of model.

For example, for an exciter you may need to select a constant block, which will serve the

purpose of being the exciter reference voltage (Vref). You may also need Qref and Pref,

depending on the type of model or controller being implemented.

The same applies to governor models. Please note that the following rules and best practices

apply to the selection of the reference constant blocks:

The following logic applies to these fields:

1) The best practice is to name the constant block in the model the same as the expected name

in the compiler. If you named the voltage reference block “AVRReFVoltage,” it may be

easier instead, to name the constant block “Vref.”

ETAP 25-59 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

2) The selection is unique. The same block may not be used as reference more than once. For

example, if you select C1 constant block for Vref, then you will not be able to select C1 as

constant block for Pref.

3) The System Reference Signals have sorting which gives preference to any constant blocks

named similarly to the expected reference signal name. For example, if we are trying to

select the constant blocks for Vref, then any block named “Vr”, “V1”, Vreference” and

“Vr1” is placed at the top of the list. Any constant block starting with “V” or “Vr” is placed

at the top of the list. All the other constants fall below with regular sorting in descending

order.

4) The system reference selection is checked at the time the model is compiled. If a selection

is not made, then there are warning messages are displayed (i.e. for exciter models Vref

needs to be selected and for Governor Wref needs to be selected as well).

The following image shows three models with their respective constant block system reference

selections:

ETAP 25-60 ETAP 18.0 User Guide

User-Defined Dynamic Models UDM Model Files

Note that ETAP 16.0.0 can automatically select the reference blocks for the system reference

section as long as they are properly configured and named using the reserved words described in

this section. Using names other than the reserved names will require user input and selection for

the mapping of the blocks to their corresponding reference values.

ETAP 25-61 ETAP 18.0 User Guide

User-Defined Dynamic Models Input and Output Blocks

Input and Output Blocks

The input/output blocks or elements are the variables that are used by the compiler to transfer

data back and forth between transient stability calculation and the UDM model. Each model type

has a specific list of inputs and outputs, which are handled by the compiler and have specific

meanings.

25.3.1 List of Inputs/Outputs based on Model Type

These inputs and outputs come from the synchronous machines, lumped loads and wind turbine

generator elements. The following tables list the inputs and outputs available for direct interface

to the transient stability calculation:

Note: Any additional input (besides those listed in the tables below) may be defined by the user

by using mathematical equations and constant blocks. Any output can be defined by using

special plotter element blocks (described later in this chapter). The list of inputs and outputs

below have been pre-defined as the most important parameters between TS and UDM Models.

List of UDM Inputs/Outputs for an Exciter Model

UDM Tool Tip Description

Input

GoToBlock input where the user can specify a variable

name from where this input reads data. Use in

In Generic Input

combination with output ports. The units are inherited

from the variable that is being read.

Synch machine control bus voltage - magnitude in pu

Vt Terminal Voltage

(bus base kV)

Synch machine control bus voltage - complex (real,

imag) in pu (bus base kV) Note: The voltage passed to

UDM from transient stability is the bus voltage without

Terminal Voltage, phase angle adjustment. The magnitude will be the same

Vt,c

Complex but the phase angle is not referenced to the system

reference angle. This does not affect the model behavior

since all the other complex values passed to UDM are not

referenced to the system angle.

Vs PSS Voltage Signal PSS voltage signal to exciter in pu (machine base)

Synch machine terminal current magnitude in pu (100

It Terminal Current

MVA Base)

Terminal Current, Synch machine terminal current- complex (real, imag) in

It,c

Complex pu (100 MVA Base)

Ifd Exciter Field Current Exciter field current in pu (machine base)*

P Real Power Output Synch machine real power output in pu (100 MVA Base)

Synch machine reactive power output in pu (100 MVA

Q Reactive Power Output

Base)

PF Power Factor Synch machine output power factor in pu

Freq Frequency Synch machine control bus frequency in pu

ETAP 25-62 ETAP 18.0 User Guide

User-Defined Dynamic Models Input and Output Blocks

UDM Tool Tip Description

Output

Efd Exc Field Voltage Exciter field voltage in pu (machine base)

GoToBlock output where the user can specify a variable

name to which this output port writes data. Use in

Out Generic Output

combination with input ports. The units or per-unit value

is inherited from the input

List of UDM Inputs/Outputs for a Governor Model

UDM Tool Tip Description

Input

GoToBlock input where the user can specify a variable

name from where this input reads data. Use in

In Generic Input

combination with output ports. The units are inherited

from the variable that is being read.

Vt Generator Speed Generator speed in pu (machine rated RPM)

Generator real power output in pu (machine rated MW

P Real Power output

base)

Load sharing power signal in pu (machine rated MW

Psh Load Sharing Signal base)

UDM Tool Tip Description

Output

Turbine/Engine mechanical power output in pu

Pm Mechanical Power

(machine rated MW base)

GoToBlock output where the user can specify a variable

name to which this output port writes data. Use in

Out Generic Output

combination with input ports. The units or per-unit value

is inherited from the input

List of UDM Inputs/Outputs for a PSS Model

UDM Tool Tip Description

Input

GoToBlock input where the user can specify a variable

name from where this input reads data. Use in

In Generic Input

combination with output ports. The units are inherited

from the variable that is being read.

Generator control bus voltage - magnitude in pu (control

Vt Terminal Voltage

bus base kV)

P Real Power output Generator real power output in pu (100 MVA base)

Turbine/ Engine mechanical power output in pu (100

Pm Mechanical Power MVA base)

W Generator Speed Generator speed in pu (machine rated RPM)

Ang Rotor Angle Generator rotor angle in radians

Freq Terminal Frequency Synch machine control bus frequency in pu

UDM Tool Tip Description

Output

ETAP 25-63 ETAP 18.0 User Guide

User-Defined Dynamic Models Input and Output Blocks

Vs PSS Voltage Signal PSS voltage signal to exciter in pu (machine base)

GoToBlock output where the user can specify a variable

name to which this output port writes data. Use in

Out Generic Output

combination with input ports. The units or per-unit value

is inherited from the input.

List of UDM Inputs/Outputs for a Generic Load Model

UDM Tool Tip Description

Input

GoToBlock input where the user can specify a variable

name from where this input reads data. Use in

In Generic Input

combination with output ports. The units are inherited

from the variable that is being read.

Terminal bus voltage - magnitude in pu (bus nominal kV

Vt Bus Voltage base)

Terminal bus voltage - complex (real, imag) in pu (bus

Vt,c Bus Voltage, Complex nominal kV base)

Freq Bus Frequency Terminal bus frequency in pu

UDM Tool Tip Description

Output

P Load Real Power Load real power in pu (1 MW base)

Q Load Reactive power Load reactive power in pu (1 MVAR base)

WTG complex (real, imag) current output in pu (1MVA

It,c Complex Current Output base)

GoToBlock output where the user can specify a variable

name to which this output port writes data. Use in

Out Generic Output

combination with input ports. The units or per-unit value

is inherited from the input.

List of UDM Inputs/Outputs for a WTG Model

UDM Tool Tip Description

Input

GoToBlock input where the user can specify a variable

name from where this input reads data. Use in

In Generic Input

combination with output ports. The units are inherited

from the variable that is being read.

Terminal bus voltage - complex (real, imag) in pu (bus

Vt,c Bus Voltage, Complex

nominal kV base)

Ws Wind Speed Wind speed in meter per second (m/s)

WTG terminal bus voltage - magnitude in pu (bus

Vt Terminal Bus Voltage nominal kV base)

WTG control bus voltage - magnitude in pu (bus nominal

Vc Control Bus Voltage kV base)

P WTG Real Power Output WTG real power output in pu (machine MVA base)

ETAP 25-64 ETAP 18.0 User Guide

User-Defined Dynamic Models Input and Output Blocks

WTG Reactive Power

Q Output WTG reactive power output in pu (machine MVA base)

WTG terminal bus frequency in pu (system frequency

Freq Frequency base)

UDM Tool Tip Description

Output

P WTG Output Real Power WTG output real power in pu (1 MW base)

WTG Output Reactive

Q power WTG output reactive power in pu (1 MVAR base)

WTG complex (real, imag) current output in pu (1MVA

It,c Complex Current Output base)

GoToBlock output where the user can specify a variable

name to which this output port writes data. Use in

Out Generic Output

combination with input ports. The units or per-unit value

is inherited from the input

*ETAP uses two different bases to UDM exciter field current.

Base Determination Method 1

When running “Non-Frequency Dependent (NFD) TS Simulations”, the Ifd base for UDM is

determined based on the field current required to produce 100% terminal voltage. The generator

open circuit saturation curve is used to determine the per-unit value for Ifd and Efd.

Base Determination Method 2

For “Frequency-Dependent (FD) Simulations”, (such as generator startup), the base value used

for UDM Ifd is 100MVA. This base value is more suitable for simulations involving the starting

of large generators where actual values of field current may be needed.

ETAP 25-65 ETAP 18.0 User Guide

User-Defined Dynamic Models Input and Output Blocks

Converting between Different Base Values

If it is required to use the same exciter in FD & NFD simulations, add a base conversion factor to

the UDM Ifd input as shown below:

GenMVA 1

Ifd NFD Ifd FD

100 MVA Lad

Where:

IfdNFD Exciter field current expressed using non-frequency dependent base

IfdFD Exciter field current expressed using 100 MVA base

Lad Xd-Xl in machine per-unit base

The image below shows how the conversion factor can be implemented into a UDM exciter

model.

Switching between Different Base for FD UDM Ifd

An ETAPS.ini entry can be added below the [ETAP PowerStation] header to change the base

used for Ifd in frequency dependent UDM exciters.

The entry is:

UDMFDIfdBase= 0 or 1

The default value (i.e. no INI entry) or with the INI entry in place with a value = 0, causes the

program to use Method 1 for Ifd base in UDM when using frequency-dependent simulations.

Setting the value of this entry to 1 causes the program to use method 2 (100 MVA base) to

determine the base for UDM Ifd in frequency-dependent simulations.

Non-frequency dependent UDM exciters always use method 1 to determine the base for Ifd.

Built-in exciters always use Method 1 to determine the Ifd base (even if FD or NFD simulations

are performed).

ETAP 25-66 ETAP 18.0 User Guide

User-Defined Dynamic Models Input and Output Blocks

25.3.2 Input/Output Blocks Data Sheet Properties

This section describes the parameters of the inputs/outputs blocks in the UDM Graphic Logic

Editor Interface.

Equations for the Input/output blocks

The equation of this block is: y = u

If the block is an input, then “u” is the input variable from ETAP Transient Stability (TS)

(whatever it may be according to tables in section 25.3.1) passed to the UDM model. If the block

is an output, then “u” is the output variable from the UDM model passed back to the ETAP TS.

Name

Input / Output name or Id. This can be a more descriptive name than the abbreviations used to

define each input by the compiler.

Input Port Number

Inherited parameter used by previous versions of ETAP, which used Matlab’s Simulink interface

input and output ports numbering system. This field is still used for import and export to

Simulink purposes.

Line Style

This section provides general symbol graphical properties customization options.

Font

This section provides parameters to configure the fonts to be used for labels of the block.

ETAP 25-67 ETAP 18.0 User Guide

User-Defined Dynamic Models Input and Output Blocks

25.3.3 List of Input/Output Blocks

The following image shows all the input/output blocks including the system defined (reserved

inputs and outputs) and those which are user-definable inputs and outputs or otherwise known as

“GoToBlocks”.

The image below shows the inputs and outputs for an exciter:

Please refer to section 25.3.1 for a complete description of each of the reserved inputs and

outputs (e.g. those which cannot be modified).

In/Out Blocks

This section focuses on the “In” and “Out” input and output blocks. The “In” input block allows

the reading of a variable value, which can originate within the same model or from another UDM

model (when the simulation is executed from transient stability).

The input block has the following parameters:

Port ID: The graphical name of the port for graphical identification

Variable ID: This field identifies the local or remote variable name. If the Input type is

set to “TS”, then this name should match the ID of the element data source (i.e. the name

of the element from the one-line diagram in ETAP).

Communication Link ID: This is a unique identifier used to create unique communication

channels between the input and output ports. If the input type is “Internal”, this link is

ETAP 25-68 ETAP 18.0 User Guide

User-Defined Dynamic Models Input and Output Blocks

read-only and the display shows an alphanumeric “GUID” identifier. For external input

port types, the link is editable and can receive the link or GUID from another model.

Initial Value: This field contains the initial value of a remote variable (e.g. variable which

does not exist within the model). This value is used for initialization purposes only when

running transient stability or as a constant value when running the test routine. This value

is not used when the variable is defined locally (e.g. the variable is defined within the

model itself).

Input Type: The input type determines the class of input data received by the input port.

The types are:

1. The internal variable means that this input variable resides within the model