Beruflich Dokumente

Kultur Dokumente

CS 34 Steel Reinforcement

Hochgeladen von

John Edsel SalavariaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

CS 34 Steel Reinforcement

Hochgeladen von

John Edsel SalavariaCopyright:

Verfügbare Formate

CS-34

CONSTRUCTION SPECIFICATION

CS 34, STEEL REINFORCEMENT

1. SCOPE

The work shall consist of furnishing and placing steel reinforcement for

reinforced concrete or pneumatically applied mortar.

2. MATERIAL

Steel reinforcement shall conform to the requirements of Material Specification

539, Steel Reinforcement (for concrete). Before reinforcement is placed, the

surface of the bars and fabric and any metal supports shall be cleaned to remove

any loose, flaky rust, mill scale, oil, grease, or other undesirable coatings or

foreign substances. Epoxy-coated steel reinforcement shall be free of surface

damage. After placement, the reinforcement shall be maintained in a clean and

serviceable condition until it is completely embedded within the concrete.

3. BAR SCHEDULE, LISTS AND DIAGRAMS

Any supplemental bar schedules, bar lists or bar-bending diagrams required in

section 10 of this specification to accomplish the fabrication and placement of

steel reinforcement shall be provided by the contractor. Before reinforcement is

placed, the contractor shall furnish four copies of any such lists or diagrams to the

contracting officer for approval. Acceptance of the reinforcement is not based on

approval of these lists or diagrams, but on inspection of the steel reinforcement

after it has been placed, tied, and supported and is ready to receive concrete.

4. BENDING

Reinforcement shall be cut and bent in compliance with the requirements of the

American Concrete Institute Standard 315. Bars shall not be bent or straightened

in a manner that will injure or weaken the material. Bars with kinks, cracks, or

improper bends will be rejected.

5. SPLICING BAR REINFORCEMENT

Method 1—Splices of reinforcement shall be made only at locations shown on the

drawings and provided by the steel schedule. Placement of bars at the lap splice

locations shown, when not in contact, shall not be farther apart than one-fifth the

shown lap length and in any case no greater than 6 inches.

Method 2—Splices of reinforcement shall be limited to those locations shown on

the drawings. Splice lengths shall be determined before fabrication and meet the

requirements of ACI Standard 318, Building Code Requirements for Reinforced

Concrete, based upon design information in section 10 of this specification. Bar

placement drawings and schedules shall be provided for approval before

fabrication. The drawings shall show all splice locations, layouts, and lap

dimensions.

6. SPLICING WELDED WIRE REINFORCEMENT

USDA-NRCS-UT 1/5 FEB 2016

CS-34

Unless otherwise specified, welded wire reinforcement shall be spliced in the

following manner:

End-to-end—Adjacent sections shall be spliced end-to-end (longitudinal

lap) by overlapping a minimum of one full mesh plus 2 inches plus the

length of the two end overhangs. The splice length is measured from the

end of the longitudinal wires in one piece of fabric to the end of the

longitudinal wire in the lapped piece of fabric.

Side-to-side—Adjacent sections shall be spliced side to side (transverse

lap) a minimum of one full mesh plus 2 inches. The splice length shall be

measured from the centerline of the first longitudinal wire in one piece of

fabric to the centerline of the first longitudinal wire in the lapped piece of

fabric.

7. PLACING

Reinforcement shall be accurately placed and secured in position to prevent its

displacement during the placement of concrete. Tack welding of bars is not

permitted. Metal chairs, metal hangers, metal spacers, and concrete chairs may be

used to support the reinforcement. Metal hangers, spacers, and ties shall be placed

in such a manner that they are not exposed in the finished concrete surface. The

legs of metal chairs or side form spacers that may be exposed on any face of

slabs, walls, beams, or other concrete surfaces shall have a protective coating or

finish. The coating or finish can be hot dip galvanizing, epoxy coating, plastic

coating, or stainless steel. Metal chairs and spacers not fully covered by a

protective coating or finish shall have a minimum cover of 0.75 inch of concrete

over the unprotected metal part. The exception is that those with plastic coatings

may have a minimum cover of 0.5 inch of concrete over the unprotected metal

part. Precast concrete chairs shall be manufactured of the same class of concrete

as specified for the structure and shall have the tie wires securely anchored in the

chair or a V-shaped groove at least 0.75 inch in depth molded into the upper

surface to receive the steel bar at the point of support. Precast concrete chairs

shall be clean and moist at the time concrete is placed.

High density or structural plastic rebar accessories designed to ensure maximum

concrete bond may be substituted for metal or concrete accessories in spacer

applications as approved by the contracting officer. Exposure of plastic rebar

accessories at the finished concrete surface shall be kept to a minimum. Plastic

rebar accessories, when used, shall be staggered along adjacent parallel bars and

shall be placed at intervals no closer than 12 inches. Plastic rebar accessories shall

not be used in concrete sections 6 inches or less in thickness.

Reinforcement shall not be placed until the prepared site has been inspected and

approved. After placement of the reinforcement, concrete shall not be placed until

the reinforcement has been inspected and approved by the contracting officer's

technical representative (COTR).

8. STORAGE

USDA-NRCS-UT 2/5 FEB 2016

CS-34

Steel reinforcement stored at the work site shall be placed on platforms, skids, or

other supports. This is done so that contact with the ground is avoided and the

material is protected from mechanical damage and/or corrosion.

9. MEASUREMENT AND PAYMENT

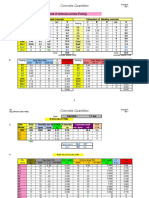

Method 1—For items of work for which specific unit prices are established in the

contract, the weight of steel reinforcement placed in the concrete in accordance

with the drawings is determined to the nearest pound by computation from the

placing drawings. Measurement of hooks and bends is based on the requirements

of ACI Standard 315. Computation of weights of reinforcement is based on the

unit weights established in tables 34–1 and 34–2 of this specification.

Computation of weights for welded wire reinforcement not shown in table 34–2

shall be based on ACI Standard 315. The area of welded wire reinforcement

placed in the concrete in accordance with the drawings is determined to the

nearest square foot by computation from the placing drawings with no allowance

for required laps. The weight of steel reinforcing in extra splices or extra-length

splices approved for the convenience of the contractor or the weight of supports

and ties is not included in the measurement for payment.

Payment for furnishing and placing reinforcing steel is made at the contract unit

price. Such payment constitutes full compensation for all labor, material,

equipment, and all other items necessary and incidental to the completion of the

work including preparing and furnishing bar schedules, lists, or diagrams;

furnishing and attaching ties and supports; and furnishing, transporting, storing,

cutting, bending, cleaning, and securing all reinforcements.

Method 2—For items of work for which specific unit prices are established in the

contract, the weight of bar reinforcement placed in the concrete in accordance

with the drawings is determined to the nearest pound by computation from the

placing drawings. Measurement of hooks and bends is based on the requirements

of ACI Standard 315. Computation of weights of bar reinforcement is based on

the unit weights established in table 34–1 of this specification. The weight of steel

reinforcing in extra splices or extra length splices approved for the convenience of

the contractor or the weight of supports and ties is not included in the

measurement for payment.

The area of welded wire reinforcement placed in the concrete in accordance with

the drawings is determined to the nearest square foot by computation from the

placing drawings with no allowance for required laps.

Payment for furnishing and placing bar reinforcing steel is made at the contract

unit price for bar reinforcement. Payment for furnishing and placing welded wire

reinforcing steel is made at the contract unit price for welded wire reinforcement.

Such payment constitutes full compensation for all labor, material, equipment,

and all other items necessary and incidental to the completion of the work

including preparing and furnishing bar schedules, lists, or diagrams; furnishing

and attaching ties and supports; and furnishing, transporting, cutting, bending,

cleaning, and securing all reinforcement.

USDA-NRCS-UT 3/5 FEB 2016

CS-34

All Methods—The following provisions apply to all methods of measurement and

payment. Compensation for any item of work described in the contract, but not

listed in the bid schedule, is included in the payment for the item of work to

which it is made subsidiary. Such items to which they are made subsidiary are

identified in section 10 of this specification.

Table 34–1 Standard reinforcing bars

- - Bar size designations - - Weight (lb/ft)

English Metric

3 10 0.376

4 13 0.668

5 16 1.043

6 19 1.502

7 22 2.044

8 25 2.670

9 29 3.400

10 32 4.303

11 36 5.313

14 43 7.650

18 57 13.600

1/ The bar diameter (inches) equals the bar size number divided by eight. For example,

the diameter of a #4 bar is 4÷8 = 0.5 inch.

2/ The metric bar size has been rounded to a whole number that represents the

approximate diameter of the bar in millimeters.

USDA-NRCS-UT 4/5 FEB 2016

CS-34

Table 34–2 Rectangular welded wire reinforcement

- - - - - - - - - - Style designation 1/ - - - - - - - - - - Weight

by W-number by steel wire gauge (lb/100 ft2)

(former designation)

6 6 – W1.4 W1.4 6 6 – 10 10 21

6 6 – W2.1 W2.1 6 6–8 8 30

6 6 – W2.9 W2.9 6 6–6 6 42

6 6 – W4.0 W4.0 6 6–4 4 58

4 4 – W1.4 W1.4 4 4 – 10 10 31

4 4 – W2.1 W2.1 4 4–8 8 44

4 4 – W2.9 W2.9 4 4–6 6 62

4 4 – W4.0 W4.0 4 4–4 4 85

4 12 – W2.1 W0.9 2/ 4 12 – 8 12 25

4 12 – W2.5 W1.1 2/ 4 12 – 7 11 31

1/ Style designation is defined in ACI Standard 315 of the American Concrete Institute.

2/ Welded smooth wire reinforcement with wires smaller than size W1.4 is manufactured

from galvanized wire.

10. ITEMS OF WORK AND CONSTRUCTION DETAILS

USDA-NRCS-UT 5/5 FEB 2016

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- CONCRETE QuantitiesDokument9 SeitenCONCRETE QuantitiesdoxoNoch keine Bewertungen

- Const Estimate Made Easy by Engr. Ronald John R. CajillaDokument25 SeitenConst Estimate Made Easy by Engr. Ronald John R. CajillaRonna Mae100% (2)

- PRODUCTIVITY RATIOS FOR CONSTRUCTION PROJECTSDokument10 SeitenPRODUCTIVITY RATIOS FOR CONSTRUCTION PROJECTSJohn Edsel SalavariaNoch keine Bewertungen

- Concrete Steel Brick CalculatorDokument12 SeitenConcrete Steel Brick CalculatorVisas Siva0% (1)

- Suppliers Price List 2018Dokument29 SeitenSuppliers Price List 2018John Edsel SalavariaNoch keine Bewertungen

- Estimating Resi BuildingDokument2 SeitenEstimating Resi Buildingraj76% (17)

- Labor Production Table BreakdownDokument2.643 SeitenLabor Production Table BreakdownJohn Edsel Salavaria0% (1)

- Project Cost Estimating Guide - PracticeDokument58 SeitenProject Cost Estimating Guide - PracticeMurat Syzdykov100% (5)

- Road Estimates SheetDokument11 SeitenRoad Estimates SheetAmal PremachandranNoch keine Bewertungen

- Proposed 2 Storey Residence Plumbing QuotationDokument4 SeitenProposed 2 Storey Residence Plumbing QuotationJohn Edsel SalavariaNoch keine Bewertungen

- Estimate of Materialand LaborDokument13 SeitenEstimate of Materialand LaborCristi Han100% (1)

- Estimates Table (Construction)Dokument3 SeitenEstimates Table (Construction)Joe A. Cagas86% (114)

- Concrete Steel Brick CalculatorDokument12 SeitenConcrete Steel Brick CalculatorVisas Siva0% (1)

- CONCRETE QuantitiesDokument9 SeitenCONCRETE QuantitiesdoxoNoch keine Bewertungen

- Blank MRDokument1 SeiteBlank MRJohn Edsel SalavariaNoch keine Bewertungen

- Const Estimate Made Easy by Engr. Ronald John R. CajillaDokument25 SeitenConst Estimate Made Easy by Engr. Ronald John R. CajillaRonna Mae100% (2)

- Estimates Table (Construction)Dokument3 SeitenEstimates Table (Construction)Joe A. Cagas86% (114)

- Estimates Table (Construction)Dokument3 SeitenEstimates Table (Construction)Joe A. Cagas86% (114)

- Equipment Rental and Labor Rates for Construction ProjectsDokument15 SeitenEquipment Rental and Labor Rates for Construction ProjectsLhin-BeeGanitoNoch keine Bewertungen

- Estimates Table (Construction)Dokument3 SeitenEstimates Table (Construction)Joe A. Cagas86% (114)

- PRODUCTIVITY RATIOS FOR CONSTRUCTION PROJECTSDokument10 SeitenPRODUCTIVITY RATIOS FOR CONSTRUCTION PROJECTSJohn Edsel SalavariaNoch keine Bewertungen

- Estimates Table (Construction)Dokument3 SeitenEstimates Table (Construction)Joe A. Cagas86% (114)

- Equipment Rental and Labor Rates for Construction ProjectsDokument15 SeitenEquipment Rental and Labor Rates for Construction ProjectsLhin-BeeGanitoNoch keine Bewertungen

- CS 34 Steel ReinforcementDokument5 SeitenCS 34 Steel ReinforcementJohn Edsel SalavariaNoch keine Bewertungen

- PRODUCTIVITY RATIOS FOR CONSTRUCTION PROJECTSDokument10 SeitenPRODUCTIVITY RATIOS FOR CONSTRUCTION PROJECTSJohn Edsel SalavariaNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Flow Through Pipes: Departmentofcivilengineering Presidency University, Bangalore-64 BY Santhosh M B Asstistant ProfessorDokument15 SeitenFlow Through Pipes: Departmentofcivilengineering Presidency University, Bangalore-64 BY Santhosh M B Asstistant ProfessorSanthoshMBSanthuNoch keine Bewertungen

- Comandos HuaweiDokument3 SeitenComandos Huaweicgottoli0% (1)

- Enbrighten Scoring Rubric - Five ScoresDokument1 SeiteEnbrighten Scoring Rubric - Five Scoresapi-256301743Noch keine Bewertungen

- NCERT Solutions For Class 12 Flamingo English Lost SpringDokument20 SeitenNCERT Solutions For Class 12 Flamingo English Lost SpringHarsh solutions100% (1)

- Corporate Subsidies On A Massive ScaleDokument2 SeitenCorporate Subsidies On A Massive ScaleBurchell WilsonNoch keine Bewertungen

- APA - 7thed - UCW Student Paper TemplateDokument4 SeitenAPA - 7thed - UCW Student Paper Templatesimerpreet3Noch keine Bewertungen

- Psyclone: Rigging & Tuning GuideDokument2 SeitenPsyclone: Rigging & Tuning GuidelmagasNoch keine Bewertungen

- ICO Basic SyllabusDokument11 SeitenICO Basic SyllabusRaúl Plasencia Salini100% (1)

- American Literature TimelineDokument2 SeitenAmerican Literature TimelineJoanna Dandasan100% (1)

- Infineum Ilsa Gf-6 API SP e JasoDokument28 SeitenInfineum Ilsa Gf-6 API SP e JasoDanielNoch keine Bewertungen

- Theories of Translation12345Dokument22 SeitenTheories of Translation12345Ishrat FatimaNoch keine Bewertungen

- Math 7: "The Nearest Approximation To An Understanding of Life Is To Feel It and Realize It To The Fullest."Dokument16 SeitenMath 7: "The Nearest Approximation To An Understanding of Life Is To Feel It and Realize It To The Fullest."benjamin ladesma0% (1)

- 05 Askeland ChapDokument10 Seiten05 Askeland ChapWeihanZhang100% (1)

- Edtpa Lesson Plan 1Dokument3 SeitenEdtpa Lesson Plan 1api-364684662Noch keine Bewertungen

- Paper23 PGDMM Public Procurement MCQ Sept2021Dokument25 SeitenPaper23 PGDMM Public Procurement MCQ Sept2021Gagan VermaNoch keine Bewertungen

- ST Veronica Giuliani For OFS PresentationDokument7 SeitenST Veronica Giuliani For OFS Presentationleo jNoch keine Bewertungen

- Biology 11th Edition Mader Test BankDokument25 SeitenBiology 11th Edition Mader Test BankAnthonyWeaveracey100% (44)

- 1.an Overview On Membrane Strategies For Rare Earths Extraction and Separation - 2017Dokument36 Seiten1.an Overview On Membrane Strategies For Rare Earths Extraction and Separation - 2017Vasile AlexandraNoch keine Bewertungen

- A. Rationale: Paulin Tomasuow, Cross Cultural Understanding, (Jakarta: Karunika, 1986), First Edition, p.1Dokument12 SeitenA. Rationale: Paulin Tomasuow, Cross Cultural Understanding, (Jakarta: Karunika, 1986), First Edition, p.1Nur HaeniNoch keine Bewertungen

- Academic Language Use in Academic WritingDokument15 SeitenAcademic Language Use in Academic WritingDir Kim FelicianoNoch keine Bewertungen

- Course Introduction: Collection and Presentation of Data The Frequency Distribution Graphical Presentation of DataDokument61 SeitenCourse Introduction: Collection and Presentation of Data The Frequency Distribution Graphical Presentation of DataShekinah Vingno LingcongNoch keine Bewertungen

- DX DiagDokument42 SeitenDX DiagVinvin PatrimonioNoch keine Bewertungen

- Harajuku: Rebels On The BridgeDokument31 SeitenHarajuku: Rebels On The BridgeChristian Perry100% (41)

- Cbydp Draft SK BaracbacDokument13 SeitenCbydp Draft SK BaracbacLikey PromiseNoch keine Bewertungen

- User Manual: C43J890DK C43J892DK C49J890DK C49J892DKDokument58 SeitenUser Manual: C43J890DK C43J892DK C49J890DK C49J892DKGeorge FiruțăNoch keine Bewertungen

- TG KPWKPDokument8 SeitenTG KPWKPDanmar CamilotNoch keine Bewertungen

- 1st ClassDokument18 Seiten1st Classchitl.23bi14075Noch keine Bewertungen

- Openstack Deployment Ops Guide PDFDokument197 SeitenOpenstack Deployment Ops Guide PDFBinank PatelNoch keine Bewertungen

- (Salim Ross) PUA 524 - Introduction To Law and The Legal System (Mid Term)Dokument4 Seiten(Salim Ross) PUA 524 - Introduction To Law and The Legal System (Mid Term)Salim RossNoch keine Bewertungen

- Communication & Collaboration: Lucy Borrego Leidy Hinojosa Scarlett DragustinovisDokument44 SeitenCommunication & Collaboration: Lucy Borrego Leidy Hinojosa Scarlett DragustinovisTeacherlucy BorregoNoch keine Bewertungen