Beruflich Dokumente

Kultur Dokumente

SOP For Lighting Job

Hochgeladen von

gulam safi100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

605 Ansichten3 SeitenSOP FOR LIGHTING JOB

Originaltitel

SOP for lighting job

Copyright

© © All Rights Reserved

Verfügbare Formate

XLSX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenSOP FOR LIGHTING JOB

Copyright:

© All Rights Reserved

Verfügbare Formate

Als XLSX, PDF, TXT herunterladen oder online auf Scribd lesen

100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

605 Ansichten3 SeitenSOP For Lighting Job

Hochgeladen von

gulam safiSOP FOR LIGHTING JOB

Copyright:

© All Rights Reserved

Verfügbare Formate

Als XLSX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 3

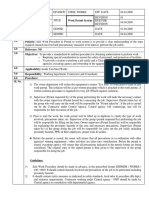

STANDARD OPERATING PROCEDURES

Form No. : QEHSMS/446/4013 Form Rev. No. : 00 Effective date: 01.07.2015

SOP No. Effective Date 01.05.2019 REVISION No 0

SOP DESC. Lighting job Section ELECTRICAL

DEPARTMENT- ENGG-SERVICES Page 01 of 02

Step Activity Associated Responsibility Remarks /

No. (WHAT) Requirements/Hazards/Impacts (WHO) Process / tools / PPEs (HOW)

Reference

• Safety induction on specific job to be given to all

• Incident caused due to lack of the concerned contractor employees on site, For foot protection –

knowledge about the job regarding the hazards and their precautions to be SS/GEN/04

taken at the work place which may occur during For hand

the execution of job. protection-

• Incident due to lack of • Prior to start of work, safety talks to be SS/GEN/05

CHARGE HAND

awareness of hazard prevailing in ELECTRICIAN /

conducted at site every day. For eye protection-

1 Job Preparation the area.. CONCERNED • Brief description regarding hazards/safety SS/GEN/06

CONTRACTOR/ measure will be given to all workmen, every day For head

Supervisor. before starting the job. protection-

• Injury due to non use of proper • Job is to be executed only by trained persons. SS/GEN/07

and adequate safety appliances. • Use safety shoes, safety helmet, safety goggles, For loose clothing-

dust mask, hand gloves and fluorescent vests. SS/GEN/02

SAFETY- Personal injury 1.Take proper work permit,in form #

CHARGE HAND EHSMSM/WORKS/446/4007

ELECTRICIAN / 2.Take gas clearance ( For Gaseous area) in form

2 Work Permit CONCERNED # EHSMSM/WORKS/446/4001 (If required) SS/GEN-25

ENVIRONME NA CONTRACTOR/ 3.Keep Gas Detector (if required.)

NT- Supervisor.

QUALITY- NA 4.Fill up six direction form

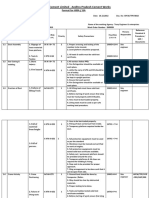

STANDARD OPERATING PROCEDURES

Form No. : QEHSMS/446/4013 Form Rev. No. : 00 Effective date: 01.07.2015

SOP No. Effective Date 01.05.2019 REVISION No 0

SOP DESC. Lighting job Section ELECTRICAL

DEPARTMENT- ENGG-SERVICES Page 02 of 02

Step Activity Associated Responsibility Remarks /

No. (WHAT) Requirements/Hazards/Impacts (WHO) Process / tools / PPEs (HOW)

Reference

SAFETY-- Body injury,Hand 1--Get clearance from control room /concerned

injury,Electric supervisor

shock,Eye injury 2-Power clearance form will be filled by

dept.supervisor and power put off by dept staff..

3-Follow positive isolation rules.

4-Ensure power off by using multimeter/power

ENVIRONMENT- Heat,Dust tester or 3phase test lamp.Do not use tester for

CHARGE HAND checking power.

Changing or

ELECTRICIAN / 5-Do the job.Replace /pepair the

repairing

3

MCB,MCCB,Isolat CONCERNED MCB,MCCB,Isolator/contactor.

or/contactor CONTRACTOR/ 6-Use proper tools and check it before use.

Supervisor. 7- Never defeat isolator interlock.

8-After completion of job remove all material

9-Return work permit to the department.

Proper fixing 10-Dept supervisor will put on the power after

QUALITY-

Proper connection filling the power getting form

11-Infrom respective area incharge/control room

SAFETY- Body injury,Hand 1-Take Work permit from department

injury,Electric 2-- Inform the area owner(respective control

shock,Eye injury room)

3-Identify the source of power of light./fan etc to

be replaced.

ENVIRONMENT- Smoke.Dust,Fume,ga 4-Arrange for proper approach ladder,platform

- s Hot Scaffolding etc.Use safety belt if required.

5- Put off the power of equipment .

CHARGE HAND 6-Replace/repair/clean the light.Replace the fan

ELECTRICIAN / or defective part.

4 Lighting Jobs

1-Take Work permit from department

STANDARD OPERATING PROCEDURES 2-- Inform the area owner(respective control

room)

3-Identify the source of power of light./fan etc to

Form No. : QEHSMS/446/4013 Form Rev. No.be replaced.

: 00 Effective date: 01.07.2015

4-Arrange for proper approach ladder,platform

SOP No. Effective Date 01.05.2019

Scaffolding REVISION

etc.Use safety belt No

if required. 0

SOP DESC. Lighting job Section 5- Put off the power of equipment .

ELECTRICAL

CHARGE HAND 6-Replace/repair/clean the light.Replace the fan

ELECTRICIAN / or defective part.

QUALITY- Proper

4 Lighting Jobs CONCERNED 7- Put On the Power and take trial.

Connection,Proper CONTRACTOR/ 8- Do not work above the running conveyor,crane

fixing of light fittings Supervisor. etc.

9. Apply pull cord before start the job in conveyor

line and press emergency switch for work safely.

10-After completion of job remove all material

11-Infrom respective area incharge/control room

12-Return work permit to the department.

PREPARED BY APPROVED BY

Name and Design: Name and Design.:

Signature with Date: Signature with Date:

Das könnte Ihnen auch gefallen

- SOP of Pump Changing JobDokument11 SeitenSOP of Pump Changing JobDwitikrushna Rout100% (1)

- SOP of Bearing ChangeDokument9 SeitenSOP of Bearing ChangeDwitikrushna Rout100% (3)

- SOP of Idler ChangeDokument9 SeitenSOP of Idler ChangeDwitikrushna RoutNoch keine Bewertungen

- 02-070302 JSA For Relocation of Monkey Ladder For Construction of Phase-I Tranformer Bay in Brown Zone.Dokument4 Seiten02-070302 JSA For Relocation of Monkey Ladder For Construction of Phase-I Tranformer Bay in Brown Zone.Mohammed MinhajNoch keine Bewertungen

- SOP For Electrical WorkDokument1 SeiteSOP For Electrical WorkRajesh100% (1)

- AFA HIRA - Electrical Control PanelDokument30 SeitenAFA HIRA - Electrical Control PaneljavedNoch keine Bewertungen

- JHA Fabrication WorkDokument4 SeitenJHA Fabrication WorkRavi thokalNoch keine Bewertungen

- Electrical InstallationDokument3 SeitenElectrical InstallationWalid KhelfaNoch keine Bewertungen

- Risk Assessment Scaffolding, Painting, Stone Cutting & Fixing and Working at Height Work ISO 45001Dokument7 SeitenRisk Assessment Scaffolding, Painting, Stone Cutting & Fixing and Working at Height Work ISO 45001123shripad100% (1)

- HIRA 003 Welding and Cutting.Dokument4 SeitenHIRA 003 Welding and Cutting.srinibas mohapatraNoch keine Bewertungen

- Risk Assessment For Shutdown Job - 21Dokument12 SeitenRisk Assessment For Shutdown Job - 21ask - ehsNoch keine Bewertungen

- 02JHA On Welding and Gas CuttingDokument8 Seiten02JHA On Welding and Gas CuttingPiyush SinghNoch keine Bewertungen

- Control System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Dokument8 SeitenControl System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Jayson EscamillanNoch keine Bewertungen

- HIRA 008 Height Work.Dokument4 SeitenHIRA 008 Height Work.srinibas mohapatraNoch keine Bewertungen

- Cable Tray Fixing - HiraDokument175 SeitenCable Tray Fixing - HiraVENKATESAN MNoch keine Bewertungen

- Brahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysisDokument2 SeitenBrahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysiszebmechNoch keine Bewertungen

- HIRA For Work at HeightDokument5 SeitenHIRA For Work at HeightMD. Nayyar Mirza100% (1)

- JHA For Belt Conveyor MaintenanceDokument2 SeitenJHA For Belt Conveyor MaintenanceShahid RazaNoch keine Bewertungen

- JSA Fire Fighting WorkDokument8 SeitenJSA Fire Fighting WorkMehul KolambkarNoch keine Bewertungen

- Draft-Procedure For Online Star Rating Audit System by Third Party-R2Dokument6 SeitenDraft-Procedure For Online Star Rating Audit System by Third Party-R2Gopal KumarNoch keine Bewertungen

- Jsa For Work at HeightDokument8 SeitenJsa For Work at HeightMuhammad Umar Gondal50% (2)

- SS - GEN-25-work Permit SystemDokument5 SeitenSS - GEN-25-work Permit SystemmadhulikaNoch keine Bewertungen

- Risk Assessment All Activities TLT HIRADokument50 SeitenRisk Assessment All Activities TLT HIRAvijay100% (2)

- HIRA JSA For Duct Assembly & ErectionDokument4 SeitenHIRA JSA For Duct Assembly & ErectionRaju100% (2)

- Job Safety Analysis - Cone ErectionDokument7 SeitenJob Safety Analysis - Cone ErectionMohammed MinhajNoch keine Bewertungen

- Jha For Painting Works Repainting of Control Room and Guard House at Switchyard (External)Dokument1 SeiteJha For Painting Works Repainting of Control Room and Guard House at Switchyard (External)Jonas GonzalesNoch keine Bewertungen

- SOP Grinding & CuttingDokument3 SeitenSOP Grinding & CuttingIMRANNoch keine Bewertungen

- Job Safety Analysis: Cooling Tower OperationDokument2 SeitenJob Safety Analysis: Cooling Tower OperationVi VekNoch keine Bewertungen

- Compulsory Ppe As Needed Ppe: Safe Operating Procedures SOP 17 - Wool Press OperationDokument2 SeitenCompulsory Ppe As Needed Ppe: Safe Operating Procedures SOP 17 - Wool Press OperationUlviyye ElesgerovaNoch keine Bewertungen

- JSA No - 08 - Grounding System Installation and Testing - Biju - (Revised - 17 July 2016)Dokument6 SeitenJSA No - 08 - Grounding System Installation and Testing - Biju - (Revised - 17 July 2016)babjihanumanthuNoch keine Bewertungen

- JSA - CivilDokument5 SeitenJSA - CivilRajuNoch keine Bewertungen

- JSA OF Fabrication and Installation Work ApproviedDokument3 SeitenJSA OF Fabrication and Installation Work Approviedsakthi venkatNoch keine Bewertungen

- HIRADokument7 SeitenHIRAmadhur chavanNoch keine Bewertungen

- Pre Commissioning Electrical EquipmentDokument4 SeitenPre Commissioning Electrical Equipmentmohammed a hseNoch keine Bewertungen

- HEAT Job Safety Analyisis (JSA)Dokument6 SeitenHEAT Job Safety Analyisis (JSA)คุณพ่อน้อง บิ๊กบอสNoch keine Bewertungen

- Job Safety Analysis Erection SiloDokument3 SeitenJob Safety Analysis Erection SiloDanangNoch keine Bewertungen

- JSA For Civil Work and MDokument22 SeitenJSA For Civil Work and MSyed Yousuf Ali100% (1)

- Jsa For Grinding WorkDokument113 SeitenJsa For Grinding WorkAmit BhattNoch keine Bewertungen

- Jsa Bearing Replacement-OverhaulingDokument2 SeitenJsa Bearing Replacement-Overhaulingashish engineeringNoch keine Bewertungen

- Safe Operating Procedures SOP 19 - Electric Arc Welder - Small Welding JobsDokument2 SeitenSafe Operating Procedures SOP 19 - Electric Arc Welder - Small Welding JobsACCELOR HRNoch keine Bewertungen

- HIRA For TATA Project - Tool RoomDokument124 SeitenHIRA For TATA Project - Tool Roomvivek vjNoch keine Bewertungen

- HIRA No. 22-Installation & Use of Temp Electrical Supplies SBDDokument2 SeitenHIRA No. 22-Installation & Use of Temp Electrical Supplies SBDVenkadesh Periathambi75% (4)

- Jha Solar Transformer ProjectDokument6 SeitenJha Solar Transformer Projectperquino oasanNoch keine Bewertungen

- Aj Infratech: Job Hazard AnalysisDokument5 SeitenAj Infratech: Job Hazard AnalysisDwitikrushna RoutNoch keine Bewertungen

- Area Hard Barrication JsaDokument4 SeitenArea Hard Barrication JsanishantNoch keine Bewertungen

- Job Safety Analysis (Jsa) Piling Activity: Document No: Rev. 01 Date: 12.03.2021Dokument7 SeitenJob Safety Analysis (Jsa) Piling Activity: Document No: Rev. 01 Date: 12.03.2021Sanjay Kumar GhadaiNoch keine Bewertungen

- RISK ASSESSMENT - TK-4742-Operation Training For Overhead CraneDokument6 SeitenRISK ASSESSMENT - TK-4742-Operation Training For Overhead CranensadnanNoch keine Bewertungen

- Jsa. Cable Laying and TerminationDokument10 SeitenJsa. Cable Laying and TerminationMon Trang NguyễnNoch keine Bewertungen

- JSA Road Routine MaintenanceDokument3 SeitenJSA Road Routine MaintenanceBen Hammadi Rym100% (2)

- Jsa PCC & RCCDokument2 SeitenJsa PCC & RCCNilesh koliNoch keine Bewertungen

- Jsa For PCCDokument6 SeitenJsa For PCCCICON EngineersNoch keine Bewertungen

- Cuplocks Scaffolding JSA UtilityDokument4 SeitenCuplocks Scaffolding JSA UtilitysoubhagyaNoch keine Bewertungen

- Jsa Grinding Welding Gas CuttingDokument3 SeitenJsa Grinding Welding Gas CuttingWidodo D PrasetyoNoch keine Bewertungen

- Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityDokument2 SeitenJob Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityJayendra PatelNoch keine Bewertungen

- HIRA & JSA - R1 Conveyor Gallery Dismantling and ErectionDokument26 SeitenHIRA & JSA - R1 Conveyor Gallery Dismantling and ErectionkrishnaengineeringhilNoch keine Bewertungen

- JSA of CentrifugeDokument8 SeitenJSA of CentrifugeGajanan NalegaonkarNoch keine Bewertungen

- Jsa - Cable TerminationDokument4 SeitenJsa - Cable TerminationD FiransyahNoch keine Bewertungen

- Cutting & Grinding & WeldingDokument2 SeitenCutting & Grinding & Weldingghazi kallelNoch keine Bewertungen

- Jsa Loading and Unloading of Pile PipesDokument4 SeitenJsa Loading and Unloading of Pile PipesOsiobe Ewomazino100% (1)

- 18 SOP CBL Trench DiggingDokument10 Seiten18 SOP CBL Trench DiggingMd Gulam SafiNoch keine Bewertungen

- Training AttendenceDokument1 SeiteTraining Attendencegulam safiNoch keine Bewertungen

- BCOC-131: Financial AccountingDokument78 SeitenBCOC-131: Financial AccountingTatparivartan BhavaNoch keine Bewertungen

- Block 2 PDFDokument148 SeitenBlock 2 PDFgulam safiNoch keine Bewertungen

- Block 5Dokument99 SeitenBlock 5gulam safiNoch keine Bewertungen

- BCOC-131: Financial AccountingDokument102 SeitenBCOC-131: Financial Accountinggulam safiNoch keine Bewertungen

- The Indonesia National Clean Development Mechanism Strategy StudyDokument223 SeitenThe Indonesia National Clean Development Mechanism Strategy StudyGedeBudiSuprayogaNoch keine Bewertungen

- Lesson 5 Designing and Developing Social AdvocacyDokument27 SeitenLesson 5 Designing and Developing Social Advocacydaniel loberizNoch keine Bewertungen

- Study 107 - The Doctrine of Salvation - Part 8Dokument2 SeitenStudy 107 - The Doctrine of Salvation - Part 8Jason MyersNoch keine Bewertungen

- DPSD ProjectDokument30 SeitenDPSD ProjectSri NidhiNoch keine Bewertungen

- Stress-Strain Modelfor Grade275 Reinforcingsteel With Cyclic LoadingDokument9 SeitenStress-Strain Modelfor Grade275 Reinforcingsteel With Cyclic LoadingRory Cristian Cordero RojoNoch keine Bewertungen

- What Is TranslationDokument3 SeitenWhat Is TranslationSanskriti MehtaNoch keine Bewertungen

- Fusion Implementing Offerings Using Functional Setup Manager PDFDokument51 SeitenFusion Implementing Offerings Using Functional Setup Manager PDFSrinivasa Rao Asuru0% (1)

- Mastertop 1230 Plus PDFDokument3 SeitenMastertop 1230 Plus PDFFrancois-Noch keine Bewertungen

- MRBR ATR 72 Rev18Dokument424 SeitenMRBR ATR 72 Rev18Juan Forero OrtizNoch keine Bewertungen

- Dialogue Au Restaurant, Clients Et ServeurDokument9 SeitenDialogue Au Restaurant, Clients Et ServeurbanuNoch keine Bewertungen

- Checklist & Guideline ISO 22000Dokument14 SeitenChecklist & Guideline ISO 22000Documentos Tecnicos75% (4)

- Hamstring - WikipediaDokument21 SeitenHamstring - WikipediaOmar MarwanNoch keine Bewertungen

- Law of EvidenceDokument14 SeitenLaw of EvidenceIsha ChavanNoch keine Bewertungen

- KP Tevta Advertisement 16-09-2019Dokument4 SeitenKP Tevta Advertisement 16-09-2019Ishaq AminNoch keine Bewertungen

- On Derridean Différance - UsiefDokument16 SeitenOn Derridean Différance - UsiefS JEROME 2070505Noch keine Bewertungen

- The Use of Air Cooled Heat Exchangers in Mechanical Seal Piping Plans - SnyderDokument7 SeitenThe Use of Air Cooled Heat Exchangers in Mechanical Seal Piping Plans - SnyderJaime Ocampo SalgadoNoch keine Bewertungen

- Existential ThreatsDokument6 SeitenExistential Threatslolab_4Noch keine Bewertungen

- Washing Machine: Service ManualDokument66 SeitenWashing Machine: Service ManualFernando AlmeidaNoch keine Bewertungen

- SimovertDokument41 SeitenSimovertRamez YassaNoch keine Bewertungen

- Monergism Vs SynsergismDokument11 SeitenMonergism Vs SynsergismPam AgtotoNoch keine Bewertungen

- Ib History Command Term PostersDokument6 SeitenIb History Command Term Postersapi-263601302100% (4)

- All You Need To Know About Egg YolkDokument7 SeitenAll You Need To Know About Egg YolkGolden Era BookwormNoch keine Bewertungen

- 5c3f1a8b262ec7a Ek PDFDokument5 Seiten5c3f1a8b262ec7a Ek PDFIsmet HizyoluNoch keine Bewertungen

- Jesus Prayer-JoinerDokument13 SeitenJesus Prayer-Joinersleepknot_maggotNoch keine Bewertungen

- Powerpoint Speaker NotesDokument4 SeitenPowerpoint Speaker Notesapi-273554555Noch keine Bewertungen

- Ron Kangas - IoanDokument11 SeitenRon Kangas - IoanBogdan SoptereanNoch keine Bewertungen

- Decision Making and The Role of Manageme PDFDokument20 SeitenDecision Making and The Role of Manageme PDFRaadmaan RadNoch keine Bewertungen

- PED003Dokument1 SeitePED003ely mae dag-umanNoch keine Bewertungen

- Carriage RequirementsDokument63 SeitenCarriage RequirementsFred GrosfilerNoch keine Bewertungen

- Ob NotesDokument8 SeitenOb NotesRahul RajputNoch keine Bewertungen