Beruflich Dokumente

Kultur Dokumente

SSC Sa 5259

Hochgeladen von

Engineering ProductionOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SSC Sa 5259

Hochgeladen von

Engineering ProductionCopyright:

Verfügbare Formate

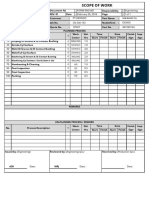

SCOPE OF PROCESS

Document No : FORM-ENG-001 Responsibility : Engineering

REV. 01 Date : February 26, 2016 Page : 1 of 1

No. : Customer : PT. KRA Part Name : Wheel Hub Sprocket

Date : September 10, 2019 Job No. : WO291185 Model/Unit : D155A-6

SSC ID : SSC SA-5259 Quote No. : Part No. : 2410019501/3400019774

PLANNED PROCESS

Work Std. Time Date Finish Insp.

No. Process Description

Center Hrs Start Finish Start Finish Sign Sign

10 Striping ID Holes CNC MILL 3,0

15 Check Crack Flange Area QC 0,5

20 Repair Crack

Remove Crack GENWELD 2,0

Check Crack GENWELD 1,0

Weld Crack GENWELD 4,0

30 Weld Build Up ID Holes GENWELD 5,0

40 Weld Build Up Flange Surface & stopper GENWELD 4,0

50 Weld Dent Surface OD Flange (Local Area) GENWELD 2,0

60 Machining Surface Flange & OD Stopper Bolt SXN/YNN 4,0

70 Striping Bearing Seat A SXN/YNN 2,0

80 Striping Bearing Seat B SXN/YNN 2,0

90 Drill Holes to Spec CNC MILL 4,0

100 Masking SPRAY 1,0

110 Blasting SPRAY 1,0

120 Metal Spray Bearing Seat A SPRAY 2,0

130 Metal Spray Bearing Seat B SPRAY 2,0

140 Polish Bearing Seat A to spec HD 1,0

150 Polish Bearing Seat B to spec HD 1,0

160 Tigweld & Polish Dent Area HD 1,0

165 Re-Tap All Thread HD 1,0

166 Polish All Corrosion Area HD 1,0

170 Handressing & Cleaning HD 2,0

180 Post Inspection QC 1,0

190 Packing HD 1,0

200 Final Inspection QC 1,0

REMARKS

UN-PLANNED PROCESS / REWORK

Work Std. Time Date Finish Insp.

No. Process Description

Center Hrs Start Finish Start Finish Sign Sign

45 Weld Build Up Stoper Bolt GENWELD 3,0

Issued by: (Engineering) Reviewed by: (Engineering Spv.) Received by: (Production Spv.)

AFN Date: Date: Date:

Process No : 10-15

Process Description : Striping ID Hole Flange

Ø31±0.5

Dimension Record (Critical Dim.) X X'

Y Y'

Process No : 30 & 50

Process Description : Weld build up flange surface & stopper & worn out & dent

28

Weld Build Up Surface & Plug Weld Hole

Mat'l : E71

Pre Heat : 125°-175°C

Weld Local Surface

Wrapped by Glasswool After Weld

Worn Out Area

Dimension Record (Critical Dim.) X X'

SSC

Y SA-5259 Y'

HUB FD D155A-6 Wheel Hub Sprocket.xls Page 1

Process No : 60

Process Description : Machining surface & OD stopper to Spec

24±0.1

12±0.1

CH.6x45°

R5

Ø753±0.5

Dimension Record (Critical Dim.) X X'

Y Y'

Process No : 90

Process Description : Drill Holes to Spec

257,12

320,85

179,52

393,92

367,29

92,25

0

400

PCD-Ø800 389,22

357,45

27 Hole x Ø26.5

306,42

238,86

158,43

69,46

23,26

114,72

200

274,5

334,2

375,88

397,3

346,41

136,81

399,32

290,95

46,44

219,8

383,2

Dimension Record (Critical Dim.) X X'

Y SSC SA-5259

Y' HUB FD D155A-6 Wheel Hub Sprocket.xls Page 2

Process No : 140 & 150

Process Description : Polish ID Bearing Seat to spec

2 4 ± 0 .1 24

121 ±0 ±0,1

0 .1

R5

HARDNESS MIN 35 HRC

A

0 .0 7 0 A

R a = 0 .8 s

+0.073

Ø380.8 +0.023

+0.073

Ø380.8 +0.023

Ø862±0.2

R a = 0 .8 s

4 9 ± 0 .0 5 5 0 .8 ± 0 .0 5

0 .1 A

Dimension Record (Critical Dim.) X X'

Y SSCY'

SA-5259 HUB FD D155A-6 Wheel Hub Sprocket.xls Page 3

Process No : 160

Process Description : Tigweld & Polish

Tigweld & Polish Dent Area

Mat'l : DM155

Dimension Record (Critical Dim.) X X'

Y Y'

Process No 90 :

Process Description :

Dimension Record (Critical Dim.) X X'

Y SSC SA-5259

Y' HUB FD D155A-6 Wheel Hub Sprocket.xls Page 4

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- SSC SA-9412 EX 3600 Thumbler (PT - SIS) Partial SowDokument7 SeitenSSC SA-9412 EX 3600 Thumbler (PT - SIS) Partial SowEngineering ProductionNoch keine Bewertungen

- Aisi 8640Dokument2 SeitenAisi 8640Engineering ProductionNoch keine Bewertungen

- Stress Analysis Report Stator Retarder Material's: MomentDokument2 SeitenStress Analysis Report Stator Retarder Material's: MomentEngineering ProductionNoch keine Bewertungen

- Worm Gears Component GeneratorDokument3 SeitenWorm Gears Component GeneratorEngineering ProductionNoch keine Bewertungen

- Spur Gears Component GeneratorDokument4 SeitenSpur Gears Component GeneratorEngineering ProductionNoch keine Bewertungen

- SSC SA-7374 Idle Gear B Engine WARRANTYDokument1 SeiteSSC SA-7374 Idle Gear B Engine WARRANTYEngineering ProductionNoch keine Bewertungen

- SSC Sa-7169 Ex2500-6 Case PtoDokument1 SeiteSSC Sa-7169 Ex2500-6 Case PtoEngineering ProductionNoch keine Bewertungen

- SSC SA-6533 YOKE Cat 16MDokument3 SeitenSSC SA-6533 YOKE Cat 16MEngineering ProductionNoch keine Bewertungen

- Understanding Water Hardness: World Aquaculture March 1993Dokument3 SeitenUnderstanding Water Hardness: World Aquaculture March 1993Engineering ProductionNoch keine Bewertungen

- Stress Analysis Report StatorDokument31 SeitenStress Analysis Report StatorEngineering ProductionNoch keine Bewertungen

- SSC SA-6543 Yoke CAT785C ThiessDokument4 SeitenSSC SA-6543 Yoke CAT785C ThiessEngineering ProductionNoch keine Bewertungen

- Machining Cyl Surface 1 Sisi & Skim 1 Sisi Machining ID Groove & ID Contact BushingDokument3 SeitenMachining Cyl Surface 1 Sisi & Skim 1 Sisi Machining ID Groove & ID Contact BushingEngineering ProductionNoch keine Bewertungen

- SSC SA-156 HD 785-7 Retainer BrakeDokument4 SeitenSSC SA-156 HD 785-7 Retainer BrakeEngineering ProductionNoch keine Bewertungen

- SA-6416 Shaft OutputDokument4 SeitenSA-6416 Shaft OutputEngineering ProductionNoch keine Bewertungen

- Steel-Hardness Conversion-Table PDFDokument2 SeitenSteel-Hardness Conversion-Table PDFEngineering ProductionNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Handbook On National Spectrum Management 2015Dokument333 SeitenHandbook On National Spectrum Management 2015Marisela AlvarezNoch keine Bewertungen

- Harriet Tubman Lesson PlanDokument7 SeitenHarriet Tubman Lesson PlanuarkgradstudentNoch keine Bewertungen

- Number CardsDokument21 SeitenNumber CardsCachipún Lab CreativoNoch keine Bewertungen

- Antenna Systems - Standard Format For Digitized Antenna PatternsDokument32 SeitenAntenna Systems - Standard Format For Digitized Antenna PatternsyokomaNoch keine Bewertungen

- Mathematics4 q4 Week4 v4Dokument11 SeitenMathematics4 q4 Week4 v4Morales JinxNoch keine Bewertungen

- Green ThumbDokument2 SeitenGreen ThumbScarlet Sofia Colmenares VargasNoch keine Bewertungen

- A Presentation On-: E-Paper TechnologyDokument19 SeitenA Presentation On-: E-Paper TechnologyRevanth Kumar TalluruNoch keine Bewertungen

- NGCP - Procedures and Requirements For Energy ProjectsDokument17 SeitenNGCP - Procedures and Requirements For Energy ProjectspurplebasketNoch keine Bewertungen

- ToiletsDokument9 SeitenToiletsAnonymous ncBe0B9bNoch keine Bewertungen

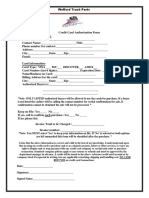

- Credit Card Authorization Form WoffordDokument1 SeiteCredit Card Authorization Form WoffordRaúl Enmanuel Capellan PeñaNoch keine Bewertungen

- ERP Solution in Hospital: Yangyang Shao TTU 2013Dokument25 SeitenERP Solution in Hospital: Yangyang Shao TTU 2013Vishakh SubbayyanNoch keine Bewertungen

- WSI - Catalogue of O-Ring PDFDokument37 SeitenWSI - Catalogue of O-Ring PDFyearetg100% (1)

- Norberto Elias: Graduation of Teach Portuguese Language With Ability in EnglishDokument14 SeitenNorberto Elias: Graduation of Teach Portuguese Language With Ability in EnglishGildo Joaquim FranciscoNoch keine Bewertungen

- Permanent Magnet Motor Surface Drive System: Maximize Safety and Energy Efficiency of Progressing Cavity Pumps (PCPS)Dokument2 SeitenPermanent Magnet Motor Surface Drive System: Maximize Safety and Energy Efficiency of Progressing Cavity Pumps (PCPS)Carla Ayelen Chorolque BorgesNoch keine Bewertungen

- MidsemDokument6 SeitenMidsemAravind SomasundaramNoch keine Bewertungen

- Energy BodiesDokument1 SeiteEnergy BodiesannoyingsporeNoch keine Bewertungen

- Brp-Rotax Chassis Approval FormDokument3 SeitenBrp-Rotax Chassis Approval Formdelta compNoch keine Bewertungen

- Classical Theories of Economic GrowthDokument16 SeitenClassical Theories of Economic GrowthLearner8494% (32)

- Emerson Mentor MP ManualDokument182 SeitenEmerson Mentor MP ManualiampedrooNoch keine Bewertungen

- Hexoloy SP Sic TdsDokument4 SeitenHexoloy SP Sic TdsAnonymous r3MoX2ZMTNoch keine Bewertungen

- Empowerment Technology Lesson 4 PDFDokument18 SeitenEmpowerment Technology Lesson 4 PDFqueenless eightyoneNoch keine Bewertungen

- Biography Worksheet: Name: Gerardo Angeles MartinezDokument1 SeiteBiography Worksheet: Name: Gerardo Angeles MartinezAlejandro AngelesNoch keine Bewertungen

- Admission: North South University (NSU) Question Bank Summer 2019Dokument10 SeitenAdmission: North South University (NSU) Question Bank Summer 2019Mahmoud Hasan100% (7)

- Hemax-530 PDFDokument2 SeitenHemax-530 PDFNice BennyNoch keine Bewertungen

- EXPERIMENT 1 - Bendo Marjorie P.Dokument5 SeitenEXPERIMENT 1 - Bendo Marjorie P.Bendo Marjorie P.100% (1)

- Code of Federal RegulationsDokument14 SeitenCode of Federal RegulationsdiwolfieNoch keine Bewertungen

- Causal Emergence - HoelDokument18 SeitenCausal Emergence - HoelFelipe LopesNoch keine Bewertungen

- Lesson Exemplar Math 7Dokument6 SeitenLesson Exemplar Math 7Pablo Jimenea100% (2)

- Performance Comparison of VxWorks Linux RTAI and Xenomai in A Hard Real-Time ApplicationDokument5 SeitenPerformance Comparison of VxWorks Linux RTAI and Xenomai in A Hard Real-Time ApplicationsatyanaryanakNoch keine Bewertungen

- Biosynthesis and Characterization of Silica Nanoparticles From RiceDokument10 SeitenBiosynthesis and Characterization of Silica Nanoparticles From Riceanon_432216275Noch keine Bewertungen