Beruflich Dokumente

Kultur Dokumente

Pipe Fabrication-1

Hochgeladen von

Mecon HyderabadOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Pipe Fabrication-1

Hochgeladen von

Mecon HyderabadCopyright:

Verfügbare Formate

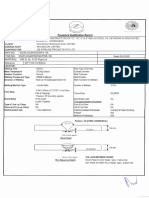

Procedure For

Fabrication & Installation

PROJECT NO.

LAYING & CONSTRUCTION OF 12”, 6” & 4” NB U/G STEEL

PROJECT NAME

P/L NETWORK & ASSOCIATED WORKS AT HYDERABAD.

OWNER BHAGYANAGAR GAS LIMITED (BGL)

CLIENT MECON LIMITED

CONTRACTOR MPEC

JOB PROCEDURE MPEC/BGL/MEC/BF/01

Rev. 0

Procedure

For

Fabrication & Installation

Material Receipt & Storage

Kindly check this with procedure for

incoming_materials

For Review &

0 30.09.2016

Approval

1 OF 4 Procedure For Incoming Material Checking

Procedure For

Fabrication & Installation

Checked &

Prepared By Approved By

Rev. Date Description

MPEC

Reviewed By

MECON

MPEC

TABLE OF CONTENTS

1. PURPOSE

2. SCOPE

3. REFERENCES

4. MAN POWER

5. METHODOLOGY

6. HEALTH, SAFETY & ENVIRONMENTS.

2 OF 4 Procedure For Incoming Material Checking

Procedure For

Fabrication & Installation

1.0 PURPOSE

To establish a documented procedure for contractor supplied materials receipt,

storage, preservation and issue of materials at site.

2.0 SCOPE:

This procedure shall be applicable to all types of contractor-supplied materials.

3.0 REFERENCES

o MEC Spec. MEC/S/05/21/06

o OISD 226

4.0 MAN POWER

4.1 Site Engineer

4.2 QC Engineer

4.3 Helper

5.0 METHODOLOGY

Materials received from the selected supplier / approved vendor shall be

checked by the store-in- charge for its physical quantity and the concerned

Engineer shall check for its quality.

Inspection shall be done as per specification.

Verification shall be carried out by the store-in-charge as per purchase order

placed and actual materials received at site.

Receipt note shall be prepared by Store-in-charge

If there is defect or extra item in the materials received, the same shall be

returned to the supplier / vendor.

5.1 STORAGE / PRESERVATION:

Location of storage at MPEC yard shall be pre decided by the concerned

technical personnel.

Materials shall be stored as per specification / contract procedure.

Record shall be maintained by the store-in-charge for the materials

received, stored and its location for easy trace ability.

The stored materials shall be preserved as per the specification / contract

procedure and the supplier's instructions for the product.

3 OF 4 Procedure For Incoming Material Checking

Procedure For

Fabrication & Installation

It shall be ensured that no deterioration and damage takes place during

storage and periodic use.

5.2 ISSUE:

Concern Engineer/ foreman shall be given the store requisition / issue slip vetted

by section-in-charge to the store for issue of materials.

5.3 INSPECTION / VERIFICATION

The received materials which shall be for MEC inspection, the prior intimation

shall be made by Concerned Engineer / Store-in-charge and same shall be

checked / inspected by MEC authorized representative for various inspections as

per specification and the same shall be issued / delivered to site for further

activity after inspection / release and approval from MEC. Also MEC will check

the Test certificate, Data sheet, approved QAP, quantity and note the verified

Necessary documentation shall be generated and the same shall be used for

records.

5.4 DOCUMENTATION:

The following documentation shall be maintained by store in charge.

Store Issue voucher

Materials reconciliation report

Test certificates, Data Structures, QAP etc

6.0 HEALTH, SAFETY & ENVIRONMENT

The health, safety & environment shall be followed as per approved HSE policy.

Note: In case of any conflict between the requirements of this procedure and

MEC Tender technical Specification; the later shall govern.

4 OF 4 Procedure For Incoming Material Checking

Das könnte Ihnen auch gefallen

- PQR 3Dokument2 SeitenPQR 3Mecon HyderabadNoch keine Bewertungen

- PQR 1Dokument2 SeitenPQR 1Mecon HyderabadNoch keine Bewertungen

- Procedure For Trenching: Laying & Construction of 12", 6" & 4" NB U/G Steel P/L Network & Associated Works at HyderabadDokument7 SeitenProcedure For Trenching: Laying & Construction of 12", 6" & 4" NB U/G Steel P/L Network & Associated Works at HyderabadMecon HyderabadNoch keine Bewertungen

- Proposed WPS For API 5LDokument1 SeiteProposed WPS For API 5LMecon HyderabadNoch keine Bewertungen

- Procedure For Stringing: Laying & Construction of 12", 6" & 4" NB U/G Steel P/L Network & Associated Works at HyderabadDokument6 SeitenProcedure For Stringing: Laying & Construction of 12", 6" & 4" NB U/G Steel P/L Network & Associated Works at HyderabadMecon HyderabadNoch keine Bewertungen

- Job Procedure For LoweringDokument5 SeitenJob Procedure For LoweringMecon HyderabadNoch keine Bewertungen

- Job Procedure For RadiographyDokument12 SeitenJob Procedure For RadiographyMecon HyderabadNoch keine Bewertungen

- Procedure For WeldingDokument7 SeitenProcedure For WeldingMecon Hyderabad100% (1)

- Procedure For ROW Clearing and GradingDokument5 SeitenProcedure For ROW Clearing and GradingMecon HyderabadNoch keine Bewertungen

- Blasting and Paintaing ProcedureDokument4 SeitenBlasting and Paintaing ProcedureMecon HyderabadNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- SRX-Manual-Final ScorpioDokument20 SeitenSRX-Manual-Final ScorpioJay KnowlesNoch keine Bewertungen

- Scanned & Edited By: Rajesh Kumar©Dokument36 SeitenScanned & Edited By: Rajesh Kumar©SoumyaNoch keine Bewertungen

- Interactive EnvironmentsDokument5 SeitenInteractive EnvironmentsCosmin009Noch keine Bewertungen

- Microprocessors and InterfacingDokument125 SeitenMicroprocessors and InterfacingRaja SekharNoch keine Bewertungen

- Parent QuestionnaireDokument2 SeitenParent QuestionnaireJoaquinNoch keine Bewertungen

- ReactivepowerComp usingSTATCOMDokument126 SeitenReactivepowerComp usingSTATCOMsreddy4svuNoch keine Bewertungen

- 10b - Crime-Mapping Technology in The Philippines..2-Crime Mapping in The Philippines-2015febDokument5 Seiten10b - Crime-Mapping Technology in The Philippines..2-Crime Mapping in The Philippines-2015febGesler Pilvan SainNoch keine Bewertungen

- Bss 101Dokument349 SeitenBss 101Sabrina MaloneNoch keine Bewertungen

- Zwave Compatibility ListDokument2 SeitenZwave Compatibility ListsupermanNoch keine Bewertungen

- ForestDokument2 SeitenForestZINEB LAHYANoch keine Bewertungen

- Data Sufficiency Number SystemDokument2 SeitenData Sufficiency Number Systemsagar283Noch keine Bewertungen

- ShipmentsDokument1 SeiteShipmentsAlif Moechyiddin SugiartoNoch keine Bewertungen

- Immigrants and The Public LibraryDokument10 SeitenImmigrants and The Public Libraryapi-250093181Noch keine Bewertungen

- Learning ObjectivesDokument2 SeitenLearning ObjectivesRezky RoeviansyahNoch keine Bewertungen

- Nebula - 150 User ManualDokument94 SeitenNebula - 150 User ManualSamuel MongeNoch keine Bewertungen

- ScaleIO Fundamentals MR 1WN SIOFUN - Student GuideDokument74 SeitenScaleIO Fundamentals MR 1WN SIOFUN - Student GuideReinaldo GuzmanNoch keine Bewertungen

- Oxygen Enters The Lungs and Then Is Passed On Into Blood. The Blood CarriesDokument9 SeitenOxygen Enters The Lungs and Then Is Passed On Into Blood. The Blood CarriesPranita PotghanNoch keine Bewertungen

- G Codes and M CodesDokument10 SeitenG Codes and M CodesHarsh YadavNoch keine Bewertungen

- PHP BitsDokument24 SeitenPHP BitskarunakarNoch keine Bewertungen

- Users Manual 3510139Dokument1 SeiteUsers Manual 3510139Marcelo GarciaNoch keine Bewertungen

- Parallel Rubik's Cube Solver: Abstract-This Report Investigates Parallel Processing ForDokument3 SeitenParallel Rubik's Cube Solver: Abstract-This Report Investigates Parallel Processing ForTejas LadheNoch keine Bewertungen

- DELL Latitude D420 COMPAL LA-3071P Rev 1.0 SchematicsDokument59 SeitenDELL Latitude D420 COMPAL LA-3071P Rev 1.0 SchematicsviniciusvbfNoch keine Bewertungen

- An Acknowledgement LetterDokument1 SeiteAn Acknowledgement LetterGovindan PerumalNoch keine Bewertungen

- Eng Fp28495 Zeppelin BrochureDokument26 SeitenEng Fp28495 Zeppelin BrochurePiese Masini100% (1)

- Dm1 Introduction ML Data MiningDokument39 SeitenDm1 Introduction ML Data MiningSubir RanjanNoch keine Bewertungen

- Trader Manual PDFDokument121 SeitenTrader Manual PDFlorenneth87% (15)

- Power Plant Manual 1Dokument8 SeitenPower Plant Manual 1Khoirul WaladNoch keine Bewertungen

- TR01 - Introduction PDFDokument25 SeitenTR01 - Introduction PDFRajNoch keine Bewertungen

- Dav DZ340 PDFDokument92 SeitenDav DZ340 PDFCurtoAVidaNoch keine Bewertungen

- Irfiz 34 NDokument8 SeitenIrfiz 34 NBase de DatosNoch keine Bewertungen