Beruflich Dokumente

Kultur Dokumente

VPS FQT Brochure

Hochgeladen von

argentum19619692Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

VPS FQT Brochure

Hochgeladen von

argentum19619692Copyright:

Verfügbare Formate

FUEL QUALITY TESTING

YOUR FUEL MANAGEMENT PARTNER

Fuel

WHY TEST YOUR MARINE

FUELS?

Unpredictable fuel quality is a regular

cause for concern among ship operators.

Quality

Apart from creating operational problems,

fuels of unknown quality may lead to

commercial losses or violation of statutory

requirements.

Testing

Contravening local or global environmental

regulations may result in penalties such

as vessel detentions and fines.

To protect your company’s assets, you

should always determine the quality of

fuel purchases before use by testing a

representative sample at an accredited

laboratory.

While some fuel buyers may argue that

they have not encountered any fuel-related

problems, it is increasingly difficult to

pinpoint the sources of quality problems

because marine fuel is an internationally

traded commodity. For this reason, ship

operators should constantly monitor the

quality of bunkers delivered to their vessels.

THE VPS CUMULATIVE REASONS FOR ENGAGING

VERITAS PETROLEUM SERVICES

TESTING VOLUME, IN

EXCESS OF 2 MILLION FUEL SUPERIOR FUEL ANALYSIS

EXPERTISE AND TECHNOLOGY

SAMPLES CONTINUES The hallmark of VPS quality is the breadth

TO ENHANCE OUR FUEL and depth of our fuel testing services.

QUALITY DATABASE, THE Veritas Petroleum Services (VPS)

MOST EXTENSIVE OF ITS introduced the first commercial bunker

testing programme in 1981. Since then,

KIND IN THE MARKET. we have been in the forefront of bunker

fuels research and development.

Our VPS Fuel Quality Testing Programme

(FQT) is supported by state-of-the-art

analytical equipment and optimum

support from a dedicated team of

specialists with a complete spectrum of

expertise in marine fuels and shipboard

operations.

SPEED OF RESPONSE SUPERIOR BUNKER QUALITY that you will receive test results and

Analysis results, alongside results from DATABASE AND APPLICATIONS technical advice promptly.

previous fuel deliveries, are evaluated by The VPS cumulative testing volume,

technical experts with vast operational which is in excess of two million fuel For your convenience, all fuel quality

experience to provide tailor made advice samples, continually enhances our fuel test results are available on Customer

on fuel handling for optimal performance quality database, the most extensive of Portal, our online customer service

and to assist in troubleshooting. its kind in the market. With this database, website. Members can retrieve vessels’

VPS can help you plan bunkering test results and make sample inquiries

As fuel onboard must always be fit activities by providing accurate, critical online based on vessel, port or supplier.

for purpose, clients will be contacted information on fuel quality characteristics

immediately if test findings show issues and trends pertaining to specific bunkering Features of the VPS Fuel Quality

that require prompt action. locations around the world. Testing Programme

• Comprehensive technical advisory

SUPERIOR QUALITY CONTROL Members of the VPS Fuel Quality services on fuel quality and proper

AND ASSURANCE Testing Programme also receive timely management of fuels, including

As a certified company with high standards Bunker Alerts and Technical Newsletters expert advice on fuel treatment

such as ISO 9001, ISO 14001 and OHSAS containing information about the latest and storage, storage tank heating,

18001, safety and quality practices are fuel quality problems detected by our blend optimisation and safe engine

of paramount importance to VPS. Our global testing network. operation

testing facilities are also accredited to

ISO 17025. With VPS, you are assured With such timely advice, you can avoid • Technical consulting for engine damage

of timely and reliable customer care. bunkering in the affected areas or take cases involving detailed investigations,

the necessary precautions if refueling or disputed cases requiring expert

COMPLIANCE WITH LEGISLATIVE has to take place. testimony at arbitration

& REGULATORY REQUIREMENTS

As a longstanding and leading member SUPERIOR SERVICE NETWORK • Bunker alerts and online fuel quality

of international regulatory bodies, VPS VPS owns and operates four specialist newsletters

helps you navigate and comply with and accredited fuel laboratories,

bunker environmental regulations strategically located in Singapore, • Monitoring of onboard fuel treatment

such as the MARPOL Annex VI and EU Rotterdam, Houston and Fujairah. plant by analysing Fuel System Check

Sulphur Directive for Emission Control Supported by our global customer service (FSC) samples taken at locations close

Areas (ECAs). and understand how these network and top courier companies, our to the fuel entry and exit points of

can impact your vessels’ operations multiple laboratories not only minimise the separators, as well as before the

and business. sample delivery time, but also ensure engine’s fuel inlet

• Optional investigative analysis • Advisory services on regulatory • MARPOL compliant VPS sampling

and repor ting, including Fuel requirements (e.g. MARPOL Annex equipment (line samplers, sample

Ignition and Combustion Analysis, VI, EU Directive 201233/EC) and bottles, seals and cubitainers). The

G a s C h ro m a to g ra p hy/ M a s s operating with distillates sampling kits contain comprehensive

Spectrometry, Fourier Transform instruction manual on recommended

Infra–red Spectrometry, Corrosive • Training courses and specially bunkering and sampling guidelines

Tes t and C ataly tic Fines Size designed in-houses seminars on as well as the VPS FQT programme

Distribution marine fuel management procedures.

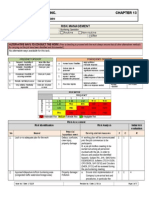

VPS FQT PROGRAMME – STANDARD SCOPE OF ANALYSIS TABLE

Residual Fuel Distillate

Test Parameters DMA/DMZ DMB

Density, kg/m3 @ 15°C ✓ ✓ ✓

Viscosity, mm /s @ 2

50°C 40°C 40°C

Water by distillation, % ✓ ✓ a

✓a

Micro Carbon Residue, % m/m ✓ ✓

Micro Carbon Residue, 10% residue, % m/m ✓

Sulphur, % m/m ✓ ✓ ✓

Total Sediment-Potential, % m/m ✓

Total Sediment-Existent, % m/m ✓a

Ash, % m/m ✓ ✓ ✓

Vanadium, mg/kg ✓ ✓ b

✓b

Sodium, mg/kg ✓ ✓b ✓b

Aluminium, mg/kg ✓ ✓b ✓b

Silicon, mg/kg ✓ ✓ b

✓b

Iron, mg/kg ✓ ✓b ✓b

Nickel, mg/kg ✓ ✓b ✓b

Calcium, mg/kg ✓ ✓b ✓b

Magnesium, mg/kg ✓ ✓ b

✓b

Zinc, mg/kg ✓ ✓b ✓b

Phosphorus, mg/kg ✓ ✓b ✓b

Potassium, mg/kg ✓ ✓ b

✓b

Flash Point, °C ✓ ✓ ✓

Pour Point, °C ✓ ✓ ✓

Visual Appearance ✓ ✓

Fatty Acid Methyl Ester (FAME) ✓ ✓

Acid Number ✓ ✓ ✓

Residual Fuel Distillate

Calculated Values DMA/DMZ DMB

Net Specific Energy, MJ/kg ✓ ✓ ✓

Calculated Carbon Aromaticity Index (CCAI) ✓

Calculated Cetane Index (CCI) ✓ ✓

Aluminium + Silicon (Al + Si) ✓ ✓ ✓

a: If not bright and clear b: If Ash ≥ 0.01%

A SUMMARY OF SPECIALISED Headspace GCMS Analysis involves

TESTS OFFERED BY VPS: two sophisticated analytical techniques,

Gas Chromatography (GC) and Mass

Fuel Ignition and Combustion Analysis Spectrometry (MS). Fuel oils are a

(FIA-100 FCA) is used to simulate and blend of several organic components.

measure the ignition delay and the The basic principles of GCMS are to

combustion of a specific fuel. The reported separate and identify these various

parameters are a calculated average of components.

25 fuel injections in to the equipment.

Vacuum distillation is employed as

Screening of catalytic fines size an analytical extraction technique to

distribution (CSD) is conducted using separate the fuel components based

a combination of techniques such as on boiling point in vacuum, before

filtration, microscopic examination and identifying by use of FTIR and GCMS.

image analysis through special software.

Simulated distillation is a gas

While most standard test scopes have chromatography technique, separating

the concentration of catalytic fines in individual hydrocarbons in order of

the fuel, VPS’ CSD tool goes a step their boiling point, routinely used

further by analyzing and quantifying the for determination of the typical or

size ranges of catalytic fines particles characteristic boiling point ranges of

present in the fuel. When used in crude oil and other refined products.

combination with Fuel System Check, The method is particularly useful in

the method provides information about determining whether the fuels being

critical cat fines sizes not removed by investigated are typical fuel oils or

the centrifuge. belonging to other product categories.

Fo u r i e r Tr a n s f o r m I n f r a - R e d Acid extraction is used for isolating

Spectrometry (FT-IR) scan is used for organic acid components. If presence

characterising and identifying certain of organic acids is confirmed through

organic molecules present in marine FTIR and Acid Number analysis, acid

fuels. Examples of components that extrac tion ser ves to extrac t and

can be detected by FT-IR are alcohols, concentrate these acidic components

esters and acids. before individual identification by GCMS.

Veritas Petroleum Services Group

EUROPE

Rotterdam

Zwolseweg 1

2994 LB Barendrecht

The Netherlands

T + 31 (0) 180 221 100

E rotterdam@v-p-s.com

ASIA, MIDDLE EAST & AFRICA

Singapore

27 Changi South Street 1

Singapore 486071

T + 65 6779 2475

E singapore@v-p-s.com

AMERICAS

Houston

318 North 16th Street

La Porte, Texas 77571

USA

T + 1 281 470 1030

E houston@v-p-s.com

www.v-p-s.com

Copyright. All rights reserved. No part of this brochure may be reproduced, transmitted or copied

in any form or by any means without the prior written consent of Veritas Petroleum Services.

Disclaimer: While every effort is made to ensure that the information contained in this brochure

is timely, accurate and complete, it should not be taken as any form of advice and should not

be relied upon without independent verification. Veritas Petroleum Services makes no claims,

promises or guarantees about the accuracy, completeness, or adequacy of the contents of this

brochure and expressly disclaims liability for errors and omissions in the contents of this brochure.

VPS/BRO02/R00_0814

Das könnte Ihnen auch gefallen

- Naval Mechanical Engineering: Gas Turbine Propulsion, Auxiliary, and Engineering Support SystemsVon EverandNaval Mechanical Engineering: Gas Turbine Propulsion, Auxiliary, and Engineering Support SystemsNoch keine Bewertungen

- Drew Marine - Vision and Mission: Fuel Management SolutionsDokument8 SeitenDrew Marine - Vision and Mission: Fuel Management SolutionsGauravNoch keine Bewertungen

- ShipCare Services BrochureDokument4 SeitenShipCare Services BrochureNimesh PereraNoch keine Bewertungen

- DNV DNPS FQT Instruction Manual 1Dokument32 SeitenDNV DNPS FQT Instruction Manual 1carlocft50% (2)

- NN Presentation Full PageDokument147 SeitenNN Presentation Full PageHashem GamNoch keine Bewertungen

- Fuel Quality Testing: Instruction ManualDokument31 SeitenFuel Quality Testing: Instruction Manualch3g44100% (1)

- Loading Master Certification For Oil, Gas and Petrochemical TerminalsDokument5 SeitenLoading Master Certification For Oil, Gas and Petrochemical TerminalsAnonymous UCveMQNoch keine Bewertungen

- Engine condition monitoring and fuel analysis insightsDokument8 SeitenEngine condition monitoring and fuel analysis insightsShiddiq QiNoch keine Bewertungen

- LPC 01-14 Prevention of Engine Damage Due To Catalytic Fines CatDokument2 SeitenLPC 01-14 Prevention of Engine Damage Due To Catalytic Fines Catcengiz kutukcuNoch keine Bewertungen

- SGS IND Marine Coating EN 18Dokument4 SeitenSGS IND Marine Coating EN 18Nanda Hendra PratamaNoch keine Bewertungen

- After Sales and Service 02 - 2013Dokument4 SeitenAfter Sales and Service 02 - 2013Arturo CalderonNoch keine Bewertungen

- Aviation Jet Fuel: 4 - 6 October 2016, London, UKDokument3 SeitenAviation Jet Fuel: 4 - 6 October 2016, London, UKKristee Ann KellyNoch keine Bewertungen

- Fuel Oil AnalysisDokument6 SeitenFuel Oil AnalysisPawan BeniwalNoch keine Bewertungen

- Chevron - FAST Service Plus Brochure - v0519 - DESKTOP - 1Dokument16 SeitenChevron - FAST Service Plus Brochure - v0519 - DESKTOP - 1Sam ChengNoch keine Bewertungen

- Drew-XP-LUBE-ANALYSIS-PROGRAM Guide-12pages FINALDokument12 SeitenDrew-XP-LUBE-ANALYSIS-PROGRAM Guide-12pages FINALGauravNoch keine Bewertungen

- DNVPS Fuel Testing Procedures Part 1Dokument23 SeitenDNVPS Fuel Testing Procedures Part 1KaiNoch keine Bewertungen

- Frac Support A4Dokument20 SeitenFrac Support A4Wade Davis100% (1)

- 2007-2008 Catalog CannonDokument76 Seiten2007-2008 Catalog CannonCorina StanculescuNoch keine Bewertungen

- Engine Inspection (Service Profile)Dokument2 SeitenEngine Inspection (Service Profile)dhavit wijayantoNoch keine Bewertungen

- Wilks InfraCal Analyzers Guide for Oil in Water, Soil and Biofuels TestingDokument45 SeitenWilks InfraCal Analyzers Guide for Oil in Water, Soil and Biofuels TestingMiguel RomanNoch keine Bewertungen

- Crude Oil Assay 2020MEDokument2 SeitenCrude Oil Assay 2020MEAtra FireNoch keine Bewertungen

- FOBAS Onboard Provides Real-Time Fuel and Lube AnalysisDokument2 SeitenFOBAS Onboard Provides Real-Time Fuel and Lube AnalysisArvind KNoch keine Bewertungen

- Effectech - Calibration GasesDokument36 SeitenEffectech - Calibration GasesThomas FinnsNoch keine Bewertungen

- Inter TekDokument3 SeitenInter TekmohamadalsoaediNoch keine Bewertungen

- DNV BQS - tcm4-482822Dokument8 SeitenDNV BQS - tcm4-482822captkcNoch keine Bewertungen

- Oily Water Separators - Ensurin - OCIMFSDokument6 SeitenOily Water Separators - Ensurin - OCIMFSOscar Costas CampuzanoNoch keine Bewertungen

- Bunkers Quality and Quantity ClaimsDokument36 SeitenBunkers Quality and Quantity ClaimsParthiban NagarajanNoch keine Bewertungen

- Astm D8185 - 18Dokument19 SeitenAstm D8185 - 18mancja100% (1)

- Kittiwake Mak19642pa F&L Cabinet DatasheetDokument4 SeitenKittiwake Mak19642pa F&L Cabinet DatasheetCorina StanculescuNoch keine Bewertungen

- Provers & Master Meters: Because Confidence Is CapitalDokument4 SeitenProvers & Master Meters: Because Confidence Is CapitalOmprakash_jana100% (1)

- Fuel AnalysisDokument17 SeitenFuel Analysiseigersumarly100% (1)

- Good Bunkering PracticeDokument6 SeitenGood Bunkering PracticeParthiban NagarajanNoch keine Bewertungen

- Textran WBT: High Performance Synthetic Wet Brake Transaxle FluidDokument2 SeitenTextran WBT: High Performance Synthetic Wet Brake Transaxle FluidCostaNoch keine Bewertungen

- UK Club Bunkers - Quality - and - Quantity - ClaimsDokument28 SeitenUK Club Bunkers - Quality - and - Quantity - Claimswalter.dekkersNoch keine Bewertungen

- Leaflet SamplingDokument2 SeitenLeaflet SamplingkorpaapNoch keine Bewertungen

- Shipping Industry Guidance On The Use of Oily Water Separators Ensuring Compliance With MarpolDokument4 SeitenShipping Industry Guidance On The Use of Oily Water Separators Ensuring Compliance With MarpolGerby G CruzNoch keine Bewertungen

- In-Service Monitoring of Mineral Turbine Oils For Steam, Gas, and Combined Cycle TurbinesDokument19 SeitenIn-Service Monitoring of Mineral Turbine Oils For Steam, Gas, and Combined Cycle TurbinesEhsan ZiaeiNoch keine Bewertungen

- 75 OptimaxDokument133 Seiten75 OptimaxRoberto ImplatiniNoch keine Bewertungen

- DNV GL Recyclable 2018-06 WebDokument2 SeitenDNV GL Recyclable 2018-06 WebrookhnNoch keine Bewertungen

- Complete OIL ANALYSIS StudyDokument10 SeitenComplete OIL ANALYSIS StudyFelix G Ortiz100% (1)

- QA of insulating oilDokument8 SeitenQA of insulating oilSellappan MuthusamyNoch keine Bewertungen

- Oil Refinery OffsitesDokument12 SeitenOil Refinery OffsitesViliame D RoqicaNoch keine Bewertungen

- Bilge water compliance issues: An Alfa Laval white paper on oily water separation systemsDokument14 SeitenBilge water compliance issues: An Alfa Laval white paper on oily water separation systemsPaliwal ANoch keine Bewertungen

- Cat Marine Engine Selection Guide LEDM3457 21 PDFDokument180 SeitenCat Marine Engine Selection Guide LEDM3457 21 PDFAnonymous EdfJOHNoch keine Bewertungen

- Technical Regulatory News No 12 2021 WebDokument2 SeitenTechnical Regulatory News No 12 2021 WebvdmNoch keine Bewertungen

- New Marpol Requirement On Designated Fuel Oil Sampling PointsDokument2 SeitenNew Marpol Requirement On Designated Fuel Oil Sampling PointsJg ShipNoch keine Bewertungen

- CMT Oil Condition MonitoringDokument39 SeitenCMT Oil Condition MonitoringGabriel OyedemiNoch keine Bewertungen

- Astm D4378-22Dokument19 SeitenAstm D4378-22Hani YilmazNoch keine Bewertungen

- Coupling Inspection (Service Profile)Dokument2 SeitenCoupling Inspection (Service Profile)dhavit wijayantoNoch keine Bewertungen

- In-Service Lubricant Viscosity Measurement: Standard Guide ForDokument19 SeitenIn-Service Lubricant Viscosity Measurement: Standard Guide Foromar TahaNoch keine Bewertungen

- PR GcuDokument1 SeitePR GcuG.kouloukasNoch keine Bewertungen

- CNG Fueling Station Maintenance Overview & Commonly Overlooked ItemsDokument6 SeitenCNG Fueling Station Maintenance Overview & Commonly Overlooked Itemseko handoyoNoch keine Bewertungen

- Fuel Oil Analysis: Know The Condition of The Fuel Oils You Use!Dokument6 SeitenFuel Oil Analysis: Know The Condition of The Fuel Oils You Use!lolo100% (1)

- Oil Production StorgeDokument5 SeitenOil Production StorgeomarNoch keine Bewertungen

- Fuel Oil PDFDokument12 SeitenFuel Oil PDFSantosh Kumar PillaiNoch keine Bewertungen

- Ahmed+Hamdy ResumeDokument5 SeitenAhmed+Hamdy ResumeAhmed Al AdawiNoch keine Bewertungen

- Urea SCR Certification & Compliance ConsiderationsDokument14 SeitenUrea SCR Certification & Compliance ConsiderationsAlex HillNoch keine Bewertungen

- Signum Oil Analysis Condition Monitoring Fundamentals English UkDokument20 SeitenSignum Oil Analysis Condition Monitoring Fundamentals English UkHim SatiNoch keine Bewertungen

- SeacorrDokument20 SeitenSeacorrSGS - Head of OperationsNoch keine Bewertungen

- 2004 International Convention For The Control and Management of Ships Ballast Water and SedimentsDokument28 Seiten2004 International Convention For The Control and Management of Ships Ballast Water and Sedimentsargentum19619692Noch keine Bewertungen

- Alfa Laval UV White-PaperDokument5 SeitenAlfa Laval UV White-PaperMichael NovotnyNoch keine Bewertungen

- Abs Guide For Fire at Container CarriersDokument59 SeitenAbs Guide For Fire at Container CarriersGert-Jan LangerakNoch keine Bewertungen

- Ballast Water Treatment PDFDokument33 SeitenBallast Water Treatment PDFTagore Pavan KumarNoch keine Bewertungen

- HE Epublic OF Iberia: Updated Appendix 1 Marine Operations Note 02-2018Dokument3 SeitenHE Epublic OF Iberia: Updated Appendix 1 Marine Operations Note 02-2018argentum19619692Noch keine Bewertungen

- Ballast Water Management Convention 2004: Frequently Asked Questions and AnswersDokument9 SeitenBallast Water Management Convention 2004: Frequently Asked Questions and Answersargentum19619692Noch keine Bewertungen

- Rec 151 New July 2017Dokument11 SeitenRec 151 New July 2017argentum19619692Noch keine Bewertungen

- Ballast T1116eDokument2 SeitenBallast T1116eargentum19619692Noch keine Bewertungen

- ICS Guidance On Implementation of 2020 Global Sulphur Cap - September 2018Dokument32 SeitenICS Guidance On Implementation of 2020 Global Sulphur Cap - September 2018Oliver CelestialNoch keine Bewertungen

- P4 Production and Application of Plastic Pipes Piping Systems On Ships P4Dokument13 SeitenP4 Production and Application of Plastic Pipes Piping Systems On Ships P4argentum19619692Noch keine Bewertungen

- LR UBWM - How To ComplyDokument20 SeitenLR UBWM - How To Complyargentum19619692Noch keine Bewertungen

- Design and Programming of Cathodic Protection For SHIPSDokument5 SeitenDesign and Programming of Cathodic Protection For SHIPSAnonymous mv84nhzNoch keine Bewertungen

- Global Sulphur Cap 2020 - How To Move Ahead: ChecklistDokument3 SeitenGlobal Sulphur Cap 2020 - How To Move Ahead: Checklistargentum19619692Noch keine Bewertungen

- Ballast Water Treatment Technology: Current StatusDokument35 SeitenBallast Water Treatment Technology: Current Statusargentum19619692Noch keine Bewertungen

- sl2019 671Dokument7 Seitensl2019 671Stefas DimitriosNoch keine Bewertungen

- Circular Letter: For InformationDokument4 SeitenCircular Letter: For Informationargentum19619692Noch keine Bewertungen

- SL2020-694 Cylinder and System OilsDokument3 SeitenSL2020-694 Cylinder and System Oilsg arv100% (1)

- Sl2012-552 Crankcase InspectionDokument4 SeitenSl2012-552 Crankcase Inspectionargentum19619692Noch keine Bewertungen

- Are You 95% Confident That Your Very Low Sulphur Fuel Is ... - GARDDokument4 SeitenAre You 95% Confident That Your Very Low Sulphur Fuel Is ... - GARDargentum19619692Noch keine Bewertungen

- Analysis Sulfur ASTM-D4294 Vs ISODokument4 SeitenAnalysis Sulfur ASTM-D4294 Vs ISOargentum19619692Noch keine Bewertungen

- White Paper - 31082018 FINALDokument10 SeitenWhite Paper - 31082018 FINALargentum19619692Noch keine Bewertungen

- sl2019 671Dokument7 Seitensl2019 671Stefas DimitriosNoch keine Bewertungen

- Mepc 207Dokument27 SeitenMepc 207argentum19619692100% (1)

- SL2020-694 Cylinder and System OilsDokument3 SeitenSL2020-694 Cylinder and System Oilsg arv100% (1)

- Anti-Fouling and In-Water Cleaning Guidelines: June 2013Dokument26 SeitenAnti-Fouling and In-Water Cleaning Guidelines: June 2013argentum19619692Noch keine Bewertungen

- Geberit Piping Catalogue 2019 PDFDokument142 SeitenGeberit Piping Catalogue 2019 PDFargentum19619692Noch keine Bewertungen

- Clean Ship Hulls and Ports - Without Compromise: White PaperDokument27 SeitenClean Ship Hulls and Ports - Without Compromise: White Paperargentum19619692Noch keine Bewertungen

- Ship Hull Cleaning & Performance ManagementDokument3 SeitenShip Hull Cleaning & Performance Managementargentum19619692Noch keine Bewertungen

- Guide biofouling evaluationDokument12 SeitenGuide biofouling evaluationargentum19619692Noch keine Bewertungen

- MEPC 1-Circ 792Dokument7 SeitenMEPC 1-Circ 792argentum19619692Noch keine Bewertungen

- Seagull - Products 16 59 14 115952Dokument11 SeitenSeagull - Products 16 59 14 115952Vardias0% (1)

- Cylinder Lubrication Guiding ACC Feed Rates For Alpha Lubricator and ME LubeDokument6 SeitenCylinder Lubrication Guiding ACC Feed Rates For Alpha Lubricator and ME Lubepescarra-1100% (1)

- JIG 4 (Joint Inspection Group) - Rev - 3Dokument108 SeitenJIG 4 (Joint Inspection Group) - Rev - 3ana claraNoch keine Bewertungen

- Guideline Filter Treatment Residual Fuel Oils PDFDokument13 SeitenGuideline Filter Treatment Residual Fuel Oils PDFStefas DimitriosNoch keine Bewertungen

- CBL Boiler BookDokument18 SeitenCBL Boiler Bookfauzi endraNoch keine Bewertungen

- Vertical Pyrolysis Plant OfferDokument5 SeitenVertical Pyrolysis Plant OfferGaurav BihaniNoch keine Bewertungen

- Bomba y Compresor Generadores Kerui 50mmbtuhDokument118 SeitenBomba y Compresor Generadores Kerui 50mmbtuhEdinsonUribeTorresNoch keine Bewertungen

- Underground Storage Tanks SystemsDokument32 SeitenUnderground Storage Tanks Systemswferry27Noch keine Bewertungen

- GEL Fuel Storage Tank Cleaning RFPDokument76 SeitenGEL Fuel Storage Tank Cleaning RFPayaz hasanNoch keine Bewertungen

- Types of S CompoundsDokument36 SeitenTypes of S CompoundsMahesh sinhaNoch keine Bewertungen

- M.V. Ramform Victory: Arrival Timor Sea 11-Jun-06 Stability FormDokument5 SeitenM.V. Ramform Victory: Arrival Timor Sea 11-Jun-06 Stability FormringboltNoch keine Bewertungen

- Separatore Pa 605Dokument4 SeitenSeparatore Pa 605Salih Tuğrul SarıNoch keine Bewertungen

- BOILER PROPER PIDs IntroductionDokument46 SeitenBOILER PROPER PIDs IntroductionHai Nguyen100% (1)

- Man Slide Valve Low Load Emissions TestDokument355 SeitenMan Slide Valve Low Load Emissions TestdongNoch keine Bewertungen

- Man S65me c8Dokument367 SeitenMan S65me c8Nihal NaralkarNoch keine Bewertungen

- Model 5 Operating and Maintenance Manual - Low Water VolumeDokument120 SeitenModel 5 Operating and Maintenance Manual - Low Water VolumeJuan C FrancoNoch keine Bewertungen

- Process Fired Heaters Training PresentationDokument108 SeitenProcess Fired Heaters Training Presentations_m_kumar100% (4)

- RA 002 - BunkeringDokument5 SeitenRA 002 - Bunkeringdassi99Noch keine Bewertungen

- Man 48 60cr Imo Tier II Marine PDFDokument428 SeitenMan 48 60cr Imo Tier II Marine PDFDavidenko IlyaNoch keine Bewertungen

- 1.1 Company ProfileDokument41 Seiten1.1 Company ProfileNagarjuna JNoch keine Bewertungen

- Diesel Generators HFO Containerized From USP&E GlobalDokument2 SeitenDiesel Generators HFO Containerized From USP&E Globalwill7662Noch keine Bewertungen

- Volatile Organic Compound Emission Calculation For Flashing: Vasquez - Beggs Solution Gas/Oil Ratio Correlation MethodDokument4 SeitenVolatile Organic Compound Emission Calculation For Flashing: Vasquez - Beggs Solution Gas/Oil Ratio Correlation MethodjnmanivannanmechNoch keine Bewertungen

- Top MonthlyPresentation 201905Dokument83 SeitenTop MonthlyPresentation 201905Aniket SharmaNoch keine Bewertungen

- Bunker Delivery NoteDokument2 SeitenBunker Delivery NoteAbhinav VermaNoch keine Bewertungen

- Main Class Renewal Surveys Carried Out AfloatDokument4 SeitenMain Class Renewal Surveys Carried Out AfloatFadhly HafelNoch keine Bewertungen

- Energy Efficiency in Thermal UtilitiesDokument183 SeitenEnergy Efficiency in Thermal UtilitiesHimanshuNoch keine Bewertungen

- Balmoral Bunded Tank InstallationDokument4 SeitenBalmoral Bunded Tank InstallationAlberto DiazNoch keine Bewertungen

- Offsite FacilitiesDokument44 SeitenOffsite FacilitiesmujeebtalibNoch keine Bewertungen

- Dipesh Questions IndexDokument12 SeitenDipesh Questions Indexकुमार निशान्तNoch keine Bewertungen

- Heavy Oil Upgrading by The Separation and Gasification of AsphaltenesDokument11 SeitenHeavy Oil Upgrading by The Separation and Gasification of Asphalteneslutfi awnNoch keine Bewertungen