Beruflich Dokumente

Kultur Dokumente

0101R096

Hochgeladen von

Eduardo Guido0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

21 Ansichten2 Seiten012

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument melden012

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

21 Ansichten2 Seiten0101R096

Hochgeladen von

Eduardo Guido012

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

Document Name: 0101r096

Section: TAPPI PRESS

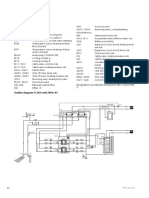

Title: Paper Machine Steam and Condensate

Systems

TAPPI PRESS

Paper Machine Steam and Condensate Systems

4th Edition, edited by Robert D. Perrault

1990. 40 pp., 8-1/2" x 11" soft cover

Item Number: 0101R096

ISBN: 0898525047

This book gives papermakers and those responsible for solving drying-related problems a basic

understanding of the design, operation, and control of paper machine steam and condensate

removal systems.

Table of Contents:

Foreword 2.2 Thermocompressor pressure control

Contributors system with differential control valve

Introduction 2.3 Dryer differential control using the

thermocompressor spindle

1 Steam Control and Condensate Evacuation 2.4 Thermocompressor cascade system

Systems Design 2.5 Yankee dryers

1.0 General

1.1 Basic steam pressure control system 3 Blow Through (Flow) Control for Dryer

1.2 Multiple pressure control sections Drainage Systems

1.3 Automatic differential pressure control 3.0 General

1.4 Dryer temperature control using a vacuum 3.1 Blow through control principles

system 3.2 Blow through control installation

1.5 Pressure and temperature control for each 3.3 Yankee or single dryer blow through

dryer section control system

1.6 Simple three-section cascade dryer

section 4 Mechanical Vapor recompression (MVR)

1.7 Positive pressure control loops for wet end 4.0 General

dryers 4.1 Advantages

1.8 Low pressure wet end dryer

1.9 Temperature control of wet end dryers 5 Dryer Drainage System Controls and

1.10 After size drying control Equipment

1.11 Single felted dryer section 5.0 General

5.1 Pressure control

2 Thermocompressors (THC) 5.2 Differential pressure control

2.0 General 5.2.1 Transmitter installation

2.0.1 Construction and operation 5.3 Separator control

2.0.2 Advantages and disadvantages of 5.4 Vacuum system

thermocompressor systems 5.4.1 Vacuum pump

2.0.3 Performance 5.4.2 condenser (heat exchanger)

Thermocompressor Systems 5.5 Effect of air in steam

2.1 Thermocompressor pressure control 5.5.1 Noncondensable bleeds

system 5.6 Syphons for paper machine dryers

5.7 Effect of centrifugal force

5.8 Drive horsepower and dryer condensate

load

6 Troubleshooting, Check-out, Start-up, and

Shutdown of Dryer Drainage Systems

6.0 Equipment Check-out

6.1 General installation

6.2 Control valves

6.3 Separators

6.4 Condensate pumps and motors

6.5 Vacuum pump

6.6 Heat exchanger (HE)

6.7 Thermocompressor (THC)

6.8 Steamfit and piping

6.9 Controllers

6.10 Systems checkout - flushing new systems

and rebuilds

6.11 Shutdown procedures

6.11.1 Cold shutdown

6.11.2 Warm shutdown

6.12 Sheet breaks

6.12.1 Long breaks

6.12.2 Short breaks

6.13 Operating problems and trouble shooting

6.13.1 Low differential pressure

6.13.2 High differential pressure

6.13.3 High drive torque

6.13.4 High separator level

6.13.5 Very low separator level

6.13.6 High steam pressure

6.13.7 Low steam pressure

6.13.8 High steam usage per pound of

water evaporated

6.13.9 Loss in production rates

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Xomox - TUFLINEDokument16 SeitenXomox - TUFLINEEduardo GuidoNoch keine Bewertungen

- 5 08 3Dokument8 Seiten5 08 3sushil kumarNoch keine Bewertungen

- TI Bearing SealsDokument3 SeitenTI Bearing SealsAlex LinsNoch keine Bewertungen

- Rotary Valve Selector Guide PDFDokument28 SeitenRotary Valve Selector Guide PDFtradehouseNoch keine Bewertungen

- Polflame 1613 enDokument3 SeitenPolflame 1613 enAnonymous Cxriyx9HIXNoch keine Bewertungen

- Tappi Press: Document Name: Section: TitleDokument6 SeitenTappi Press: Document Name: Section: TitleEduardo GuidoNoch keine Bewertungen

- Canales MecanicaDokument3 SeitenCanales MecanicaEduardo GuidoNoch keine Bewertungen

- Lubricantes CMXDokument1 SeiteLubricantes CMXEduardo GuidoNoch keine Bewertungen

- Chemical: Process Machinery Component Parts Mobil Product(s) Mobil AdvantageDokument2 SeitenChemical: Process Machinery Component Parts Mobil Product(s) Mobil AdvantageEduardo GuidoNoch keine Bewertungen

- PDE1 MichiganDokument64 SeitenPDE1 MichiganEduardo GuidoNoch keine Bewertungen

- 0101R096Dokument2 Seiten0101R096Eduardo GuidoNoch keine Bewertungen

- Preguntas y Respuestas de Neumatica Marine EngineeringDokument4 SeitenPreguntas y Respuestas de Neumatica Marine EngineeringEduardo GuidoNoch keine Bewertungen

- Modeling and Control of The Paper Machine Drying Section: Slätteke, OlaDokument253 SeitenModeling and Control of The Paper Machine Drying Section: Slätteke, OlaEduardo GuidoNoch keine Bewertungen

- PDE1 MichiganDokument64 SeitenPDE1 MichiganEduardo GuidoNoch keine Bewertungen

- Golden OldieDokument43 SeitenGolden OldieEduardo GuidoNoch keine Bewertungen

- Tablas de Transformadas Integrales PDFDokument23 SeitenTablas de Transformadas Integrales PDFAnni bannNoch keine Bewertungen

- Scope: TIP Category: Automatically Periodically Reviewed (Five-Year Review)Dokument6 SeitenScope: TIP Category: Automatically Periodically Reviewed (Five-Year Review)Samsung KzoomNoch keine Bewertungen

- Drivepower 2nded 161024201601Dokument20 SeitenDrivepower 2nded 161024201601Eduardo GuidoNoch keine Bewertungen

- US4314878Dokument20 SeitenUS4314878Eduardo GuidoNoch keine Bewertungen

- How To Calculate Drum Nip LoadDokument1 SeiteHow To Calculate Drum Nip Loadsushil kumar100% (2)

- 1582 GBDokument7 Seiten1582 GBMohamed Shehata100% (1)

- Aa Automation Simulation Yankee Drying DataDokument11 SeitenAa Automation Simulation Yankee Drying DataEduardo GuidoNoch keine Bewertungen

- Reporte Motores v1Dokument69 SeitenReporte Motores v1Eduardo GuidoNoch keine Bewertungen

- Reporte Motores v1Dokument69 SeitenReporte Motores v1Eduardo GuidoNoch keine Bewertungen

- Chapter 4Dokument3 SeitenChapter 4franzNoch keine Bewertungen

- Topic 15 Papermaking Drying TextDokument14 SeitenTopic 15 Papermaking Drying TextEduardo GuidoNoch keine Bewertungen

- Topic 7 Mechanical Pulping Low Consistency RefiningDokument44 SeitenTopic 7 Mechanical Pulping Low Consistency RefiningEduardo GuidoNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Performance Curve - Service1 - Item 1Dokument1 SeitePerformance Curve - Service1 - Item 1Fernando SanchezNoch keine Bewertungen

- Viscoelastic Flow Simulation in OpenFOAMDokument131 SeitenViscoelastic Flow Simulation in OpenFOAMSatish Kumar BonthuNoch keine Bewertungen

- Schema NIBE F1345 Cu HPAC45Dokument1 SeiteSchema NIBE F1345 Cu HPAC45Istvan MadacsyNoch keine Bewertungen

- Air Handling UnitsDokument14 SeitenAir Handling UnitsMichael FutolNoch keine Bewertungen

- Half-Life Experiment With BubblesDokument1 SeiteHalf-Life Experiment With BubblesHriday AmpavatinaNoch keine Bewertungen

- Man Hour Estimation For SRUDokument2 SeitenMan Hour Estimation For SRUnas_mech8208Noch keine Bewertungen

- 432F Esquema Hidraulico PDFDokument11 Seiten432F Esquema Hidraulico PDFJorge PoveaNoch keine Bewertungen

- Septic Tank Design ComputationDokument1 SeiteSeptic Tank Design ComputationEngilbert AragonNoch keine Bewertungen

- Comeo BrochureDokument2 SeitenComeo BrochureRicardo BarrosNoch keine Bewertungen

- CHAP03Dokument28 SeitenCHAP03Dheeraj ShuklaNoch keine Bewertungen

- Hydraulic schematic componentsDokument2 SeitenHydraulic schematic componentsAtaa AssaadNoch keine Bewertungen

- KeerthanaDokument120 SeitenKeerthanagokiNoch keine Bewertungen

- Assignments-Design of Dam Appurtenant Structures-2022Dokument2 SeitenAssignments-Design of Dam Appurtenant Structures-2022Marew Getie100% (1)

- DRILLING HYDRAULICS (Introduction)Dokument27 SeitenDRILLING HYDRAULICS (Introduction)Yusuf Maringga100% (1)

- NASA Contractor Report 2920 Details Calibration of Transonic and Supersonic Wind TunnelsDokument289 SeitenNASA Contractor Report 2920 Details Calibration of Transonic and Supersonic Wind TunnelsAerocse EceitmechNoch keine Bewertungen

- Soil mechanics assignment calculates permeability and stressesDokument6 SeitenSoil mechanics assignment calculates permeability and stressesRex SabersonNoch keine Bewertungen

- Air Cooled Chillers Scroll MGBT PD CPDokument5 SeitenAir Cooled Chillers Scroll MGBT PD CPJOSENoch keine Bewertungen

- H2O On The Go BrochureDokument4 SeitenH2O On The Go BrochureJoanne DavisNoch keine Bewertungen

- Natural Gas Regulator Grove 83Dokument5 SeitenNatural Gas Regulator Grove 83montanovillarroelfabiolalourdeNoch keine Bewertungen

- Sizing Optimass 2000 - s150 (32000mpas)Dokument2 SeitenSizing Optimass 2000 - s150 (32000mpas)acastillo1339Noch keine Bewertungen

- BAP-00-30-SD-0001-R - Rev.0 - Piping Standard Drawing.Dokument72 SeitenBAP-00-30-SD-0001-R - Rev.0 - Piping Standard Drawing.papathsheilaNoch keine Bewertungen

- Dibujo - Chller 300 TR - IDokument1 SeiteDibujo - Chller 300 TR - Ijuan yenqueNoch keine Bewertungen

- Vacuum Distillation Colume: Mass Transfer Lab AssignmentDokument4 SeitenVacuum Distillation Colume: Mass Transfer Lab AssignmentMalik HamidNoch keine Bewertungen

- 651 - Burst Pressure Versus Casing Wear Calculation DDDokument4 Seiten651 - Burst Pressure Versus Casing Wear Calculation DDQuality controllerNoch keine Bewertungen

- Horizontal Well Drill String DesignDokument23 SeitenHorizontal Well Drill String DesignTarek HassanNoch keine Bewertungen

- Flixborough DisasterDokument20 SeitenFlixborough DisasterEshan BhatNoch keine Bewertungen

- Chapter - One - IntroductionDokument30 SeitenChapter - One - Introductionyonastegene638Noch keine Bewertungen

- M.Tech Thermal Engineering Teaching SchemeDokument19 SeitenM.Tech Thermal Engineering Teaching SchemeNavneet KumarNoch keine Bewertungen

- AHE NotesDokument35 SeitenAHE NotesmynameisgunaNoch keine Bewertungen

- Veraflux-PDS-2022-2 (Phosphorous-Free)Dokument1 SeiteVeraflux-PDS-2022-2 (Phosphorous-Free)Quốc Anh KhổngNoch keine Bewertungen