Beruflich Dokumente

Kultur Dokumente

Anticorrosion - Technical Data Sheet - Materials 15022017 Poland

Hochgeladen von

Rajesh MotghareOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Anticorrosion - Technical Data Sheet - Materials 15022017 Poland

Hochgeladen von

Rajesh MotghareCopyright:

Verfügbare Formate

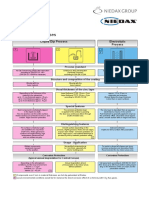

Technical Data Sheet - MATERIALS

II. Information about the materials from which BAKS products are made from

C1 C2 C3 C4 C5-I C5-M.

Corrosiveness class

very low low medium high very high (industry grade) very high (maritime grade)

Reduction in protective coating (µm) < 0.1 > 0.1 to 0.7 > 0.7 to 2.1 > 2.1 to 4.2 > 4.2 to 8.4 > 4.2 to 8,4

Indoors: heated buildings Indoors: non-heated Indoors: manufacturing Indoors: chemical Indoors: buildings or areas Indoors: buildings or areas

with clean atmosphere, buildings in which premises with a high level of plants, swimming pools, with almost constant with almost constant

Examples of typical environments e.g. shops, offices condensation may occur, e.g. humidity and some air repair yards condensation and high condensation and high

for moderate climate sports halls, warehouses pollution, e.g. laundries, Outdoors: industrial pollution pollution

(for reference only) Outdoors: – Outdoors: atmospheres breweries, dairies zones and littoral areas Outdoors: industrial areas with Outdoors: Littoral areas and

with a low degree of Outdoors: urban and of medium salinity high humidity and an areas further into the sea, with

pollution industrial atmospheres aggressive atmosphere high salinity

Sendzimir method Products meant for use in dry spaces of class C1 and C2.

PN-EN 10346:2011 Zinc coating thickness of about 19 µm

hot-dip galv. Products meant for use in spaces of corrosiveness classes of C1, C2, C3,

F PN-EN ISO 1461:2011 C4, C5-I and C5-M.

Local Thickness Mean Thickness

of ZincProtective of Zinc Protective The table applies to zinc-coating by hot dip galvanizing method according

Part and Thickness

Coating Coating to the PN-EN ISO 1461:2011

(minimum value µm) (minimum value µm)

Steel >6mm 70 85 Insignificant Low Moderate High Very high

Atmosphere type corrosion corrosion corrosion corrosion corrosion

Steel >3mm to<6mm 55 70 load load load load load

Corrosion aggressiveness

category C1 C2 C3 C4 C5-I, C5-M

Steel >1.5mm to<3mm 45 55

Warranty extension

Steel <1.5mm 35 45 Up to 5 years Up to 5 years Up to 5 years Up to 5 years Up to 2 years

option

galvanizing Electrolytic galvanizing Small products (bolts, nuts, washers) are coated in electrolytic baths with

Construction steel

method G PN-EN 12329 a thin and even coat of zinc. The coating is about 5-20 µm thick, bright and shiny.

Products are coated with a mixture of a special zinc powder in the temperature

Thermal diffusion of 360 - 450°C. Due to the diffusion of zinc particles to the steel, a very durable

T galvanizing PN-EN 12329 anti-corrosion coating is produced. The coating, unlike in the previous zinc

coatings, is matt and its colour ranges from pale grey to dark grey.

The thickness of the zinc coating ranges from 45-120 µm.

The base coat in the zinc flake coating technology is a kind of lacquer

containing “flakes” of zinc and aluminium. The mixture reacts with the

steel surface producing, after firing, a coherent, conductive, and non-toxic

Zinc-flake coating

Z PN-EN ISO 10683:2014-09

zinc + aluminium coating. This method is characterised by very high resistance

to corrosion – up to 1000 hours in a salt spray cabinet according to ISO 9227

before red corrosion appears. It is accepted by the world leading manufacturers

in the motor, energy and aviation sectors and popularly applied to threaded

elements due to trouble-free joining.

General purpose metal sheets with good resistance to atmospheric corrosion,

to numerous organic and non-organic chemical substances according

to PN-EN 10088, in the following grades:

- 1.4301 (304) used in the production of milk containers, dairy equipment, milk

grade 14301 production systems, beer barrels, in beer fermentation, storage tanks in

(304) breweries, corn product refining equipment; equipment for nuclear power

plants, drains, pipes, tanks for liquid oxygen, nitrogen or hydrogen, parts of

Stainless/Acid-proof

Stal grade 14404 carbonated drink dispensers, pots and cryogenic parts, furniture, interior

nierdzewna/kwasoodporna

steel E (316L) and exterior panelling.

grade 14571 - 1.4404 (316L) used for white wine tanks, in brewing industry, paper industry,

(316Ti) medicine, for fatty acids, in the production of acetic acid compounds, for the

production of parts coming in contact with artificial fertilizers, ketchup boiling

cauldrons, phosphate industry, film processing equipment, chimneys, tanks

in water softening plants, yeast pipes, in the maritime environment

- 1.4571 (316Ti) used in the chemical industry, in the production of devices

requiring high resistance to corrosion – radiators, condensers, pipelines,

tanks; in the food, cellulose and pharmaceutical industries.

Attention! By dint of shot-blasting we get high quality of our products.

To avoid corrosion which might appear on welding spots, all products made

with stainless steel are shot blasted using chrome and nickel medium. Using

that technology we get smooth and shiny surface on whole surface of the

product.

Aluminium Resistance to atmospheric corrosion as well as numerous organic

AL PN-EN 485-2 and non-organic chemical substances

Powder

coating L

Coating with polyester and epoxy powders (internal coating). The thickness of the coating ranges from 60 to 120 µm. The paint is applied directly to metal without any primers or thinners.

Powder coating produces smooth surfaces, without any cracks, tears or wrinkling. Powder coats are characterised by high corrosion and chemical resistance, very good mechanic properties

and resistance to water. They are used where resistance to corrosion is to be enhanced (by applying powder coats on galvanized metal sheets), when the aesthetics of the interior is to be

enhanced by using colours that would match the furniture and fittings, for marking a system depending on its function. Durability of the coating depends on the observance of the rules

of transporting and storage, the mounting method, the chemical environment in which the structure will be fitted and on maintenance. In the standard option, 14 colours are offered (see the

palette below). Non-standard colour of coating may be ordered, but it will entail a higher price and longer order fulfilment times.

RAL1015 RAL1023 RAL2004 RAL7016 RAL7024 RAL7032 RAL7035 RAL9002 RAL9003 RAL9005 RAL9006 RAL9010

RAL5012 RAL5015 anthracite white

light ivory traffic yellow pure orange light blue sky blue graphite grey pebble grey light grey grey white signal white jet black pure white

grey aluminium

info 4 info

Das könnte Ihnen auch gefallen

- Standard Corrosion Protection Systems For BuildingsDokument14 SeitenStandard Corrosion Protection Systems For BuildingsshnauserNoch keine Bewertungen

- EN10346:2015Dokument2 SeitenEN10346:2015Adriano Onairda0% (1)

- Selection Table: Type of Surface Treatments Related To The Corrosion Class and Risks Per Type of Environment (EN ISO 14713 - EN ISO 12944)Dokument1 SeiteSelection Table: Type of Surface Treatments Related To The Corrosion Class and Risks Per Type of Environment (EN ISO 14713 - EN ISO 12944)màrio ferreiraNoch keine Bewertungen

- EN ISO 12944 Výňatok BESA Firma PDFDokument7 SeitenEN ISO 12944 Výňatok BESA Firma PDFZoltán PálfyNoch keine Bewertungen

- Cellulosic Presentation RAWDokument56 SeitenCellulosic Presentation RAWOsama KheadryNoch keine Bewertungen

- QSM Five Rib Technical ManualDokument5 SeitenQSM Five Rib Technical ManualAnchor YauNoch keine Bewertungen

- Painting Standards For Different EnvironmentsDokument2 SeitenPainting Standards For Different Environmentsmadhu_bedi12Noch keine Bewertungen

- Stanvac-Superon Catalogue Valve Repairing - Venugoalan.vDokument51 SeitenStanvac-Superon Catalogue Valve Repairing - Venugoalan.vvinayg85Noch keine Bewertungen

- Neral Project DeatilsDokument4 SeitenNeral Project DeatilsanupamabNoch keine Bewertungen

- MP Bolagen Product CatalogueDokument148 SeitenMP Bolagen Product CatalogueMindaugas PepperNoch keine Bewertungen

- Product Data Sheet: Sikacor® Zinc RDokument4 SeitenProduct Data Sheet: Sikacor® Zinc RMohammedBayrakdarNoch keine Bewertungen

- Engineering Corrosion Protection at Hub Power Station: Tariq Aziz Nace Level 2Dokument50 SeitenEngineering Corrosion Protection at Hub Power Station: Tariq Aziz Nace Level 2Hasan AhmedNoch keine Bewertungen

- Highest Corrosion Protection.: LESER-Coating SystemsDokument10 SeitenHighest Corrosion Protection.: LESER-Coating SystemsMoe MozhganNoch keine Bewertungen

- G 020 Classifying Environments v2 Sept 2017Dokument8 SeitenG 020 Classifying Environments v2 Sept 2017Nuno FerreiraNoch keine Bewertungen

- AGEPAN OSB 4 PUR Technical Data SheetDokument2 SeitenAGEPAN OSB 4 PUR Technical Data SheetDore EmilNoch keine Bewertungen

- Type YSZ ZypDokument1 SeiteType YSZ ZyptabibkarimNoch keine Bewertungen

- Corrosion Protection Guide - CORUSDokument6 SeitenCorrosion Protection Guide - CORUSShanmuganantha (MRT)Noch keine Bewertungen

- Corrosion and Protection GuideDokument6 SeitenCorrosion and Protection Guidexaekne100% (4)

- WEG Coatings Industrial Maintenance 50021180 Brochure en Print With MarksDokument20 SeitenWEG Coatings Industrial Maintenance 50021180 Brochure en Print With MarksJacksonNoch keine Bewertungen

- SIMONA PVC-C CORZAN Engineered From Post-Chlorinated PVC For Exceptional PerformanceDokument6 SeitenSIMONA PVC-C CORZAN Engineered From Post-Chlorinated PVC For Exceptional PerformanceIsrael AristaNoch keine Bewertungen

- Corrosion PDFDokument5 SeitenCorrosion PDFAntonio MartinNoch keine Bewertungen

- ISO 12944 Brochure - 011921Dokument16 SeitenISO 12944 Brochure - 011921BERSE MAJU INDONESIANoch keine Bewertungen

- Properties of Cover Grades (As Per IS: 1891)Dokument2 SeitenProperties of Cover Grades (As Per IS: 1891)Raja NarenderNoch keine Bewertungen

- Transocean - C5-I Typical Coating System INDUSTRIALDokument1 SeiteTransocean - C5-I Typical Coating System INDUSTRIALfpiccoli_4Noch keine Bewertungen

- Permabond AdhesivesDokument2 SeitenPermabond AdhesivesPDDELUCANoch keine Bewertungen

- Permabond AdhesivesDokument2 SeitenPermabond AdhesivesPDDELUCANoch keine Bewertungen

- Cement and Lime Rotary Kiln RefractoriesDokument20 SeitenCement and Lime Rotary Kiln RefractoriesSyed Kazam RazaNoch keine Bewertungen

- ISO 12944 - tcm279-213128Dokument16 SeitenISO 12944 - tcm279-213128rodrigogomez87100% (1)

- Ott Over NixDokument1 SeiteOtt Over NixSelinNoch keine Bewertungen

- SMD Durability of Metal DecksDokument5 SeitenSMD Durability of Metal DecksMike DaviesNoch keine Bewertungen

- BECHEM High Lub LFB 2000 TDS enDokument1 SeiteBECHEM High Lub LFB 2000 TDS enluisvictorbariteNoch keine Bewertungen

- Concept of CENA1Dokument6 SeitenConcept of CENA1taknevNoch keine Bewertungen

- Corrosione - Abstract From SchneiderDokument5 SeitenCorrosione - Abstract From SchneiderMaxNoch keine Bewertungen

- Standards Spec Brochure ME WEBDokument44 SeitenStandards Spec Brochure ME WEBLaxman Duggirala100% (1)

- Tech Trol Gold Synthetic LubricantDokument2 SeitenTech Trol Gold Synthetic LubricantAzhar1109Noch keine Bewertungen

- Corro-Coat PE-F Façade: Series 1301, 1303, 1307 and 1308Dokument2 SeitenCorro-Coat PE-F Façade: Series 1301, 1303, 1307 and 1308girlie fabroNoch keine Bewertungen

- Waterproofing & Painting Tech PT Propan Raya - PpsDokument56 SeitenWaterproofing & Painting Tech PT Propan Raya - PpsVincent WongNoch keine Bewertungen

- Carboguard 703Dokument2 SeitenCarboguard 703Achraf BoudayaNoch keine Bewertungen

- Etals Nternational Imited: Table 9.3 Summary of Hot-Dipped Coatings, Their Structures and UsesDokument1 SeiteEtals Nternational Imited: Table 9.3 Summary of Hot-Dipped Coatings, Their Structures and UsesSSMNoch keine Bewertungen

- Fireproof ROOF Panels Technical InformationDokument4 SeitenFireproof ROOF Panels Technical InformationMarko MiticNoch keine Bewertungen

- Brilube ULTRA 2Dokument1 SeiteBrilube ULTRA 2Rodrigo PorcaroNoch keine Bewertungen

- Inaba - Brochure - New 83e26-2622 - 102Dokument4 SeitenInaba - Brochure - New 83e26-2622 - 102Denis William Librahim Rahardjo GNoch keine Bewertungen

- 03 Wear Phenomena Vietnam Seminar HK 2011Dokument51 Seiten03 Wear Phenomena Vietnam Seminar HK 2011quỳnh lêNoch keine Bewertungen

- Recubrimiento CeramicoDokument6 SeitenRecubrimiento CeramicoAlberto DiazNoch keine Bewertungen

- TI 100 Pre Treatment For MetalsDokument7 SeitenTI 100 Pre Treatment For Metalsmahesh rodiyaNoch keine Bewertungen

- DSMTS-0010.6 ZN WireDokument4 SeitenDSMTS-0010.6 ZN WireMario Cortes FariasNoch keine Bewertungen

- Presentation Industrial PaintDokument46 SeitenPresentation Industrial Paintpriya jadhavNoch keine Bewertungen

- Special Collections: Jotun Powder CoatingsDokument10 SeitenSpecial Collections: Jotun Powder Coatingsviet nguyen caoNoch keine Bewertungen

- Ucrete Ud200 AseanDokument2 SeitenUcrete Ud200 AseanDoby YuniardiNoch keine Bewertungen

- EI ServicesDokument2 SeitenEI ServicesAnonymous P8Bt46mk5INoch keine Bewertungen

- Galvanizing Processes: Liquid Dip Process Electrolytic ProcessDokument3 SeitenGalvanizing Processes: Liquid Dip Process Electrolytic ProcessAlin MoicaNoch keine Bewertungen

- Iso 12944Dokument4 SeitenIso 12944Penisactif80% (10)

- Brushbond (M) : Acrylic Polymer Modified Cementitous Waterproofing Coating For Concrete and Masonry SurfacesDokument4 SeitenBrushbond (M) : Acrylic Polymer Modified Cementitous Waterproofing Coating For Concrete and Masonry SurfacesSean HarshaNoch keine Bewertungen

- PipeWrap CTDokument2 SeitenPipeWrap CTVineet KhanduriNoch keine Bewertungen

- Sib Metal A3Dokument4 SeitenSib Metal A3abdo youtubeNoch keine Bewertungen

- Berutox FE 18 EP: Technical Product InformationDokument1 SeiteBerutox FE 18 EP: Technical Product InformationMauricio SánchezNoch keine Bewertungen

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Von EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Noch keine Bewertungen

- Ceramics and Ceramic Composites: Materialographic PreparationVon EverandCeramics and Ceramic Composites: Materialographic PreparationNoch keine Bewertungen

- BS 2872-1989 Copper and Copper Alloy Forging Stock and Forgings PDFDokument28 SeitenBS 2872-1989 Copper and Copper Alloy Forging Stock and Forgings PDFRajesh Motghare100% (1)

- AISI 1018 Mild Low Carbon Steel PDFDokument3 SeitenAISI 1018 Mild Low Carbon Steel PDFRajesh MotghareNoch keine Bewertungen

- Steel Construction Manual of AISC PDFDokument440 SeitenSteel Construction Manual of AISC PDFneedo8710% (1)

- Wet Storage Stain On Galvanized Steel PDFDokument8 SeitenWet Storage Stain On Galvanized Steel PDFmariustudoracheNoch keine Bewertungen

- SSPC SP1Dokument3 SeitenSSPC SP1Rajesh MotghareNoch keine Bewertungen

- Scaffolding Price ListDokument7 SeitenScaffolding Price ListAl Patrick Dela CalzadaNoch keine Bewertungen

- Hot Dip GalvanizingDokument3 SeitenHot Dip Galvanizingapply19842371Noch keine Bewertungen

- Checklist For BPI Structure Design & DrawingDokument4 SeitenChecklist For BPI Structure Design & DrawingRupesh KhandekarNoch keine Bewertungen

- Pipe Components PDFDokument179 SeitenPipe Components PDFmatevzartacNoch keine Bewertungen

- VATER Elgate Fence & Gate Systems INFO List JULY19Dokument6 SeitenVATER Elgate Fence & Gate Systems INFO List JULY19GarryNoch keine Bewertungen

- Steel Fence CatalogDokument4 SeitenSteel Fence CatalogtempfencingNoch keine Bewertungen

- Piping Material Take Off - For Tender PDFDokument79 SeitenPiping Material Take Off - For Tender PDFdhaferjab100% (1)

- Application Guide Barrier 80Dokument8 SeitenApplication Guide Barrier 80adeoye_okunoyeNoch keine Bewertungen

- Lighting Poles SpecificationsDokument20 SeitenLighting Poles Specificationszulfiqaralimalik100% (1)

- G I Wire No. 8 & 10Dokument5 SeitenG I Wire No. 8 & 10Dharmendra KumarNoch keine Bewertungen

- Samontec 2021Dokument500 SeitenSamontec 2021Vladimir Kljajić LagottoNoch keine Bewertungen

- ITP For Cable Ladder, Tray and ConduitDokument6 SeitenITP For Cable Ladder, Tray and ConduitHamid Taghipour ArmakiNoch keine Bewertungen

- 005-Ms-Painting and Repair Works PDFDokument24 Seiten005-Ms-Painting and Repair Works PDFKöksal Patan100% (1)

- Zinc-Coated Steel Chain-Link Fence Fabric: Standard Specification ForDokument5 SeitenZinc-Coated Steel Chain-Link Fence Fabric: Standard Specification ForRed RedNoch keine Bewertungen

- Termooo StandardDokument106 SeitenTermooo Standardlaguna028Noch keine Bewertungen

- Hose ReelDokument2 SeitenHose ReelQuang LeNoch keine Bewertungen

- FABX1LEDokument2 SeitenFABX1LEJulian Augusto Morantes MorantesNoch keine Bewertungen

- Transformation Induced PlasticityDokument6 SeitenTransformation Induced PlasticityKarthick RamNoch keine Bewertungen

- Ball Transfer Units PDFDokument28 SeitenBall Transfer Units PDFLOPESABILIOLOPESNoch keine Bewertungen

- Structural Analysis and Design Lectures PDFDokument354 SeitenStructural Analysis and Design Lectures PDFgongmaozheNoch keine Bewertungen

- ASTM-F844 Washers, Steel, Plain (Flat), Unhardened For General UseDokument5 SeitenASTM-F844 Washers, Steel, Plain (Flat), Unhardened For General UseleandroschroederNoch keine Bewertungen

- Bristorm Zero Fence DatasheetDokument1 SeiteBristorm Zero Fence Datasheetمحمد مصرىNoch keine Bewertungen

- Thern5122FF 2Dokument4 SeitenThern5122FF 2BaronAlfonsoNoch keine Bewertungen

- Guidelines For Ferrous Scrap-FS2009-IsRIDokument6 SeitenGuidelines For Ferrous Scrap-FS2009-IsRIAgustine SetiawanNoch keine Bewertungen

- Wiring Methods and Materials: Summary of SAES-P-104Dokument7 SeitenWiring Methods and Materials: Summary of SAES-P-104Afzal Asif100% (3)

- Astm F436M.-11Dokument5 SeitenAstm F436M.-11abhishek yadav100% (1)

- Wheatland RMC Spec Sheet 2008Dokument2 SeitenWheatland RMC Spec Sheet 2008abd mohamedNoch keine Bewertungen

- Pre Painted SteelDokument80 SeitenPre Painted SteelCao SonNoch keine Bewertungen

- Surface Preparation For Coating. Good Practice in Corrosion ControlDokument34 SeitenSurface Preparation For Coating. Good Practice in Corrosion ControlLla Vvi InniaNoch keine Bewertungen

- 9 FencingDokument11 Seiten9 FencingkashifNoch keine Bewertungen