Beruflich Dokumente

Kultur Dokumente

FirePro - Vinayaka Enterprises - HZL - 2m3 Storage Tank Area - Design Proposal - Offer 136 - 09.12.2019

Hochgeladen von

ananthu.uOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

FirePro - Vinayaka Enterprises - HZL - 2m3 Storage Tank Area - Design Proposal - Offer 136 - 09.12.2019

Hochgeladen von

ananthu.uCopyright:

Verfügbare Formate

1

Condensed Aerosol

Fire Suppression System Design

09-12-2019

Reference number: FirePro_Vinayaka Enterprises

Offer 136

FirePro Dealer Company

2

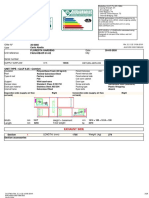

Condensed Aerosol Fire Suppression System Design

Company: Vinayaka Enterprises

Contact Person: Laxmi Purohit

Telephone Number: 09893161687

Address: Jaipur

Country: India

Project: 2m3 Strorage Tank Area

Project Type/Application: Other

Room Name: 2m3 Stroage Tank Area

Design as per Standard: UL/ULC Standards - UL 2775, ULC/ORD-C2775-12

Class of Fire: Class A Fire - Combustible Solids

Room Volume: 15m³

--------------------------------------------------------------------

-

m = V * da

m = V * DAD

m = V * (EAD * SF * fa)

where:

m: Solid Mass of FirePro Compound (FPC) Required (g)

V: Protected Volume (m3)

da: Design Application Density (g/m3)

EAD: Extinguishing Application Density (g/m3)

SF: Safety factor (30%) = 1.3

fa: Additional Design Factors (%)

Important Remarks

1. THIS SOFTWARE IS ONLY A GUIDING TOOL - SELECTION OF GENERATORS IS THE USER's RESPONSIBILITY.

2. ABOVE SELECTION IS JUST A RECOMMENDATION. ENGINEERING JUDGMENT SHOULD BE APPLIED FOR PROPER SELECTION OF

GENERATORS TAKING INTO CONSIDERATION ROOM HEIGHT (STREAM LENGTH), GENERATOR ORIENTATION IN RELATION TO THE

VOLUME ARRANGEMENT, OPENINGS etc.

3. FOR PROTECTED VOLUMES EXCEEDING 4M HEIGHT GENERATORS SHOULD BE INSTALLED IN STAGGERED ARRANGEMENT TO

ENABLE PROPER TOTAL FLOODING - PLEASE CONSULT MANUFACTURER.

4. ALWAYS CHECK CALCULATIONS FOR CORRECTNESS

FirePro Dealer Company

3

Condensed Aerosol Fire Suppression System Design

Room Volume, Solid Mass of FirePro Compound (FPC) Calculations

V (m³) = L (m) x W (m) x H (m)

V (m³) = 2.5 (m) x 2.5 (m) x 2.4 (m)

V = 15(m³)

EAD = 84(g/m³)

SF = 30%

m = V(m³) * EAD(g / m³) * SF * fₐ

m = 15(m³) * 84(g/m³) * 1.3 = 1638(g)

Fire Suppression System Discharge Aerosol Generators Selection

Total Solid Mass of

Solid Mass of FirePro

CAG Model QTY FirePro Compound

Compound (FPC) (g)

(FPC) (g)

FP-2000T 2000 1 2000

Solid Mass of FirePro Compound (FPC) Required: 1638 (g)

Solid Mass of FirePro Compound (FPC) Selected: 2000 (g)

FirePro Dealer Company

4

Bill of Materials

Fire Detection and Extinguishing Equipment - Part List

Product

No. Item Description Model QTY

Code

1 10279 FirePro - Kentec Sigma A-XT K1810-13 1

Extinguishant Control Panel 230V

2 10486 FirePro - Kentec Sequential Activator - FP- 1

Larger Box SA/GEN3.0M

8

3 10248 Fire Resistant Cable 4x1 mm2 4x1 200

mm2/EQUIVA

LENT

4 10424 Fire Alarm Bell GB6- 1

24/EQUIVAL

ENT

5 10446 Horn Strobe GEC24- 1

15/75WR/EQ

UIVALENT

6 Gas Release Sign Board FP-FL24 1

7 Earthing Tags for Aerosol Generators M- 1

16/EQUIVAL

ENT

8 10515 Manual Extinguishant Disablement Switch K1832-10 1

9 10423 Abort Switch Surface Mount K1823-10 1

10 10199 Sealed Lead Acid Battery 12V/7Ah NP7-12 2

11 10332 Simulation Test lamp JKL Lamp 1

12 10907 Conventional 4-inch Base for Detector (VF-2050- 2

00/EQUIVAL

ENT

13 10961 Conventional Photo Electric Smoke VF2044- 1

Detector 00/EQUIVAL

ENT

14 11002 Conventional Heat Detector 190°F VF2021- 1

00/EQUIVAL

ENT

15 10317 FirePro Fire Extinguishing Condensed FP-2000T 1

Aerosol Generator

FirePro Dealer Company

5

Notes:

In this report, the following information should be submitted:

1) Notes and Assumptions

2) EMI and Earthing

3) Attachment A Indicative System Diagram

4) Attachment B Indicative Wire Diagram

5) Attachment C Manuals (Electronic Components)

6) Attachment D Datasheet (Electronic Components)

7) Attachment E FirePro User and Instruction Manual

FirePro Dealer Company

6

Installation

Room Volume Aerosol Generator maximum installation height

-FP-2000T model, maximum installation height for vertical discharge

is 3.5m, or for side wall installation with angle of 30 degrees is:

3.03m, maximum stream length for horizontal discharge is: 3.5m.

Multi configuration scenario above maximum tested stream lengths: For

multi-level configuration scenario, 2/3 of the condensed aerosol

generators should be installed between the ground and maximum

installation height of the units referred as level 1 and 1/3 of the

condensed aerosol generators above this level referred as level 2

within the maximum installation height

Aerosol Generator Dimensions

FP-2000T model: Width: 300 (mm), Height 185 (mm), Height with Bracket

310 (mm)

FirePro Dealer Company

7

Disclaimer

a.Any information provided by FirePro Systems, relevant to the system

engineering of the project is indicative and for guidance purposes

only.

b.It is the contractor’s responsibility to verify whether any circuit

design is compatible with the equipment used in the system.

Furthermore, the responsibility for the preparation and/ or approval

of a project, subject to its specifications/ technical features and

its related documentation, designs or drawings adherence (e.g. design

documentation, construction, as-built drawings, circuit diagram,

cable lengths and voltage drop calculations, etc.) to local, national

and international laws and regulations, falls entirely within the

scope of the contractor/ consultant assigned for the installation and

commissioning.

FirePro Dealer Company

8

Notes and Assumptions

1. The aerosol design calculations of FirePro fire extinguishing systems are

in accordance with the UL/NFPA standards (UL 2775 and NFPA 2010).

2. All calculations and diagrams are based solely on the information provided

by the customer and should be treated as indicative for guiding during

indicative system design and definition of BOM (see Disclaimer below).

The design is indicative and subject to change depending on future updated

information and clarifications during detailed design. This may have an

impact on the final price.

3. The calculations, for the determination of FirePro extinguishing agent

quantities, are made by assuming the existence of Class of Fire A as

worst-case scenario. In case a fire scenario is possible having Class of

Fire D (burning metals) or having apparatus being exposed on hazardous

areas (explosive atmosphere), this would require further detailed

attention and possibly system re-design (if feasible).

4. It is assumed that all the protected areas are adequately sealed for Total

Flooding application, without having any openings leading to leakages

externally from the protected volume. In case of existence of any

openings, to prevent loss of agent through openings to adjacent hazards

or work areas, openings shall be permanently sealed or equipped with

automatic closures, in accordance with FirePro Guidelines “Technical

Guidelines Condensed Aerosol - Fire Extinguishing System Solutions”.

5. An Emergency Power-Off System should be implemented and activated prior

the release of the fire extinguishing agent to:

a. Switch off any ventilation systems installed within the protected

compartments /areas.

b. Power off all electrical and electronic equipment within the

protected compartment / area, to prevent possibility of re-

ignition in accordance with relevant industry standards.

6. The location of installation of the Condensed Aerosol Generators shall be

in accordance and compliance with the applicable standards. The Condensed

Aerosol Generators should be installed in such a way, by considering the

minimum safe distances from the escape routes, combustible materials and

other areas where personnel may be present. During detailed / final design

and installation it is strongly advised to consider the minimum clearance

distances L2 (< 200oC, safe distance from equipment or combustible

material) and L3 (<75oC, safe distance from persons). For further

information, please refer to chapter 8 of EN FirePro Information,

Instruction and User Manual.

7. The positioning and direction of discharge of each Condensed Aerosol Unit

shall be done by considering the safe distances, height restrictions, and

by following the guidelines included on the FirePro Information,

Instruction and User Manual.

8. It is assumed that the protected areas are normally unoccupied. For

safety, precautionary reasons and good engineering practice, in case any

of the protected areas become occupied (e.g. personnel may enter for work

/ maintenance) the system shall be set from “Auto/Manual” to “Manual Only”

mode until the area becomes again unoccupied.

Project specific – Additional notes (DELETE OR MODIFY AS REQUIRED)

FirePro Dealer Company

9

1. In case of Electrical Cabinet / Server Rack protection, it is assumed

that each cabinet is fully enclosed and separated from any surrounding

compartments.

2. In case of Electrical Cabinet / Server Rack protection, special attention

to Appendix 7 of FirePro Information, Instruction and User Manual (EN)

shall be given.

3. In case of Electrical Cabinet / Server Rack protection, it is assumed

that any panel louvres have outlet filters which are thick enough to

prevent or at least minimize (significantly slow down) potential agent

loss/dissipation towards outside the panel enclosure, in the event of

extinguishing agent discharge.

4. In case any of the permanent openings contributing / resulting to a leakage

area larger than 0.17% of the protected volume (Area m2 to Volume m3 ratio

to be greater than 0.17%), then the extinguishing agent calculations need

to be re-checked and re-adjusted to account for leakages by compensating

with additional aerosol mass (if this is feasible).

5. For High Voltage applications (>1000 Volts), special attention should be

taken for maintaining the minimum electrical clearance distances, as per

relevant standards (e.g. NFPA 70:2017), of any object which could be in

close proximity with High Voltage equipment.

6. In case of Room protection, in occasion of the existence of a slightly

sloped roof, an average individual height for each room has been assumed

while preparing the indicative system design.

7. In case of Room protection, in occasion where there are any additional

compartments to consider, either a false ceiling or raised floor (or both)

in the two rooms to be protected, then the system design needs to be re-

evaluated and adjusted accordingly. Such compartments can be ignored and

remain unprotected only in case the material, separating those unprotected

compartments from the protected areas, is made of fire-resistant material.

8. In case where the compartment(s) / areas to be protected are comprised of

a Room (main area) along with either a False Ceiling or a Raised Floor or

both, these have been considered as a single total enclosure for Total

Flooding Fire Extinguishing Application and are therefore part of one

single Conventional Fire Alarm and Extinguishing System. This implies that

for calculation purposes, these compartments have been treated as separate

volumes, but for the purpose of fire detection, at any location of either

of these protected compartments (double knock – smoke and heat detection),

the Fire Alarm and Extinguishing System is designed to release the

extinguishing agent simultaneously in the entire protected volume.

9. In relation to fire detection, with reference to in BS 5839-1:2017 or

equivalent, in case when the room height is greater than the maximum

height limit, 9.0m for Heat (RoR) and 10.5m for Smoke Detectors

respectively, Conventional Smoke and Conventional Heat detection becomes

unreliable for providing early detection.

Some other national standards could have different height limitations,

which could allow installation of conventional detection systems at higher

heights, however, those are requiring further attention and detailed study

by the consultant / installer of the project.

10. In case when the use of conventional fire detection is not feasible,

an Aspirating Smoke System is normally suggested as an alternative in

conjunction with Intelligent Heat detection. It is strongly advised that

double-knock detection feature to be implemented, by using two different

detection technologies, and this to be interfaced accordingly with the

fire extinguishing panel (detection zone 1, detection zone 2).

11. In case where the room height of the protected areas is excessive

(greater than maximum stream length of the Condensed Aerosol Generators),

FirePro Dealer Company

10

the positioning of the Condensed Aerosol Generators shall be such that

the direction of each unit to be facing the floor at various angles. Also,

the installation of the units shall be implemented at two levels, where

at the lower level (level 1) 2/3 of the required units are being installed

and on the upper level (level 2) 1/3 of the required units are being

installed. See diagram below for an illustrating example:

1/3 of total

Condensed

Aerosol

Generators

30o

Level 2

3.66m 45o

60o

70o

2/3 of total

Condensed

2.56m 3.66m 6.34m 10.06m

Aerosol

Generators 30o

45o

60o

70o

Level 1

7.33m

5.13m 7.33m 12.69m 20.14m

FirePro Dealer Company

11

FirePro Dealer Company

12

Earthing / Grounding details:

Multiple grounds throughout an installation could result in a

difference of potential between Condensed Aerosol Generators and

possibly could also create ground fault problems to the Fire

Extinguishing Panel. Use of local bonding to earth (grounding) of the

Condensed Aerosol Generator metallic enclosure could be beneficial

for the following reasons, such as:

a. Lightning Protection

b. Protection against voltage surges

c. Provision of “clean earth” system

d. Shielding against electromagnetic interference noise

e. Protection against electrostatic discharge

However, the above benefits would be effective only in case the

bonding/grounding is done properly. It is advised that the bonding /

grounding of the Condensed Aerosol Generator metallic enclosure is

done locally, and individually from the braid of the cable. The cable

braid should be grounded at the common earthing terminal within the

Fire Alarm and Extinguishant Panel side only.

Interconnected cable screens:

Condensed Aerosol Generator

Indicative Installation Detail – LFMC as per UL 2775 (UL 514B)

Fire Alarm and

Sequential Activator

Extinguishant Panel

Condensed Aerosol

Generator Unit

UL Listed

LFMC

Aerosol Generator metallic Cable braid

Bracket bonded to to be cut & insulated at

Insulated

Earth / Ground Aerosol Generator end

reference earth

bus bar

Cable braid

FirePro Aerosol Generator UL Listed Liquid-tight Flexible path to Earth / Ground back to

NPT threaded Metal Conduit Fitting, Model the panel

Adapter / Component Number 3402-8

- UL listed

NOTES:

UL Listed Liquid-tight Flexible Metal Conduit Fitting, Model Number 3402-8

a. A UL Listed Liquid-tight Flexible Metal Conduit Fitting, Model

Number 3402-8, manufactured by Hubble Incorporated for the

wiring of 1/2 inch trade size liquid-tight flexible metal conduit is

provided for all FP Series aerosol generaros.

b. Remove the lock nut from the Liquid-tight Flexible Metal

1.27

Conduit Fitting, Model Number 3402-8, before installing it on the

[ 29.8 ]

aerosol generator.

c. These fittings are to be torqued to a value of 25 N-m during 1.35

[ 34.2 ]

installation.

d. Dimensions can be changed by the manufacturer without Keep the yellow 0.54

[ 13.8 ]

notice. sealing washer

e. Dimensions do not imply tolerance. 0.15 1.56

[ 3.8 ] [ 39.5 ]

Remove lock nut

before installation Units: inches [mm]

Connector, Liquid Tight, ½ TS STL, Non-Insulated

FirePro Dealer Company

Das könnte Ihnen auch gefallen

- The Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsVon EverandThe Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsSylvain ClercNoch keine Bewertungen

- Datasheet Kf2 RDokument2 SeitenDatasheet Kf2 RjohnzepolNoch keine Bewertungen

- 26 Fire Protection-A330FDokument26 Seiten26 Fire Protection-A330Fpratt777Noch keine Bewertungen

- Boitier de Commande PDFDokument4 SeitenBoitier de Commande PDFAnonymous oDi9mLNoch keine Bewertungen

- Manual de Celda UXDokument2 SeitenManual de Celda UXvhcamiloNoch keine Bewertungen

- Exxon IP 7-3-1 Sootblowers For Fired EquipmentDokument3 SeitenExxon IP 7-3-1 Sootblowers For Fired EquipmentGilvan SilvaNoch keine Bewertungen

- P.1.87.01 Linear Heat Detection CableDokument5 SeitenP.1.87.01 Linear Heat Detection CableMartin LlontopNoch keine Bewertungen

- Rociador Cobertura Extendida k8.0Dokument6 SeitenRociador Cobertura Extendida k8.0Anthony OneillNoch keine Bewertungen

- Conventional Fire DetectionDokument18 SeitenConventional Fire DetectionkarlamoraNoch keine Bewertungen

- Horizontal Sidewall SprinklerDokument6 SeitenHorizontal Sidewall SprinklerAhrian BenaNoch keine Bewertungen

- Emergency Light Fitting Data SheetDokument4 SeitenEmergency Light Fitting Data SheetSriram SubramanianNoch keine Bewertungen

- Safety QuoteDokument3 SeitenSafety Quoteرائد احمدNoch keine Bewertungen

- Installation Instructions: GP/GPC, XP/XPC, XR SeriesDokument8 SeitenInstallation Instructions: GP/GPC, XP/XPC, XR SeriesSai Sunil ChandraaNoch keine Bewertungen

- Model 5000 Prefco Damper-4Dokument4 SeitenModel 5000 Prefco Damper-4Inventor SolidworksNoch keine Bewertungen

- Control station-ENDokument79 SeitenControl station-ENFlorin MNoch keine Bewertungen

- Upright and Pendent Sprinkler, Quick ResponseDokument6 SeitenUpright and Pendent Sprinkler, Quick ResponseAhrian BenaNoch keine Bewertungen

- 008 Manual v1.01cDokument0 Seiten008 Manual v1.01cDota NgNoch keine Bewertungen

- 888 Manual Ver1.06Dokument0 Seiten888 Manual Ver1.06Dota NgNoch keine Bewertungen

- JetfanDokument10 SeitenJetfanDaneliuc SimionNoch keine Bewertungen

- Material List: Produced On 25/04/2019 With Xpress Selection V8.6.4 - Database DIL 13.8.5Dokument10 SeitenMaterial List: Produced On 25/04/2019 With Xpress Selection V8.6.4 - Database DIL 13.8.5richar calderon espinozaNoch keine Bewertungen

- Material List: Produced On 30/03/2021 With Xpress Selection V9.2.0 - Database DIL 16.4.4Dokument19 SeitenMaterial List: Produced On 30/03/2021 With Xpress Selection V9.2.0 - Database DIL 16.4.4Sicologo CimeNoch keine Bewertungen

- Epcos DatasheetDokument5 SeitenEpcos DatasheetMostafa ElSayedNoch keine Bewertungen

- Perdaman-Attachment-B Fire SystemDokument60 SeitenPerdaman-Attachment-B Fire SystemLorena Dávila100% (1)

- Guideline For TSP FM200 Systems Rev8Dokument12 SeitenGuideline For TSP FM200 Systems Rev8binhhnNoch keine Bewertungen

- TFP330 10 2013Dokument4 SeitenTFP330 10 2013Mihai CatalinNoch keine Bewertungen

- Self-Recuperative Burners High Speed Free FlameDokument17 SeitenSelf-Recuperative Burners High Speed Free FlameKarl WeierstrassNoch keine Bewertungen

- Segment ProtectorDokument4 SeitenSegment ProtectorQuayo DeejayNoch keine Bewertungen

- FW SuperLite Standard Range Catalogue 2012-13Dokument212 SeitenFW SuperLite Standard Range Catalogue 2012-13majortayNoch keine Bewertungen

- 40-5 Strap (Pipe Outlet)Dokument2 Seiten40-5 Strap (Pipe Outlet)Valentin A.Noch keine Bewertungen

- 27 - 512 MHZ AntennasDokument192 Seiten27 - 512 MHZ AntennasGiorgi PapavaNoch keine Bewertungen

- Ignition Transformers For Burners: AccessoriesDokument20 SeitenIgnition Transformers For Burners: AccessoriesNattakorn sangmarkNoch keine Bewertungen

- FPF1-ST-G00001-E-SPE-0009 - CableDokument49 SeitenFPF1-ST-G00001-E-SPE-0009 - Cablebmanojkumar16Noch keine Bewertungen

- Stat-X Vs Other Gaseous SystemsDokument13 SeitenStat-X Vs Other Gaseous SystemsKhaled OmarNoch keine Bewertungen

- Techniical DetailDokument42 SeitenTechniical DetailAhmed AbdelgawadNoch keine Bewertungen

- Webasto Airtop VW T5Dokument30 SeitenWebasto Airtop VW T5pavli999Noch keine Bewertungen

- Technical Proposal: BKT Wellhead PlatformDokument43 SeitenTechnical Proposal: BKT Wellhead PlatformMaina MathengeNoch keine Bewertungen

- Zeta Conventional Systems BrochureDokument12 SeitenZeta Conventional Systems Brochurech_nassim7679100% (2)

- TFP228 08 2022Dokument5 SeitenTFP228 08 2022mohammaddownloadingNoch keine Bewertungen

- A5e32299685 002 Ab PDFDokument116 SeitenA5e32299685 002 Ab PDFifa afidahrNoch keine Bewertungen

- B285 - PAGA & PABX Telephone SystemDokument731 SeitenB285 - PAGA & PABX Telephone SystemGian SastroNoch keine Bewertungen

- Atex PDFDokument115 SeitenAtex PDFSanjay Kumar SinghNoch keine Bewertungen

- Failure Report For Cathodic Protection SystemDokument6 SeitenFailure Report For Cathodic Protection SystemHoang Thang0% (1)

- Tyco TFP332 - 01 - 2005 K Factor 16 PDFDokument4 SeitenTyco TFP332 - 01 - 2005 K Factor 16 PDFAhmad SirojiNoch keine Bewertungen

- Upright and Pendent Intermediate Level SprinklerDokument6 SeitenUpright and Pendent Intermediate Level SprinklerAhrian BenaNoch keine Bewertungen

- Material List: 2.1. Table of AbbreviationsDokument8 SeitenMaterial List: 2.1. Table of AbbreviationsRochmad FauziNoch keine Bewertungen

- Damper - FuegoDokument4 SeitenDamper - FuegoNicolas Alvarez GomezNoch keine Bewertungen

- Chalmit Industrial LightingDokument143 SeitenChalmit Industrial LightingSaswita SaktiNoch keine Bewertungen

- AD OPTIFLUX2000 4000 IFC100 ATEX-IECEx en 140916 7312092200 R02Dokument20 SeitenAD OPTIFLUX2000 4000 IFC100 ATEX-IECEx en 140916 7312092200 R02SofiaNoch keine Bewertungen

- Material List: Produced On 11/07/2019 With Xpress Selection V8.6.4 - Database DIL 13.8.6Dokument23 SeitenMaterial List: Produced On 11/07/2019 With Xpress Selection V8.6.4 - Database DIL 13.8.6Sicologo CimeNoch keine Bewertungen

- Rociador Tyco Ec-25Dokument4 SeitenRociador Tyco Ec-25Raúl Antonio MacíasNoch keine Bewertungen

- TB 429-15-42-RB Page 1 of 27 Approved For Public ReleaseDokument27 SeitenTB 429-15-42-RB Page 1 of 27 Approved For Public ReleaseDadangNoch keine Bewertungen

- Speed SensorDokument7 SeitenSpeed SensorsinasayedanaNoch keine Bewertungen

- Technical Data: 1. DescriptionDokument18 SeitenTechnical Data: 1. DescriptionitaloNoch keine Bewertungen

- Data Sheet Unit ENERGENCE Info LCH 3 4 5 y 6 Tons ENGDokument56 SeitenData Sheet Unit ENERGENCE Info LCH 3 4 5 y 6 Tons ENGAnonymous qg0hpB2xNUNoch keine Bewertungen

- Technical Data - Fan Model APS1004BA7/19: Location: Designation: Performance - Required ActualDokument6 SeitenTechnical Data - Fan Model APS1004BA7/19: Location: Designation: Performance - Required Actualgaru2529Noch keine Bewertungen

- Ahu SelectionDokument28 SeitenAhu SelectionkaamNoch keine Bewertungen

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsVon EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsBewertung: 5 von 5 Sternen5/5 (1)

- Top Safety Measures at Construction SitesDokument3 SeitenTop Safety Measures at Construction Sitesananthu.uNoch keine Bewertungen

- Event Tree Analysis: SverdrupDokument13 SeitenEvent Tree Analysis: Sverdrupananthu.u100% (1)

- SOPs-Craning and Rigging StandardDokument37 SeitenSOPs-Craning and Rigging Standardananthu.u100% (1)

- Week 2 - Element 4: Electrical Hazards and ControlDokument33 SeitenWeek 2 - Element 4: Electrical Hazards and Controlananthu.u100% (2)

- Calculating The Time Weighted Average TWA Noise Level and Noise Dose Levels PDFDokument1 SeiteCalculating The Time Weighted Average TWA Noise Level and Noise Dose Levels PDFananthu.uNoch keine Bewertungen

- CoBDiploma OHP 1C5.Rev1Dokument71 SeitenCoBDiploma OHP 1C5.Rev1ananthu.uNoch keine Bewertungen

- CoBDiploma OHP 1E3.Rev1Dokument38 SeitenCoBDiploma OHP 1E3.Rev1ananthu.uNoch keine Bewertungen

- Tata Projects Limited: Hazard Identification and Risk Assessment (HIRA)Dokument7 SeitenTata Projects Limited: Hazard Identification and Risk Assessment (HIRA)ananthu.u100% (3)

- CoBDiploma OHP 1E4.Rev1Dokument65 SeitenCoBDiploma OHP 1E4.Rev1ananthu.uNoch keine Bewertungen

- Job Hazard Analysis: IP-OPS-066Dokument9 SeitenJob Hazard Analysis: IP-OPS-066ananthu.uNoch keine Bewertungen

- Near Miss ReportingDokument14 SeitenNear Miss Reportingananthu.u100% (4)

- Smoke Alarm Maintenance ChecklistDokument2 SeitenSmoke Alarm Maintenance Checklistananthu.u100% (2)

- BSI Standards PublicationDokument14 SeitenBSI Standards Publicationananthu.uNoch keine Bewertungen

- ISO 14001 2015 Audit Checklist. DQSDokument19 SeitenISO 14001 2015 Audit Checklist. DQSananthu.u100% (3)

- Spirax Sarco Ball Float PDFDokument12 SeitenSpirax Sarco Ball Float PDFchanayireNoch keine Bewertungen

- Design For Area of Steel For Continuous/fixed Deep Beam - Limit State DesignDokument1 SeiteDesign For Area of Steel For Continuous/fixed Deep Beam - Limit State DesignHoàng NgọcNoch keine Bewertungen

- Wait EventDokument8 SeitenWait Eventgetsatya347Noch keine Bewertungen

- Problem Set 001Dokument2 SeitenProblem Set 001Yss CastañedaNoch keine Bewertungen

- EchoLife HG8247 GPON Terminal Product Description - (V100R002C00& C01 - 03)Dokument20 SeitenEchoLife HG8247 GPON Terminal Product Description - (V100R002C00& C01 - 03)Tiến Hồ VănNoch keine Bewertungen

- Children of MenDokument135 SeitenChildren of Mensda27Noch keine Bewertungen

- Kerio Connect Adminguide en 7.1.3 2461Dokument412 SeitenKerio Connect Adminguide en 7.1.3 2461James OmaraNoch keine Bewertungen

- Lec14s SecurityDokument24 SeitenLec14s SecurityPrincess Gladys Ingrid SupitNoch keine Bewertungen

- Truss PDFDokument46 SeitenTruss PDFphamducquangNoch keine Bewertungen

- TMS Security System Quick StartDokument11 SeitenTMS Security System Quick Startwilker2Noch keine Bewertungen

- Red Hat 80 VmwareDokument57 SeitenRed Hat 80 VmwareKhalid Hussain KhosoNoch keine Bewertungen

- 2a. Final - Pemadatan Tanah Dan CBR Ver KuliahDokument60 Seiten2a. Final - Pemadatan Tanah Dan CBR Ver KuliahDavid GurningNoch keine Bewertungen

- Cad Grade 10Dokument96 SeitenCad Grade 10Ezeclay P. TumolvaNoch keine Bewertungen

- VILLA SAVOYE - Architecture of France by David A. HanserDokument7 SeitenVILLA SAVOYE - Architecture of France by David A. HanserErleNoch keine Bewertungen

- BlowitDokument6 SeitenBlowitasdfjhbaoNoch keine Bewertungen

- Fast Cables LTD.: Manufacturing ProcessDokument7 SeitenFast Cables LTD.: Manufacturing ProcessYaredNoch keine Bewertungen

- Axapta Hardware Guide 250usersDokument14 SeitenAxapta Hardware Guide 250usersRomeo AlamNoch keine Bewertungen

- Scavenger Hunt Worksheet 2Dokument3 SeitenScavenger Hunt Worksheet 2api-339507152Noch keine Bewertungen

- Assignment 1 - Computer Lab Network Proposal - DRAFTDokument6 SeitenAssignment 1 - Computer Lab Network Proposal - DRAFTShew NahNoch keine Bewertungen

- Fish Tape & Cable PullersDokument1 SeiteFish Tape & Cable PullersmountaindewdaresNoch keine Bewertungen

- Swartland Kayo PDFDokument16 SeitenSwartland Kayo PDFOwenNoch keine Bewertungen

- Home Automation With Raspberry PiDokument5 SeitenHome Automation With Raspberry PiObserver123Noch keine Bewertungen

- Layout Arrangement ContainerDokument1 SeiteLayout Arrangement ContainerChristella Ekaristi SitorusNoch keine Bewertungen

- 02 CONSTRUCTION & Structural Details of Gothic Arch.Dokument13 Seiten02 CONSTRUCTION & Structural Details of Gothic Arch.AbhiNoch keine Bewertungen

- Cable SizesDokument2 SeitenCable SizesBassem MostafaNoch keine Bewertungen

- Autoclaved Aerated Concrete (AAC) We Put Concrete Into ShapeDokument6 SeitenAutoclaved Aerated Concrete (AAC) We Put Concrete Into ShapeeduardoaffreNoch keine Bewertungen

- Features of An Ornamental GardenDokument12 SeitenFeatures of An Ornamental GardenDr.Eswara Reddy SiddareddyNoch keine Bewertungen

- ST KPS 10Dokument2 SeitenST KPS 10ecosistemisolariNoch keine Bewertungen

- Readme SolidsquadDokument2 SeitenReadme Solidsquadjonathan AnthonyNoch keine Bewertungen

- Design of Pile CapDokument17 SeitenDesign of Pile CapMd. Adilur Rahman100% (9)