Beruflich Dokumente

Kultur Dokumente

LIT - Air Audits - AA01EN

Hochgeladen von

Swapnil PatadeOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

LIT - Air Audits - AA01EN

Hochgeladen von

Swapnil PatadeCopyright:

Verfügbare Formate

Sullair Air Audits

Walk-Through ▪ Assessment ▪ Audit

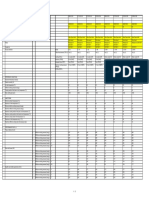

The U.S. Department of Energy determined that on average 䡲 Reduce operating costs 25% to 50%

up to 50%, or more, of the $40,000 a year in energy it takes 䡲 Reduce maintenance costs 10% to 80%

to run one 100 hp air compressor is wasted!

䡲 Get the most accurate possible data on current system

Sullair Audits review the entire compressed air system to conditions

identify ways to maximize efficiency; reduce waste; and 䡲 Receive documentation on power usage and your

reduce energy, maintenance, and equipment costs. Audits system’s interrelationships

provide the most accurate possible data on the current 䡲 Can be conducted without downtime or disruption to

system conditions to help manage the system, identify productivity

component upgrades, and ensure the entire system operates

as it should.

And, Sullair is the only compressor manufacturer to offer

three levels of air system audit that are tailored around the

Department of Energy’s standards.

Achieve Maximum Efficiency and Savings

A compressed air audit by Sullair’s team of certified auditors power and pressure readings, and accurately calculates true

is the best way to maximize the efficiency of a compressed system flow output and requirements, automatically

air system. A Sullair audit is designed to help identify savings generating reports that graph system parameters. This entire

opportunities. Audit solutions are often simple, such as process can be completed without interrupting production.

minor piping corrections, inexpensive compressor control

adjustments, and/or additional storage capacity LogAir™

complemented with precision flow controllers. Every system

In accordance with the guidelines from the government,

has its unique characteristics. Frequently one can find

Sullair’s LogAir™ auditing system uses the first data logging

enough savings to even turn compressors off. Audits can be

built into existing system maintenance contracts, allowing for system specifically designed to meet the comprehensive

re-audits as facilities, systems, environments, and the air requirements of today’s compressed air systems. Sullair’s

system needs change. certified auditors provide superior compressed air system

analysis and optimization. They work with you to understand

Sullair’s Audit Tools Are Tailored Around the Department your needs, often going beyond the requirements defined by

of Energy’s Standards… the Department of Energy’s Compressed Air Challenge.

SystemWizard™ The complete LogAir™ auditing system can log virtually any

parameter in the system, including true power (actual kW

Using the SystemWizard™ analysis software, Sullair can measurements), flow, pressure, dew point and temperature

quickly evaluate the cost and efficiency of a compressed air and all at rates as fast as once a second for up to 14 days.

system, compare multiple compressor alternatives, identify With all the data acquisition expertise, capability and

opportunities, and calculate investment paybacks on energy software, Sullair certified auditors can use the LogAir™

saved. SystemWizard™ is also an ideal tool for evaluating system and software to provide accurate data analysis to

changes to the system after a full audit or assessment. evaluate financial options and offer the best choices for

managing a compressed air system investment.

SysteMate™

Sullair’s SysteMate™ solution provides real-time, objective In addition, Sullair and authorized distributor partners will be

measurements of compressed air usage. SysteMate™ takes happy to validate any audit with a follow-up assessment.

Fundamental to Sullair’s leadership is a dedication to reduce not only the amount of natural resources consumed to create energy, but to minimize

environmental impact, in both the manufacture and use of all our products. We are constantly exploring new ideas and seeking new technologies to meet the

ever-increasing need for high quality, energy-efficient compressed air products and environmental sustainability.

www.sullair.com

© Copyright 2012 Sullair. All rights reserved.

The color green is a registered trademark of Sullair.

Specifications subject to change without notice.

AA01EN 1212R

Like us on Facebook.

The paper used in printing this literature was manufactured using recycled fiber, either pre-consumer or

post-consumer waste, therefore less harmful to the environment because less virgin fiber is used,

thereby reducing tree harvesting, water usage, energy consumption, emission of greenhouse gases and

pollution.

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Oil-Free Series Screw Air CompressorsDokument20 SeitenOil-Free Series Screw Air CompressorsSwapnil PatadeNoch keine Bewertungen

- Kaishan-Kaitain-Screw-Compressor-Direct-Couple-ISO-50Hz - JN SeriesDokument10 SeitenKaishan-Kaitain-Screw-Compressor-Direct-Couple-ISO-50Hz - JN SeriesSwapnil PatadeNoch keine Bewertungen

- 8.5bar 50Hz R00Dokument2 Seiten8.5bar 50Hz R00Swapnil PatadeNoch keine Bewertungen

- Ze 3S - en PDFDokument24 SeitenZe 3S - en PDFSwapnil PatadeNoch keine Bewertungen

- Compressed Air Audit - Plant Services 2Dokument11 SeitenCompressed Air Audit - Plant Services 2Swapnil PatadeNoch keine Bewertungen

- Neos DatasheetDokument4 SeitenNeos DatasheetSwapnil PatadeNoch keine Bewertungen

- Energy Saving in Compressed Air PointsDokument2 SeitenEnergy Saving in Compressed Air PointsSwapnil PatadeNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hard Work and Black Swans - Economists Are Turning To Culture To Explain Wealth and Poverty - Schools Brief - The EconomistDokument9 SeitenHard Work and Black Swans - Economists Are Turning To Culture To Explain Wealth and Poverty - Schools Brief - The EconomistMaría Paula ToscanoNoch keine Bewertungen

- Packing List PDFDokument1 SeitePacking List PDFKatherine SalamancaNoch keine Bewertungen

- Fabozzi Ch13 BMAS 7thedDokument36 SeitenFabozzi Ch13 BMAS 7thedAvinash KumarNoch keine Bewertungen

- Nissan Leaf - The Bulletin, March 2011Dokument2 SeitenNissan Leaf - The Bulletin, March 2011belgianwafflingNoch keine Bewertungen

- Quasha, Asperilla, Ancheta, Peña, Valmonte & Marcos For Respondent British AirwaysDokument12 SeitenQuasha, Asperilla, Ancheta, Peña, Valmonte & Marcos For Respondent British Airwaysbabyclaire17Noch keine Bewertungen

- What Is Zoning?Dokument6 SeitenWhat Is Zoning?M-NCPPCNoch keine Bewertungen

- Fire Service Resource GuideDokument45 SeitenFire Service Resource GuidegarytxNoch keine Bewertungen

- BAIN REPORT Global Private Equity Report 2017Dokument76 SeitenBAIN REPORT Global Private Equity Report 2017baashii4Noch keine Bewertungen

- Production Planning & Control: The Management of OperationsDokument8 SeitenProduction Planning & Control: The Management of OperationsMarco Antonio CuetoNoch keine Bewertungen

- E Money PDFDokument41 SeitenE Money PDFCPMMNoch keine Bewertungen

- GL July KoreksiDokument115 SeitenGL July KoreksihartiniNoch keine Bewertungen

- CMACGM Service Description ReportDokument58 SeitenCMACGM Service Description ReportMarius MoraruNoch keine Bewertungen

- PT Berau Coal: Head O CeDokument4 SeitenPT Berau Coal: Head O CekresnakresnotNoch keine Bewertungen

- Situatie Avize ATRDokument291 SeitenSituatie Avize ATRIoan-Alexandru CiolanNoch keine Bewertungen

- Monsoon 2023 Registration NoticeDokument2 SeitenMonsoon 2023 Registration NoticeAbhinav AbhiNoch keine Bewertungen

- HQ01 - General Principles of TaxationDokument14 SeitenHQ01 - General Principles of TaxationJimmyChao100% (1)

- Ekspedisi Central - Google SearchDokument1 SeiteEkspedisi Central - Google SearchSketch DevNoch keine Bewertungen

- Kennedy 11 Day Pre GeneralDokument16 SeitenKennedy 11 Day Pre GeneralRiverheadLOCALNoch keine Bewertungen

- Scheme For CBCS Curriculum For B. A Pass CourseDokument18 SeitenScheme For CBCS Curriculum For B. A Pass CourseSumanNoch keine Bewertungen

- Revenue Procedure 2014-11Dokument10 SeitenRevenue Procedure 2014-11Leonard E Sienko JrNoch keine Bewertungen

- IAS 41 - AgricultureDokument26 SeitenIAS 41 - AgriculturePriya DarshiniNoch keine Bewertungen

- Coconut Oil Refiners Association, Inc. vs. TorresDokument38 SeitenCoconut Oil Refiners Association, Inc. vs. TorresPia SottoNoch keine Bewertungen

- Approaches To Industrial RelationsDokument39 SeitenApproaches To Industrial Relationslovebassi86% (14)

- Readymade Plant Nursery in Maharashtra - Goa - KarnatakaDokument12 SeitenReadymade Plant Nursery in Maharashtra - Goa - KarnatakaShailesh NurseryNoch keine Bewertungen

- Financial Astrology by Mahendra SharmaDokument9 SeitenFinancial Astrology by Mahendra SharmaMahendra Prophecy33% (3)

- Boquet 2017, Philippines, Springer GeographyDokument856 SeitenBoquet 2017, Philippines, Springer Geographyfusonegro100% (3)

- Ship Breaking Report Dec 2010Dokument105 SeitenShip Breaking Report Dec 2010rezababakhaniNoch keine Bewertungen

- InvoiceDokument2 SeitenInvoiceiworldvashicmNoch keine Bewertungen

- Chap014 Solution Manual Financial Institutions Management A Risk Management ApproachDokument19 SeitenChap014 Solution Manual Financial Institutions Management A Risk Management ApproachFami FamzNoch keine Bewertungen

- BNI Mobile Banking: Histori TransaksiDokument1 SeiteBNI Mobile Banking: Histori TransaksiWebi SuprayogiNoch keine Bewertungen