Beruflich Dokumente

Kultur Dokumente

tp0610k PDF

Hochgeladen von

Babar KhanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

tp0610k PDF

Hochgeladen von

Babar KhanCopyright:

Verfügbare Formate

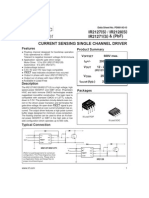

TP0610K

Vishay Siliconix

P-Channel 60 V (D-S) MOSFET

FEATURES

PRODUCT SUMMARY • Halogen-free According to IEC 61249-2-21

VDS (V) RDS(on) () VGS(th) (V) ID (mA) Definition

- 60 6 at VGS = - 10 V - 1 to - 3 - 185 • TrenchFET® Power MOSFET

• High-Side Switching

• Low On-Resistance: 6

• Low Threshold: - 2 V (typ.)

• Fast Swtiching Speed: 20 ns (typ.)

TO-236 • Low Input Capacitance: 20 pF (typ.)

(SOT-23) • 2000 V ESD Protection

Marking Code: 6Kwll

6K = Part Number Code for TP0610K • Compliant to RoHS Directive 2002/95/EC

G 1

w = Week Code

ll = Lot Traceability

APPLICATIONS

3 D • Drivers: Relays, Solenoids, Lamps, Hammers, Display,

Memories, Transistors, etc.

S 2 • Battery Operated Systems

• Power Supply Converter Circuits

Top View • Solid-State Relays

Ordering Information: TP0610K-T1-E3 (Lead (Pb)-free) BENEFITS

TP0610K-T1-GE3 (Lead (Pb)-free and Halogen-free)

• Ease in Driving Switches

• Low Offset (Error) Voltage

• Low-Voltage Operation

• High-Speed Circuits

• Easily Driven without Buffer

ABSOLUTE MAXIMUM RATINGS TA = 25 °C, unless otherwise noted

Parameter Symbol Limit Unit

Drain-Source Voltage VDS - 60

V

Gate-Source Voltage VGS ± 20

TA = 25 °C - 185

Continuous Drain Currenta ID

TA = 100 °C - 115 mA

Pulsed Drain Currentb IDM - 800

TA = 25 °C 350

Power Dissipationa PD mW

TA = 100 °C 140

Maximum Junction-to-Ambienta RthJA 350 °C/W

Operating Junction and Storage Temperature Range TJ, Tstg - 55 to 150 °C

Notes:

a. Surface mounted on FR4 board.

b. Pulse width limited by maximum junction temperature.

Document Number: 71411 www.vishay.com

S10-1476-Rev. H, 05-Jul-10 1

TP0610K

Vishay Siliconix

SPECIFICATIONS TA = 25 °C, unless otherwise noted

Limits

Parameter Symbol Test Conditions Min. Typ.a Max. Unit

Static

Drain-Source Breakdown Voltage VDS VGS = 0 V, ID = - 10 µA - 60

V

Gate-Threshold Voltage VGS(th) VDS = VGS, ID = - 250 µA -1 -3

VDS = 0 V, VGS = ± 20 V ± 10 µA

VDS = 0 V, VGS = ± 10 V ± 200

Gate-Body Leakage IGSS

VDS = 0 V, VGS = ± 10 V, TJ = 85 °C ± 500

VDS = 0 V, VGS = ± 5 V ± 100 nA

VDS = - 60 V, VGS = 0 V - 25

Zero Gate Voltage Drain Current IDSS

VDS = - 60 V, VGS = 0 V, TJ = 85 °C - 250

VGS = - 10 V, VDS = - 4.5 V - 50

On-State Drain Currenta ID(on) mA

VGS = - 10 V, VDS = - 10 V - 600

VGS = - 4.5 V, ID = - 25 mA 10

Drain-Source On-Resistancea RDS(on) VGS = - 10 V, ID = - 500 mA 6

VGS = - 10 V, ID = - 500 mA, TJ =125 °C 9

Forward Transconductancea gfs VDS = - 10 V, ID = - 100 mA 80 mS

Diode Forward Voltage VSD IS = - 200 mA, VGS = 0 V - 1.4 V

Dynamic

Total Gate Charge Qg 1.7

VDS = - 30 V, VGS = - 15 V

Gate-Source Charge Qgs 0.26 nC

ID - 500 mA

Gate-Drain Charge Qgd 0.46

Input Capacitance Ciss 23

VDS = - 25 V, VGS = 0 V

Output Capacitance Coss 10 pF

f = 1 MHz

Reverse Transfer Capacitance Crss 5

Switchingb

Turn-On Time td(on) VDD = - 25 V, RL = 150 20

ns

Turn-Off Time td(off) ID - 200 mA, VGEN = - 10 V, Rg = 10 35

Notes:

a. Pulse test: PW 300 µs duty cycle 2 %.

b. Switching time is essentially independent of operating temperature.

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional operation

of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute maximum

rating conditions for extended periods may affect device reliability.

www.vishay.com Document Number: 71411

2 S10-1476-Rev. H, 05-Jul-10

TP0610K

Vishay Siliconix

TYPICAL CHARACTERISTICS 25 °C, unless otherwise noted

1.0 1200

VGS = 10 V TJ = - 55 °C

7V

0.8

8V 900

I D - Drain Current (mA)

ID - Drain Current (A)

25 °C

0.6

125 °C

6V 600

0.4

5V

300

0.2

4V

0.0 0

0 1 2 3 4 5 0 2 4 6 8 10

VDS - Drain-to-Source Voltage (V) VGS - Gate-to-Source Voltage (V)

Output Characteristics Transfer Characteristics

20 40

VGS = 0 V

VGS = 4.5 V

16 32

RDS(on) - On-Resistance (Ω)

Ciss

C - Capacitance (pF)

12 24

VGS = 5 V

8 16

Coss

VGS = 10 V

4 8

Crss

0 0

0 200 400 600 800 1000 0 5 10 15 20 25

ID - Drain Current (mA) V DS - Drain-to-Source Voltage (V)

On-Resistance vs. Drain Current Capacitance

15 1.8

ID = 500 mA

1.5

VGS - Gate-to-Source Voltage (V)

12

VDS = 30 V VGS = 10 V at 500 mA

RDS(on) - On-Resistance

VDS = 48 V 1.2

(Normalized)

9

VGS = 4.5 V at 25 mA

0.9

6

0.6

3

0.3

0 0.0

0.0 0.3 0.6 0.9 1.2 1.5 1.8 - 50 - 25 0 25 50 75 100 125 150

Qg - Total Gate Charge (nC) TJ - Junction Temperature (°C)

Gate Charge On-Resistance vs. Junction Temperature

Document Number: 71411 www.vishay.com

S10-1476-Rev. H, 05-Jul-10 3

TP0610K

Vishay Siliconix

TYPICAL CHARACTERISTICS 25 °C, unless otherwise noted

1000 10

VGS = 0 V

8 ID = 500 mA

RDS(on) - On-Resistance (Ω)

I S - Source Current (A)

100

6

TJ = 125 °C

4

ID = 200 mA

10 TJ = 25 °C

2

TJ = - 55 °C

1 0

0.00 0.3 0.6 0.9 1.2 1.5 0 2 4 6 8 10

V SD - Source-to-Drain Voltage (V) VGS - Gate-to-Source Voltage (V)

Source-Drain Diode Forward Voltage On-Resistance vs. Gate-Source Voltage

0.5 3

0.4

ID = 250 µA 2.5

0.3

VGS(th) Variance (V)

2

0.2

Power (W)

0.1 1.5

- 0.0

1

TA = 25 °C

- 0.1

0.5

- 0.2

- 0.3 0

- 50 - 25 0 25 50 75 100 125 150 0.01 0.1 1 10 100 600

TJ - Junction Temperature (°C) Time (s)

Threshold Voltage Variance Over Temperature Single Pulse Power, Junction-to-Ambient

1

Normalized Effective Transient

Duty Cycle = 0.5

Thermal Impedance

0.2

Notes:

0.1

0.1 PDM

0.05

t1

t2

t1

0.02 1. Duty Cycle, D =

t2

2. Per Unit Base = RthJA = 350 °C/W

3. TJM - TA = PDMZthJA(t)

Single Pulse

4. Surface Mounted

0.01

10-4 10-3 10-2 10-1 1 10 100 600

Square Wave Pulse Duration (s)

Normalized Thermal Transient Impedance, Junction-to-Ambient

Vishay Siliconix maintains worldwide manufacturing capability. Products may be manufactured at one of several qualified locations. Reliability data for Silicon

Technology and Package Reliability represent a composite of all qualified locations. For related documents such as package/tape drawings, part marking, and

reliability data, see www.vishay.com/ppg?71411.

www.vishay.com Document Number: 71411

4 S10-1476-Rev. H, 05-Jul-10

Package Information

Vishay Siliconix

SOT-23 (TO-236): 3-LEAD

3

E1 E

1 2

S e

e1

0.10 mm

C

0.004" C 0.25 mm

A A2 q

Gauge Plane

Seating Plane Seating Plane

A1 C

L

L1

MILLIMETERS INCHES

Dim

Min Max Min Max

A 0.89 1.12 0.035 0.044

A1 0.01 0.10 0.0004 0.004

A2 0.88 1.02 0.0346 0.040

b 0.35 0.50 0.014 0.020

c 0.085 0.18 0.003 0.007

D 2.80 3.04 0.110 0.120

E 2.10 2.64 0.083 0.104

E1 1.20 1.40 0.047 0.055

e 0.95 BSC 0.0374 Ref

e1 1.90 BSC 0.0748 Ref

L 0.40 0.60 0.016 0.024

L1 0.64 Ref 0.025 Ref

S 0.50 Ref 0.020 Ref

q 3° 8° 3° 8°

ECN: S-03946-Rev. K, 09-Jul-01

DWG: 5479

Document Number: 71196 www.vishay.com

09-Jul-01 1

AN807

Vishay Siliconix

Mounting LITTLE FOOTR SOT-23 Power MOSFETs

Wharton McDaniel

Surface-mounted LITTLE FOOT power MOSFETs use integrated ambient air. This pattern uses all the available area underneath the

circuit and small-signal packages which have been been modified body for this purpose.

to provide the heat transfer capabilities required by power devices.

Leadframe materials and design, molding compounds, and die

attach materials have been changed, while the footprint of the

packages remains the same. 0.114

2.9

0.081

2.05

See Application Note 826, Recommended Minimum Pad

0.150

Patterns With Outline Drawing Access for Vishay Siliconix 3.8

MOSFETs, (http://www.vishay.com/doc?72286), for the basis

of the pad design for a LITTLE FOOT SOT-23 power MOSFET 0.059

footprint . In converting this footprint to the pad set for a power 1.5

device, designers must make two connections: an electrical

connection and a thermal connection, to draw heat away from the

0.0394 0.037

package. 1.0 0.95

FIGURE 1. Footprint With Copper Spreading

The electrical connections for the SOT-23 are very simple. Pin 1 is

the gate, pin 2 is the source, and pin 3 is the drain. As in the other

LITTLE FOOT packages, the drain pin serves the additional Since surface-mounted packages are small, and reflow soldering

function of providing the thermal connection from the package to is the most common way in which these are affixed to the PC

the PC board. The total cross section of a copper trace connected board, “thermal” connections from the planar copper to the pads

to the drain may be adequate to carry the current required for the have not been used. Even if additional planar copper area is used,

application, but it may be inadequate thermally. Also, heat spreads there should be no problems in the soldering process. The actual

in a circular fashion from the heat source. In this case the drain pin solder connections are defined by the solder mask openings. By

is the heat source when looking at heat spread on the PC board. combining the basic footprint with the copper plane on the drain

pins, the solder mask generation occurs automatically.

Figure 1 shows the footprint with copper spreading for the SOT-23 A final item to keep in mind is the width of the power traces. The

package. This pattern shows the starting point for utilizing the absolute minimum power trace width must be determined by the

board area available for the heat spreading copper. To create this amount of current it has to carry. For thermal reasons, this

pattern, a plane of copper overlies the drain pin and provides minimum width should be at least 0.020 inches. The use of wide

planar copper to draw heat from the drain lead and start the traces connected to the drain plane provides a low-impedance

process of spreading the heat so it can be dissipated into the path for heat to move away from the device.

Document Number: 70739 www.vishay.com

26-Nov-03 1

Application Note 826

Vishay Siliconix

RECOMMENDED MINIMUM PADS FOR SOT-23

0.037 0.022

(0.950) (0.559)

(2.692)

(1.245)

0.106

0.049

(0.724)

0.029

0.053

(1.341)

0.097

(2.459)

Recommended Minimum Pads

Dimensions in Inches/(mm)

Return to Index Return to Index

APPLICATION NOTE

Document Number: 72609 www.vishay.com

Revision: 21-Jan-08 25

Legal Disclaimer Notice

www.vishay.com

Vishay

Disclaimer

ALL PRODUCT, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE TO IMPROVE

RELIABILITY, FUNCTION OR DESIGN OR OTHERWISE.

Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf (collectively,

“Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained in any datasheet or in any other

disclosure relating to any product.

Vishay makes no warranty, representation or guarantee regarding the suitability of the products for any particular purpose or

the continuing production of any product. To the maximum extent permitted by applicable law, Vishay disclaims (i) any and all

liability arising out of the application or use of any product, (ii) any and all liability, including without limitation special,

consequential or incidental damages, and (iii) any and all implied warranties, including warranties of fitness for particular

purpose, non-infringement and merchantability.

Statements regarding the suitability of products for certain types of applications are based on Vishay’s knowledge of

typical requirements that are often placed on Vishay products in generic applications. Such statements are not binding

statements about the suitability of products for a particular application. It is the customer’s responsibility to validate that a

particular product with the properties described in the product specification is suitable for use in a particular application.

Parameters provided in datasheets and / or specifications may vary in different applications and performance may vary over

time. All operating parameters, including typical parameters, must be validated for each customer application by the customer’s

technical experts. Product specifications do not expand or otherwise modify Vishay’s terms and conditions of purchase,

including but not limited to the warranty expressed therein.

Except as expressly indicated in writing, Vishay products are not designed for use in medical, life-saving, or life-sustaining

applications or for any other application in which the failure of the Vishay product could result in personal injury or death.

Customers using or selling Vishay products not expressly indicated for use in such applications do so at their own risk.

Please contact authorized Vishay personnel to obtain written terms and conditions regarding products designed for

such applications.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this document

or by any conduct of Vishay. Product names and markings noted herein may be trademarks of their respective owners.

© 2017 VISHAY INTERTECHNOLOGY, INC. ALL RIGHTS RESERVED

Revision: 08-Feb-17 1 Document Number: 91000

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Electronic Instrumentation: Experiment 8: DiodesDokument55 SeitenElectronic Instrumentation: Experiment 8: DiodesCharie MaeNoch keine Bewertungen

- Study Material On IgbtDokument13 SeitenStudy Material On IgbtSandipan DebNoch keine Bewertungen

- Week1 - Diode Semiconductor1Dokument42 SeitenWeek1 - Diode Semiconductor1ALEN chiaNoch keine Bewertungen

- GaN Sequencing CircuitDokument5 SeitenGaN Sequencing Circuitbharathi83Noch keine Bewertungen

- 122DL DatasheetDokument3 Seiten122DL Datasheetgabriel rondonNoch keine Bewertungen

- 5W 10W ChargerDokument12 Seiten5W 10W ChargerAnonymous n30qTRQPoINoch keine Bewertungen

- Monocrystalline Vs Polycrystalline Solar Panels AllDokument8 SeitenMonocrystalline Vs Polycrystalline Solar Panels AllFanda Doet100% (1)

- Assignment 1Dokument13 SeitenAssignment 1Pirzada SwatiNoch keine Bewertungen

- ASIC vs. ASSP vs. SoC vs. FPGA - What's The DifferenceDokument9 SeitenASIC vs. ASSP vs. SoC vs. FPGA - What's The DifferencejackNoch keine Bewertungen

- Fds6982S: Dual Notebook Power Supply N-Channel Powertrench SyncfetDokument12 SeitenFds6982S: Dual Notebook Power Supply N-Channel Powertrench SyncfetAlejandro DelgadoNoch keine Bewertungen

- Transistor (PNP) : Unless Otherwise Noted)Dokument2 SeitenTransistor (PNP) : Unless Otherwise Noted)Mardy BiNoch keine Bewertungen

- IRGP50B60PD1PBFDokument11 SeitenIRGP50B60PD1PBFenriquevazquez27Noch keine Bewertungen

- FiringCct PDF CrdownloadDokument26 SeitenFiringCct PDF Crdownloaddivakar r vlNoch keine Bewertungen

- Ir 2127Dokument16 SeitenIr 2127kimonspNoch keine Bewertungen

- Layout Manual - CMOS Inverter - Exp 3Dokument22 SeitenLayout Manual - CMOS Inverter - Exp 3ApoorvaNoch keine Bewertungen

- Toshiba Power MosfetsDokument9 SeitenToshiba Power MosfetsmacroendrixNoch keine Bewertungen

- Chapter 2Dokument54 SeitenChapter 2Ankit SinghNoch keine Bewertungen

- Finfet Application Operation PDFDokument7 SeitenFinfet Application Operation PDFSatishEducatioNoch keine Bewertungen

- CMOS Interview QuestionsDokument9 SeitenCMOS Interview QuestionsarunNoch keine Bewertungen

- Silicon NPN Power Transistors: Savantic Semiconductor Product SpecificationDokument4 SeitenSilicon NPN Power Transistors: Savantic Semiconductor Product SpecificationSebastian ChaileNoch keine Bewertungen

- Analysis of 6T SRAM Cell in Different TechnologiesDokument4 SeitenAnalysis of 6T SRAM Cell in Different TechnologiesRaj sambhavNoch keine Bewertungen

- Vlsi Static Inverter Lab ReortDokument8 SeitenVlsi Static Inverter Lab ReortSsemakula FrankNoch keine Bewertungen

- IRG4PC50UDPbF Data SheetDokument10 SeitenIRG4PC50UDPbF Data SheetBob HabNoch keine Bewertungen

- Test I Test II Test III Test IVDokument4 SeitenTest I Test II Test III Test IVAnisha SooryagayathramNoch keine Bewertungen

- EXP9 NPN and PNP Transistors Operating As A SwitchDokument4 SeitenEXP9 NPN and PNP Transistors Operating As A SwitchMohammed Dyhia AliNoch keine Bewertungen

- IO Design, ESDDokument18 SeitenIO Design, ESDashishmanyanNoch keine Bewertungen

- PN Junction DiodeDokument10 SeitenPN Junction DiodeAriffuzzaman TipuNoch keine Bewertungen

- VA7208 VimicroDokument11 SeitenVA7208 VimicroHimanshuDixitNoch keine Bewertungen

- Vlsi DesignDokument31 SeitenVlsi Designajas777BNoch keine Bewertungen

- Datasheet STP3NB100 Mosfet N IndigoDokument6 SeitenDatasheet STP3NB100 Mosfet N Indigopepemex3Noch keine Bewertungen