Beruflich Dokumente

Kultur Dokumente

Spec 2014-02 A00 PDF

Hochgeladen von

Sivareddy InduriOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Spec 2014-02 A00 PDF

Hochgeladen von

Sivareddy InduriCopyright:

Verfügbare Formate

DEP SPECIFICATION

MANUFACTURING REPORT FOR PRESSURE VESSELS

Copyright Shell Group of Companies. No reproduction or networking permitted without license from Shell. Not for resale

DEP 31.22.10.35-Gen.

February 2014

ECCN EAR99

DESIGN AND ENGINEERING PRACTICE

© 2014 Shell Group of companies

All rights reserved. No part of this document may be reproduced, stored in a retrieval system, published or transmitted, in any form or by any means, without the prior

written permission of the copyright owner or Shell Global Solutions International BV.

This document contains information that is classified as EAR99 and, as a consequence, can neither be exported nor re-exported to any country which is under an

embargo of the U.S. government pursuant to Part 746 of the Export Administration Regulations (15 C.F R. Part 746) nor can be made available to any national of such

country. In addition, the information in this document cannot be exported nor re-exported to an end-user or for an end-use that is prohibited by Part 744 of the Export

Administration Regulations (15 C.F.R. Part 744).

This document has been supplied under license by Shell to:

Nooter Eriksen lmatza@ne.com 02/07/2018 16:24:25

ECCN EAR99 DEP 31.22.10.35-Gen.

February 2014

Page 2

PREFACE

DEP (Design and Engineering Practice) publications reflect the views, at the time of publication, of Shell Global Solutions

International B.V. (Shell GSI) and, in some cases, of other Shell Companies.

These views are based on the experience acquired during involvement with the design, construction, operation and

maintenance of processing units and facilities. Where deemed appropriate DEPs are based on, or reference international,

regional, national and industry standards.

The objective is to set the standard for good design and engineering practice to be applied by Shell companies in oil and

gas production, oil refining, gas handling, gasification, chemical processing, or any other such facility, and thereby to help

achieve maximum technical and economic benefit from standardization.

The information set forth in these publications is provided to Shell companies for their consideration and decision to

implement. This is of particular importance where DEPs may not cover every requirement or diversity of condition at each

locality. The system of DEPs is expected to be sufficiently flexible to allow individual Operating Units to adapt the

information set forth in DEPs to their own environment and requirements.

When Contractors or Manufacturers/Suppliers use DEPs, they shall be solely responsible for such use, including the

quality of their work and the attainment of the required design and engineering standards. In particular, for those

requirements not specifically covered, the Principal will typically expect them to follow those design and engineering

practices that will achieve at least the same level of integrity as reflected in the DEPs. If in doubt, the Contractor or

Manufacturer/Supplier shall, without detracting from his own respons bility, consult the Principal.

The right to obtain and to use DEPs is restricted, and is typically granted by Shell GSI (and in some cases by other Shell

Companies) under a Service Agreement or a License Agreement. This right is granted primarily to Shell companies and

other companies receiving technical advice and services from Shell GSI or another Shell Company. Consequently, three

categories of users of DEPs can be distinguished:

1) Operating Units having a Service Agreement with Shell GSI or another Shell Company. The use of DEPs by these

Operating Units is subject in all respects to the terms and conditions of the relevant Service Agreement.

2) Other parties who are authorised to use DEPs subject to appropriate contractual arrangements (whether as part of

a Service Agreement or otherwise).

3) Contractors/subcontractors and Manufacturers/Suppliers under a contract with users referred to under 1) or 2)

which requires that tenders for projects, materials supplied or - generally - work performed on behalf of the said

users comply with the relevant standards.

Subject to any particular terms and conditions as may be set forth in specific agreements with users, Shell GSI disclaims

any liability of whatsoever nature for any damage (including injury or death) suffered by any company or person

whomsoever as a result of or in connection with the use, application or implementation of any DEP, combination of DEPs

or any part thereof, even if it is wholly or partly caused by negligence on the part of Shell GSI or other Shell Company. The

benefit of this disclaimer shall inure in all respects to Shell GSI and/or any Shell Company, or companies affiliated to these

companies, that may issue DEPs or advise or require the use of DEPs.

Without prejudice to any specific terms in respect of confidentiality under relevant contractual arrangements, DEPs shall

not, without the prior written consent of Shell GSI, be disclosed by users to any company or person whomsoever and the

DEPs shall be used exclusively for the purpose for which they have been provided to the user. They shall be returned after

use, including any copies which shall only be made by users with the express prior written consent of Shell GSI. The

copyright of DEPs vests in Shell Group of companies. Users shall arrange for DEPs to be held in safe custody and Shell

GSI may at any time require information satisfactory to them in order to ascertain how users implement this requirement.

All administrative queries should be directed to the DEP Administrator in Shell GSI.

This document has been supplied under license by Shell to:

Nooter Eriksen lmatza@ne.com 02/07/2018 16:24:25

ECCN EAR99 DEP 31.22.10.35-Gen.

February 2014

Page 3

TABLE OF CONTENTS

1. INTRODUCTION ........................................................................................................ 4

1.1 SCOPE........................................................................................................................ 4

1.2 DISTRIBUTION, INTENDED USE AND REGULATORY CONSIDERATIONS ......... 4

1.3 DEFINITIONS ............................................................................................................. 4

1.4 CROSS REFERENCES.............................................................................................. 4

1.5 SUMMARY OF MAIN CHANGES ............................................................................... 5

1.6 COMMENTS ON THIS DEP ....................................................................................... 5

1.7 NON NORMATIVE TEXT (COMMENTARY) .............................................................. 6

2. GENERAL REQUIREMENTS .................................................................................... 7

3. COMPILATION OF THE MANUFACTURING REPORT ........................................... 7

3.1 COVER SHEET .......................................................................................................... 7

3.2 LIST OF CONTENTS.................................................................................................. 7

3.3 SHEETS ...................................................................................................................... 8

3.4 ATTACHMENTS ......................................................................................................... 8

3.5 DEVIATIONS AND CONCESSIONS .......................................................................... 8

4. GUIDANCE FOR USE OF SHEETS .......................................................................... 8

4.1 FULL MANUFACTURING REPORT .......................................................................... 8

4.2 ABRIDGED MANUFACTURING REPORT .............................................................. 10

5. REFERENCES ......................................................................................................... 12

This document has been supplied under license by Shell to:

Nooter Eriksen lmatza@ne.com 02/07/2018 16:24:25

ECCN EAR99 DEP 31.22.10.35-Gen.

February 2014

Page 4

1. INTRODUCTION

1.1 SCOPE

This DEP specifies requirements and gives recommendations for the compilation of a

manufacturing report to be prepared by the Manufacturer for each pressure vessel

manufactured in accordance with DEP 31.22.00.31-Gen.

This DEP is a revision of the DEP of the same number dated September 2012; see (1.5)

regarding the changes.

1.2 DISTRIBUTION, INTENDED USE AND REGULATORY CONSIDERATIONS

Unless otherwise authorised by Shell GSI, the distribution of this DEP is confined to Shell

companies and, where necessary, to Contractors and Manufacturers/Suppliers nominated

by them. Any authorised access to DEPs does not for that reason constitute an

authorisation to any documents, data or information to which the DEPs may refer.

This DEP is intended for use in oil refineries, chemical plants, gas plants, exploration and

production facilities and, where applicable, supply/marketing installations. This DEP may

also be applied in other similar facilities.

When DEPs are applied, a Management of Change (MOC) process shall be implemented;

this is of particular importance when existing facilities are to be modified.

If national and/or local regulations exist in which some of the requirements could be more

stringent than in this DEP, the Contractor shall determine by careful scrutiny which of the

requirements are the more stringent and which combination of requirements will be

acceptable with regards to the safety, environmental, economic and legal aspects. In all

cases, the Contractor shall inform the Principal of any deviation from the requirements of

this DEP which is considered to be necessary in order to comply with national and/or local

regulations. The Principal may then negotiate with the Authorities concerned, the objective

being to obtain agreement to follow this DEP as closely as possible.

1.3 DEFINITIONS

1.3.1 General definitions

The Contractor is the party that carries out all or part of the design, engineering,

procurement, construction and commissioning or management of a project or operation of a

facility. The Principal may undertake all or part of the duties of the Contractor.

The Manufacturer/Supplier is the party that manufactures or supplies equipment and

services to perform the duties specified by the Contractor.

The Principal is the party that initiates the project and ultimately pays for it. The Principal

may also include an agent or consultant, authorised to act for, and on behalf of, the

Principal.

The word shall indicates a requirement.

The word should indicates a recommendation.

1.3.2 Specific definitions

Term Definition

pressure Vessel used for containing, storing, distributing, processing or otherwise

vessel handling an expansible fluid under pressure. This term excludes rotating or

reciprocating equipment, fired heaters, and piping.

1.4 CROSS REFERENCES

Where cross-references to other parts of this DEP are made, the referenced section or

clause number is shown in brackets ( ). Other documents referenced by this DEP are listed

in (5).

This document has been supplied under license by Shell to:

Nooter Eriksen lmatza@ne.com 02/07/2018 16:24:25

ECCN EAR99 DEP 31.22.10.35-Gen.

February 2014

Page 5

1.5 SUMMARY OF MAIN CHANGES

This DEP is a full revision of the DEP of the same number dated September 2012. The

following are the main, non-editorial changes.

Section/Clause Change

2 Updated reference to the new Pressure Vessel DEP 31.22.00.31-Gen.

Added option for Manufacturer’s equivalent manufacturing report.

3.2 Removed requirement for name and address of the inspection

organization and nominated inspector.

4.1 Sections A2 and A3 – Removed requirement for certificate of

conformance prior to manufacture or shipping.

Section E sheets 1 and 2 – Added requirement for WPS and PQR

documents.

Section F2 – Added requirement for NDE reports for all NDE testing.

Section F3/4 – Clarified requirements for UT thickness reading.

Section F5 – Removed detailed list of requirements for glass lined

equipment.

Section H – Clarified requirement for heat treatment records.

Section I, J1, and J2 – Added reference to Appendix 2 of

DEP 31.22.00.31-Gen.

Section K – Updated requirements for QC documentation on coatings.

Section L – Added reference to DEP 31.22.00.31-Gen. clause 7.8.

Section M – Added requirement for nameplate documentation.

5. Added reference to DEP 30.48.00.31-Gen.

Removed reference to ASTM D5162

1.6 COMMENTS ON THIS DEP

Comments on this DEP may be submitted to the Administrator using one of the following

options:

Shell DEPs Online Enter the Shell DEPs Online system at

https://www.shelldeps.com

(Users with access to

Shell DEPs Online) Select a DEP and then go to the details screen for

that DEP.

Click on the “Give feedback” link, fill in the online

form and submit.

DEP Feedback System Enter comments directly in the DEP Feedback

(Users with access to System which is accessible from the Technical

Shell Wide Web) Standards Portal http://sww.shell.com/standards.

Select “Submit DEP Feedback”, fill in the online form

and submit.

DEP Standard Form Use DEP Standard Form 00.00.05.80-Gen. to record

(Other users) feedback and email the form to the Administrator at

standards@shell.com.

Feedback that has been registered in the DEP Feedback System by using one of the above

options will be reviewed by the DEP Custodian for potential improvements to the DEP.

This document has been supplied under license by Shell to:

Nooter Eriksen lmatza@ne.com 02/07/2018 16:24:25

ECCN EAR99 DEP 31.22.10.35-Gen.

February 2014

Page 6

1.7 NON NORMATIVE TEXT (COMMENTARY)

Text shown in italic style in this DEP indicates text that is non-normative and is provided as

explanation or background information only.

Non-normative text is normally indented slightly to the right of the relevant DEP clause.

This document has been supplied under license by Shell to:

Nooter Eriksen lmatza@ne.com 02/07/2018 16:24:25

ECCN EAR99 DEP 31.22.10.35-Gen.

February 2014

Page 7

2. GENERAL REQUIREMENTS

1. The manufacturing report for each pressure vessel shall be compiled in accordance

with this DEP and DEP 31.22.00.31-Gen.

2. The manufacturing report shall be written in English, or shall include an English

translation, unless otherwise specified by the Principal.

3. The contents of the manufacturing report shall:

a. reflect in detail the fabrication history of the pressure vessel concerned;

b. provide all information to demonstrate that applicable quality procedures have

been followed and standards adhered to;

c. state the compliance with the specifications invoked by the purchase order.

4. Standard Forms DEP 31.22.10.41-Gen. and DEP 31.22.10.42-Gen. provide layouts of

a full and an abridged manufacturing report, respectively. They identify the minimum

contents to be included in the reports. These forms or a Manufacturer’s equivalent

containing all identified information shall be used.

5. An abridged manufacturing report may be provided for pressure vessel parts or

vessels subject to non-severe operating conditions and for non-code vessels, if

agreement is obtained from the Principal. Abridged manufacturing reports shall be

provided only for category 3 vessels as defined in DEP 31.22.00.31-Gen.

6. As fabrication of the equipment progresses, the Manufacturer shall compile the

manufacturing report with the original manufacturing documents and shall keep it up to

date. If an original manufacturing document (including certificate) cannot be provided,

a legible certified master copy shall be provided, duly marked as such.

7. The manufacturing report shall be endorsed by stamp, date and signature of the

Manufacturer’s nominated inspector on each page,

8. The manufacturing report shall be submitted to the Principal on request.

9. The original and the required number of copies shall be forwarded promptly after the

completion of the equipment in accordance with the terms and conditions of the

purchase order.

10. If the order is subject to inspection by the Principal, the release note for the

acceptance of the equipment shall only be issued when the manufacturing report,

including the required number of copies, is presented.

3. COMPILATION OF THE MANUFACTURING REPORT

3.1 COVER SHEET

1. Each manufacturing report shall have a cover sheet of A-4 or letter size paper. The

cover sheet shall include the following:

a. Manufacturing Report,

b. Equipment tag number, e.g., C-201, E-201, V-201,

c. Name of the project/plant (if available),

d. Principal's purchase order number.

2. The report shall be provided in loose-leaf form with numbered pages (Page ... of ...).

3.2 LIST OF CONTENTS

1. The list of contents shall contain the following data:

a. Name and address of the Manufacturer,

b. Principal's complete purchase order number,

This document has been supplied under license by Shell to:

Nooter Eriksen lmatza@ne.com 02/07/2018 16:24:25

ECCN EAR99 DEP 31.22.10.35-Gen.

February 2014

Page 8

c. Equipment tag number and name, e.g., E-303 'Charge effluent exchanger',

d. Manufacturer's production works order number.

3.3 SHEETS

1. All manufacturing report sheets shall contain:

a. Name and address of the Manufacturer,

b. Principal's purchase order number,

c. Equipment tag number and name,

d. Page number,

e. Manufacturer's production works order number.

For further details see (4).

2. If any item on the sheet is not relevant, it shall be indicated on the list of contents as:

'Not Applicable' or 'NA'.

3.4 ATTACHMENTS

1. Each page of pertinent attachment documents, e.g., certificates, repair reports,

sketches, deviations and concessions etc., shall be attached immediately behind the

relevant sheets and shall be clearly marked with:

a. Principal's purchase order number,

b. Equipment tag number and name,

c. Relevant section letter and page number.

2. Certificates for a part of the vessel, e.g., shell, channel, head, nozzle A-2, tubes,

flanges, bolts, internals etc., shall show the name of the relevant part, its purchase

order and item numbers.

3. If material mill certificates are applicable only to certain parts of the vessel, the

applicable items shall be marked with an arrow and numbered on an included, duly

marked copy of the original certificate. A cross-reference of this certificate number

should be included in as-built drawings, alongside appropriate parts.

3.5 DEVIATIONS AND CONCESSIONS

1. Copies of the Principal's written approval of any deviations or concessions from the

purchase order requirements shall be included in the manufacturing report.

4. GUIDANCE FOR USE OF SHEETS

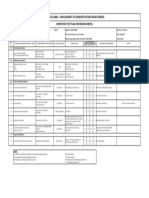

4.1 FULL MANUFACTURING REPORT

(See DEP 31.22.10.41-Gen.)

1. Section A1

a. This section shall be completed with all applicable data.

2. Section A2

a. This section shall be completed with all applicable data.

3. Section A3

a. This section shall be completed with all applicable data.

This document has been supplied under license by Shell to:

Nooter Eriksen lmatza@ne.com 02/07/2018 16:24:25

ECCN EAR99 DEP 31.22.10.35-Gen.

February 2014

Page 9

4. Section B

a. All deviations and concessions shall be listed and described. Evidence of

authorized approvals shall be attached to this sheet, e.g., copy of email, fax or

letter.

5. Section C

a. All construction materials shall be listed.

b. If alloy verification is required, this shall be indicated. For certificates see (3.4).

7. Section D

a. Design strength values shall be stated for all parts of the equipment subject to

stress calculations.

8. Section E, Sheets 1 and 2

a. Weld procedure specifications and weld procedure qualification records shall

be provided for all weld procedures utilized.

9. Section E, Sheets 3 and 4

a. Details of welders involved in production welding of pressure vessel shall be

provided.

10. Section F1

a. Indicate the applied inspection methods, e.g.:

i. Radiography (X-ray, gamma-ray)

ii. Ultrasonics

iii. Magnetic particle

iv. Liquid penetrant

v. Hardness testing

11. Section F2 (no sheet provided)

a. Nondestructive examination (NDE) reports shall be provided for all NDE

testing.

12. Section F3/4

a. Ultrasonic testing (UT) wall thickness readings shall be taken to determine the

“new, as-built” thickness of pressure retaining and support skirt materials. See

DEP 31.22.00.31-Gen., clause 7.4.

13. Section F5 (no sheet provided)

a. Full details of all quality control activities on glass lining or other non-

conductive protective coating (if applicable) shall be provided. These should

satisfy specific order requirements.

14. Section F6 (no sheet provided)

a. Full details of all quality control activities on rubber lining (if applicable) shall

be entered. Activities shall conform to requirements of DEP 30.48.60.10-Gen.

15. Section G (no sheet provided)

a. All repairs and related heat treatments shall be reported. Locations of repairs

shall be shown on the as-built drawings. The results of additional NDE shall be

reported in the appropriate sections.

16. Section H

a. Records of all heat treatment performed on the vessel or components shall be

attached including chart recording of the measured temperatures. In case of

This document has been supplied under license by Shell to:

Nooter Eriksen lmatza@ne.com 02/07/2018 16:24:25

ECCN EAR99 DEP 31.22.10.35-Gen.

February 2014

Page 10

re-heat treatment due to repair, an additional sheet for the re-heat treatment

shall also be completed.

17. Section I

a. Vessel tolerances are shown in Appendix 2 of DEP 31.22.00.31-Gen.

Deviations from the design location of nozzles, manholes, etc., shall be shown

with plus or minus values.

18. Section J1

a. Acceptable vessel tolerances are shown in Appendix 2 of DEP 31.22.00.31-

Gen. The vessel circularity (out of roundness) shall be documented for each

section of the vessel.

19. Section J2

a. Acceptable vessel tolerances are shown in Appendix 2 of DEP 31.22.00.31-

Gen. The vessel straightness shall be documented for each section of the

vessel.

20. Section K

a. Full details of all quality control activities for both internal and external coatings

shall be provided as specified in DEP 30.48.00.31-Gen. and in the specific

order requirements.

21. Section L

a. See DEP 31.22.00.31-Gen. clause 7.8 for pressure testing requirements.

22. Section M

a. A photograph or rubbing of the nameplate is required.

22. Section N (no sheet provided)

a. This is a copy of the final release note.

23. Section O (no sheet provided)

a. This is the as-built drawing. It shall be certified and signed by the

Manufacturer.

24. Section P

a. A copy of the Manufacturer's accepted quality control plan to be incorporated.

25. Section Q

a. If applicable, vessels supplied with separate lifting devices, such as lifting

beams or spreader bars, require load testing certification.

26. Section R

a. Weight certificates are required.

4.2 ABRIDGED MANUFACTURING REPORT

(See DEP 31.22.10.42-Gen.)

1. The documents required for an abridged manufacturing report depend on the specific

duty of the equipment.

2. Factors which should be taken into consideration when deciding if an abridged

manufacturing report is applicable include:

a. Requirements of design code,

b. Criticality of service,

c. Simplicity of design,

This document has been supplied under license by Shell to:

Nooter Eriksen lmatza@ne.com 02/07/2018 16:24:25

ECCN EAR99 DEP 31.22.10.35-Gen.

February 2014

Page 11

d. Size/volume,

e. Total cost.

3. In each case, the decision to provide an abridged manufacturing report should be

made at the time of placing the purchase order and the decision shall be acceptable to

the Principal.

This document has been supplied under license by Shell to:

Nooter Eriksen lmatza@ne.com 02/07/2018 16:24:25

ECCN EAR99 DEP 31.22.10.35-Gen.

February 2014

Page 12

5. REFERENCES

In this DEP, reference is made to the following publications:

NOTES: 1. Unless specifically designated by date, the latest edition of each publication shall be used,

together with any amendments/supplements/revisions thereto.

2. The DEPs and most referenced external standards are available to Shell staff on the SWW (Shell

Wide Web) at http://sww.shell.com/standards/.

SHELL STANDARDS

DEP feedback form DEP 00.00.05.80-Gen.

Protective coatings for onshore and offshore facilities DEP 30.48.00.31-Gen.

Rubber lining of process equipment and tanks DEP 30.48.60.10-Gen.

Unfired pressure vessels DEP 31.22.00.31-Gen.

Full manufacturing report (form) DEP 31.22.10.41-Gen.

Abridged manufacturing report (form) DEP 31.22.10.42-Gen.

This document has been supplied under license by Shell to:

Nooter Eriksen lmatza@ne.com 02/07/2018 16:24:25

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- ECU Remapping SolutionDokument19 SeitenECU Remapping SolutionMuhammad Novianto85% (13)

- CENTRIFUGAL FANS (AMENDMENTS/SUPPLEMENTS TO ISO 13705, Annex E)Dokument18 SeitenCENTRIFUGAL FANS (AMENDMENTS/SUPPLEMENTS TO ISO 13705, Annex E)Sivareddy InduriNoch keine Bewertungen

- Pipenet Vision Training Manual Spray: Chapter 2 Page 1 of 45 REVISION 2.1, OCT 2010Dokument45 SeitenPipenet Vision Training Manual Spray: Chapter 2 Page 1 of 45 REVISION 2.1, OCT 2010Sivareddy Induri100% (1)

- Auditing Test Bank Chapter 15Dokument34 SeitenAuditing Test Bank Chapter 15Heejin Kwon100% (10)

- Manual Servicio Linde t18 Modelo 360Dokument53 SeitenManual Servicio Linde t18 Modelo 360colive133% (3)

- Passat Fuse and Relay LocationsDokument10 SeitenPassat Fuse and Relay Locationsgosa46100% (3)

- Design, Installation and Fabrication of Reciprocating PumpDokument40 SeitenDesign, Installation and Fabrication of Reciprocating PumpSivareddy InduriNoch keine Bewertungen

- Spec 2014-02 A00Dokument12 SeitenSpec 2014-02 A00Sivareddy InduriNoch keine Bewertungen

- Installation and Commissioning of Onshore Cathodic Protection SystemsDokument149 SeitenInstallation and Commissioning of Onshore Cathodic Protection SystemsSivareddy Induri100% (1)

- Cylinder Filling Plants and Bulk Transfer Facilities For Depots and Filling PlantsDokument67 SeitenCylinder Filling Plants and Bulk Transfer Facilities For Depots and Filling PlantsSivareddy InduriNoch keine Bewertungen

- 1) The Junction Box Certification Shall Be Ex (D) and Weather Proof To IP-66. Quantity: 5 Nos'Dokument1 Seite1) The Junction Box Certification Shall Be Ex (D) and Weather Proof To IP-66. Quantity: 5 Nos'Sivareddy InduriNoch keine Bewertungen

- 31 Samss 009Dokument7 Seiten31 Samss 009Sivareddy InduriNoch keine Bewertungen

- Material SelectionDokument58 SeitenMaterial SelectionSivareddy InduriNoch keine Bewertungen

- 5.1 Pvrv-Fa - VD - Ts - Ka - 7 - GBDokument4 Seiten5.1 Pvrv-Fa - VD - Ts - Ka - 7 - GBSivareddy InduriNoch keine Bewertungen

- 4.1psv - CatalogueDokument96 Seiten4.1psv - CatalogueSivareddy InduriNoch keine Bewertungen

- Nalco - 1800 - Corrosion InhibitorDokument15 SeitenNalco - 1800 - Corrosion InhibitorSivareddy Induri50% (2)

- Magnatic Level GaugesDokument16 SeitenMagnatic Level GaugesSivareddy InduriNoch keine Bewertungen

- Process Design, CV, Line Size, Hazard, Safety Valve GuideDokument60 SeitenProcess Design, CV, Line Size, Hazard, Safety Valve GuideSivareddy InduriNoch keine Bewertungen

- 3phase Separator Size 2010 VerADokument24 Seiten3phase Separator Size 2010 VerACristina BarbulescuNoch keine Bewertungen

- The News Wheel Used Car Inspection ChecklistDokument7 SeitenThe News Wheel Used Car Inspection ChecklistTom KentNoch keine Bewertungen

- AHRI-880 (I-P) - 2011 With Addendum 1Dokument19 SeitenAHRI-880 (I-P) - 2011 With Addendum 1RCYABONoch keine Bewertungen

- Cisco 4000 SeriesDokument47 SeitenCisco 4000 SeriesoscmmNoch keine Bewertungen

- Internal MixerDokument6 SeitenInternal MixerThaiGarLockNoch keine Bewertungen

- Solarwinds Solution ComponentsDokument8 SeitenSolarwinds Solution ComponentsJohn MarcialNoch keine Bewertungen

- Samsung SonoAce R3 Ultrasound - Service Manual PDFDokument178 SeitenSamsung SonoAce R3 Ultrasound - Service Manual PDFRamilson Machado67% (3)

- SPAC265-3W: AC-DC Switch Mode Power SupplyDokument12 SeitenSPAC265-3W: AC-DC Switch Mode Power SupplyradugaNoch keine Bewertungen

- Semi-Detailed Lesson Plan: Area: TVL - Computer Hardware Servicing Date: April 2, 2019 Prepared By: REYNALD M. MANZANODokument5 SeitenSemi-Detailed Lesson Plan: Area: TVL - Computer Hardware Servicing Date: April 2, 2019 Prepared By: REYNALD M. MANZANOReynald Manzano100% (1)

- Non-Destructive Testing - Ultrasonic Examination - : Part 4: Examination For Discontinuities Perpendicular To The SurfaceDokument20 SeitenNon-Destructive Testing - Ultrasonic Examination - : Part 4: Examination For Discontinuities Perpendicular To The SurfacesupreetNoch keine Bewertungen

- DOC00305 Verix Evo Porting GuideDokument34 SeitenDOC00305 Verix Evo Porting Guidebestleopard100% (1)

- ITP For Drum Screen InspectionDokument1 SeiteITP For Drum Screen InspectionkapsarcNoch keine Bewertungen

- Esm 9453Dokument3 SeitenEsm 9453Cristian SerbanoiuNoch keine Bewertungen

- Using Sockets in PHPDokument7 SeitenUsing Sockets in PHPJaNoLeRRoNoch keine Bewertungen

- Five S (5S) : The First Step Toward World Class ManagementDokument27 SeitenFive S (5S) : The First Step Toward World Class ManagementFirda BasbethNoch keine Bewertungen

- Amazon New Hire Training Expectations and GuidelinesDokument4 SeitenAmazon New Hire Training Expectations and GuidelinesIan Carlos FajardoNoch keine Bewertungen

- WiMAX TutorialDokument9 SeitenWiMAX TutorialpathlossanwarNoch keine Bewertungen

- 7 Product Realization RequirementsDokument10 Seiten7 Product Realization RequirementsArman Ul Nasar0% (1)

- Hager Isolators SwitchesDokument12 SeitenHager Isolators SwitchesDhanTimNoch keine Bewertungen

- ISO17020 2020 CertificateDokument2 SeitenISO17020 2020 CertificatemohdfirdausNoch keine Bewertungen

- 2020 Super Duty SpecsDokument81 Seiten2020 Super Duty SpecsBorneo BudiNoch keine Bewertungen

- Voyager DVD ManualDokument80 SeitenVoyager DVD ManualGianniNoch keine Bewertungen

- Table 1a - Rated Insulation Levels For Rated Voltages of Range I, Series IDokument1 SeiteTable 1a - Rated Insulation Levels For Rated Voltages of Range I, Series IavinashuklaNoch keine Bewertungen

- Pemh9 Pimh9 Pumh9 Sot-363 Ht9Dokument17 SeitenPemh9 Pimh9 Pumh9 Sot-363 Ht9kumbrovNoch keine Bewertungen

- Analysis of The Integrity of A Single Stud Assembly With Externally Corroded NutsDokument19 SeitenAnalysis of The Integrity of A Single Stud Assembly With Externally Corroded NutsrandyooiscribdNoch keine Bewertungen

- Combined Structural and Piping Analysis Methodology - ANSYSDokument45 SeitenCombined Structural and Piping Analysis Methodology - ANSYS2challengersNoch keine Bewertungen

- PanelboardsDokument15 SeitenPanelboardsMohamed FaragNoch keine Bewertungen