Beruflich Dokumente

Kultur Dokumente

Factsheet Iron PDF

Hochgeladen von

Vincent MartinezOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Factsheet Iron PDF

Hochgeladen von

Vincent MartinezCopyright:

Verfügbare Formate

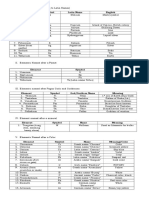

ESAT Environmental and Social Assessment Tool

Sector Fact Sheet

Iron, Steel and other Metals High Risk Sector

Processing ore into metal such as iron, steel or precious metals as raw

materials for further activities.

For product manufacturing refer to related sectors.

Related Sectors:

• Mining and Quarrying

• Metal Products and Machinery

• Electronic Products

• Precision Instruments

Production Processes Sustainability Issues

The production of iron, steel, non-ferrous metals such as copper and Energy

precious metals such as silver starts with metal ores, raw metals and scrap

metal. As the chemical and physical characteristics of metals differ widely Water Use

(aluminum, steel, mercury), the metals industry employs a wide range of Emissions to Water

technologies.

Waste

Iron: After mining, the ore is crushed and milled, sorted by size and

sintered. In a blast furnace coke is added to the ore and the sinter, reacting Emissions to Air

with oxygen and producing carbon monoxide. Carbon monoxide then Ecosystems

interacts with the ore, generating liquid metal. Impurities like silicium dioxide

are removed by adding lime. Workplace Health & Safety

Precious and non-ferrous metals are produced from ore, concentrates or Disaster Risk

secondary raw materials by metallurgical, chemical or electrolytic processes.

Aluminum, for example, is extracted from bauxite, which is produced mainly Site Contamination

in Australia, Guinea, Brazil and Jamaica. Via a wet chemical leach method,

Sector Rating

the alumina is purified and then turned into aluminum metal via an

electrolytic reduction. The production of gold may involve liquid mercury as High risk issue

an auxiliary or chemicals such as cyanides. Medium risk issue

Steel is an alloy made of low-carbon iron. It is obtained by blowing oxygen

Low risk issue

through molten iron, thereby reducing its carbon content. Fluxes are added

to remove any remaining impurities. The properties of steel can be adapted

by alloying it with other metals such as copper, chromium, titanium or

vanadium. Usually the steel is then cast, forged or rolled into sheets, strips,

bars or plates.

Risks & Opportunities

• The production of iron, steel and other metals requires large amounts of energy.

The most common sources of energy for generating heat are coal (often in the form of coke) and natural gas. Metal

producers are the largest energy consumers in the manufacturing sector.

• Wastewater may contain heavy metals and oils.

Wastewater from processes such as coating may contain (heavy) metals in high concentrations. Water used for cooling

processes may also be contaminated.

• Waste from metals production includes furnace slag and collected dust. Quantities may be huge.

Solid waste stems in particular from dismantled refractories and furnace scale. In the iron and steel industry, risks related

to solid waste arise from the quantity rather than from toxicity.

• Furnaces and smelters are the main sources of emissions in metal production.

Exhaust gases may present a temporary nuisance and a health risk for residents in the surroundings. Metal dusts can

result in long-term contamination and poisoning. Air pollution depends upon the metals produced, the fuel used and the

level of technology.

• The main risks to workers' health are: Exposure to heat and hot materials, noise, metal dust, vapours and fumes

as well as exposure to heavy machinery.

In order to mitigate substantial risks to workers exposed to extreme conditions, adequate training, process and workflow

design as well as state-of-the-art protective equipment are essential.

Environmental and Social Assessment for SMEs www.ifc-esat.org Page 1 of 1

Version 1.0 - August 2005

Das könnte Ihnen auch gefallen

- Environmetal ReportbDokument7 SeitenEnvironmetal ReportbVincent MartinezNoch keine Bewertungen

- Power Plant Engineering ReviewerDokument50 SeitenPower Plant Engineering Reviewermikulo77% (13)

- NAVEDTRA 14251A STEELWORKER ADVANCED Reduced PDFDokument233 SeitenNAVEDTRA 14251A STEELWORKER ADVANCED Reduced PDFDuc Anh MaterialNoch keine Bewertungen

- Autocad ShortcutsDokument13 SeitenAutocad ShortcutsKriscel CaraanNoch keine Bewertungen

- Factsheet IronDokument1 SeiteFactsheet IronVincent MartinezNoch keine Bewertungen

- Study on effect of air space in arsenic biosand filterDokument74 SeitenStudy on effect of air space in arsenic biosand filterOcta AceNoch keine Bewertungen

- MDSP Set 1Dokument32 SeitenMDSP Set 1Jan Edward L. Suarez50% (2)

- 10m703 Power Plant EngineeringDokument2 Seiten10m703 Power Plant EngineeringERKATHIR100% (1)

- Get started with the all-in-one WPS Office mobile appDokument6 SeitenGet started with the all-in-one WPS Office mobile appBryan GintingNoch keine Bewertungen

- Study on effect of air space in arsenic biosand filterDokument74 SeitenStudy on effect of air space in arsenic biosand filterOcta AceNoch keine Bewertungen

- Iron and SteelDokument8 SeitenIron and Steelnishant361Noch keine Bewertungen

- Power Plant Engineering by Frederick T Morse Book SummaryDokument1 SeitePower Plant Engineering by Frederick T Morse Book SummaryVincent Martinez50% (4)

- YgDokument2 SeitenYgVincent Martinez0% (1)

- GGDokument153 SeitenGGVincent MartinezNoch keine Bewertungen

- G01D G01G G06K 11/00: Definition StatementDokument22 SeitenG01D G01G G06K 11/00: Definition StatementVincent MartinezNoch keine Bewertungen

- Cooling TowerDokument6 SeitenCooling TowerVincent MartinezNoch keine Bewertungen

- Pumps Problems 20 ItemsDokument10 SeitenPumps Problems 20 ItemsDexter Contawe86% (21)

- 039Dokument5 Seiten039Raghu RamNoch keine Bewertungen

- Academic Affairs Office: Bataan Heroes Memorial CollegeDokument1 SeiteAcademic Affairs Office: Bataan Heroes Memorial CollegeVincent MartinezNoch keine Bewertungen

- Psych Exercise02 SolutionsDokument9 SeitenPsych Exercise02 Solutionsjasson ponce100% (3)

- Psych Exercise02 SolutionsDokument9 SeitenPsych Exercise02 Solutionsjasson ponce100% (3)

- Introduction To Machinery Vibration and Noise: Significance of Vibration CharacteristicDokument1 SeiteIntroduction To Machinery Vibration and Noise: Significance of Vibration CharacteristicVincent MartinezNoch keine Bewertungen

- Can Crusher SummaryDokument14 SeitenCan Crusher SummaryOsama Abdelaleem100% (1)

- Bataan Heroes Memorial College OJT DocumentsDokument6 SeitenBataan Heroes Memorial College OJT DocumentsVincent MartinezNoch keine Bewertungen

- Fully Automatic Can Crusher-1280Dokument5 SeitenFully Automatic Can Crusher-1280fadya100% (1)

- SIMEONDokument7 SeitenSIMEONVincent Martinez100% (1)

- KeysDokument6 SeitenKeysÐÅzurin67% (3)

- Design and Fabrication of Aluminium Tin Can Crusher: A.S.Shinde, A.D. Landge, A.K. Biradar, S.M. KondawarDokument6 SeitenDesign and Fabrication of Aluminium Tin Can Crusher: A.S.Shinde, A.D. Landge, A.K. Biradar, S.M. KondawarVincent MartinezNoch keine Bewertungen

- Can Crusher SummaryDokument14 SeitenCan Crusher SummaryOsama Abdelaleem100% (1)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Principle of Extraction of MetalsDokument28 SeitenPrinciple of Extraction of MetalsShivam Gupta100% (1)

- Electroplating (Learning Material of Chemistry) by HariyantoDokument34 SeitenElectroplating (Learning Material of Chemistry) by HariyantoHARIYANTO100% (4)

- Common Abbreviations in The Valve IndustryDokument10 SeitenCommon Abbreviations in The Valve IndustryNath BoyapatiNoch keine Bewertungen

- Welding Inspection CSWIP (ANSWER)Dokument131 SeitenWelding Inspection CSWIP (ANSWER)Manoj PaudelNoch keine Bewertungen

- NG GalvanizingHandbook DigitalversionDokument31 SeitenNG GalvanizingHandbook DigitalversionRafee RevaldiNoch keine Bewertungen

- 20 Manufacturing of Surface LayersDokument14 Seiten20 Manufacturing of Surface LayersqwertgyhuxNoch keine Bewertungen

- Deduplication Test CasesDokument3 SeitenDeduplication Test Casessita rautelaNoch keine Bewertungen

- Unit 5 - Metals and AlloysDokument6 SeitenUnit 5 - Metals and AlloysDanielle AdelanteNoch keine Bewertungen

- US Gold Recycling Rate 29% in 1998Dokument182 SeitenUS Gold Recycling Rate 29% in 1998humejiasNoch keine Bewertungen

- ADVANCE MANUFACTURING OooDokument7 SeitenADVANCE MANUFACTURING OooAshish SharmaNoch keine Bewertungen

- Melting, Remelting, and Casting For Clean Steel: July 2016Dokument14 SeitenMelting, Remelting, and Casting For Clean Steel: July 2016tabibkarimNoch keine Bewertungen

- Effects of FSW Parameters on Microstructures and Properties of Brass JointsDokument4 SeitenEffects of FSW Parameters on Microstructures and Properties of Brass JointsAdi PriyantoNoch keine Bewertungen

- Aktiphos-4180 enDokument2 SeitenAktiphos-4180 enJorge Luis Castillo VargasNoch keine Bewertungen

- Ore Deposits and Prospects of Northern ChileDokument94 SeitenOre Deposits and Prospects of Northern ChileeliosNoch keine Bewertungen

- Materials: Effect of Secondary Phase Precipitation On The Corrosion Behavior of Duplex Stainless SteelsDokument37 SeitenMaterials: Effect of Secondary Phase Precipitation On The Corrosion Behavior of Duplex Stainless Steelscharles_acNoch keine Bewertungen

- Nickel Aluminum Bronze PropertiesDokument6 SeitenNickel Aluminum Bronze Propertiesdheeraj616Noch keine Bewertungen

- 19.sec.1900 (Structural Steel)Dokument31 Seiten19.sec.1900 (Structural Steel)aalignup arc & const. pvt ltdNoch keine Bewertungen

- 3331901Dokument9 Seiten3331901Himanshu ChaudhariNoch keine Bewertungen

- Caution - Turbine 2 - 13961340 - Pt. SKS Listrik Kalimantan - Turbine Lube Oil - 1Dokument2 SeitenCaution - Turbine 2 - 13961340 - Pt. SKS Listrik Kalimantan - Turbine Lube Oil - 1dhavit wijayantoNoch keine Bewertungen

- f2 PDFDokument14 Seitenf2 PDFagus effendyNoch keine Bewertungen

- Welding Technology SyllabusDokument1 SeiteWelding Technology SyllabusShankaranarayanan100% (1)

- Latin Names and Origins of Noble ElementsDokument3 SeitenLatin Names and Origins of Noble ElementsAlma Mae CasabayNoch keine Bewertungen

- Cladding Systems: Protecting Your InsulationDokument11 SeitenCladding Systems: Protecting Your InsulationHaytham ElsayedNoch keine Bewertungen

- Process Quality Control Sheet (I) : Grade 4135Dokument7 SeitenProcess Quality Control Sheet (I) : Grade 4135Vandana MehraNoch keine Bewertungen

- Quenched and Tempered Alloyed Engineering Steel DINDokument2 SeitenQuenched and Tempered Alloyed Engineering Steel DINkazdoelahNoch keine Bewertungen

- DC Stock ListDokument38 SeitenDC Stock Listfarman ali ahmedNoch keine Bewertungen

- A Study On Zirconium Rich Uranium-Zirconium Alloys PDFDokument8 SeitenA Study On Zirconium Rich Uranium-Zirconium Alloys PDFOmar VillanuevaNoch keine Bewertungen

- WEM 600 - Offshore Platform WeldingDokument26 SeitenWEM 600 - Offshore Platform Weldingriqto100% (1)

- WA Hardfacing Fundamentals by Arc WeldingDokument37 SeitenWA Hardfacing Fundamentals by Arc WeldingNimal100% (1)

- Performing Fillet Welding On Carbon Steel PlateDokument35 SeitenPerforming Fillet Welding On Carbon Steel PlateJM Llaban Ramos72% (18)