Beruflich Dokumente

Kultur Dokumente

Foam chamberFCA

Hochgeladen von

chintanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Foam chamberFCA

Hochgeladen von

chintanCopyright:

Verfügbare Formate

FOAM CHAMBER

MODEL - FCA & FCA-S HD FIRE PROTECT

PVT. LTD.

TECHNICAL DATA

MODELS FCA-65, FCA-80 & FCA-100

FCA-150

Carbon Steel Construction

FCA-S 65, FCA-S 80 &

FCA-S 100, FCA-S 150

Stainless Steel Construction

INLET SIZE 65, 80, 100 NB & 150 NB

WORKING Min 2.8 Kg/cm2 (40 PSI)

PRESSURE Max 7 Kg/cm2 (100 PSI)

FLANGE ANSI B16.5 Class 150#SORF

CONNECTION LISTED

WEIGHT 65 NB - 34.5 Kg

(Approx) 80 NB - 49.5 Kg

100 NB - 72.0 Kg FEATURES

150 NB - 110 Kg

• UL Listed & FM Approved

VAPOUR SEAL 0.7 to 1.75 Kg/sq.cm.

• Heavy duty welded construction with choice of

RUPTURE (10 PSI to 25 PSI)

Carbon Steel or Stainless Steel material

PRESSURE Running water/ water foam

solution pressure at inlet of • Frangible Glass Vapour Seal

Foam Chamber

• Controlled Air Flow proportional to liquid flow for

MAXIMUM 0.07 Kg/sq.cm. (1.0 PSI) optimum foam quality and rupture of vapour

PERMISSIBLE BACK seal in narrow pressure tolerances for

PRESSURE ON increased reliability

VAPOUR SEAL

• Field replaceable orifice plate fitted with Foam

VAPOUR SEAL Glass standard supply, Chamber

Graphite optional only with

FM Approvals APPLICATION

DEFLECTOR Solid or Split Deflector Foam Chamber is used in one of the most common

applications to protect vertical fixed roof (cone) liquid

FINISH Red RAL 3001 Standard storage tanks, with or without internal floating roof

supply, other shade optional with the low expansion foam system. The application

APPROVAL UL Listed & FM Approved of foam is on the basis that the risk comprises the

Ref Table-I total surface area of the fuel. The foam system design

guidelines generally used are in accordance with

ORDERING a) Model & Size NFPA-11 standard.

INFORMATION b) Flow & Pressure at inlet

of each Foam Chamber Foam Chambers are defined by NFPA-11 as Type II

discharge outlets for delivering foam to the surface

c) Inlet, outlet flange

of a flammable liquid. Foam Chambers are widely

specification

used with the Balance Pressure Foam Proportioning

d) Type of Deflector

System, Bladder Tank Proportioner or Foam Tender.

e) Type of Foam concentrate

used

f) Tank number / Tag number

SEPTEMBER, 2018 PAGE 1 OF 8 HD 254

HD FIRE PROTECT

PVT. LTD.

SPECIFICATION (a) Number of Foam Chamber:

Foam Chamber is an air aspirating foam discharge The number of foam chambers required is

device, covering wide range of flow from 150 to 3300 determined by tank diameter. Where two

litres per minute at 2.8 to 7 kg/sq.cm. inlet pressure. or more foam chambers are required, they shall

The Foam Chamber contains a vapour seal to prevent be spaced equally around the tank periphery and

the entry of vapour into the foam chamber and the each Foam Chamber shall be sized to deliver

foam solution pipe. Each foam chamber is supplied foam at an approximately same rate. Please

with an orifice plate, designed for the required flow refer graph to select unit that will provide

and inlet pressure. The orifice is field replaceable in required minimum foam solution application

the event of change in design parameters. rate at the available operating pressure of the

Foam Chamber.

Foam is produced by introducing air into the foam

solution stream. The inlet of foam chamber is For minimum number of Foam Chamber

designed to create venturi jet which draws air into requirement, kindly follow the recommendations

the foam solution stream. Air is drawn into the as per NFPA/OISD or as per the governmental

foam solution through the holes located on the foam codes or ordinances wherever applicable.

chamber covered with stainless steel screen to (b) Minimum Foam Solution Application Rate:

exclude nesting birds and insects. The aerated foam

is directed into the deflector for the gentle application The minimum foam solution application rate is

of the expanded foam. The deflectors are available in the rate at which the water and foam

different models. concentrate in correctly proportioned ratio

should be delivered to the surface of a storage

Removal of cover plate from the top of the chamber tank under protection to control and

allows the system to be tested and a sample of the extinguish the fire.

expanded foam can be collected without removing

the vapour seal or disconnecting the foam chamber For minimum application rate requirement,

from the tank. Frangible glass bursting disc graphite follow the recommendations as per NFPA/OISD

(vapour seal) can be replaced easily. or governmental codes or ordinances

wherever applicable.

The vapour seal is designed to rupture within 0.7

to 1.75 Kg/sq.cm. (10 to 25 PSI) pressure at inlet

TESTING & MAINTENANCE

flange of Foam Chamber, as required by NFPA, UL &

FM standard. The vapour seal will withstand maximum Carefully unpack Foam Chamber. While unpacking

back pressure of 0.07 Kg/sq.cm. (1.0 PSI) or equal to and installation it is to be handled with care and

686mm of water column as specified by API for welded shocks to be avoided. Check visually for any damag-

storage tank. If the requirement exceeds 0.07 Kg/ es. While installing ensure that Foam Chamber is not

sq.cm. (1.0 PSI) as in case of nitrogen blanketing under stress due to any misalignments in installation

system, then this equipment may not be suitable. or variations of system piping. Ensure that the strainer

assembly is clear from any blockages or damages. If

The vapour seal is frangible glass. Vapour seal is

strainer assembly is either blocked or damaged, it will

supplied with holder and for spares it can be with or

adversely affect the performance of the equipment.

without holder. The ‘O’ ring used for seal are Nitrile

rubber and optional Viton is recomended for polar Qualified and trained person must commission

solvent. the system. After few initial successful tests,

an authorized person must be trained to perform

SYSTEM DESIGN REQUIREMENT inspection and testing of the system.

The NFPA-11, a standard for low expansion foam, It is recommended to carry out physical inspection

provides the essential requirements of an appropriate of the system regularly. The system must be fully

designed foam pouring system, these are identified tested at least once in a year or in accordance with

and outlined as below: applicable NFPA/OISD standards or in accordance with

The Foam Deflector is used with the Foam Chamber. authority having local jurisdiction.

The aerated foam from the Foam Chamber is directed Do not turn off the system or any valve to make

in to the deflector for the gentle application of the repair or test the system, without placing a roving

expanded foam. The deflector reduces the expanded Fire Patrol in the area covered by the system. The

foam velocity and allows the foam to slide down the Patrol should continue until the system is put back

tank wall. in service. Also inform the local security guard and

control alarm station, so as to avoid false alarm.

Each system is to be flushed properly. The vapour seal

must be replaced if the system has been operated.

SEPTEMBER, 2018 PAGE 2 OF 8 HD 254

HD FIRE PROTECT

PVT. LTD.

Normal testing of the chamber can be carried out by NOTE:

removing the cover plate from the top of the chamber.

1. A PROVISION IS TO BE MADE FOR PRESSURE

This allows the system to draw a sample of the

GAUGE MOUNTING AT INLET OF FOAM

expanded foam without removing the vapour seal or

CHAMBER, WHICH MAY BE PLUGGED AFTER

disconnecting the Foam Chamber from the tank.

SUCCESSFUL COMMISSIONING OF THE

The air screen is to be inspected periodically for the SYSTEM. THIS PROVISION WILL HELP TO

obstruction of air inlet holes. If any obstruction is ANALYSE THE SYSTEM WHILE

noticed, remove the same and flush if necessary. COMMISSIONING.

It is recommended to have regular maintenance 2. FM APPROVAL AND UL LISTING OF

programme to inspect the Vapour Seal Chamber EQUIPMENT ARE VALID ONLY WHEN USED

discharge area and deflector for possible deposit or WITH HD FOAM CONCENTRATE IN A MANNER

obstruction. AS LISTED AND AS FM APPROVAL DATA.

The owner is responsible for the testing, inspection & 3. FM APPROVAL IS VALID ONLY WHEN TOTAL

maintenance of the Foam Chamber. SYSTEM IS HAVING FM APPROVED PRODUCT.

CAUTION 4. REFER TO THE INDIVIDUAL FOAM UL LISTING

AND FM APPROVAL FOR OPERATING &

Do not install Foam chambers on pressured storage

LIMITATION WITH EACH FOAM CONCENTRATE

tanks (Inert gas blanketed tanks) and storage tanks

AND FOAM CHAMBER.

containing products, which may attack the foam

chamber standard construction material.

Maximum permissible back pressure on vapour seal

is 0.07 Kg/sq.cm.2 (1.0 PSI)

Selection of HD Foam Chamber:

TABLE-1 gives the K-Factor of Foam Chamber at various pressures for selection of correct size of Foam

Chamber. UL & FM Approvals have different Flow/K-factors.

TABLE-I

APPROVALS UL LISTED FM APPROVED

WORKING PRESSURE 2.8 KG/CM2 To 7 KG/CM2 2.8 KG/CM2 To 7 KG/CM2 3.5 KG/CM2 To 7 KG/CM2

FOAM CONCENTRATE AFFF3% & AR-AFFF 3X3% AFFF 3% AR-AFFF 3X3%

MODELS K-FACTOR K-FACTOR

FCA 65 & FCAS 65 89.6 To 207.8 92.6 To 215.8 84.5 To 207.3

FCA 80 & FCAS 80 179.2 To 385.9 184 To 429 167.8 To 396

FCA 100 & FCAS 100 358.5 To 972 370.5 To 960 320.7 To 952.5

FCA 150 & FCAS 150 ---- 884.5 To 1247.3 783 To 1258.6

To select the size of the Foam Chamber use the following formula:

Q=K√P

Q = Total solution flow in litres per minute

K = Constant for Foam Chamber

P = Inlet pressure in kg/sq.cm.

SEPTEMBER, 2018 PAGE 3 OF 8 HD 254

HD FIRE PROTECT

PVT. LTD.

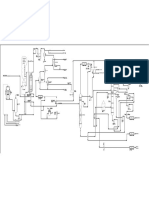

FOAM CHAMBER

C

6

DIMENSIONS

INLET OUTLET

MODEL in millimeter F2

SIZE SIZE

(Approximate) 5 9

F1 F2 A B C

8

FCA 65 &

65NB 100NB 756 600 175 7

FCA-S 65

FCA 80 &

80NB 150NB 1093 908 225

FCA-S 80

A

FCA 100 &

100NB 200NB 1221 996 275

B

FCA-S 100

4

FCA 150 &

150NB 250NB 1250 1018 325

FCA-S 150

2

1 F1

PART LIST

ITEM MATERIAL SPECIFICATON

DESCRIPTION

NO. FCA FCA-S

1 ORIFICE ASSEMBLY STAINLESS STEEL STAINLESS STEEL

2 INLET FLANGE STEEL STAINLESS STEEL

3 STRAINER ASSEMBLY STAINLESS STEEL STAINLESS STEEL

4 FOAM MAKING CHAMBER STEEL PIPE SS PIPE

5 FOAM CHAMBER STEEL STAINLESS STEEL

6 INSPECTION COVER STEEL STAINLESS STEEL

7 DISCHARGE PIPE STEEL PIPE SS PIPE

8 OUTLET FLANGE STEEL STAINLESS STEEL

9 VAPOUR SEAL ASSEMBLY GLASS GLASS

NOTE:

1. Strainer Assembly consists of SS perforated sheet, SS Strainer holder & Galvanised Nut/Bolt.

2. Vapour Seal is Glass as standard supply (UL & FM Approved) & Graphite disc is optional only for FM

Approved model.

3. Pipes used are ERW (Seamless Pipe are optional)

4. Foam chambers are open to atmosphere & do not have internal shutoff device,hence no hydrotest is

offered during inspection.

SEPTEMBER, 2018 PAGE 4 OF 8 HD 254

HD FIRE PROTECT

PVT. LTD.

TYPICAL FOAM CHAMBER INSTALLATION WITH DEFLECTOR

TYPICAL INSTALLATION OF FOAM CHAMBER WITH STUD FLANGED SPLIT DEFLECTOR

FOAM CHAMBER

OUTLET FLANGE

GASKETS FOAM CHAMBER

MODEL FCA

TANK SHELL SPLIT DEFLECTOR

MODEL SD

MOUNTING PAD SPLIT DEFLECTOR

ASSEMBLY

INLET FLANGE STUD MOUNTING PAD

STORAGE TANK

NOTE:

Stud Mounting Pad with gasket & split deflector

are optional items. To be ordered separately.

TANK CUTOUT FOR MOUNTING OF SPLIT DEFLECTOR

FLANGE OUTLINE FOAM CHAMBER SIZE CUTOUT SIZE

PCD

RØ

INLET OUTLET

TYPE FLANGE FLANGE RØ PCD HOLE

Ø’d’

NO OF

HOLES

*

SIZE SIZE

FCA 65 65 100 116 190.5 19 8

FCA 80 80 150 170 241 22 8

Ø'd'

FCA 100 100 200 221 298 22 8

* BY INSTALLER

FCA 150 150 250 276 362 25 12

TYPICAL INSTALLATION OF FOAM CHAMBER WITH STUD FLANGED TANK NOZZLE AND SOLID DEFLECTOR

FOAM CHAMBER TANK NOZZLE

(BY OTHERS)

200

MODEL FCA

SOLID DEFLECTOR

* MODEL FD

**

150 150

STORAGE TANK

GLASS VAPOUR SEAL GRAPHITE VAPOUR SEAL WITH HOLDER, *

WITH HOLDER (STANDARD SUPPLY) (OPTIONAL SUPPLY ONLY WITH FM APPROVAL)

* BY INSTALLER

NOTE:

1. Above dimensions are general guidelines only. The system designer can adopt the dimensions as per

NFPA/TAC/OISD or as per the governing rules & ordinance having local jurdiction.

2. Tank Nozzle nutbolts & gasket are optional to be ordered separately.

3. Split deflector Model SD and solid deflector Model FD is standard supply in carbon steel material and

optional in stainless steel.

SEPTEMBER, 2018 PAGE 5 OF 8 HD 254

HD FIRE PROTECT

PVT. LTD.

PRESSURE VS FLOW PERFORMANCE CHARACTERISTIC

UL LISTED WITH FOAM CONCENTRATE AFFF 3%

600

1000

500

FOAM SOLUTION FLOW

FOAM SOLUTION FLOW

800

FLOW IN LPM

400

FLOW IN LPM

600

300

400

200

100 200

2 3 4 5 6 7 2 3 4 5 6 7

INLET PRESSURE (KG/SQ.CM)

INLET PRESSURE (KG/SQ.CM)

FCA & FCA-S 65 NB

FCA & FCA-S 80 NB

2600

2400

2200

2000

1800

FOAM SOLUTION FLOW

1600

1400

FLOW IN LPM

1200

1000

800

600

2 3 4 5 6 7

INLET PRESSURE (KG/SQ.CM)

FCA & FCA-S 100 NB

SEPTEMBER, 2018 PAGE 6 OF 8 HD 254

HD FIRE PROTECT

PVT. LTD.

PRESSURE VS FLOW PERFORMANCE CHARACTERISTIC

FM APPROVED WITH FOAM CONCENTRATE AFFF 3%

600 1200

500 1000

FOAM SOLUTION FLOW

FOAM SOLUTION FLOW

400

FLOW IN LPM

800

FLOW IN LPM

300

600

200

400

100

2 3 4 5 6 7

INLET PRESSURE (KG./SQ.CM) 200

2 3 4 5 6 7

FCA 65 NB

INLET PRESSURE (KG./SQ.CM)

FCA 80 NB

2600 3400

2400 3200

2200 3000

FOAM SOLUTION FLOW

2000 2800

FOAM SOLUTION FLOW

FLOW IN LPM

1800 2600

FLOW IN LPM

1600 2400

1400 2200

1200 2000

1000 1800

800 1600

600 1400

2 3 4 5 6 7 2 3 4 5 6 7

INLET PRESSURE (KG./SQ.CM)

INLET PRESSURE (KG./SQ.CM)

FCA 100 NB

FCA 150 NB

SEPTEMBER, 2018 PAGE 7 OF 8 HD 254

HD FIRE PROTECT

PVT. LTD.

PRESSURE VS FLOW PERFORMANCE CHARACTERISTIC

FM APPROVED WITH FOAM CONCENTRATE AR-AFFF 3X3-C6

600

1000

500

FOAM SOLUTION FLOW

FOAM SOLUTION FLOW

800

FLOW IN LPM

FLOW IN LPM

400

600

300

400

200

100 200

2 3 4 5 6 7 2 3 4 5 6 7

INLET PRESSURE (KG./SQ.CM) INLET PRESSURE (KG./SQ.CM)

FCA 65 NB FCA 80 NB

2600 3400

2400 3200

2200 3000

FOAM SOLUTION FLOW

FOAM SOLUTION FLOW

2000 2800

FLOW IN LPM

1800

FLOW IN LPM

2600

1600 2400

1400 2200

1200 2000

1000 1800

800 1600

600 1400

2 3 4 5 6 7 2 3 4 5 6 7

INLET PRESSURE (KG./SQ.CM) INLET PRESSURE (KG./SQ.CM)

FCA 100 NB FCA 150 NB

LIMITED WARRANTY

HD FIRE PROTECT PVT. LTD. hereby referred to as HD FIRE warrants to the original purchaser of the fire protection products manufactured by HD FIRE and to any other person

to whom such equipment is transferred, that such products will be free from defect in material and workmanship under normal use and care, for two (2) years from the date of

shipment by HD FIRE. Products or Components supplied or used by HD FIRE, but manufactured by others, are warranted only to the extent of the manufacturer’s warranty.

No warranty is given for product or components which have been subject to misuse, improper installation, corrosion, unauthorized repair, alteration or un-maintained.

HD FIRE shall not be responsible for system design errors or improper installation or inaccurate or incomplete information supplied by buyer or buyer’s representatives.

HD FIRE will repair or replace defective material free of charge, which is returned to our factory, transportation charge prepaid, provided after our inspection the material is

found to have been defective at the time of initial shipment from our works. HD FIRE shall not be liable for any incidental or consequential loss, damage or expense arising directly

or indirectly from the use of the product including damages for injury to person, damages to property and penalties resulting from any products and components manufactured

by HD FIRE. HD FIRE shall not be liable for any damages or labour charges or expense in making repair or adjustment to the product. HD FIRE shall not be liable for any

damages or charges sustained in the adaptation or use of its engineering data & services. In no event shall HD Fire’s product liability exceed an amount equal to the sale price.

The foregoing warranty is exclusive and in lieu of all other warranties and representation whether expressed, implied, oral or written, including but not limited

to, any implied warranties or merchantability or fitness for a particular purpose. All such other warranties and representations are hereby cancelled.

NOTICE :

The equipment presented in this bulletin is to be installed in accordance with the latest publication standards of NFPA or other similar organisations and also with the

provision of government codes or ordinances wherever applicable.

The information provided by us is to the best of our knowledge and belief, and consist of general guidelines only. Site handling and installation control is not in our scope.

Hence we give no guarantee for result and take no liability for damages, loss or penalties whatsoever, resulting from our suggestion, information, recommendation or

damages due to our product.

Product development is a continuous programme of HD FIRE PROTECT PVT. LTD. and hence the right to modify any specification without prior notice is reserved with

the company.

D-6/2, ROAD NO. 34, WAGLE INDUSTRIAL ESTATE, THANE 400 604, INDIA.

HD FIRE PROTECT PVT. LTD. • TEL: + (91) 22 2158 2600 • FAX: +(91) 22 2158 2602

Protecting What Matters Most to You • EMAIL: info@hdfire.com • WEB: www.hdfire.com

SEPTEMBER, 2018 PAGE 8 OF 8 HD 254

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Flexible Hose DatasheetDokument7 SeitenFlexible Hose DatasheetchintanNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Guideline for Safe Transportation of Dry Chlorine Gas by PipelineDokument40 SeitenGuideline for Safe Transportation of Dry Chlorine Gas by PipelineDarshan PatelNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Conversion FactorDokument2 SeitenConversion FactorchintanNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Mixed Plastics Waste To Ethylene and Propylene FeedstocksDokument296 SeitenMixed Plastics Waste To Ethylene and Propylene FeedstockschintanNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- 21-00312 REPORT AdvancedRecycling WEBDokument74 Seiten21-00312 REPORT AdvancedRecycling WEBchintanNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- How To Present - PHD Progress Report - To Doctoral Committee Members - Research VoyageDokument6 SeitenHow To Present - PHD Progress Report - To Doctoral Committee Members - Research VoyagechintanNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Pipe insulation and classification documentDokument6 SeitenPipe insulation and classification documentchintanNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Steam Trap PDFDokument2 SeitenSteam Trap PDFDhim131267Noch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- M514 Flanged Style Excess Flow Check ValvesDokument2 SeitenM514 Flanged Style Excess Flow Check ValveschintanNoch keine Bewertungen

- Zone MeltingDokument99 SeitenZone MeltingchintanNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- NFIL Piping SpecsDokument2 SeitenNFIL Piping SpecschintanNoch keine Bewertungen

- Design Calculation For Coil in The HFO Tank - TK14 & TK 15Dokument4 SeitenDesign Calculation For Coil in The HFO Tank - TK14 & TK 15chintanNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- LPC Line Iso-ModelDokument1 SeiteLPC Line Iso-ModelchintanNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- IBR Regulation 43Dokument2 SeitenIBR Regulation 43chintanNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Lyophilization - The Basics - Drug Discovery and DevelopmentDokument10 SeitenLyophilization - The Basics - Drug Discovery and DevelopmentchintanNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Ion Exchange ChromatographyDokument20 SeitenIon Exchange ChromatographychintanNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Alternative Fuels Answer SheetDokument11 SeitenAlternative Fuels Answer SheetchintanNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- Fossil Fuels : Characteristics, Origin, Applications and Effects of Fossil FuelsDokument2 SeitenFossil Fuels : Characteristics, Origin, Applications and Effects of Fossil FuelschintanNoch keine Bewertungen

- Q.1 Count and Choose The Correct Answer:: Subject: Mathematics Class 1 Worksheet 1Dokument3 SeitenQ.1 Count and Choose The Correct Answer:: Subject: Mathematics Class 1 Worksheet 1chintanNoch keine Bewertungen

- W Fraa03Dokument2 SeitenW Fraa03chintanNoch keine Bewertungen

- P&id HydrocrackerDokument1 SeiteP&id HydrocrackerchintanNoch keine Bewertungen

- Universal Education: ICSE 2021 - 22 Grade 1 Subject - EvsDokument2 SeitenUniversal Education: ICSE 2021 - 22 Grade 1 Subject - EvschintanNoch keine Bewertungen

- All EquationsDokument3 SeitenAll EquationschintanNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Design Calculation For Coil in The HFO Tank - TK14 & TK 15Dokument4 SeitenDesign Calculation For Coil in The HFO Tank - TK14 & TK 15chintanNoch keine Bewertungen

- Hypothesis & Its TypesDokument14 SeitenHypothesis & Its Typesshahnawaz ahmed100% (1)

- Null Hypothesis and Alternative Hypothesis With 9 DifferencesDokument16 SeitenNull Hypothesis and Alternative Hypothesis With 9 DifferenceschintanNoch keine Bewertungen

- How to Separate Chemical MixturesDokument47 SeitenHow to Separate Chemical MixtureschintanNoch keine Bewertungen

- General Instructions For Ph. D. Writtern TestDokument1 SeiteGeneral Instructions For Ph. D. Writtern TestchintanNoch keine Bewertungen

- Syllabus PH D Admission Test - June 2020Dokument21 SeitenSyllabus PH D Admission Test - June 2020chintanNoch keine Bewertungen

- Data Privacy and Data Protection PolicyDokument3 SeitenData Privacy and Data Protection PolicychintanNoch keine Bewertungen

- Infoprint 6700 Series PDFDokument384 SeitenInfoprint 6700 Series PDFOCDtechNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Personal Injury Workshop Claims GuideDokument7 SeitenPersonal Injury Workshop Claims GuideMelissa HanoomansinghNoch keine Bewertungen

- Torts and DamagesDokument6 SeitenTorts and DamagesAce PatriarcaNoch keine Bewertungen

- Industrial Insurance V BondizzleDokument2 SeitenIndustrial Insurance V BondizzleJet SiangNoch keine Bewertungen

- Acw2 XN Installation Guide enDokument26 SeitenAcw2 XN Installation Guide enM Aditia FirmansyahNoch keine Bewertungen

- Tison V Pomasin DigestDokument3 SeitenTison V Pomasin DigestAngelo Raphael B. DelmundoNoch keine Bewertungen

- Bank Mistakenly Freezes Account - Awarded Nominal DamagesDokument3 SeitenBank Mistakenly Freezes Account - Awarded Nominal DamagesNicorobin RobinNoch keine Bewertungen

- City of Dagupan v. Maramba, G.R. No. 174411, July 2, 2014'Dokument2 SeitenCity of Dagupan v. Maramba, G.R. No. 174411, July 2, 2014'Mharey AlmachaNoch keine Bewertungen

- Bacolod Miling Vs CA - GR 81100-01Dokument20 SeitenBacolod Miling Vs CA - GR 81100-01jovelyn davoNoch keine Bewertungen

- Zulueta vs. Pan-Am (G.r. No. L-28589Dokument2 SeitenZulueta vs. Pan-Am (G.r. No. L-28589Rhea CalabinesNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Public Bank's Right to Receive Rent from Tenant of Charged LandDokument86 SeitenPublic Bank's Right to Receive Rent from Tenant of Charged LandSarannRajSomasakaranNoch keine Bewertungen

- Lecture 9 14Dokument39 SeitenLecture 9 14marieNoch keine Bewertungen

- Nikko Hotel Manila Vs ReyesDokument7 SeitenNikko Hotel Manila Vs ReyesfrozenwizardNoch keine Bewertungen

- Blue Star Corp. v. CKF Properties, CUMcv-07-448 (Cumberland Super. CT., 2008)Dokument26 SeitenBlue Star Corp. v. CKF Properties, CUMcv-07-448 (Cumberland Super. CT., 2008)Chris BuckNoch keine Bewertungen

- Luo v. Schedule A - ComplaintDokument9 SeitenLuo v. Schedule A - ComplaintSarah BursteinNoch keine Bewertungen

- Municipal Court ComplaintDokument8 SeitenMunicipal Court ComplaintapbacaniNoch keine Bewertungen

- Try & Buy AgreementDokument2 SeitenTry & Buy AgreementOriana OrdosgoiteNoch keine Bewertungen

- NIA v. IACDokument1 SeiteNIA v. IACKaren Joy MasapolNoch keine Bewertungen

- Song Fo v. Hawaiian PH, G.R. 23769, 16 Sept. 1925Dokument3 SeitenSong Fo v. Hawaiian PH, G.R. 23769, 16 Sept. 1925Homer SimpsonNoch keine Bewertungen

- Puma v. Brooks Sports - ComplaintDokument18 SeitenPuma v. Brooks Sports - ComplaintSarah BursteinNoch keine Bewertungen

- Complaint (Unlawful Detainer and Damages With Preliminary AttachmentDokument7 SeitenComplaint (Unlawful Detainer and Damages With Preliminary AttachmentapbacaniNoch keine Bewertungen

- Consti Full Case Chapter 3 and 4Dokument647 SeitenConsti Full Case Chapter 3 and 4Crisha Jean OrbongNoch keine Bewertungen

- (Digest) Ledesma vs. Court of Appeals, G.R No. L-54598, April 15,1988Dokument2 Seiten(Digest) Ledesma vs. Court of Appeals, G.R No. L-54598, April 15,1988Michelle T. Catadman100% (1)

- RA 386 Civil CodeDokument142 SeitenRA 386 Civil CodeRoms AvilaNoch keine Bewertungen

- Nutrimix Feeds Corp. V. Court of Appeals 441 SCRA 357 (2004)Dokument3 SeitenNutrimix Feeds Corp. V. Court of Appeals 441 SCRA 357 (2004)Rando TorregosaNoch keine Bewertungen

- Statement of ClaimDokument13 SeitenStatement of ClaimCTV VancouverNoch keine Bewertungen

- Malow Mayek v. City and County of Denver, Et Al.Dokument21 SeitenMalow Mayek v. City and County of Denver, Et Al.Michael_Roberts2019Noch keine Bewertungen

- Southeastern College v. CA - Case DigestDokument3 SeitenSoutheastern College v. CA - Case DigestLulu RodriguezNoch keine Bewertungen

- Catastrophe Claims Guide 2007Dokument163 SeitenCatastrophe Claims Guide 2007cottchen6605100% (1)

- C4 - Voidable ContractDokument12 SeitenC4 - Voidable ContractHUI MIN TEHNoch keine Bewertungen