Beruflich Dokumente

Kultur Dokumente

18-TC5-FD-Potain MD 265-Staitionary Undercarriage - 04-10-2018 PDF

Hochgeladen von

bassem muhannaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

18-TC5-FD-Potain MD 265-Staitionary Undercarriage - 04-10-2018 PDF

Hochgeladen von

bassem muhannaCopyright:

Verfügbare Formate

Masri Engineering & Contracting Est.

(MEC) Date: 10/04/2018

P.O Box 45437, Abu Dhabi, UAE. Tel. +971 2 634 6633 Fax +97126346632

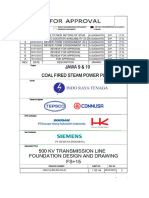

TOWER CRANE FOUNDATION DESIGN

Project : AL Falah Residential Complex

Plot No : 1F

Sector : 997

Location : AL Falah, Abu Dhabi

Structural Design Report

Prepared by MEC engineering and contracting EST.

Eng. Bassem Muhanna

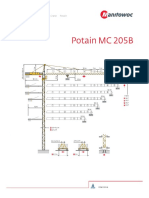

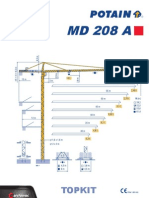

TOWER CRANE Potain MD 265 J12

Tower Crane Foundation Design

1 of 28

Masri Engineering & Contracting Est.(MEC) Date: 10/04/2018

P.O Box 45437, Abu Dhabi, UAE. Tel. +971 2 634 6633 Fax +97126346632

1.0.0 GENERAL

1.1.0 Abstract

This report is prepared to address the design calculations for a Tower Crane Foundation.

1.2.0 Brief Structural Description

The tower crane configuration is stationary undercarriage type with a height under the hook

HSC 36.3m, accordingly 4 concrete pads under each corner will be adopted, comprehencive

structural study will be carried on to verify the adequacy of the selected concrete pads

dimensions.

2.0.0 DESIGN DATA

2.1.0 Material Properties

2.1.1 Soil

Bearing capacity of soil is σall ≔ 80

Average Bulk Density γs ≔ 17 ――

3

Friction angle ϕ ≔ 32

(1 − sin (ϕ)))

Active earth pressure coefficient Ka ≔ ――――= 0.307

(1 + sin (ϕ)))

(1 + sin (ϕ)))

Passive earth pressure coefficient Kp ≔ ――――= 3.255

(1 − sin (ϕ)))

Friction Coefficient μ ≔ 0.3

2.1.2 Concrete

Density of the Concrete is: γc ≔ 24.5 ――

3

Characteristic strength of concrete for the foundation is fcu ≔ 45

Cylindrical Concrete strength f'c ≔ 0.8 fcu = 36

2.1.3 Reinforcement Steel

Characteristic strength of reinforcement steel is (Deformed bars) fy ≔ 460

Yield strength of steel for shear calculation fys ≔ 420

Tower Crane Foundation Design

2 of 28

Masri Engineering & Contracting Est.(MEC) Date: 10/04/2018

P.O Box 45437, Abu Dhabi, UAE. Tel. +971 2 634 6633 Fax +97126346632

2.2.0 Loads

The Tower crane maximum reactions (Working loads) on chassis base Type V60A given by

the crane Instruction manual are as follows.

In-service Out of service

Moment Mi ≔ 0 ⋅ Mo ≔ 0 ⋅

Axial Force Pi ≔ 608 Po ≔ 502

70 135

Horizontal Reaction Hi ≔ ― = 17.5 Ho ≔ ―― = 33.75

4 4

Total Slewing torque Cmax ≔ 276 ⋅

3.0.0 STANDARDS REFERRED

3.1.0 Design codes of practices

BUILDING CODE REQUIREMENTS FOR STRUCTURAL CONCRETE (ACI 318M-14)

AND COMMENTARY (ACI 318RM-14)

3.2.0 Manuals and Hand books

Structural Foundation Designer's Manual by W.G Curtin, G.Shaw, G.I Parkinson & J.M

Golding.

Tower Crane Foundation Design

3 of 28

Masri Engineering & Contracting Est.(MEC) Date: 10/04/2018

P.O Box 45437, Abu Dhabi, UAE. Tel. +971 2 634 6633 Fax +97126346632

Case-1 Tower crane in service

Tower Crane Foundation Design

4 of 28

Masri Engineering & Contracting Est.(MEC) Date: 10/04/2018

P.O Box 45437, Abu Dhabi, UAE. Tel. +971 2 634 6633 Fax +97126346632

4.0.0 SLS Checks

4.1.0 Checks for bearing

The bearing capacity of the soil is σall = 80

Base size B ≔ 3.1 L ≔ 3.1 h ≔ 0.35

Slewing torque is resisted by the dk ≔ h = 0.35

foundation side faces.

Foundation depth df ≔ 1

Weight of the base Wbase ≔ γc ⋅ B ⋅ L ⋅ h = 82.406

Axial Force-P (from the Tower) Pi = 608

Eccentricity of to the Axial Force x direction epx ≔ 0.025

Eccentricity of to the Axial Force y direction epy ≔ 0.025

Moment -M (from the Tower) Mi = 0 ⋅

Horizontal Reaction-H (from the Tower) Hi = 17.5

Total axial load on the footing at SLS T ≔ Pi + Wbase = 690.406

Pi ⋅ epx L

Total Eccentricity of to the Axial Force x eTx ≔ ――― = 0.022 ―= 0.517

direction T 6

Mi + Pi ⋅ epy + Hi ⋅ h B

Total Eccentricity of to the Axial Force eTy ≔ ――――――= 0.031 ―= 0.517

y direction T 6

Hence total Moments on the footing at SLS MTx ≔ T ⋅ eTx = 15.2 ⋅

MTy ≔ T ⋅ eTy = 21.325 ⋅

Tower Crane Foundation Design

5 of 28

Masri Engineering & Contracting Est.(MEC) Date: 10/04/2018

P.O Box 45437, Abu Dhabi, UAE. Tel. +971 2 634 6633 Fax +97126346632

Figure 4.1 : Extract from Structural Foundation Designer's Manual

As per Figure 4.1,

Maximum pressure beneath the footing can be evaluated as below.

T MTx MTy

σmax ≔ ――+ 6 ―― + 6 ―― = 79.199

B⋅L B⋅L

2

L⋅B

2

Minimum pressure beneath the footing can be evaluated as below.

T MTx MTy

σmin ≔ ――− 6 ―― − 6 ―― = 64.486

B⋅L B⋅L

2

L⋅B

2

The footing is fully in compression and max bearing Pressure on soil is less than the allowable

bearing capacity of the soil.

Tower Crane Foundation Design

6 of 28

Masri Engineering & Contracting Est.(MEC) Date: 10/04/2018

P.O Box 45437, Abu Dhabi, UAE. Tel. +971 2 634 6633 Fax +97126346632

4.2.0 Checks for sliding

Horizontal reaction from tower crane is resisted by the Footing side face bearing on

the adjacent soil and the friction between the foundation bottom face and the soil:

2

Resisting force to the sliding Hr ≔ B ⋅ 0.5 ⋅ Kp ⋅ γs ⋅ (h) + μ ⋅ T = 217.627

Horizontal Reaction-H (from the Tower) Hi = 17.5

Hr

FOS against sliding ―― = 12.436

Hi

Hence FOS against sliding is adequate.

4.3.0 Checks against overturning

L ⎛L ⎞

Resisting moment Mst ≔ Wbase ⋅ ―+ Pi ⋅ ⎜―− epx⎟ = 1054.929 ⋅

2 ⎝2 ⎠

Overturning moment Mdest ≔ Mi + Hi ⋅ h = 6.125 ⋅

Mst

FOS against overturning ――= 172.233

Mdest

Hence Foundation is safe against overturning.

4.4.0 Checks against Rotation

Slewing torque is resisted by a 2 numbers of a dk = 0.35

Force couple acting on sides of the four footings

as per figure-1

distance between resultant forces at each side lk ≔ 6

available resistance by passive soil pressure

⎛ ⎛ dk ⎞ ⎞

Cr ≔ 2 ⋅ ⎜⎛⎝Kp − Ka⎞⎠ ⎜df − ―⎟ ⋅ γs ⋅ dk ⋅ B⎟ ⋅ lk = 538.199 ⋅

⎝ ⎝ 2⎠ ⎠

Slewing torque Cmax = 276 ⋅

0.5

Torsion Due to eccentricity Ti ≔ Hi ⋅ ⎛⎝epx + epy ⎞⎠

2 2

= 0.619 ⋅

Cr

FOS against rotaion ――――= 1.933

Cmax + 4 ⋅ Ti

Hence Foundation is safe against rotation.

Tower Crane Foundation Design

7 of 28

Masri Engineering & Contracting Est.(MEC) Date: 10/04/2018

P.O Box 45437, Abu Dhabi, UAE. Tel. +971 2 634 6633 Fax +97126346632

5.0.0 Ultimate Limit State Design

leg base plate FD ≔ 600

Assume a F.O.S of 1.6 at Ultimate Limit State.

The maximum bending moment at tower face can be found as follows.

The Pressure on soil at the base plate side

⎛ σmax ⎛ B F D ⎞⎞

σ1 ≔ ⎜―― ⋅ ⎜―+ epy + ―― ⎟⎟ = 47.902

⎝ B ⎝2 2 ⎠⎠

The Ultimate shear at the base plate side per 1m strip

will be

⎛⎝σ1 + σmax⎞⎠ ⎛ B FD ⎞

Vu ≔ 1.6 ―――― ⋅ ⎜―− epy − ―― ⎟⋅1 = 124.559

2 ⎝2 2 ⎠

the ultimate moment at base plate side

⎛B FD ⎞

⎜―− epy − ―― ⎟

⎝2 2 ⎠

Mu ≔ Vu ⋅ ―――――= 76.292 ⋅

2

(it should be noted that the moment is calculated for a 1m width strip of the footing)

Tower Crane Foundation Design

8 of 28

Masri Engineering & Contracting Est.(MEC) Date: 10/04/2018

P.O Box 45437, Abu Dhabi, UAE. Tel. +971 2 634 6633 Fax +97126346632

5.1.0 Check the adequacy of the Footing section for flexure:

Design for maximum ultimate bending moment:

Mu = 76.292 ⋅

GEOMETRY, PROPERTIES AND LOADING

Width of strip b ≔ 1000

Depth to tensile reinf dc ≔ 75

Effective depth d ≔ h − dc = 0.275

Depth to comp. reinf d' ≔ 100

Concrete strength f'c ≔ 0.8 fcu = 36

Yield strength of steel fy = 460

Concrete unit weight Wc ≔ 25 ――

3

‾‾‾‾‾

f'c

Modulus of elasticity Ec ≔ 4700 ⋅ ――= 28200

Modulus of elasticity Es ≔ 200000

The following quantities are computed for the load combination:

ϕ ≔ 0.9

‖ ⎛ ⎛⎝f'c − 28 ⎞⎠ ⎞ ||

β1 ≔ ‖ if ⎜0.85 − 0.05 ⋅ ――――― ⎟ > 0.85 ||

‖ ⎝ 7 ⎠

||

‖ ‖ β

‖ 1 ← 0.85 ||

‖ ||

⎛ ⎛⎝f'c − 28 ⎞⎠ ⎞

‖ else if 0.85 − 0.05 ⋅ ―――――

⎜ ⎟ < 0.65| |

‖ ⎝ 7 ⎠ ||

‖ ‖ β ← 0.65 ||

‖ ‖

1

||

‖ else ||

‖ ‖⎛ ⎛⎝f'c − 28 ⎞⎠ ⎞ ||

‖ ‖ ⎜0.85 − 0.05 ⋅ ――――― 7

⎟

⎝ ⎠

‖ ‖ ||

β1 = 0.793

0.003

Cmax ≔ ―――――⋅ d = 103.125

(0.003 + 0.005)

Tower Crane Foundation Design

9 of 28

Masri Engineering & Contracting Est.(MEC) Date: 10/04/2018

P.O Box 45437, Abu Dhabi, UAE. Tel. +971 2 634 6633 Fax +97126346632

amax ≔ β1 ⋅ Cmax = 81.763

Mu = 76.292 ⋅

The depth of the compression block is given by:

‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾

⎛ 2 2 ⋅ ||Mu|| ⎞

a≔d− ⎜d − ――――― ⎟ = 10.265

⎝ 0.85 ⋅ f'c ⋅ ϕ ⋅ b ⎠

check

a ≤ amax

The area of tensile steel reinforcement is then given by:

Mu 2

Asreq ≔ ――――― = 683

⎛ a⎞

ϕ ⋅ fy ⋅ ⎜d − ―

⎝ 2 ⎟⎠

h 2

Asmin ≔ 0.0025 ⋅ b ⋅ ―= 437.5

2

⎛ ⎛ 4 ⎞⎞ 2

As_req ≔ max ⎜Asreq , min ⎜Asmin , ―⋅ Asreq⎟⎟ = 683

⎝ ⎝ 3 ⎠⎠

2

Used steel: T16@150 As_used ≔ 1353

As_used > As_req

Tower Crane Foundation Design

10 of 28

Masri Engineering & Contracting Est.(MEC) Date: 10/04/2018

P.O Box 45437, Abu Dhabi, UAE. Tel. +971 2 634 6633 Fax +97126346632

5.2.0 Checks for shear

5.2.1 Check the adequacy of the foundation section for shear:

coefficient of static friction, .

ACI Sec. 11.6.4 defines the coefficient of friction as follows:

For concrete placed monolithically, = 1 4 .

For concrete placed against hardened and deliberately roughened concrete, with surface clean and

roughened to a minimum amplitude of 1/4 in, =1 0 .

For concrete placed against hardened concrete cleaned of laitance, but not roughened, = 0 6 .

For concrete placed against as-rolled, unpainted structural steel, = 0 7 .

The constant is 1.0 for normal weight concrete, 0.85 for sand-lightweight concrete, and 0.75 for

alllightweight concrete.

When shear friction reinforcement with an area of crosses the shear plane at right angles, which

is the usual case, the nominal shear strength is general expression for shear transfer when tensile

shear friction reinforcement crosses the shear plane at an acute angle.

GEOMETRY, PROPERTIES AND LOADING

coefficient of static friction: μ ≔ 0.6

shear Strength reduction factor: ϕ ≔ 0.75

Normal weight concrete: λ≔1

2

Area of reinforcement: Av ≔ As_used = 1353

Strip width: b ≔ 1000

section depth: h = 350

Area of concrete section: Ac ≔ b ⋅ h

V1 ≔ λ ⋅ μ ⋅ Av ⋅ fys = 340.956

V2 ≔ 0.2 ⋅ f'c ⋅ Ac = 2520

V3 ≔ (5.5 ) ⋅ Ac = 1925

Vn ≔ min ⎛⎝V1 , V2 , V3⎞⎠

Vn = 340.956

Ultimate shear friction capacity: ϕ ⋅ Vn = 255.717

Ultimate shear Force: Vu = 124.559

Vu < ϕ ⋅ Vn

Tower Crane Foundation Design

11 of 28

Masri Engineering & Contracting Est.(MEC) Date: 10/04/2018

P.O Box 45437, Abu Dhabi, UAE. Tel. +971 2 634 6633 Fax +97126346632

5.2.2 Check for punching shear:

(Design of punching shear according to ACI318-11)

Material properties:

Concrete compressive strength f'c = 36

Reinforcement yield strength fys ≔ 420

Shear strength reduction factor ϕs ≔ 0.75

Normal weight concrete strength reduction factor: Lm ≔ 1

Applied forces:

Ultimate reaction per leg: Vu ≔ 1.6 ⋅ Pi = 972.8

Ultimate bending moment: Mu1 ≔ 0 ⋅

Section properties:

Footing thickness h = 0.35

Cover to center of steel rebars Cc ≔ 75

Foundation effective depth: d ≔ h − Cc = 0.275

leg base plate FD ≔ 600

Punching side parallel to bending: b1 ≔ FD + d = 0.875

Punching side perpendicular to bending: b2 ≔ FD + d = 0.875

Punching perimeter of critical section

located at d/2 from Base plate perimeter:b0 ≔ 2 ⎛⎝b1 + b2⎞⎠ = 3500

2

Punching area of critical section Ac ≔ b0 ⋅ d = 962500

⎛b ⋅ d ⋅ ⎛b + 3 b ⎞ + d 3 ⎞

⎝ 1 ⎝ 1 2⎠ ⎠ 3

Modulus of critical section JC ≔ ―――――――― = 287661458.33

3

Tower Crane Foundation Design

12 of 28

Masri Engineering & Contracting Est.(MEC) Date: 10/04/2018

P.O Box 45437, Abu Dhabi, UAE. Tel. +971 2 634 6633 Fax +97126346632

Applied shear stress:

Portion of unbalanced moment transferred by eccentricity of shear

⎛ 1 ⎞

av ≔ 1 − ⎜――――― = 0.4

⎛ 2⎞⎟

2 ⎛ b ⎞

⎜ ⎜1 + ― ⋅ ⎜―⎟ ⎟ ⎟

1

⎜⎝ ⎝ 3 ⎝ b2 ⎠ ⎠ ⎟⎠

Vu

Direct Shear stress: Vu1 ≔ ―― = 1.011

Ac

Mu1

Indirect shear stress due to unbalanced moment Vu2 ≔ av ⋅ ―― =0

transferred by eccentricity of shear JC

Maximum applied shear stress on critical side of Base plate Vu ≔ Vu1 + Vu2 = 1.011

Check adequacy of foundation effective depth:

‾‾‾‾‾

⎛⎝f'c⎞⎠

vu_max ≔ ϕs ⋅ 0.5 ⋅ ――⋅ = 2.25

Vu < vu_max

Concrete shear stress for foundation without shear

reinforcement:

FD

pc ≔ ―― =1 ratio of long to short side of Base plate as ≔ 40 interior Base plate

FD

b0

po ≔ ― = 12.727 ratio of punching perimeter to slab effective depth for interior Base plate

d

Concrete shear stress is the minimum of the following three values :

⎛ 2⎞ ‾‾‾‾‾

⎛⎝f'c⎞⎠

Vc1 ≔ ϕs ⋅ 0.17 ⋅ ⎜1 + ―⎟ ⋅ Lm ⋅ ――⋅ = 2.295

⎝ pc ⎠

⎛ as ⎞ ‾‾‾‾‾

⎛⎝f'c⎞⎠

Vc2 ≔ ϕs ⋅ 0.083 ⋅ ⎜2 + ―⎟ ⋅ Lm ⋅ ――⋅ = 1.921

⎝ po ⎠

‾‾‾‾‾

⎛⎝f'c⎞⎠

Vc3 ≔ ϕs ⋅ 0.33 ⋅ Lm ⋅ ――⋅ = 1.485

Vc ≔ min ⎛⎝Vc1 , Vc2 , Vc3⎞⎠ = 1.485

Check Section requirement for shear reinforcement:

Vu = 1.011 Vc = 1.485

Vu < Vc

Tower Crane Foundation Design

13 of 28

Masri Engineering & Contracting Est.(MEC) Date: 10/04/2018

P.O Box 45437, Abu Dhabi, UAE. Tel. +971 2 634 6633 Fax +97126346632

5.3.0 Check for Crack Width:

GEOMETRY, PROPERTIES AND LOADING

Foundation thickness h = 0.35

Width of strip b = 1000

Cover to center of tension reinforcement ct ≔ 75

Cover to center of compression reinforcement cc ≔ 75

Effective depth d ≔ h − ct = 0.275

Concrete strength f'c = 36

Yield strength of steel fy = 460

‾‾‾‾‾

f'c

Modulus of elasticity Ec ≔ 4700 ⋅ ――= 28200

Modulus of elasticity Es ≔ 200000

Es

Modular ratio n ≔ ― = 7.092

Ec

Mu

Applied service moment Ma ≔ ―― = 47.683 ⋅

1.6

Tension reinforcement:

diameter of tension bars dt ≔ 16

tension bars spacing c/c St ≔ 150

2

dt 2

Area of tension steel per strip width Ast ≔ ⋅ ―― ⋅ 1000 ―― = 1340.413

4 St

Compression reinforcement:

diameter of compression bars dc ≔ 16

Compression bars spacing c/c Sc ≔ 150

2

dt 2

Area of Compression steel per strip width Asc ≔ ⋅ ―― ⋅ 1000 ―― = 1340.413

4 Sc

Tower Crane Foundation Design

14 of 28

Masri Engineering & Contracting Est.(MEC) Date: 10/04/2018

P.O Box 45437, Abu Dhabi, UAE. Tel. +971 2 634 6633 Fax +97126346632

Section properties at cracking stage

b 1

b1 ≔ ――― = 0.105 ――

⎛⎝n ⋅ Ast⎞⎠

⎛⎝(n − 1) ⋅ Asc⎞⎠

r ≔ ――――― = 0.859

⎛⎝n ⋅ Ast⎞⎠

⎛ ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾

⎛ ⎛ cc ⎞ 2⎞ ⎞

⎜ ⎜2 ⋅ d ⋅ b1 ⋅ ⎜1 + r ⋅ ―⎟ + (1 + r) ⎟ − (1 + r)⎟

⎝ ⎝ ⎝ d⎠ ⎠ ⎠

y ≔ ―――――――――――――― = 64.582

b 1

⎛⎝b ⋅ h 3 ⎞⎠ 4

Ig ≔ ――― = 3572916666.67

12

⎛⎝b ⋅ y 3 ⎞⎠ ⎛ 2⎞ 2 4

Icr ≔ ――― + ⎝n ⋅ Ast ⋅ (d − y) ⎠ + (n − 1) ⋅ Asc ⋅ (y − cc) = 511579381.48

3

‾‾‾‾‾

f'c

fr ≔ 0.62 ⋅ ――= 3.72

⎛⎝fr ⋅ Ig⎞⎠

Mcr ≔ ――― = 75.95 ⋅

h

―

2

Stress strain compatibility analysis characteristics

(d − y)

fs ≔ n ⋅ Ma ⋅ ――― = 139.095

Icr

y

fc ≔ Ma ⋅ ― = 6.019

Icr

Calculating crack width

(h − y)

β ≔ ――― = 1.356

(d − y)

⎛ dt ⎞

ctused ≔ min ⎜ct , 50 + ―⎟ = 58 ACI350, clause R10.6.4

⎝ 2⎠

t ≔ 2 ⋅ ⎛⎝ctused⎞⎠ = 116

b t 2

nt ≔ ―= 6.667 ac ≔ b ⋅ ―= 17400

St nt

Gergely-Lutz equation for estimated crack width:

⎛ fs 3 ⎞

‾‾‾‾‾‾‾‾

⎜0.011 ⋅ β ⋅ ―― ⎛⎝ac ⋅ ctused⎞⎠ ⎟

⎝ ⎠

Wcrack ≔ ―――――――――― = 0.208 <0.3 mm

1000

Tower Crane Foundation Design

15 of 28

Masri Engineering & Contracting Est.(MEC) Date: 10/04/2018

P.O Box 45437, Abu Dhabi, UAE. Tel. +971 2 634 6633 Fax +97126346632

Case-2 Tower crane out of service

Tower Crane Foundation Design

16 of 28

Masri Engineering & Contracting Est.(MEC) Date: 10/04/2018

P.O Box 45437, Abu Dhabi, UAE. Tel. +971 2 634 6633 Fax +97126346632

6.0.0 SLS Checks

6.1.0 Checks for bearing

The bearing capacity of the soil is σall = 80

Base size B = 3.1 L = 3.1 h = 0.35

Slewing torque is resisted by the footing side dk ≔ h = 0.35

faces

Weight of the base Wbase ≔ γc ⋅ B ⋅ L ⋅ h = 82.406

Axial Force-P (from the Tower) Po = 502

Eccentricity of to the Axial Force x direction epx ≔ 0.025

Eccentricity of to the Axial Force y direction epy ≔ 0.025

Moment -M (from the Tower) Mo = 0 ⋅

Horizontal Reaction-H (from the Tower) Ho = 33.75

Hence total axial load on the footing at SLS T ≔ Po + Wbase = 584.406

Po ⋅ epx L

Total Eccentricity of to the Axial Force x eTx ≔ ――― = 0.021 ―= 0.517

direction T 6

Mo + Po ⋅ epy + Ho ⋅ h B

Total Eccentricity of to the Axial Force eTy ≔ ――――――― = 0.042 ―= 0.517

y direction T 6

Hence total Moments on the footing at SLS MTx ≔ T ⋅ eTx = 12.55 ⋅

MTy ≔ T ⋅ eTy = 24.363 ⋅

Tower Crane Foundation Design

17 of 28

Masri Engineering & Contracting Est.(MEC) Date: 10/04/2018

P.O Box 45437, Abu Dhabi, UAE. Tel. +971 2 634 6633 Fax +97126346632

Figure 4.1 : Extract from Structural Foundation Designer's Manual

As per Figure 4.1,

Maximum pressure beneath the footing can be evaluated as below.

T MTx MTy

σmax ≔ ――+ 6 ―― + 6 ―― = 68.247

B⋅L B⋅L

2

L⋅B

2

Minimum pressure beneath the footing can be evaluated as below.

T MTx MTy

σmin ≔ ――− 6 ―― − 6 ―― = 53.378

B⋅L B⋅L

2

L⋅B

2

The footing is fully in compression and max bearing Pressure on soil is less than the allowable

bearing capacity of the soil .

Tower Crane Foundation Design

18 of 28

Masri Engineering & Contracting Est.(MEC) Date: 10/04/2018

P.O Box 45437, Abu Dhabi, UAE. Tel. +971 2 634 6633 Fax +97126346632

6.2.0 Checks for sliding

Horizontal reaction from tower crane is resisted by the Footing side face bearing on

the adjacent soil and the friction between the foundation bottom face and the soil:

Hr ≔ B ⋅ 0.5 ⋅ ⎛⎝Kp ⋅ γs ⋅ (h) ⎞⎠ + μ ⋅ T = 361.149

2

Resisting force to the sliding

Horizontal Reaction-H (from the Tower) Ho = 33.75

Hr

FOS against sliding ―― = 10.701

Ho

Hence FOS against sliding is adequate.

4.3.0 Checks against overturning

L ⎛L ⎞

Resisting moment Mst ≔ Wbase ⋅ ―+ Po ⋅ ⎜―− epx⎟ = 893.279 ⋅

2 ⎝2 ⎠

Overturning moment Mdest ≔ Mi + Hi ⋅ h = 6.125 ⋅

Mst

FOS against overturning ――= 145.841

Mdest

Hence Foundation is safe against overturning.

4.4.0 Checks against Rotation

Slewing torque in case of out of service: Cmax ≔ 0 ⋅

no check for rotation is required.

Tower Crane Foundation Design

19 of 28

Masri Engineering & Contracting Est.(MEC) Date: 10/04/2018

P.O Box 45437, Abu Dhabi, UAE. Tel. +971 2 634 6633 Fax +97126346632

7.0.0 Ultimate Limit State Design

leg base plate width: FD ≔ 0.6

Assume a F.O.S of 1.6 at Ultimate Limit State.

The maximum bending moment at base plate side can be found as follows.

The Pressure on soil at the base plate side

⎛ σmax ⎛ B F D ⎞⎞

σ1 ≔ ⎜―― ⋅ ⎜―+ epy + ―― ⎟⎟ = 41.278

⎝ B ⎝2 2 ⎠⎠

The Ultimate shear at the base plate side per 1m strip will be

⎛⎝σ1 + σmax⎞⎠ ⎛ B FD ⎞

Vu ≔ 1.6 ―――― ⋅ ⎜―− epy − ―― ⎟⋅1 = 107.334

2 ⎝2 2 ⎠

the ultimate moment at base plate side

⎛B FD ⎞

⎜―− epy − ―― ⎟

⎝2 2 ⎠

Mu ≔ Vu ⋅ ―――――= 65.742 ⋅

2

(it should be noted that the moment is calculated for a 1m width strip of the footing)

Tower Crane Foundation Design

20 of 28

Masri Engineering & Contracting Est.(MEC) Date: 10/04/2018

P.O Box 45437, Abu Dhabi, UAE. Tel. +971 2 634 6633 Fax +97126346632

7.1.0 Check the adequacy of the Footing section for flexure:

Design for maximum ultimate bending moment:

Mu = 65.742 ⋅

GEOMETRY, PROPERTIES AND LOADING

Width of strip b ≔ 1000

Depth to tensile reinf dc ≔ 75

Effective depth d ≔ h − dc = 0.275

Depth to comp. reinf d' ≔ 75

Concrete strength f'c ≔ 0.8 fcu = 36

Yield strength of steel fy = 460

Concrete unit weight Wc ≔ 25 ――

3

‾‾‾‾‾

f'c

Modulus of elasticity Ec ≔ 4700 ⋅ ――= 28200

Modulus of elasticity Es ≔ 200000

The following quantities are computed for the load combination:

ϕ ≔ 0.9

‖ ⎛ ⎛⎝f'c − 28 ⎞⎠ ⎞ ||

β1 ≔ ‖ if ⎜0.85 − 0.05 ⋅ ――――― ⎟ > 0.85 ||

‖ ⎝ 7 ⎠

||

‖ ‖ β

‖ 1 ← 0.85 ||

‖ ||

⎛ ⎛⎝f'c − 28 ⎞⎠ ⎞

‖ else if 0.85 − 0.05 ⋅ ―――――

⎜ ⎟ < 0.65| |

‖ ⎝ 7 ⎠ ||

‖ ‖ β ← 0.65 ||

‖ ‖

1

||

‖ else ||

‖ ‖⎛ ⎛⎝f'c − 28 ⎞⎠ ⎞ ||

‖ ‖ ⎜0.85 − 0.05 ⋅ ――――― 7

⎟

⎝ ⎠

‖ ‖ ||

β1 = 0.793

0.003

Cmax ≔ ―――――⋅ d = 103.125

(0.003 + 0.005)

Tower Crane Foundation Design

21 of 28

Masri Engineering & Contracting Est.(MEC) Date: 10/04/2018

P.O Box 45437, Abu Dhabi, UAE. Tel. +971 2 634 6633 Fax +97126346632

amax ≔ β1 ⋅ Cmax = 81.763

Mu = 65.742 ⋅

The depth of the compression block is given by:

‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾

⎛ 2 2 ⋅ ||Mu|| ⎞

a≔d− ⎜d − ――――― ⎟ = 8.822

⎝ 0.85 ⋅ f'c ⋅ ϕ ⋅ b ⎠

check

a ≤ amax

The area of tensile steel reinforcement is then given by:

Mu 2

Asreq ≔ ――――― = 587

⎛ a⎞

ϕ ⋅ fy ⋅ ⎜d − ―

⎝ 2 ⎟⎠

h 2

Asmin ≔ 0.0025 ⋅ b ⋅ ―= 437.5

2

⎛ ⎛ 4 ⎞⎞ 2

As_req ≔ max ⎜Asreq , min ⎜Asmin , ―⋅ Asreq⎟⎟ = 587

⎝ ⎝ 3 ⎠⎠

2

Used steel: T16@150 As_used ≔ 1353

As_used > As_req

Tower Crane Foundation Design

22 of 28

Masri Engineering & Contracting Est.(MEC) Date: 10/04/2018

P.O Box 45437, Abu Dhabi, UAE. Tel. +971 2 634 6633 Fax +97126346632

7.2.0 Checks for shear

7.2.1 Check the adequacy of the foundation section for shear:

coefficient of static friction, .

ACI Sec. 11.6.4 defines the coefficient of friction as follows:

For concrete placed monolithically, = 1 4 .

For concrete placed against hardened and deliberately roughened concrete, with surface clean and

roughened to a minimum amplitude of 1/4 in, =1 0 .

For concrete placed against hardened concrete cleaned of laitance, but not roughened, = 0 6 .

For concrete placed against as-rolled, unpainted structural steel, = 0 7 .

The constant is 1.0 for normal weight concrete, 0.85 for sand-lightweight concrete, and 0.75 for

alllightweight concrete.

When shear friction reinforcement with an area of crosses the shear plane at right angles, which

is the usual case, the nominal shear strength is general expression for shear transfer when tensile

shear friction reinforcement crosses the shear plane at an acute angle.

GEOMETRY, PROPERTIES AND LOADING

coefficient of static friction: μ ≔ 0.6

shear Strength reduction factor: ϕ ≔ 0.75

Normal weight concrete: λ≔1

2

Area of reinforcement: Av ≔ As_used = 1353

Strip width: b ≔ 1000

section depth: h = 350

Area of concrete section: Ac ≔ b ⋅ h

V1 ≔ λ ⋅ μ ⋅ Av ⋅ fys = 340.956

V2 ≔ 0.2 ⋅ f'c ⋅ Ac = 2520

V3 ≔ (5.5 ) ⋅ Ac = 1925

Vn ≔ min ⎛⎝V1 , V2 , V3⎞⎠

Vn = 340.956

Ultimate shear friction capacity: ϕ ⋅ Vn = 255.717

Ultimate shear Force: Vu = 107.334

Vu < ϕ ⋅ Vn

Tower Crane Foundation Design

23 of 28

Masri Engineering & Contracting Est.(MEC) Date: 10/04/2018

P.O Box 45437, Abu Dhabi, UAE. Tel. +971 2 634 6633 Fax +97126346632

7.2.2 Check for punching shear:

(Design of punching shear according to ACI318-11)

Material properties:

Concrete compressive strength f'c = 36

Reinforcement yield strength fys ≔ 420

Shear strength reduction factor ϕs ≔ 0.75

Normal weight concrete strength reduction factor: Lm ≔ 1

Applied forces:

Ultimate reaction per leg: Vu ≔ 1.6 ⋅ Po = 803.2

Ultimate bending moment: Mu1 ≔ 0 ⋅

Section properties:

Footing thickness h = 0.35

Cover to center of steel rebars Cc ≔ 75

Foundation effective depth: d ≔ h − Cc = 0.275

leg base plate FD ≔ 600

Punching side parallel to bending: b1 ≔ FD + d = 875

Punching side perpendicular to bending: b2 ≔ FD + d = 875

Punching perimeter of critical section

located at d/2 from Base plate perimeter:b0 ≔ 2 ⎛⎝b1 + b2⎞⎠ = 3500

2

Punching area of critical section Ac ≔ b0 ⋅ d = 962500

⎛b ⋅ d ⋅ ⎛b + 3 b ⎞ + d 3 ⎞

⎝ 1 ⎝ 1 2⎠ ⎠ 3

Modulus of critical section JC ≔ ―――――――― = 287661458.33

3

Tower Crane Foundation Design

24 of 28

Masri Engineering & Contracting Est.(MEC) Date: 10/04/2018

P.O Box 45437, Abu Dhabi, UAE. Tel. +971 2 634 6633 Fax +97126346632

Applied shear stress:

Portion of unbalanced moment transferred by eccentricity of shear

⎛ 1 ⎞

av ≔ 1 − ⎜――――― = 0.4

⎛ 2⎞⎟

2 ⎛ b ⎞

⎜ ⎜1 + ― ⋅ ⎜―⎟ ⎟ ⎟

1

⎜⎝ ⎝ 3 ⎝ b2 ⎠ ⎠ ⎟⎠

Vu

Direct Shear stress: Vu1 ≔ ―― = 0.834

Ac

Mu1

Indirect shear stress due to unbalanced moment Vu2 ≔ av ⋅ ―― =0

transferred by eccentricity of shear JC

Maximum applied shear stress on critical side of Base plate Vu ≔ Vu1 + Vu2 = 0.834

Check adequacy of foundation effective depth:

‾‾‾‾‾

⎛⎝f'c⎞⎠

vu_max ≔ ϕs ⋅ 0.5 ⋅ ――⋅ = 2.25

Vu < vu_max

Concrete shear stress for foundation without shear

reinforcement:

FD

pc ≔ ―― =1 ratio of long to short side of Base plate as ≔ 40 interior Base plate

FD

b0

po ≔ ― = 12.727 ratio of punching perimeter to slab effective depth for interior Base plate

d

Concrete shear stress is the minimum of the following three values :

⎛ 2⎞ ‾‾‾‾‾

⎛⎝f'c⎞⎠

Vc1 ≔ ϕs ⋅ 0.17 ⋅ ⎜1 + ―⎟ ⋅ Lm ⋅ ――⋅ = 2.295

⎝ pc ⎠

⎛ as ⎞ ‾‾‾‾‾

⎛⎝f'c⎞⎠

Vc2 ≔ ϕs ⋅ 0.083 ⋅ ⎜2 + ―⎟ ⋅ Lm ⋅ ――⋅ = 1.921

⎝ po ⎠

‾‾‾‾‾

⎛⎝f'c⎞⎠

Vc3 ≔ ϕs ⋅ 0.33 ⋅ Lm ⋅ ――⋅ = 1.485

Vc ≔ min ⎛⎝Vc1 , Vc2 , Vc3⎞⎠ = 1.485

Check section requirement for shear reinforcement:

Vu = 0.834 Vc = 1.485

Vu < Vc

Tower Crane Foundation Design

25 of 28

Masri Engineering & Contracting Est.(MEC) Date: 10/04/2018

P.O Box 45437, Abu Dhabi, UAE. Tel. +971 2 634 6633 Fax +97126346632

7.3.0 Check for Crack Width:

GEOMETRY, PROPERTIES AND LOADING

Foundation thickness h = 0.35

Width of strip b = 1000

Cover to center of tension reinforcement ct ≔ 75

Cover to center of compression reinforcement cc ≔ 75

Effective depth d ≔ h − ct = 0.275

Concrete strength f'c = 36

Yield strength of steel fy = 460

‾‾‾‾‾

f'c

Modulus of elasticity Ec ≔ 4700 ⋅ ――= 28200

Modulus of elasticity Es ≔ 200000

Es

Modular ratio n ≔ ― = 7.092

Ec

Mu

Applied service moment Ma ≔ ―― = 41.089 ⋅

1.6

Tension reinforcement:

diameter of tension bars dt ≔ 16

tension bars spacing c/c St ≔ 150

2

dt 2

Area of tension steel per strip width Ast ≔ ⋅ ―― ⋅ 1000 ―― = 1340.413

4 St

Compression reinforcement:

diameter of compression bars dc ≔ 16

Compression bars spacing c/c Sc ≔ 150

2

dc 2

Area of Compression steel per strip width Asc ≔ ⋅ ―― ⋅ 1000 ―― = 1340.413

4 St

Tower Crane Foundation Design

26 of 28

Masri Engineering & Contracting Est.(MEC) Date: 10/04/2018

P.O Box 45437, Abu Dhabi, UAE. Tel. +971 2 634 6633 Fax +97126346632

Section properties at cracking stage

b 1

b1 ≔ ――― = 0.105 ――

⎛⎝n ⋅ Ast⎞⎠

⎛⎝(n − 1) ⋅ Asc⎞⎠

r ≔ ――――― = 0.859

⎛⎝n ⋅ Ast⎞⎠

⎛ ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾

⎛ ⎛ cc ⎞ 2⎞ ⎞

⎜ ⎜2 ⋅ d ⋅ b1 ⋅ ⎜1 + r ⋅ ―⎟ + (1 + r) ⎟ − (1 + r)⎟

⎝ ⎝ ⎝ d⎠ ⎠ ⎠

y ≔ ―――――――――――――― = 64.582

b 1

⎛⎝b ⋅ h 3 ⎞⎠ 4

Ig ≔ ――― = 3572916666.67

12

⎛⎝b ⋅ y 3 ⎞⎠ ⎛ 2⎞ 2 4

Icr ≔ ――― + ⎝n ⋅ Ast ⋅ (d − y) ⎠ + (n − 1) ⋅ Asc ⋅ (y − cc) = 511579381.48

3

‾‾‾‾‾

f'c

fr ≔ 0.62 ⋅ ――= 3.72

⎛⎝fr ⋅ Ig⎞⎠

Mcr ≔ ――― = 75.95 ⋅

h

―

2

Stress strain compatibility analysis characteristics

(d − y)

fs ≔ n ⋅ Ma ⋅ ――― = 119.86

Icr

y

fc ≔ Ma ⋅ ― = 5.187

Icr

Calculating crack width

(h − y)

β ≔ ――― = 1.356

(d − y)

⎛ dt ⎞

ctused ≔ min ⎜ct , 50 + ―⎟ = 58 ACI350, clause R10.6.4

⎝ 2⎠

t ≔ 2 ⋅ ⎛⎝ctused⎞⎠ = 116

b t 2

nt ≔ ―= 6.667 ac ≔ b ⋅ ―= 17400

St nt

Gergely-Lutz equation for estimated crack width:

⎛ fs 3 ⎞

‾‾‾‾‾‾‾‾

⎜0.011 ⋅ β ⋅ ―― ⎛⎝ac ⋅ ctused⎞⎠ ⎟

⎝ ⎠

Wcrack ≔ ―――――――――― = 0.179 <0.3 mm

1000

Tower Crane Foundation Design

27 of 28

Masri Engineering & Contracting Est.(MEC) Date: 10/04/2018

P.O Box 45437, Abu Dhabi, UAE. Tel. +971 2 634 6633 Fax +97126346632

8.0.0 Conclusion:

The analysis and design of the crane foundation was carried out as per applicable codes

based on the loads and reactions of the tower crane as provided in the crane

datasheets, accordingly, The tower crane foundation with dimensions B = 3.1 ,

L = 3.1 & h = 0.35 was found to be structural adequate and safe to withstand the

tower crane reactions.

Tower Crane Foundation Design

28 of 28

8.0 CHOICE OF SUITABLE TYPE OF FOUNDATION & RECOMMENDATIONS

The suitable type of foundations for a given structure depends mostly on the character of the

soil, the presence of the water at the site and the magnitude of the imposed loads and project

characteristics.

The following site surface and subsurface conditions, project characteristics and the results of

the field and laboratory tests are considered in choosing the appropriate foundations. For this

particular site:

1. It is proposed to construct Al Falah Plaza Residential Complex.

2. Medium dense to dense, sandy layer encountered at a depth of 1.5m to 5.5m below

the existing ground level (made ground).

3. Rock layer was encountered at a depth of 4.5m to 6.0mm and up to the end of boring

20.0m below the existing ground level.

Therefore, the recommended suitable type of foundation to be used for the main structures,

project is deep (pile) foundation. For light weight structures & boundary wall, shallow

foundation could also be used.

* Suspended Slab or Slab on grade could also be used.

* The foundation shall be protected by using water proof membrane or bitumen coating.

8.1. SHALLOW FOUNDATIONS FOR LIGHT WEIGHT STRUCTURE (Boundary Wall)

Based on the results of the Standard Penetration Test and the equations presented before, it is

recommended to lay the foundation of the proposed boundary wall at a depth not shallower than

1.0m below the existing ground level considering a factor of safety of three (F.S=3) against shear

failure and total settlement not exceeding 25.0mm. The recommended net allowable bearing pressure

value of 80 kPa could be used for the design of the foundation.

Foundation ground should be compacted to a degree of compaction not less than 95 percent

of its maximum dry density as obtained by modified proctor test (ASTM D-1557).

8.2 DEEP PILE FOUNDATION (PILES ON ROCK)

8.2.1. Pile Bearing Capacity

Based on the results of the unconfined compressive strength for intact rock and the equations

presented before the estimated ultimate unit skin friction and base resistance of ground materials are

presented in Table No.2 and the allowable working loads of piles considering factor of safety 3.0 are

presented in Table No.3.

18

S17.SI.0243

Das könnte Ihnen auch gefallen

- MC 205 B - Jib50m - P20a - h50.4 - Foundation - CompleteDokument29 SeitenMC 205 B - Jib50m - P20a - h50.4 - Foundation - CompleteNageswar Rao100% (2)

- Zoomlion TC6520-10D Foundation 101114Dokument25 SeitenZoomlion TC6520-10D Foundation 101114Amud S'hyosokaNoch keine Bewertungen

- Microsoft Word - Annex L Tower Crane Footing Structural Design For TC 1, 3, 4 & 5Dokument14 SeitenMicrosoft Word - Annex L Tower Crane Footing Structural Design For TC 1, 3, 4 & 5Revathy RanjithNoch keine Bewertungen

- Operation Manual: Temporarily Installed Suspended Access EquipmentDokument35 SeitenOperation Manual: Temporarily Installed Suspended Access EquipmentfuadkhoirulNoch keine Bewertungen

- F0.23B Tower CranDokument52 SeitenF0.23B Tower Cranlayaljamal2Noch keine Bewertungen

- Ctl140 Ts16 NewDokument11 SeitenCtl140 Ts16 NewRobert XieNoch keine Bewertungen

- Concise Manual RCVC.1.4 ENG PDFDokument58 SeitenConcise Manual RCVC.1.4 ENG PDFdsn_sarma0% (1)

- Back ProppingDokument6 SeitenBack ProppingMihai CojocaruNoch keine Bewertungen

- Anupam - TowerCrane - A806Dokument6 SeitenAnupam - TowerCrane - A806JnanamNoch keine Bewertungen

- Ijirae:: Tower Crne Mast Anchorage Tie DesignDokument8 SeitenIjirae:: Tower Crne Mast Anchorage Tie DesignIJIRAE- International Journal of Innovative Research in Advanced EngineeringNoch keine Bewertungen

- Tower Crane Loading CalculationDokument5 SeitenTower Crane Loading CalculationFranklyn Genove100% (1)

- CTL630B Tower Crane Erection Method StatementDokument52 SeitenCTL630B Tower Crane Erection Method StatementDhanjay SinghNoch keine Bewertungen

- Crane SpecificationDokument17 SeitenCrane Specificationrasiuom100% (1)

- Tower Crane Foundation DesignDokument25 SeitenTower Crane Foundation Designyousuf79Noch keine Bewertungen

- TEL Derrick Brochure - WebsiteDokument8 SeitenTEL Derrick Brochure - WebsitePete ANoch keine Bewertungen

- Foundation Reaction Force - HankookDokument6 SeitenFoundation Reaction Force - HankookPapa KingNoch keine Bewertungen

- 2016-FL3030说明书50m臂长最后版-2016 11 3 PDFDokument96 Seiten2016-FL3030说明书50m臂长最后版-2016 11 3 PDFMohammed SumerNoch keine Bewertungen

- Tower Crane Anchoring Frame DesignDokument12 SeitenTower Crane Anchoring Frame Designmosros123100% (1)

- Tower Crane Sun - STT293Dokument60 SeitenTower Crane Sun - STT293Ignacio Luis Reig Mataix50% (2)

- Potain Md208aDokument4 SeitenPotain Md208aMiguel F. SalasNoch keine Bewertungen

- Operation Manual GuindolasDokument24 SeitenOperation Manual GuindolasReyes VargasNoch keine Bewertungen

- Design Calculation Tower Crane Soil OnlyDokument2 SeitenDesign Calculation Tower Crane Soil OnlyJohn Rom CabadonggaNoch keine Bewertungen

- Daf1 Tower Crane DesignDokument21 SeitenDaf1 Tower Crane DesignnabilNoch keine Bewertungen

- Tower Mobile Scaffolds Information SheetDokument2 SeitenTower Mobile Scaffolds Information SheetthecrowdedhouseNoch keine Bewertungen

- Daily Maintenance of Tower CraneDokument79 SeitenDaily Maintenance of Tower Craneedward dennis salvador quintoNoch keine Bewertungen

- TECHNICAL NOTE 011 Lateral Loads On Falsework - Is Cross-Bracing Really Not Required at All PDFDokument2 SeitenTECHNICAL NOTE 011 Lateral Loads On Falsework - Is Cross-Bracing Really Not Required at All PDFmyduyen75Noch keine Bewertungen

- 130 HC Liebherr ChartDokument6 Seiten130 HC Liebherr ChartMohamed Elsayed100% (1)

- Corner pressures, foundation loadings, ballast data for 200 EC-HM 6/10 Tower CranesDokument66 SeitenCorner pressures, foundation loadings, ballast data for 200 EC-HM 6/10 Tower CranespgiautNoch keine Bewertungen

- Tower Crane Foundation RevisedDokument11 SeitenTower Crane Foundation Revisedajith chandranNoch keine Bewertungen

- 3 Tower Crane FoundationDokument16 Seiten3 Tower Crane FoundationASearthNoch keine Bewertungen

- Tower-Cranes Range-Brochure A4 en PDFDokument24 SeitenTower-Cranes Range-Brochure A4 en PDFFejzulla MurtezaniNoch keine Bewertungen

- DG7 Gass Design Guide Rev G PDFDokument54 SeitenDG7 Gass Design Guide Rev G PDFAnonymous BAYE9xVnLNoch keine Bewertungen

- Structural Report for Tower Crane 7 Steel BracingDokument64 SeitenStructural Report for Tower Crane 7 Steel BracingFranklyn Genove100% (2)

- Luffing jib tower crane load diagram and specificationsDokument1 SeiteLuffing jib tower crane load diagram and specificationsDahanTowerCraneNoch keine Bewertungen

- LC 1600 load chart diagram documentDokument4 SeitenLC 1600 load chart diagram documentJuan P RuizNoch keine Bewertungen

- Guide To Safe Lifting & ProppingDokument34 SeitenGuide To Safe Lifting & ProppingAlly KhooNoch keine Bewertungen

- Tower CraneDokument4 SeitenTower Cranemordidomi50% (2)

- Efficiency at Height: Tower CranesDokument16 SeitenEfficiency at Height: Tower Cranesmd.amer mohiuddinNoch keine Bewertungen

- Project Info Board Detail DimensionsDokument1 SeiteProject Info Board Detail Dimensionsrakib06Noch keine Bewertungen

- Tower Crane TieDokument2 SeitenTower Crane TieLem Teoh100% (1)

- Crane Tower MC - 125 - Footing StabilityDokument8 SeitenCrane Tower MC - 125 - Footing StabilityLutswing Ral Carrera Uwak100% (1)

- Tower Crane Raft Design ReportDokument22 SeitenTower Crane Raft Design ReportFranklyn Genove100% (4)

- Slip Form (Our Report)Dokument16 SeitenSlip Form (Our Report)Simran DeepNoch keine Bewertungen

- ST 100 Stacking Tower: ShoringDokument32 SeitenST 100 Stacking Tower: ShoringPrimelift Safety Resources LimitedNoch keine Bewertungen

- Shisham Props Technical Data SheetDokument1 SeiteShisham Props Technical Data SheetCatherine Fatima Mae LeynoNoch keine Bewertungen

- Liebherr 316 ECH 12Dokument8 SeitenLiebherr 316 ECH 12Dusty RockNoch keine Bewertungen

- Tower Crane FDN On Permanent Raft Check For StabilityDokument5 SeitenTower Crane FDN On Permanent Raft Check For Stabilityvenkatram PadalaNoch keine Bewertungen

- Tower Crane: Jaso Equipos de Obras Y Construcciones, S.LDokument4 SeitenTower Crane: Jaso Equipos de Obras Y Construcciones, S.LCosmin StanciuNoch keine Bewertungen

- FPS Bearing PDFDokument5 SeitenFPS Bearing PDFrohitgorasiaNoch keine Bewertungen

- Wolff 180b ManualDokument422 SeitenWolff 180b ManualRichardNoch keine Bewertungen

- Potain Tower Cranes Spec 7aa631Dokument8 SeitenPotain Tower Cranes Spec 7aa631Ismail SaziliNoch keine Bewertungen

- Versatile Ringlock Scaffold SystemDokument9 SeitenVersatile Ringlock Scaffold SystemJyles SirabNoch keine Bewertungen

- Chapter 1 Survey of Tower Crane Technical Specs and Safety RulesDokument50 SeitenChapter 1 Survey of Tower Crane Technical Specs and Safety RuleskrmchariNoch keine Bewertungen

- Tower Crane Footing Structural Design For All Cranes PDFDokument14 SeitenTower Crane Footing Structural Design For All Cranes PDFmordidomi92% (71)

- 2.foundation Design-Cal - SC7-ETC3A-FS+15 - Rev2Dokument33 Seiten2.foundation Design-Cal - SC7-ETC3A-FS+15 - Rev2ratmaja100% (1)

- Structural Design Calculation Report: Block No. Lot No. Document No. Rev. NoDokument52 SeitenStructural Design Calculation Report: Block No. Lot No. Document No. Rev. NoMin KhantNoch keine Bewertungen

- Lifting lug calculator sheetDokument3 SeitenLifting lug calculator sheetMbalekelwa Mpembe100% (1)

- Calculation of Slab Punching Resistance: M. Zafer GEÇİM and Haşmet Z. SIDDIKİ February 2009Dokument6 SeitenCalculation of Slab Punching Resistance: M. Zafer GEÇİM and Haşmet Z. SIDDIKİ February 2009Gia GuallarNoch keine Bewertungen

- 21a Lifting Lugs - Calculator For Standard Lifting LugsDokument4 Seiten21a Lifting Lugs - Calculator For Standard Lifting LugsMbalekelwa MpembeNoch keine Bewertungen

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionVon EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNoch keine Bewertungen

- Nitocote CM210Dokument4 SeitenNitocote CM210sivakumar ramaiahNoch keine Bewertungen

- Map ElasticDokument6 SeitenMap Elastic폴로 쥰 차Noch keine Bewertungen

- Mapei GroutDokument4 SeitenMapei Groutbassem muhannaNoch keine Bewertungen

- Mastertile 530: Description Coverage / YieldDokument2 SeitenMastertile 530: Description Coverage / Yieldbassem muhannaNoch keine Bewertungen

- Mapei Tile GlueDokument4 SeitenMapei Tile Gluebassem muhannaNoch keine Bewertungen

- Fischer NaanDokument8 SeitenFischer Naanprompt consortiumNoch keine Bewertungen

- Sikalastic®-560 GCC Co-Elastic TechnologyDokument1 SeiteSikalastic®-560 GCC Co-Elastic Technologybassem muhannaNoch keine Bewertungen

- DBASF Mastertile30Dokument3 SeitenDBASF Mastertile30bassem muhannaNoch keine Bewertungen

- Flat Bread Technology PDFDokument213 SeitenFlat Bread Technology PDFbassem muhanna100% (1)

- Flat Bread Technology PDFDokument213 SeitenFlat Bread Technology PDFbassem muhanna100% (1)

- Flat Bread Technology PDFDokument213 SeitenFlat Bread Technology PDFbassem muhanna100% (1)

- Cooling Tower FundamentalsDokument117 SeitenCooling Tower Fundamentalsapi-375105488% (16)

- 1819 Level C Final Exam Schedule and Study List Final T3 UpdatedDokument8 Seiten1819 Level C Final Exam Schedule and Study List Final T3 Updatedbassem muhannaNoch keine Bewertungen

- CNC ExempleDokument118 SeitenCNC Exempleadict26Noch keine Bewertungen

- Rifss GuitarDokument160 SeitenRifss GuitarCarlos Abixybarraba Jr.100% (9)

- AMCRPS Piling Handbook 9th Web-3Dokument455 SeitenAMCRPS Piling Handbook 9th Web-3loketeloko100% (1)

- Konstantinos Mylonas Dean Miller Dorothy Whitti B-Ok - Xyz CompressedDokument431 SeitenKonstantinos Mylonas Dean Miller Dorothy Whitti B-Ok - Xyz Compressedrmpalmav100% (1)

- 7.1 Spread FootingsDokument14 Seiten7.1 Spread FootingstucupaNoch keine Bewertungen

- Eurocodes Essential GuideDokument38 SeitenEurocodes Essential GuidePavlos VardoulakisNoch keine Bewertungen

- Method Statement For Steel Structure & Erection PDFDokument16 SeitenMethod Statement For Steel Structure & Erection PDFDomie Neil Bucag Salas83% (24)

- Hempacore Aq 48860Dokument2 SeitenHempacore Aq 48860Murat TopbaştekinNoch keine Bewertungen

- Shepherd Bridge 2000 EngDokument18 SeitenShepherd Bridge 2000 Engsrfa20Noch keine Bewertungen

- Nu Division 22 Combined 20170330Dokument235 SeitenNu Division 22 Combined 20170330Jothimanikkam SomasundaramNoch keine Bewertungen

- As Sent 03 March 2012Dokument35 SeitenAs Sent 03 March 2012skumarsrNoch keine Bewertungen

- CHANNELDokument10 SeitenCHANNELSaad AkramNoch keine Bewertungen

- Comparison of Ansiaisc 360-05 To 1989 Asd SpecificationDokument32 SeitenComparison of Ansiaisc 360-05 To 1989 Asd SpecificationH.Hamdan Neo100% (1)

- Auto Restoration Rotisserie PlansDokument26 SeitenAuto Restoration Rotisserie PlansbeegoodNoch keine Bewertungen

- SEPA15014 MFSTD CV 00 DBS 0001 - Civil and Structural Design Basis - Rev 0Dokument33 SeitenSEPA15014 MFSTD CV 00 DBS 0001 - Civil and Structural Design Basis - Rev 0Pruthviraj JuniNoch keine Bewertungen

- PCC - 0043 Blinding Concrete KM 2 SAR P210-P207 Right SiteDokument2 SeitenPCC - 0043 Blinding Concrete KM 2 SAR P210-P207 Right SiteMvomoNoch keine Bewertungen

- Draft StructuralSteel DesignGuideDokument79 SeitenDraft StructuralSteel DesignGuideSheila Rose Bacerra-VillafloresNoch keine Bewertungen

- 18256544880Dokument9 Seiten18256544880Mahnaz KarimNoch keine Bewertungen

- BridgesDokument444 SeitenBridgesgiovanniNoch keine Bewertungen

- Homemade Bandsawmill Plans HMZ1 2.01Dokument50 SeitenHomemade Bandsawmill Plans HMZ1 2.01Steven90% (10)

- BOQTibbiCollegeDokument38 SeitenBOQTibbiCollegeVinay KumarNoch keine Bewertungen

- Construction Works Bidding Document for Bio-Tech Science Cluster Campus Phase-1Dokument288 SeitenConstruction Works Bidding Document for Bio-Tech Science Cluster Campus Phase-1SNRajeev100% (1)

- Technical Article SSAB Structural Hollow Sections For Functional Design According To Eurocode3Dokument17 SeitenTechnical Article SSAB Structural Hollow Sections For Functional Design According To Eurocode3sharunnizamNoch keine Bewertungen

- Parallel Flange Beams from Jindal Steel & PowerDokument15 SeitenParallel Flange Beams from Jindal Steel & PoweraudiihussainNoch keine Bewertungen

- Norsok Standard Structural DesignDokument19 SeitenNorsok Standard Structural Designsamprof4vwNoch keine Bewertungen

- F 83179Dokument6 SeitenF 83179pcmfilhoNoch keine Bewertungen

- JIS 3653-1994 Underground CableDokument19 SeitenJIS 3653-1994 Underground CableTuong Nguyen Duc Minh100% (2)

- Triton Alloys Hardox 400 - Hardox 400 Plate-Triton Alloys IncDokument8 SeitenTriton Alloys Hardox 400 - Hardox 400 Plate-Triton Alloys IncAnonymous hj68hZmoNoch keine Bewertungen

- Q245RDokument2 SeitenQ245RAnonymous 9zykaX6TNoch keine Bewertungen

- SPDG + BridgeCor 2013Dokument118 SeitenSPDG + BridgeCor 2013Marlongua100% (1)

- Range and Properties of Open Sections - bk122Dokument2 SeitenRange and Properties of Open Sections - bk122GustavNoch keine Bewertungen

- Hydraulic Turbine and Associated EquipmentDokument47 SeitenHydraulic Turbine and Associated Equipmentpavankumar0010% (1)

- Mechnical Property For Q235B Carbon SteelDokument3 SeitenMechnical Property For Q235B Carbon SteelPritom Ahmed100% (1)

- NTT-COOLING TOWER - Structural Priced BOQ R3-09-03-2021Dokument18 SeitenNTT-COOLING TOWER - Structural Priced BOQ R3-09-03-2021Corrosion Factory100% (1)

- Fabrication of Steel StructureDokument200 SeitenFabrication of Steel Structurekesharinaresh100% (1)