Beruflich Dokumente

Kultur Dokumente

Measuring Well Water Levels

Hochgeladen von

Danniel TubalCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Measuring Well Water Levels

Hochgeladen von

Danniel TubalCopyright:

Verfügbare Formate

EC 1368 • Reprinted August 2000

Measuring Well Water Levels

W.L. Trimmer

AAA

AAA Groundwater is an important resource in

AAA Oregon. As more people depend on groundwater,

AAA

A

AAAAA

AAAAA

AA

some water tables around the State are dropping,

AAA

threatening their water supplies. State law

AAA

AAA

requires that groundwater be managed as a

renewable resource, and that water tables do not

AAA

AAAA

AAAAAA

drop permanently.

AAA

AAAAAA

To assess the size of the groundwater resource

and monitor the effects of development and

AAA

AAA

drought, State law requires an aquifer test on

every well with a water right. Part of that test is to

AAA

A

AA

AAA

AAAAA

AA measure the depth of water in the well. We’ll

AAA

discuss three methods of measuring water levels

AAA

in this publication.

AAA

First, let’s define our terms.

AAAA

AAAAA

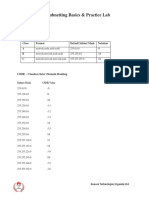

AAA A Glossary Figure 1.—Reading the distance from the water to the

Aquifer. A water-bearing geologic formation. top of casing on the line.

Column. Pipe leading from the surface down to

the pump. measure to measure the distance between the

Drawdown. The vertical distance the water level marks on the line.

is lowered when the well is pumped. Because of the low electrical conductivity of

Groundwater. Water that naturally occurs in most groundwater, use a meter in the circuit rather

porous rock materials underground. than a light bulb. Electrical sounders, which

Static water level. The depth below ground level include a reel of wire, meter, and battery, are

where water stands in a well when it’s not being available commercially. If your well casing is

pumped (also water table). plastic, extend the ground wire from the battery

and submerge it in the water.

Electric sounder

or electric depth gauge Problems

This is perhaps the handiest method for mea- 1. State law requires an access to the well. Most

suring well water levels. It consists of a weight wellheads have an access hole in the base; if one

suspended on #16 or #18 stranded insulated wire isn’t present, you can drill or cut a hole in most

with depth markings and an ammeter to indicate a situations.

closed circuit. 2. Drilled wells aren’t straight; they spiral down,

Current flows through the circuit when the end and the column sometimes presses against the

of the wire touches the water surface. Current is casing. This can block the path of the sounder

supplied by a small 9- or 12-volt battery. To make when you lower it. Carefully jiggling the

a reading, lower the electric wire or sounding line weighted sounder can move the tip past the

until the needle deflects. obstruction.

Read the distance from the water to the top of Occasionally, the sounder will become stuck

casing on the line (see Figure 1). Mark the refer- in the well. Don’t pull so hard that the wire

ence point on the casing where you measured the breaks. Tie off the wire so it can’t slip into the

depth. Most commercial models use two conduc- well—then abandon it. Check periodically to see

tors and mark the distance with paint or brass tags if vibration has freed the sounder.

crimped on every 5 feet. Use a standard tape

Walter L. Trimmer, former Extension irrigation special-

ist, Oregon State University, prepared this revision of

WRAES 54, Measuring Well Water Levels, by Marvin N.

Shearer, Extension irrigation specialist emeritus, Oregon

State University.

AAA

AAA

AAA

AAA

A

AAAAA

AAAAA

AA

AAA

3. Deep well turbines with oil-lubricated shafts suction intake of the pump to avoid pulling air

AAA

AAA

tend to leak oil onto the water surface. As oil is

lighter than water, it displaces the water level.

through the pump.

By noting the number of pipe joints you install,

AAA

AAAA

AAAAAA

Oil is also a poor electrical conductor, which you’ll know the depth of the air line tip. If pos-

AAA

AAAAAA

means it interferes with electrical contact.

A cheesecloth sack can protect the end of the

sible, leave a permanent marker on the wellhead to

indicate the depth of the air line.

AAA

AAA

sounder until it hits water. Coating the tip of the

sounder with salt can increase its sensitivity

Fit the upper end with a tee and pressure gauge

plus a valve to which a hand pump is attached.

AAA

A

AA

AAA

AAAAA

AA when it reaches the water. You can calibrate the gauge to indicate pressure

AAA

directly in feet of water or pounds per square inch

AAA Wetted tape (psi). You can use any pressure gauge, but one

AAA

with a full scale that’s just higher than any

This method is very accurate for measuring

AAAA

AAAAAA

expected drawdown will provide the greatest

water levels to depths up to about 90 feet. To use

AAA

accuracy.

this method satisfactorily, you must know the Special pressure gauges are available to read

approximate depth to water (A in Figure 1). directly the depth of water in the well.

Attach a lead weight to the end of a 100-foot Once you’ve installed it, with pressure gauge

steel measuring tape. Dry 8 to 10 feet of tape end connected, pump air into the air line until the

and coat with carpenter’s chalk or keel (ocher dust) pressure shown by the gauge levels off at a con-

before each measurement. Lower the tape down stant maximum—indicating that all water has been

the well until a part of the chalked section is below forced out of the line.

water. At this point, air pressure in the tube (as shown

At this point, align and note an even foot mark by the gauge) just supports the column of water

on the tape exactly at the top of the casing or some from water level in the well to the bottom of the

other measuring point. Pull the tape up, read the tube. This water column length is equal to the

mark where the line is wet, and determine the amount of air line submerged.

actual depth from the top of the casing to water Deduct this pressure, converted to feet (pounds

level by subtracting the wetted mark from the pressure x 2.31 = feet), from the known length of

mark you held at the top of the casing. the air line to determine the amount of submer-

Wetted tapes have many of the same problems gence. For example:

encountered by electric sounders—lowering into

Assume that L (see Figure 1) is 150 ft long.

the well and encountering oil.

Pressure gauge shows 26 psi.

Air line Then the distance from the water level to the

This method consists of a small-diameter pipe bottom end of the air line (B) is 26 x 2.31 or 60 ft.

or tube long enough to extend from the top of the

Therefore, the distance of water level (A) is

well to a point about 20 feet below the lowest

150 – 60 or 90 ft. An air line provides the most

anticipated water level. As you pump air into the

convenient method for repeated testing of deep

line, excess air bubbles are forced out the end,

wells over 300 ft deep.

equalizing the pressure in the line with the pres-

sure created by the depth of water outside the line. AAA

AA

AAAA

AAAAA AA

AA

Measure the exact length of air line as you place AAAAA

AAA AA

AAAAAAA

AA AA

AAA

AAAAA

AA

AAAAAA

AA AA AA

it in the well. Make sure the air line is airtight; AAAAA

AA

AAA

AAA

AA

hang it vertically, taking care that it doesn’t spiral Conversion table AAAAA

AAAAA

AAA AAA

AAAAAA

inside the well casing. Quarter-inch copper or To convert from: AAA

AAA Multiply by:

brass tubing, or 1⁄4-inch steel or plastic pipe,

feet to meters 0.3048

commonly is used. You can use plastic tubing, but

meters to feet 3.28

it’s quite easy to pinch it off during installation.

feet water to psi 0.433

The best way is to attach the air line securely to

psi to feet water 2.31

a known point on the pump column. Attach the

psi to kPa 6.895

end of the air line low enough so that it’s sub-

kPa to psi 0.145

merged when the pump operates at full dis-

meters water to kPa 9.81

charge—but be sure it’s at least 5 feet above the

© 2000 Oregon State University. This publication may be photocopied or reprinted in its entirety for noncommercial purposes. Produced and

distributed in furtherance of the Acts of Congress of May 8 and June 30, 1914. Extension work is a cooperative program of Oregon State

University, the U.S. Department of Agriculture, and Oregon counties. Oregon State University Extension Service offers educational programs,

activities, and materials—without discrimination based on race, color, religion, sex, sexual orientation, national origin, age, marital status,

disability, or disabled veteran or Vietnam-era veteran status. Oregon State University Extension Service is an Equal Opportunity Employer.

Published October 1991. Reprinted August 2000.

Das könnte Ihnen auch gefallen

- Design Raft Foundation MAT or RAFTDokument13 SeitenDesign Raft Foundation MAT or RAFTMqAshladyNoch keine Bewertungen

- Water Colored Splashes PowerPoint TemplateDokument36 SeitenWater Colored Splashes PowerPoint TemplateDanniel TubalNoch keine Bewertungen

- Water Colored Splashes PowerPoint TemplateDokument36 SeitenWater Colored Splashes PowerPoint TemplateDanniel TubalNoch keine Bewertungen

- Business Products StatusDokument2 SeitenBusiness Products StatusDanniel TubalNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 13 - Wool-And-Coir-Fiber-Reinforced-Gypsum-Ceiling-Tiles-Wit - 2021 - Journal-of-BuilDokument9 Seiten13 - Wool-And-Coir-Fiber-Reinforced-Gypsum-Ceiling-Tiles-Wit - 2021 - Journal-of-BuilJenifer TejadaNoch keine Bewertungen

- Low-Complexity Iterative Detection For Large-Scale Multiuser MIMO-OFDM Systems Using Approximate Message PassingDokument14 SeitenLow-Complexity Iterative Detection For Large-Scale Multiuser MIMO-OFDM Systems Using Approximate Message PassingNitin KumarNoch keine Bewertungen

- Appliance ShipmentsDokument10 SeitenAppliance ShipmentsnNoch keine Bewertungen

- PTP - Level MethodsDokument23 SeitenPTP - Level Methodssasikiran mNoch keine Bewertungen

- NEC Article 250Dokument42 SeitenNEC Article 250unknown_3100% (1)

- Ikan Di Kepualauan Indo-AustraliaDokument480 SeitenIkan Di Kepualauan Indo-AustraliaDediNoch keine Bewertungen

- UG WeibullDokument776 SeitenUG WeibullCharles GuzmanNoch keine Bewertungen

- VRV A 12 PDFDokument1 SeiteVRV A 12 PDFMoe Thiri ZunNoch keine Bewertungen

- Network Layer: Computer Networking: A Top Down ApproachDokument83 SeitenNetwork Layer: Computer Networking: A Top Down ApproachMuhammad Bin ShehzadNoch keine Bewertungen

- Iso 10042Dokument5 SeitenIso 10042Nur Diana100% (3)

- Cec 103. - Workshop Technology 1Dokument128 SeitenCec 103. - Workshop Technology 1VietHungCao92% (13)

- Classification of Differential Equations For Finding Their SolutionsDokument2 SeitenClassification of Differential Equations For Finding Their SolutionsakhileshNoch keine Bewertungen

- Product - 20V4000G24F 3B FODokument32 SeitenProduct - 20V4000G24F 3B FOmohammed khadrNoch keine Bewertungen

- Velocity profiles and incompressible flow field equationsDokument2 SeitenVelocity profiles and incompressible flow field equationsAbdul ArifNoch keine Bewertungen

- Sequelize GuideDokument5 SeitenSequelize Guidemathur1995Noch keine Bewertungen

- SERVICE MANUAL CRAWLER EXCAVATOR R210LC-7Dokument1 SeiteSERVICE MANUAL CRAWLER EXCAVATOR R210LC-7DmitryNoch keine Bewertungen

- Bab 8Dokument29 SeitenBab 8Nurul AmirahNoch keine Bewertungen

- A320 CBT Test 1 PDFDokument107 SeitenA320 CBT Test 1 PDFCesarNoch keine Bewertungen

- Lesson 1Dokument24 SeitenLesson 1Jayzelle100% (1)

- Astm A6 A6m-08Dokument62 SeitenAstm A6 A6m-08Vũ Nhân HòaNoch keine Bewertungen

- Water Reducing - Retarding AdmixturesDokument17 SeitenWater Reducing - Retarding AdmixturesAbdullah PathanNoch keine Bewertungen

- HowTo Work With CR 90Dokument87 SeitenHowTo Work With CR 90WagBezerraNoch keine Bewertungen

- ChamSys Touchscreen SupportDokument2 SeitenChamSys Touchscreen SupportKayla PadillaNoch keine Bewertungen

- Craig Vaughan CHPTR 07Dokument44 SeitenCraig Vaughan CHPTR 07Jorge CananeaNoch keine Bewertungen

- How To Publish A Package in RDokument14 SeitenHow To Publish A Package in Rtoton1181Noch keine Bewertungen

- SubNetting Practice LabDokument3 SeitenSubNetting Practice LabOdoch HerbertNoch keine Bewertungen

- Defense Cheat SheetDokument4 SeitenDefense Cheat SheetCarl Dhaniel Garcia SalenNoch keine Bewertungen

- Camshaft Test SheetDokument4 SeitenCamshaft Test SheetsughieantoNoch keine Bewertungen

- GL Setup ListDokument88 SeitenGL Setup ListSundaroraclefinNoch keine Bewertungen

- Enzyme Inhibition and ToxicityDokument12 SeitenEnzyme Inhibition and ToxicityDaniel OmolewaNoch keine Bewertungen