Beruflich Dokumente

Kultur Dokumente

Trunnion Calculations

Hochgeladen von

pmech consultantOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Trunnion Calculations

Hochgeladen von

pmech consultantCopyright:

Verfügbare Formate

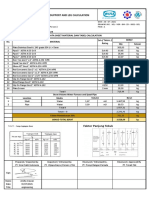

Trunnion Local Stress Calculations

Project Palembang LPG Plant Expansion Rev 0

Customer PTSEP Indonesia Date 10/18/2019

CAESAR-II Node No: 898

Sl. No. Description Symbol Formula Value Unit

1 Pipe Data

Pipe Size Do 219.075 mm

Mean Radius of Pipe R (Do-t)/2 103.1875 mm

Pipe Wall Thickness tp 12.7 mm

Corrosion Allowance C.A 1.5 mm

Design Pressure P 1300 kPa

Design Temperature T 350 °C

Pipe Material of Construction A335 Gr.P5

Basic Cold Allowable Stress SC 127895 kPa

Basic Hot Allowable Stress SH 127895 kPa

Stress Range Factor f 1

Local Allowable Stress SA f(1.25 SC + 0.25 SH) 191842.5255 kPa

191.8425255 N/mm2

2 Trunion Data

Trunion Size do 168.275 mm

Trunion Wall Thickness td 7.112 mm

Trunion Outside Radius r (do-td)/2 80.582 mm

Moment Arm/Trunion Length\ L 512.000 mm

3 R.F.Pad Data

Reinforcement Pad Thickness tr 0.000 mm

Total Thickness Available (Pipe+R.F Pad) t tp+tr 12.700 mm

4 Loads on Trunion

Radial Force FA -25991.000 N

Longitudinal Force FL -1853.000 N

Circumferential Force FC -12370.000 N

5 Calculations

Longitudinal Moment ML FL X L -948736.000 N-mm

Circumferential Moment MC FC X L -6333440.000 N-mm

Unit Loading due to Radial Thrust fa FA / 2 π r -51.334 N/mm

Unit Loading due to applied Longitudinal Bending

fl ML / π r 2

-46.508 N/mm

Moment

Unit Loading due to applied Circumferential Bending

fc MC / π r2 -310.470 N/mm

Moment

Resultant Unit loading due to applied Longitudinal &

fr (fl2 + fc2)^0.5 313.934 N/mm2

Circumferential Bending Moments

Longitudinal Primary Stress σl PDo / 4t 5.606 N/mm2

Hoop Stress σc PDo / 2t 11.213 N/mm2

Combined Local Longitudinal Bending Stress f1 1.17 (R^0.5) [ fl + 1.5 fa] / t ^1.5 + σl -26.827 N/mm2

Combined Local Circumferential Bending Stress f2 1.17 (R^0.5) [1.5( fc + fa)] / t ^1.5 + σc -131.302 N/mm2

Combined Local Longitudinal & Circumferential

f3 1.17 (R^0.5) [1.5( fr + fa)] / t ^1.5 + σc 114.650 N/mm2

Bending Stress

Maximum of f1, f2 and f3 fmax MAX ( f1, f2, f3) 114.650 N/mm2

6 Trunion Check

Ratio of Maximum Local Stress to Local Allowble Stress RATIO [fmax / SA] * 100 59.763 %

SAFE

Reference: Design of Piping Systems by M.W.Kellog.

Interpolation

Temperature Allowable Stress Required Value

T1 650 F

O

S1 14.5 ksi

T2 662 F

O

S2 14.476 ksi 14476 psi

T3 700 F

O

S3 14.4 ksi

Temperature Thermal Expansion Required Value

T1 650 F

O

∆1 5.11 in/100ft.

T2 662 F

O

∆2 5.2348 in/100ft. 0.052348 in./ft

T3 675 F

O

∆3 5.37 in/100ft.

Das könnte Ihnen auch gefallen

- API 650 - Using WRC 297 With RepadDokument1 SeiteAPI 650 - Using WRC 297 With RepadGuochao SongNoch keine Bewertungen

- Kvaerner E & C Uk LTDDokument3 SeitenKvaerner E & C Uk LTDVaniya GoelNoch keine Bewertungen

- Summary Table For Dimensions and External Loads SSP01NDokument2 SeitenSummary Table For Dimensions and External Loads SSP01NJ A S JASNoch keine Bewertungen

- Process Data Sheet For Main Air Compressor Rev00Dokument4 SeitenProcess Data Sheet For Main Air Compressor Rev00mahan moradiNoch keine Bewertungen

- Fsa PSJ 701 06 PDFDokument9 SeitenFsa PSJ 701 06 PDFAshitava SenNoch keine Bewertungen

- Chapter 1 - Section 3 When To Use NozzleproDokument3 SeitenChapter 1 - Section 3 When To Use Nozzleprojohnnyr_5Noch keine Bewertungen

- Welding Design For Rebar To Cast in PlateDokument1 SeiteWelding Design For Rebar To Cast in PlateMyat Thu Zar KhineNoch keine Bewertungen

- Ace Mersen Armylor 2 Ptfe Pfa Lined Pipes DinDokument32 SeitenAce Mersen Armylor 2 Ptfe Pfa Lined Pipes DinClaire GrecoNoch keine Bewertungen

- Nozzle Thermal Movement and Evaluation Sheet For Shell & Tube ExchagerDokument21 SeitenNozzle Thermal Movement and Evaluation Sheet For Shell & Tube ExchagerJ A S JASNoch keine Bewertungen

- The Performance and Service Life of Wire Ropes Under Deep Koepe and Drum Winders Conditions - Laboratory SimulationDokument9 SeitenThe Performance and Service Life of Wire Ropes Under Deep Koepe and Drum Winders Conditions - Laboratory SimulationRicardo Ignacio Moreno MendezNoch keine Bewertungen

- Compaction: Prof. (DR) K.S. WaghDokument60 SeitenCompaction: Prof. (DR) K.S. WaghAshish KondalwadeNoch keine Bewertungen

- Masinloc Power Partners Co., LTDDokument1 SeiteMasinloc Power Partners Co., LTDariyakkannaaNoch keine Bewertungen

- Nozzle Thermal Movement and Evaluation Sheet For PumpDokument14 SeitenNozzle Thermal Movement and Evaluation Sheet For PumpJ A S JASNoch keine Bewertungen

- BEARING STRESS To THIN WALLED PRESSURE VESSELSDokument21 SeitenBEARING STRESS To THIN WALLED PRESSURE VESSELSDenver NieverasNoch keine Bewertungen

- Pipe SupportDokument8 SeitenPipe SupportVignesh GandhirajNoch keine Bewertungen

- Air RecieverDokument9 SeitenAir RecieverMichael Belmonte UrdanetaNoch keine Bewertungen

- Is 1893 (Part 4) :2005Dokument24 SeitenIs 1893 (Part 4) :2005ashishigit59100% (3)

- Basalt RockDokument25 SeitenBasalt Rocksaqib mujtabaNoch keine Bewertungen

- Nozzle Node No. 4950Dokument6 SeitenNozzle Node No. 4950Christopher BrownNoch keine Bewertungen

- Nozzle Thermal Movement and Evaluation Sheet For ColumnDokument27 SeitenNozzle Thermal Movement and Evaluation Sheet For ColumnJ A S JASNoch keine Bewertungen

- Guide Document For Itemized Spring Hangers and Tie-Rod Data SheetsDokument19 SeitenGuide Document For Itemized Spring Hangers and Tie-Rod Data SheetsAHMED AMIRANoch keine Bewertungen

- Strength of Materials NotesDokument7 SeitenStrength of Materials NotesGokulraju RangasamyNoch keine Bewertungen

- BHP SpecDokument29 SeitenBHP Spectam ngoNoch keine Bewertungen

- Standard Specification For Hot Insulation Piping EquipmentDokument62 SeitenStandard Specification For Hot Insulation Piping EquipmentAri SupramonoNoch keine Bewertungen

- FPSO - Automating Structural DeflectionsDokument10 SeitenFPSO - Automating Structural DeflectionsJP EDSNoch keine Bewertungen

- Review On Early Strength ConcreteDokument6 SeitenReview On Early Strength ConcreteNarasimha ReddyNoch keine Bewertungen

- Spec On Well GroutingDokument23 SeitenSpec On Well GroutingMohd IllahiNoch keine Bewertungen

- One Span Steel BeamDokument38 SeitenOne Span Steel BeamNhuVan NguyenNoch keine Bewertungen

- Material Handling Boq 2Dokument4 SeitenMaterial Handling Boq 2biliiardiansyahNoch keine Bewertungen

- Product Data Sheet Sheave and Frame Assemblies PDFDokument1 SeiteProduct Data Sheet Sheave and Frame Assemblies PDFCraciun PaulNoch keine Bewertungen

- OneSteel Valve Product CatalogueDokument40 SeitenOneSteel Valve Product CatalogueEr Pupone de Naza100% (1)

- Brackets For Circular Platforms at Vertical VesselsDokument4 SeitenBrackets For Circular Platforms at Vertical Vesselsameya natuNoch keine Bewertungen

- Basalt CostDokument9 SeitenBasalt CostAnand ThiyagarajanNoch keine Bewertungen

- FV10 Excel Flux Tutorial en 2Dokument36 SeitenFV10 Excel Flux Tutorial en 2Ahcene BouzidaNoch keine Bewertungen

- Technical SpecificationDokument6 SeitenTechnical Specificationjimboy_123Noch keine Bewertungen

- Alloy C Shell Thickness CalculationDokument9 SeitenAlloy C Shell Thickness Calculation9913489806Noch keine Bewertungen

- 08 Tombo Naflon Lined Pipe and Fitting PDFDokument36 Seiten08 Tombo Naflon Lined Pipe and Fitting PDFsrikandi marketingNoch keine Bewertungen

- Expansion Bellow Tech ComparisonDokument10 SeitenExpansion Bellow Tech ComparisonSabariMechyNoch keine Bewertungen

- Support and Leg Calculation: Data Sheet Material Dan Tabel CalculationDokument3 SeitenSupport and Leg Calculation: Data Sheet Material Dan Tabel CalculationliusNoch keine Bewertungen

- HeatExchanger ReportDokument5 SeitenHeatExchanger ReportNur Izzati KamrulnizamNoch keine Bewertungen

- CEMA 6 Belt Conveyors Belt AlignmentDokument2 SeitenCEMA 6 Belt Conveyors Belt Alignmentali kajbaf100% (1)

- The Highest Efficiency Turbo Blower: Oilless Gearless Vibrationless StainlessDokument13 SeitenThe Highest Efficiency Turbo Blower: Oilless Gearless Vibrationless Stainlessxiong du100% (1)

- Wind Load Calculations Per India STD (With Vortex Shedding)Dokument5 SeitenWind Load Calculations Per India STD (With Vortex Shedding)mechmohan26Noch keine Bewertungen

- Design and Calculation For Secondary Chilled Water Pump SkidDokument25 SeitenDesign and Calculation For Secondary Chilled Water Pump SkidSuresh D100% (1)

- Mulitilayer Winindg - Grooves - KOMAGDokument14 SeitenMulitilayer Winindg - Grooves - KOMAGkazdanoNoch keine Bewertungen

- Employee Performance TrackerDokument3 SeitenEmployee Performance Trackerrinosh rajuNoch keine Bewertungen

- Lift Tender DrawingDokument1 SeiteLift Tender DrawingAmal KarunasenaNoch keine Bewertungen

- VRV Electrical RequirementDokument6 SeitenVRV Electrical RequirementShrenikShahNoch keine Bewertungen

- Compressed Air GuidelinesDokument7 SeitenCompressed Air Guidelinesj_moellersNoch keine Bewertungen

- When Is An Expansion Bellows Required in A Heat ExchangerDokument3 SeitenWhen Is An Expansion Bellows Required in A Heat ExchangerTiHoRNoch keine Bewertungen

- Westinghouse Electric Wall Oven WVE665S User ManualDokument48 SeitenWestinghouse Electric Wall Oven WVE665S User ManualalexNoch keine Bewertungen

- Fan Calculator (Axial & Centrifugal) - Pressure & Flow - CalQlataDokument10 SeitenFan Calculator (Axial & Centrifugal) - Pressure & Flow - CalQlataany oneNoch keine Bewertungen

- Weld Stress CalculationsDokument19 SeitenWeld Stress CalculationsMichael WaltersNoch keine Bewertungen

- 13.375 Inch Geoconn 64-QDokument1 Seite13.375 Inch Geoconn 64-QBalkis FatihaNoch keine Bewertungen

- Technical Specifications Premium 5-1/2" OD Heavy-Weight Drill Pipe, 1340, TT-550 Conn's. NewDokument2 SeitenTechnical Specifications Premium 5-1/2" OD Heavy-Weight Drill Pipe, 1340, TT-550 Conn's. NewbkprodhNoch keine Bewertungen

- Calc Tensionador 30PLG 600Dokument1 SeiteCalc Tensionador 30PLG 600Cristhian De La BarraNoch keine Bewertungen

- C7CH20050 - Wall - Reinforcement - WR2Dokument20 SeitenC7CH20050 - Wall - Reinforcement - WR2Mahadev Sastry100% (1)

- Docs 1055727 DP 5 08 Spec SheetDokument2 SeitenDocs 1055727 DP 5 08 Spec SheetkbgwseNoch keine Bewertungen

- Technical Specifications New Premium 5" OD Drill Pipe, S-135, NC-50 Conn'sDokument2 SeitenTechnical Specifications New Premium 5" OD Drill Pipe, S-135, NC-50 Conn'sمحمد المحموديNoch keine Bewertungen

- 19 DP 5 01 Ows Spec SheetDokument2 Seiten19 DP 5 01 Ows Spec SheetresapradistaNoch keine Bewertungen

- FG1100E Vs PAN 3260Dokument6 SeitenFG1100E Vs PAN 3260Cwsta LbaumNoch keine Bewertungen

- Sqlassignment 03Dokument3 SeitenSqlassignment 03pokegex798Noch keine Bewertungen

- Spring Framework 3.1Dokument284 SeitenSpring Framework 3.1Rakesh PatelNoch keine Bewertungen

- The Death of Science.Dokument1 SeiteThe Death of Science.sam iam / Salvatore Gerard MichealNoch keine Bewertungen

- The Salvation Army Chikankata College of Biomedical Sciences The Ministry of HealthDokument7 SeitenThe Salvation Army Chikankata College of Biomedical Sciences The Ministry of HealthChabala Ng'anduNoch keine Bewertungen

- Edexcel Chemistry AS NotesDokument101 SeitenEdexcel Chemistry AS NotesMary Mannu100% (8)

- ME415 CondensersDokument4 SeitenME415 Condensersagafina0Noch keine Bewertungen

- TPS51117 Single Synchronous Step-Down Controller: 1 Features 3 DescriptionDokument33 SeitenTPS51117 Single Synchronous Step-Down Controller: 1 Features 3 Descriptionjhon agredoNoch keine Bewertungen

- Toshiba VFS15 User ManualDokument361 SeitenToshiba VFS15 User ManualdanyNoch keine Bewertungen

- Cat ElcDokument17 SeitenCat ElcJoel Cunha100% (1)

- Multiple Choice QuestionsDokument12 SeitenMultiple Choice QuestionsSarath Bhushan Kaluturi85% (13)

- P 278 - GN 1007Dokument25 SeitenP 278 - GN 1007Doben DalisayNoch keine Bewertungen

- SMSCP Level 1 System Analysis: Analyzing A Mechatronic SystemDokument25 SeitenSMSCP Level 1 System Analysis: Analyzing A Mechatronic SystemIsaac GisoreNoch keine Bewertungen

- Arithmetic Progressons (Part-1)Dokument16 SeitenArithmetic Progressons (Part-1)shambhaviNoch keine Bewertungen

- 7805Dokument2 Seiten7805pandiNoch keine Bewertungen

- Chem301 Lab3Dokument5 SeitenChem301 Lab3Gobe JamNoch keine Bewertungen

- Owner's ManualDokument208 SeitenOwner's ManualChantal LilouNoch keine Bewertungen

- Jurnal AutorefractometerDokument11 SeitenJurnal AutorefractometerNeida Valeria DanunNoch keine Bewertungen

- REPORT On GrapheneDokument22 SeitenREPORT On GrapheneA.s.jNoch keine Bewertungen

- VD 2Dokument4 SeitenVD 2Hồ BảoNoch keine Bewertungen

- Cognitive Development of Primary SchoolersDokument9 SeitenCognitive Development of Primary SchoolersKVNDRW100% (2)

- Frugal Marketing Strategies ReportDokument23 SeitenFrugal Marketing Strategies ReportManuj DixitNoch keine Bewertungen

- Borgwarneredrive PDFDokument34 SeitenBorgwarneredrive PDFddstoneNoch keine Bewertungen

- Unit I. Bascis of Manufacturing ProcessesDokument30 SeitenUnit I. Bascis of Manufacturing Processes070 ARITRITA BRAHMA ECENoch keine Bewertungen

- DehoffDokument11 SeitenDehoffVictor Manuel Romero Herrera100% (4)

- Unit 6 Chapter 1 Parallel Programming Tools Cuda - ProgrammingDokument28 SeitenUnit 6 Chapter 1 Parallel Programming Tools Cuda - ProgrammingPallavi BhartiNoch keine Bewertungen

- BUILDING SERVICES-I Sanitary Fixtures, Fittings & Wellness-1Dokument48 SeitenBUILDING SERVICES-I Sanitary Fixtures, Fittings & Wellness-1Vidya Hitti100% (2)

- Genome Annotation and ToolsDokument20 SeitenGenome Annotation and ToolsKumar KunalNoch keine Bewertungen

- Prospect ATR901.RevB Eng PDFDokument25 SeitenProspect ATR901.RevB Eng PDFUntea LiviuNoch keine Bewertungen