Beruflich Dokumente

Kultur Dokumente

4 Jaw Chuck

Hochgeladen von

avksekar_701032284Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

4 Jaw Chuck

Hochgeladen von

avksekar_701032284Copyright:

Verfügbare Formate

SELF CENTERING SYSTEM FOR 4 JAW CHUCK

ABSTRACT

A chuck is a specialized type of clamp used to hold an object,

usually an object with radial symmetry, especially a cylindrical object. It

is most commonly used to hold a rotating tool or a rotating workpiece.

In some applications, the tool or workpiece being held by the chuck

remains stationary while another tool or workpiece rotates.

Many chucks have jaws, which are dogs that are arranged in a

radially symmetrical pattern to hold the tool or workpiece. Often the jaws

will be tightened or loosened with the help of a chuck key, which is a

wrench-like tool made for the purpose

A self-centering chuck, also known as a scroll chuck, uses dogs

(usually called jaws), interconnected via a scroll gear (scroll plate), to

hold onto a tool or workpiece. Because they most often have three jaws,

the term three-jaw chuck without other qualification is understood by

machinists to mean a self-centering three-jaw chuck. The term universal

chuck also refers to this type.

A 4-jaw chuck is a great, almost essential, accessory for any

serious lathe worker. While it lacks the self-centering convenience of the

the 3-jaw chuck, it has other capabilities. Some things you can do with

the 4-jaw are...

Grip rectangular and other non-cylindrical shapes for turning or

facing

Form rectangular shaped objects

Precisely center cylindrical stock to within the limits of the lathe's

accuracy

Hold stock off-center for turning cams or drilling off-center holes

ADVANTAGES AND APPLICATIONS

As auxiliary features that complement the main lathe chuck:

o To hold the bar or workpiece at the back end of the spindle

bore and support it concentrically, so that it resists wobbling

or whipping while the spindle is turning. Gun barrels and oil

pipes are examples of workpieces that benefit.

o To hold the bar or workpiece at the tailstock end (thus

serving as a steady rest) or following the tool (thus serving

as a follower rest).

In place of the main lathe chuck

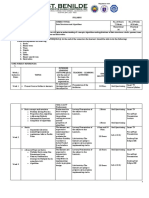

ASSEMBLY DIAGRAM

DC

MOTOR

3

DC DC

MOTOR MOTOR

4 2

OBJECT SENSOR

DC

MOTOR

1

M1

SENSING CONTROL RELAY M2

SENSOR CIRCUIT M3

M4

Das könnte Ihnen auch gefallen

- The Mechanics of Clockwork - Lever Escapements, Cylinder Escapements, Verge Escapements, Shockproof Escapements, and Their Maintenance and RepairVon EverandThe Mechanics of Clockwork - Lever Escapements, Cylinder Escapements, Verge Escapements, Shockproof Escapements, and Their Maintenance and RepairBewertung: 5 von 5 Sternen5/5 (1)

- ChuksDokument4 SeitenChuksPraveen P JoseNoch keine Bewertungen

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsVon EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsBewertung: 5 von 5 Sternen5/5 (1)

- Experiment No. 1: Study of Universal 3 Jaw Chuck Lathe MachineDokument5 SeitenExperiment No. 1: Study of Universal 3 Jaw Chuck Lathe MachineHasnain AshrafNoch keine Bewertungen

- The Inner Workings of a Watch - A Simple Guide for Enthusiasts of Clockwork MechanismsVon EverandThe Inner Workings of a Watch - A Simple Guide for Enthusiasts of Clockwork MechanismsNoch keine Bewertungen

- 5.workshop Practice - Machine Shop - ES-ME192 - or - 292Dokument10 Seiten5.workshop Practice - Machine Shop - ES-ME192 - or - 292Priyanshu BanerjeeNoch keine Bewertungen

- Workshop Technology-II, Unit I: TurningDokument8 SeitenWorkshop Technology-II, Unit I: TurningRamkrishnaSutharNoch keine Bewertungen

- Introduction To The Lathe Machine-M3 - ADokument17 SeitenIntroduction To The Lathe Machine-M3 - ASagar JaatNoch keine Bewertungen

- M AchingDokument10 SeitenM AchingSnehasishNoch keine Bewertungen

- Design and Fabrication Mini Lathe MachineDokument17 SeitenDesign and Fabrication Mini Lathe MachineBrij Bhushan Monu86% (7)

- Machine ShopDokument22 SeitenMachine ShopAbeer NasirNoch keine Bewertungen

- Unit - 2 (Lathes)Dokument17 SeitenUnit - 2 (Lathes)suryaNoch keine Bewertungen

- Turning Machines: Unit - 2Dokument11 SeitenTurning Machines: Unit - 2chinnarasu132Noch keine Bewertungen

- Mahine LabDokument9 SeitenMahine LabArun kumar rouniyarNoch keine Bewertungen

- Three-Jaw Universal Chuck Is Used To Hold Round and Hexagonal WorkDokument3 SeitenThree-Jaw Universal Chuck Is Used To Hold Round and Hexagonal WorkRafiaNoch keine Bewertungen

- Lathe Accessories and Attachments Lathe Accessories:: 1. Face PlateDokument7 SeitenLathe Accessories and Attachments Lathe Accessories:: 1. Face PlateRohan SahaNoch keine Bewertungen

- Lathe MachineDokument6 SeitenLathe MachineJuno Eron TalamayanNoch keine Bewertungen

- Machining Processes - I MT 164: LatheDokument45 SeitenMachining Processes - I MT 164: LatheMusab LatifNoch keine Bewertungen

- Lathe Machine Definition Parts Types Operation Specification Advantages Application Notes PDFDokument20 SeitenLathe Machine Definition Parts Types Operation Specification Advantages Application Notes PDFMark Angelo M. BubanNoch keine Bewertungen

- Types of Lathe ChucksDokument6 SeitenTypes of Lathe ChucksSEENU VASANNoch keine Bewertungen

- Cam Analysis MachineDokument14 SeitenCam Analysis MachineAurangzebNoch keine Bewertungen

- Chapter 6 Sawing MachinesDokument18 SeitenChapter 6 Sawing MachinesPRASAD326100% (3)

- Turning Machine or LatheDokument35 SeitenTurning Machine or Lathelei dyluNoch keine Bewertungen

- English ClassDokument14 SeitenEnglish ClassAdje EKLOUNoch keine Bewertungen

- P.P CNC LatheDokument23 SeitenP.P CNC LatheRohaibi Abu BakarNoch keine Bewertungen

- Lathe MachineDokument13 SeitenLathe Machinemboniface763Noch keine Bewertungen

- Class 5Dokument6 SeitenClass 5BINAYAK DATTA ROYNoch keine Bewertungen

- TurningDokument6 SeitenTurningShivshankar Singh0% (1)

- Naya Nangal UnitDokument24 SeitenNaya Nangal UnitprabhjotbhangalNoch keine Bewertungen

- Unit-4 Machine ToolsDokument77 SeitenUnit-4 Machine ToolsSOURABH GANGWARNoch keine Bewertungen

- Types of Lathes and Their PartsDokument32 SeitenTypes of Lathes and Their PartsErnesto HernándezNoch keine Bewertungen

- LatheDokument16 SeitenLathepokalNoch keine Bewertungen

- Subject: Machine Tools and Metrology: Course: B Tech - Mechanical EngineeringDokument341 SeitenSubject: Machine Tools and Metrology: Course: B Tech - Mechanical EngineeringTharun GTNoch keine Bewertungen

- Diploma Workshop Practice IIDokument30 SeitenDiploma Workshop Practice IISagir Musa SaniNoch keine Bewertungen

- Assignment NO: 2: Mechanical Engineering DepartmentDokument16 SeitenAssignment NO: 2: Mechanical Engineering DepartmentMohsin TariqNoch keine Bewertungen

- Lathe Machine AssignmentDokument23 SeitenLathe Machine AssignmentChristopher Rohrer100% (1)

- Rajshahi University of Engineering & TechnologyDokument7 SeitenRajshahi University of Engineering & TechnologyMD Mahmudul Hasan MasudNoch keine Bewertungen

- Turret & Capstan LathesDokument10 SeitenTurret & Capstan LathesRenjith Rajendraprasad100% (2)

- Layout of Mechanical Work ShopkkkkDokument7 SeitenLayout of Mechanical Work ShopkkkkChaudhary Rizwan MeoNoch keine Bewertungen

- Quiz1 ReviewerDokument17 SeitenQuiz1 ReviewerJag MasterNoch keine Bewertungen

- Maintenance Manual: Rotary Valves RV-SDokument25 SeitenMaintenance Manual: Rotary Valves RV-Saloknayak123Noch keine Bewertungen

- Lathe Machine Parts and FunctionDokument58 SeitenLathe Machine Parts and Functionjas081603Noch keine Bewertungen

- Chapter 11Dokument32 SeitenChapter 11Mark Angelo M. BubanNoch keine Bewertungen

- 4.conventional MachiningDokument7 Seiten4.conventional MachiningpriyanshuvraoNoch keine Bewertungen

- Machine Shop: Principal Parts of A LatheDokument7 SeitenMachine Shop: Principal Parts of A LatheArchika YaduNoch keine Bewertungen

- Study of LatheDokument5 SeitenStudy of Lathekb210538Noch keine Bewertungen

- Diagram of Lathe Machine: Explanation of The Standard Components of Most LathesDokument5 SeitenDiagram of Lathe Machine: Explanation of The Standard Components of Most LathesKaushik SreenivasNoch keine Bewertungen

- Case Study Lathe.....Dokument16 SeitenCase Study Lathe.....Zul AimanNoch keine Bewertungen

- Tool Holder MaintenanceDokument6 SeitenTool Holder Maintenanceenamicul50Noch keine Bewertungen

- Chucks: Clamp Radial Symmetry Cylindrical Drill Bit Power Tool Bar Spindle LatheDokument14 SeitenChucks: Clamp Radial Symmetry Cylindrical Drill Bit Power Tool Bar Spindle LatheIrtaza Husnain100% (1)

- Lathe Machine Definition Parts Types Operation Specification Advantages Application Notes PDFDokument23 SeitenLathe Machine Definition Parts Types Operation Specification Advantages Application Notes PDFNeeraj JithuNoch keine Bewertungen

- Agma MachineDokument6 SeitenAgma MachineNursena SEVİNÇNoch keine Bewertungen

- Lathe Machine: Description and Function of Lathe PartsDokument16 SeitenLathe Machine: Description and Function of Lathe PartsRenjith Rajendraprasad100% (1)

- Practical 7 Lathe MachineDokument5 SeitenPractical 7 Lathe MachineTendayiBonzo100% (7)

- Elijah Swatt - Metal Lathes 2Dokument6 SeitenElijah Swatt - Metal Lathes 2api-626529107Noch keine Bewertungen

- MCMT Unit-IIDokument190 SeitenMCMT Unit-IISai RamNoch keine Bewertungen

- MTM Lab ManualDokument23 SeitenMTM Lab ManualMian Abdul Rehman100% (1)

- Unidad Rotacion Serie L30 PDFDokument22 SeitenUnidad Rotacion Serie L30 PDFJairo BVNoch keine Bewertungen

- Machine ShopDokument6 SeitenMachine ShopAmarjeet Singh (Assistant Professor- Mechanical Engineer)Noch keine Bewertungen

- Lathe AccessoriesDokument10 SeitenLathe AccessoriesJeremiah FernandezNoch keine Bewertungen

- Alem Ketema Proposal NewDokument25 SeitenAlem Ketema Proposal NewLeulNoch keine Bewertungen

- Enemies Beyond Character Creation SupplementDokument8 SeitenEnemies Beyond Character Creation SupplementCain BlachartNoch keine Bewertungen

- T Rex PumpDokument4 SeitenT Rex PumpWong DaNoch keine Bewertungen

- Sco 8th Class Paper - B Jee-Main Wtm-15 Key&Solutions Exam DT 17-12-2022Dokument4 SeitenSco 8th Class Paper - B Jee-Main Wtm-15 Key&Solutions Exam DT 17-12-2022Udaya PrathimaNoch keine Bewertungen

- Bahan Ajar Application LetterDokument14 SeitenBahan Ajar Application LetterNevada Setya BudiNoch keine Bewertungen

- The Fluency Course Teacher Instructions PDFDokument9 SeitenThe Fluency Course Teacher Instructions PDFGabriel da RochaNoch keine Bewertungen

- Story 1Dokument3 SeitenStory 1api-296631749Noch keine Bewertungen

- Research Paper On Marketing PlanDokument4 SeitenResearch Paper On Marketing Planfvhacvjd100% (1)

- Human Capital PlanningDokument27 SeitenHuman Capital Planningalokshri25Noch keine Bewertungen

- Polyembryony &its ImportanceDokument17 SeitenPolyembryony &its ImportanceSURIYA PRAKASH GNoch keine Bewertungen

- Letter of Acceptfor TDokument3 SeitenLetter of Acceptfor TCCSNoch keine Bewertungen

- Data Structures and Algorithms SyllabusDokument9 SeitenData Structures and Algorithms SyllabusBongbong GalloNoch keine Bewertungen

- New - BMP3005 - ABF - Assessment Brief - FDokument5 SeitenNew - BMP3005 - ABF - Assessment Brief - Fmilka traykovNoch keine Bewertungen

- CBSE Class 10 Science Sample Paper SA 2 Set 1Dokument5 SeitenCBSE Class 10 Science Sample Paper SA 2 Set 1Sidharth SabharwalNoch keine Bewertungen

- Tanque: Equipment Data SheetDokument1 SeiteTanque: Equipment Data SheetAlonso DIAZNoch keine Bewertungen

- CSR Report On Tata SteelDokument72 SeitenCSR Report On Tata SteelJagadish Sahu100% (1)

- QuerySurge Models Mappings DocumentDokument28 SeitenQuerySurge Models Mappings Documentchiranjeev mishra100% (1)

- Space Saving, Tight AccessibilityDokument4 SeitenSpace Saving, Tight AccessibilityTran HuyNoch keine Bewertungen

- Corregidor Title DefenseDokument16 SeitenCorregidor Title DefenseJaydee ColadillaNoch keine Bewertungen

- Datalogic tl46 A Manual - 230104 - 140343Dokument2 SeitenDatalogic tl46 A Manual - 230104 - 140343Emmanuel Baldenegro PadillaNoch keine Bewertungen

- New Compabloc IMCP0002GDokument37 SeitenNew Compabloc IMCP0002GAnie Ekpenyong0% (1)

- Ezpdf Reader 1 9 8 1Dokument1 SeiteEzpdf Reader 1 9 8 1AnthonyNoch keine Bewertungen

- Javascript NotesDokument5 SeitenJavascript NotesRajashekar PrasadNoch keine Bewertungen

- 2 Year Spares List For InstrumentationDokument2 Seiten2 Year Spares List For Instrumentationgudapati9Noch keine Bewertungen

- 506 Koch-Glitsch PDFDokument11 Seiten506 Koch-Glitsch PDFNoman Abu-FarhaNoch keine Bewertungen

- Choosing An Effective Visual ToolDokument9 SeitenChoosing An Effective Visual ToolAdil Bin KhalidNoch keine Bewertungen

- The Function and Importance of TransitionsDokument4 SeitenThe Function and Importance of TransitionsMarc Jalen ReladorNoch keine Bewertungen

- Cuentos CADEDokument6 SeitenCuentos CADEMäuricio E. González VegaNoch keine Bewertungen

- Retail Visibility Project of AircelDokument89 SeitenRetail Visibility Project of Aircelabhishekkraj100% (1)

- Discover It For StudentsDokument1 SeiteDiscover It For StudentsVinod ChintalapudiNoch keine Bewertungen

- Beginning AutoCAD® 2022 Exercise Workbook: For Windows®Von EverandBeginning AutoCAD® 2022 Exercise Workbook: For Windows®Noch keine Bewertungen

- Certified Solidworks Professional Advanced Weldments Exam PreparationVon EverandCertified Solidworks Professional Advanced Weldments Exam PreparationBewertung: 5 von 5 Sternen5/5 (1)

- FreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsVon EverandFreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsBewertung: 5 von 5 Sternen5/5 (1)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchVon EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchBewertung: 4 von 5 Sternen4/5 (10)

- Beginning AutoCAD® 2020 Exercise WorkbookVon EverandBeginning AutoCAD® 2020 Exercise WorkbookBewertung: 2.5 von 5 Sternen2.5/5 (3)

- Up and Running with AutoCAD 2020: 2D Drafting and DesignVon EverandUp and Running with AutoCAD 2020: 2D Drafting and DesignNoch keine Bewertungen

- Design Research Through Practice: From the Lab, Field, and ShowroomVon EverandDesign Research Through Practice: From the Lab, Field, and ShowroomBewertung: 3 von 5 Sternen3/5 (7)

- SolidWorks 2015 Learn by doing-Part 1Von EverandSolidWorks 2015 Learn by doing-Part 1Bewertung: 4.5 von 5 Sternen4.5/5 (11)