Beruflich Dokumente

Kultur Dokumente

Diagnosis of Rotor Broken Bar in Induction Machines

Hochgeladen von

Arturo Ga PeCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Diagnosis of Rotor Broken Bar in Induction Machines

Hochgeladen von

Arturo Ga PeCopyright:

Verfügbare Formate

CoDIT'13

Diagnosis of Rotor Broken Bar in Induction Machines

under Time–Varying Condition

Y. Gritli*,**, L. Zarri**, IEEE, Senior Member, C. Rossi**, IEEE, Member,

F. Filippetti**, IEEE, Member, D. Casadei**, IEEE, Senior Member.

* University of Bologna,

Dipartimento di Ingegneria dell’Energia Elettrica e dell’Informazione «Guglielmo Marconi», Italy.

yasser.gritli@unibo.it, luca.zarri2@unibo.it,

claudio.rossi@unibo.it, fiorenzo.filippetti@unibo.it, domenico.casadei@unibo.it.

** University of Tunis El Manar,

Department of Electrical Engineering, LARA – National Engineering School of Tunis, Tunis, Tunisia.

yasser.gritli@esti.rnu.tn.

Abstract— The diagnosis of rotor broken bars in induction solutions, high resolution frequency estimation [3], Signal

machines (IMs) is commonly carried out by means of Motor Demodulation (SD) technique [4], and more recently High

Current Signature Analysis, i.e., by classical spectrum analysis of order spectral analysis [5] have been developed to reduce the

the input currents. Specifically in case of broken bars, the

amplitude of the left and right sideband components of a phase

effect of the non periodicity on the analyzed signals. These

current is monitored in order to sense their signature. However techniques, based on FA, give high quality discrimination

Motor Current Signature Analysis, based on Fourier Analysis, between healthy and faulty conditions but do not provide time

has some drawbacks that are still under investigation. domain information. This shortcoming was overcome by

The main concern is that an efficient frequency transformation Wavelet Analysis, which provide greater resolution in time for

cannot be made under speed–varying condition, since slip and high frequency components and greater resolution in

speed vary and so does the left and right sideband frequency

components. In this paper, an advanced use of the Discrete

frequency for low frequency components. Wavelets have a

Wavelet Transform is proposed to extract the contribution of the window that automatically adjusts to give the appropriate

most relevant rotor fault components, under time-varying resolution observed on approximations and details signals.

condition with high accuracy. Experimental results show the This method was used with different approaches for the

validity of the developed approach, leading to an effective diagnosis of rotor anomalies in induction machines such as

diagnosis method for broken bars in IMs operating under non- wavelet ridge method [6] or wavelet coefficients analysis [7].

stationary conditions .

Keywords—Fault diagnosis; rotor broken bar; induction motor; Later, approximations and details signals were investigated for

time-varying condition; wavelet analysis. reproducing the instantaneous evolution of rotor fault

frequency components [8]-[9] and quantifying the fault extents

I. INTRODUCTION [10], [11]. More recently, new interesting approach based on

Fault detection and diagnosis at incipient stage in induction stationary wavelet packet transform, has been proposed in [12]

machines have attracted the attention of researchers, since they for the same purposes. In the majority of the listed

allow reducing maintenance costs and down-time. contributions, tracking rotor fault frequency components on

Investigations on different failure modes in induction motors multi frequency bands complicates the diagnosis process. The

have revealed that 19% of the overall motor faults are related use of a single detail signal in [6] and more recently a single

to the rotor part [1]. Rotor faults can be initiated by thermal approximation signal in [11], whose level is imposed by the

stress, electromagnetic forces, electromagnetic noise and sampling frequency, were proposed for the same purposes.

vibration, centrifugal forces, environmental stress, mechanical Other quadratic transforms, such as the Wigner-Ville

stress owing to lose laminations, fatigue parts, bearing Distribution , suffers from the same constraint [13]. This

failures, or defects in connections. A detailed analysis of this limitation can be overcome by new advanced time-frequency

type of fault can be found in [2]. Cracked end ring or Broken distributions such as Smoothed Pseudo Wigner-Ville

bar share a percentage of only 10% of the total induction distributions [13], Choi-Williams distribution [13], [14], and

machine failures, but its detectability at an early stage still Zhao-Atlas-Marks distribution [15]. However the dependency

remain a key issue. For several applications, the motors on an appropriate choice of the sampling frequency penalizes

operate continuously in time-varying conditions. In these these approaches, because the band of the fault harmonic

contexts, the classical application of Fourier Analysis for component is not known in advance, due to the time varying

operating conditions. On the other hand, the change of the

processing variables fails as slip and speed vary. Thus the fault

sampling frequency in order to isolate rotor fault frequency

frequency components are spread over a bandwidth

components, as proposed in the most of the previous works,

proportional to the speed variations. Among different

978-1-4673-5549-0/13/$31.00 ©2013 IEEE 893

CoDIT'13

complicates considerably the processes of rotor fault detection

based on wavelet analysis. d1(n)

H.P.F 2

In this paper, a simple and effective method is presented to

i(n)

solve the above open points in time-varying operating d2(n)

H.P.F

conditions. The technique has been first investigated for the 2

diagnosis of stator and rotor electrical faults in Doubly Fed L.P.F 2

a1(n)

Induction Machine (DFIM) [16-17]. Hence, the proposed

contribution is intended to be a validation of this new 1st Level L.P.F 2 a2(n)

decomposition

approach, based on DWT, applied to the detection of rotor bar

breakage. This paper is organized as follows. Section II 2nd level

presents a diagnosis approach for fault detection based on an decomposition

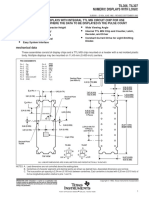

Fig. 2. Wavelet Transform using a filter banks

improved use of DWT. Experimental results for rotor broken-

bar fault analysis under speed transient conditions are

presented and commented in section III. Finally conclusions the stator current shows a series of fault components at the

and perspectives are given in section IV. following frequencies:

II. FAULT FREQUENCY TRACKING – THE PROPOSED fbrb=(1±2ks)f (with k=1,2,3,…). (1)

APPROACH The propagation principle of this chain of frequency

A. Rotor fault frequency propagation components is illustrated in Fig. 1. Under speed–varying

Like any other rotating electrical machine, the squirrel cage condition, the sideband components expressed by (1), whose

induction motor is subjected to both electromagnetic and amplitudes have to be monitored for diagnostic purposes, are

mechanical forces symmetrically repartitioned. Induction spread in frequency. It turns out that the direct application of

machines are known as highly symmetrical electric systems, the classical FA to machine stator currents is not effective. A

due to the rotating magnetic field, so any type of anomaly simple solution for an efficient diagnosis of rotor broken bars

modifies their symmetrical proprieties. In healthy conditions for induction machines, under speed-varying conditions, is

only the fundamental frequency f exists in stator currents. presented in the next section.

If the rotor part is damaged, the rotor symmetry of the B. Rotor fault frequency tracking under time-varying

machine is lost and a reverse rotating magnetic field related to operating conditions

an inverse sequence component of the rotor currents, at

The main feature of wavelet analysis is its high

frequency –sf (s denotes the slip), appears. This inverse

multiresolution analysis capability. Wavelet analysis is a

sequence is reflected on the stator side and produces the

signal decomposition, using successive combinations of

frequency component (1−2s)f. Consequently a torque ripple

approximation and detail signals. The procedure for two-level

and a speed ripple are generated at frequency 2sf, which

decomposition is shown in Fig. 2, where (LPF) and (HPF) are

modulates the rotating magnetic flux [2]. This modulation

respectively a low pass filter and a high pass filter. By using

produces two current components, i.e., an additional left-side

Nyquist sampling criterion, the signal is then down sampled

component at (1−4s)f and a right side component at (1+2s)f.

by factor 2. The coefficients a1 and d1 represent respectively

Following this interaction process, the frequency content of

approximation and detail signals at first level of

decomposition. The procedure is repeated until the original

Rotor Stator Mechanical Time-Frequencies Propagation signal is decomposed to a pre-defined decomposition level.

freq. freq. speed

freq.

With the well known dyadic down sampling procedure,

Frequency Propagation

±3sf

(1+2s)f

frequency bands of the jth level decomposition are related to

2sf

(1 - 2s)f

the sampling frequency fs. Hence, these bands given by [0, 2-

(J+1)

fs] or [2-(J+1)fs , 2-Jfs] cannot be changed unless a new

±sf acquisition with different sampling frequency is made [18].

f This fact complicates any fault detection based on DWT,

±1/sf* ±1/3sf* Rotor particularly in speed-varying condition. In this paper, an

periods

efficient solution to overcome this limitation is proposed.

1/f 1/(1-2s)f 1/(1+2s)f Stator

periods Hereafter the sampling frequency fs is assumed equal to

3.2kHz, and a nine level decomposition (J=9) is chosen to

Mechanical

1/2sf speed

periods cover the frequency bands in which the fault component is

Time Propagation tracked. With regard to the type of mother wavelet, a 10th

Fig. 1. Time-frequency propagation of rotor fault components: the sign (–) in

order Daubechies family is chosen, although other families

time domain corresponds to inverse current sequence components. (Dmeyer and Coiflet) also allow a clear detection of the

978-1-4673-5549-0/13/$31.00 ©2013 IEEE 894

CoDIT'13

TABLE I

''a j'' signa l

FREQUENCY BANDS AT EACH LEVEL

Approximations Frequency Details Frequency Time

«aj » bands (Hz) « dj » bands (Hz)

a9 : [0 – 3.125] d9 : [3.125 – 6.25]

a8 : [0 – 6.25] d8 : [6.25 – 12.5] Δn TIN=1

''a j'' signal

a7 : [0 – 12.5] d7 : [12.5 – 25]

seq uences

TIN=2

a6 : [0 – 25] d6 : [25 – 50] δn TIN=3

a5 : [0 – 50] d5 : [50 – 100]

a4 : [0 – 100] d4 : [100 – 200]

a3 : [0 – 200] d3 : [200 – 400]

a2 : [0 – 400] d2 : [400 – 800] Samples

a1 : [0 – 800] d1 : [800 – 1600] Fig. 4. Principle of time interval calculation, TIN: Time Interval Number.

phenomenon. Under healthy conditions, only the fundamental frequency interval [0, 3.125] Hz corresponding to

component f exists in the stator currents. If the rotor part is approximation a9 (see Table I). The proposed approach was

damaged, the first fault frequency component that occurs in applied to the stator current with fsl=45.5Hz to isolate the

the stator currents is (1–2s)f (Fig. 1). contribution of the (1-2s)f and fsl=48.3Hz to isolate the

In time varying conditions the magnitudes of this fault contribution of the (1+2s)f component, which allow a great

component cannot be detected through a classical frequency precision in filtering the effects of the fundamental component

analysis since it is spread in a wide frequency range. A simple and of other harmonics around the fault component of interest.

processing of the stator phase current allows shifting the fault With regard to the type of mother wavelet, the use of low

component (1-2sf) to a prefixed frequency band. In such a order Daubechies mother wavelet (db10) has provided

way, all the information related to the fault is isolated and satisfactory results. Several types of mother wavelets

confined in a single frequency band. More in details, a (Daubechies, Coiflet, and Symlet) were tested in the analysis.

frequency sliding fsl is applied to the stator phase current at Regardless of its different properties, the qualitative analysis

each time slice as shown in (2), so that the harmonic of the results showed that no significant advantages appeared.

component of interest is moved to a frequency band in which Once the state of the machine has been qualitatively

the fault component will be tracked. Then the real part of the diagnosed, a quantitative evaluation of the fault degree is

shifted signal is analyzed by means of DWT. necessary. For this purpose a dynamic multiresolution mean

− j 2π f sl t ⎤ power indicator mPaj at different resolution levels j was

I s l ( t ) = R e ⎡ is a ( t ) e (2)

⎣ ⎦ introduced as a diagnostic index to quantify the extent of the

fault. This index is defined as shown in (3):

The choice of fsl is made by taking into account the speed

Δn

range of the considered transient. The evaluation of fsl is made 1

∑ (3)

2

m P a j ( isa ) = a j (n)

in such a way that the contribution of the fault frequency Δn n =1

component, for the whole considered slip range, is shifted into

where aj(n) is the approximation signal of interest (a9 in our

one of the intervals [0, 2-(J+1)fs] or [2-(J+1)fs , 2-J fs] and

case), Δn denotes the number of samples and j the

consequently the DWT is applied to analyze only the

decomposition level. The fault indicator is periodically

frequency band of interest. In this way, the detection and

calculated over time, every 400 samples using a window of

quantification get easier. As illustrated in Fig. 3, the DWT

6400 samples as depicted in Fig. 4 where δn is a set of 400

analysis divides the signal into logarithmically–spaced

samples and Δn a set of 6400 samples. These values were

frequency bands. From this bandwidth segmentation, it is

regulated experimentally to reduce variations that can lead to

possible to realize that the approximation aJ and detail dJ have

false alarms in healthy operating conditions of the motor.

the same and the smallest frequency band width equal to

fsam/2J+1. Moreover, approximation aJ is less subjected to the When the fault occurs, the energy distribution of the signal is

overlapping effect than dJ due to its proximity to 0Hz [19]. changed in the resolution levels related to the characteristic

frequency bands of the default. Hence, the energy excess

Finally, approximation a9 was chosen for extracting the

localized in the approximation is considered as an anomaly

contribution of the fault component (1-2s)f. Therefore the

indication in case of rotor broken bar.

choice of fsl is made to shift these fault components inside the

978-1-4673-5549-0/13/$31.00 ©2013 IEEE 895

CoDIT'13

-a-

20

10

Current (A)

0

-10

-20

0 1 2 3 4 5 6 7 8 9 10

Time (s)

-b-

1

0.5

Fig. 5. Test bed photo (left). The faulty rotor with one drilled rotor bar (right).

a9

0

-a- -b- -0.5

1510 1510

1500 1500 -1

Speed (rpm)

Speed (rpm)

1490 1490 0 1 2 3 4 5 6 7 8 9 10

Time (s)

1480 1480

Fig. 7. DWT analysis of stator phase current under speed-varying condition,

1470 1470

for tracking the fault component (1-2s)f ; Healthy condition.

1460 1460

-a-

1450 1450

0 2 4 6 8 10 0 2 4 6 8 10

Time (s) Time (s) 20

-c- -d- 10

Current (A)

20 20 0

10 10

Current (A)

Current (A)

-10

0 0

-20

-10 -10 0 1 2 3 4 5 6 7 8 9 10

Time (s)

-20 -20

-b-

0 2 4 6 8 10 0 2 4 6 8 10

Time (s) Time (s) 1

Fig. 6. Instantaneous values of a-b) speed and c-d) stator phase currents under 0.5

healthy and one rotor broken bar respectively.

a9

-0.5

-1

III. EXPERIMENTAL RESULTS 0 1 2 3 4 5 6 7 8 9 10

Time (s)

In order to test the effectiveness of the proposed rotor fault Fig. 8. DWT analysis of stator phase current under speed-varying condition,

for tracking the fault component (1-2s)f ; Healthy condition.

diagnostic procedures a test bed was realized. A 7.5 kW, 2

poles pair induction machine was used (see Appendix). Two

rotors are available, one healthy and one with a drilled rotor s=0.002 to s=0.026. Another test, for the same speed transient

bar. The induction machine is coupled to a 9kW separately was made with the machine operating with one rotor broken

excited DC machine controlled in speed. This allows to realize bar. The instantaneous values of speed and phase currents,

speed transients. Photos of the experimental test bed are corresponding to the healthy and faulty cases, are depicted in

shown in Fig. 5. Machine currents and speed are sampled at Fig. 6 (a-b) and Fig. 6 (c-d) respectively.

3.2 kHz with a time duration of 10 seconds. A smaller number

of points could be used without affecting the performances of As explained in section III, the frequency band of interest for

the proposed procedure. The induction motor has been initially tracking the (1-2s)f and (1+2s)f fault components contribution

tested in healthy conditions during a prefixed transient from is the approximation signal a9. For the sake of clarity only the

1496 rpm to 1460 rpm, corresponding to slip ranges from a9 signal will be reported. In healthy condition, the 9th

approximation signal a9, resulting from the wavelet

decomposition of the stator phase current, does not show any

aJ dJ dJ-1 d1 kind of variation (Fig. 7-b). This indicates the absence of the

fault component (1-2s)f, leading to diagnose the healthy

condition of the motor under speed-varying condition.

Frequency However, in faulty condition (one rotor broken bar)

[0 : fsam/2J+1] [fsam/2J+1 : fsam/2J] [fsam/2J : fsam/2J-1] [fsam/4 : fsam/2]

approximation a9 shows significant variation in magnitude

observed in Fig.8-b. During the first time period (t=0s to

Fig. 3. The DWT filtering process; the overlapping effect. t=2s), under a constant speed of 1496 rpm, the 9th

978-1-4673-5549-0/13/$31.00 ©2013 IEEE 896

CoDIT'13

-a-

0.5

20 Healthy Broken bar

0.45

10

Current (A)

0 0.4

-10 0.35

-20

0.3

0 1 2 3 4 5 6 7 8 9 10

mPa9

Time (s)

0.25

-b-

1.2

0.2

0.8

0.4 0.15

a9

0

0.1

-0.4

0.05

-0.8

-1.2 0

0 1 2 3 4 5 6 7 8 9 10 0 10 20 30 40 50 60 70 80

Time (s)

TIN

Fig. 9. DWT analysis of stator phase current under speed-varying condition, Fig. 11. Cyclic values of the fault indicator mPa9, resulting from the 9th

for tracking the fault component (1+2s)f ; Healthy condition. wavelet decomposition level of the signals Isl under healthy and rotor broken

-a- bar (red and blue) during the tracking of (1-2s)f component.

20

0.125

Current (A)

10

Healthy Broken bar

0

-10 0.1

-20

0 1 2 3 4 5 6 7 8 9 10

Time (s)

-b-

mPa9

1.2

0.8

0.4 0.05

a9

-0.4

-0.8

-1.2

0 1 2 3 4 5 6 7 8 9 10

Time (s)

0

Fig. 10. DWT analysis of stator phase current under speed-varying condition, 0 10 20 30 40 50 60 70 80

for tracking the fault component (1+2s)f ; One rotor broken bar. TIN

Fig. 12. Cyclic values of the fault indicator mPa9, resulting from the 9th

wavelet decomposition level of the signals Isl under healthy and rotor broken

bar (red and blue) during the tracking of (1+2s)f component.

approximation signal, representative of the (1-2s)f frequency

component, do not show any important variations. This is due

of the stator phase current, under healthy (Fig. 9-b) and rotor

to the fact that at low load level (under 4% of the nominal

broken bar (Fig. 10-b) reproduce clearly the magnitude

torque) the fault frequencies are practically superimposed to

evolution of the fault component (1+2s)f dynamically over

the fundamental and magnitudes are not detectable. During

time. If we confine our attention on the approximation signal

deceleration (around t=2s), a9 shows particular magnitude

a9 depicted in Fig. 7-b and Fig. 10-b, we can notice that the

escalation proportional to the abrupt deceleration until

rotor fault signature issued from the fault component (1-2s)f is

reaching a quasi steady-state magnitude (under 66% of the

more relevant than the corresponding one related to the

nominal torque). More in detail, the oscillations observed in

(1+2s)f component. This is mainly due to the damping

the signal a9, with quasi-constant amplitude, follow a

machine-load inertia effect on high order rotor fault

characteristic pattern that fits the evolution in frequency of the

harmonics. The 9th approximation signal obtained from the

fault component (1-2s)f, during the speed transient. The

experimental results shows the sensitivity and the

second rotor fault signature tracked is related to the fault

effectiveness of this particular signal a9 to reproduce the

component at frequency (1+2s)f. The corresponding

contribution of the frequency components (1-2s)f and (1+2s)f

experimental results, under healthy and rotor broken bar are

under large speed varying conditions. As introduced in the

presented in Fig. 9 and Fig. 10. The same observations as for

previous section, a fault indicator based on a cyclic mean

the signature of the side band (1-2s)f under the considered

power calculation of the approximation a9, resulting from the

rotor unbalance, are reached; the comparison of the

wavelet decomposition applied to one stator current, has been

approximation signal a9, issued from wavelet decomposition

proposed to evaluate quantitatively the degree of the fault

978-1-4673-5549-0/13/$31.00 ©2013 IEEE 897

CoDIT'13

extent. The cyclic evolution of the fault indicator mPa9, IEEE Transactions on Industrial Electronics, Vol. 54, Issue 4, pp. 2305

– 2314, Aug. 2007.

representative of the contributions of the fault components

[4] A. Stefani, F. Filippetti, A. Bellini, "Diagnosis of Induction Machines in

components (1-2s)f and (1+2s)f , issued from the experimental Time-varying Conditions", IEEE Transactions on Industry Applications,

tests (Figs. 7-10), under healthy and rotor broken bar Vol. 56, N° 11, Nov. 2009.

conditions are depicted in Fig. 11 and Fig. 12 respectively. In [5] L. Saidi, F. Fnaiech, H. Henao, and G-A. Capolino, G. Cirrincione,

healthy condition, and under large range of speed variations, "Diagnosis of broken-bars fault in induction machines using higher

order spectral analysis", International Society of Automation

mPa9 does not show any significant change. Consequently, the Transactions, Vol. 52, Issue 1, pp. 140-148, Jan. 2013.

indicator values for the healthy motor are considered as a [6] Z. Zhang, Z. Ren, and W. Huang, "A novel detection method of motor

baseline to set the threshold for discriminating healthy from broken rotor bars based on wavelet ridge", IEEE Transactions Energy

Conversion, vol. 18, N° 3, pp. 417–423, Sep. 2003.

faulty conditions. Under rotor broken bar condition the

[7] A. Ordaz-Moreno, R.J.Romero-Troncoso, J. A. Vite-Frias, J. R. Rivera-

calculated mPa9 indicator shows a noteworthy increase. The Gillen, and A. Garcia-Perez, "Automatic Online Diagnosis Algorithm

large energy deviation observed in faulty condition proves the for Broken-Bar Detection on Induction Motors Based on Discrete

effectiveness of the proposed approach, since the transient Wavelet Transform for FPGA Implementation", IEEE IEEE

Transactions on Industrial Electronics, Vol. 55, N° 5, pp. 1361–1368,

speed motor operation does not disturb the fault assessment, in May. 2008.

comparison with the healthy case. [8] J.A. Antonino-Daviu, M.Riera-Guasp , J. Roger-Folch, R. B. Pérez , "An

analytical comparison between DWT and Hilbert-Huang-based methods

IV. CONCLUSION for the diagnosis of rotor asymmetries in induction machines", Industry

Applications Conference Record of the 42nd IAS Annual Meeting,

A diagnosis procedure for detection and quantification of rotor pp.1932 – 1939, Sept.2007.

broken bar in squirrel cage motor, in speed-varying condition [9] J. Cusido, L. Romeral, J.A. Ortega, J.A. Rosero, A. G. Espinosa, ''Fault

Detection in Induction Machines Using Power Spectral Density in

is proposed here. The presented approach is based on an Wavelet Decomposition'', IEEE Transactions on Industrial Electronics,

improved use of the DWT by a simple pre-processing of the Vol. 55, N° 2, pp. 633–643, Feb. 2008.

stator phase current. Once the state of the machine is [10] S. H. Kia, H. Henao, G.-A. Capolino, "Diagnosis of Broken Bar Fault in

Induction Machines Using Discrete Wavelet Transform Without Slip

qualitatively diagnosed, a cyclic time-frequency fault indicator Estimation", IEEE Transactions on Industry Applications, Vol. 45, Issue

was introduced to quantify the fault extent. It is obvious that 4, pp. 1395-1404, 2009.

the method is particularly advantageous even when the fault [11] M. Riera-Guasp, Jose A. Antonino-Daviu, M. Pineda-Sanchez, R.

component of interest is very close to the fundamental one or Puche-Panadero, and J. Perez-Cruz, "A General Approach for the

Transient Detection of Slip-Dependent Fault Components Based on the

in case of other faults that would produce their appearance of a Discrete Wavelet Transform", IEEE Transactions on Industrial

peculiar fault frequency. The proposed approach allows, with Electronics, Vol. 55, N° 12, Dec. 2008.

high precision, the extraction of the contribution of the most [12] H. Keskes, A. Braham, Z. Lachiri, “On the use of stationary wavelet

relevant rotor frequency components separately. packet transform and multiclass wavelet SVM for broken rotor bar

detection”, the 38th Annual Conference on IEEE Industrial Electronics

Experimental results demonstrate the effectiveness of this new Society- IECON 2012, pp. 3919 – 3924, Montréal (Canada), Oct. 2012.

approach for the detection of rotor broken bar in squirrel cage [13] S. Rajagopalan, J. M. Aller, J. A. Restrepo, T. G. Habetler, and R. G.

motor, under time varying conditions. Eventually, the Harley, “Detection of rotor faults in brushless DC motors operating

under non-stationary conditions,” IEEE Trans. Ind. Appl., vol. 42, pp.

technique can be extended to the investigation of mixed 1464–1477, Nov./Dec. 2006.

mechanical or/and electrical fault conditions. [14] S. Rajagopalan, J. A. Restrepo, J. M. Aller, T. G. Habetler, and R. G.

Harley, “Non-stationary motor fault detection using recent quadratic

time-frequency representations,” IEEE Trans. Ind. Appl., vol. 44, no. 3,

V. APPENDIX pp. 735–744, May/Jun. 2006.

Rated data Value [15] Y. Zhao, L. E. Atlas, and R. J. Marks II, “The use of cone-shaped

Rated Power kW 7.5 kernels for generalized time-frequency representations of nonstationary

Nominal stator current A 15.3 signals,” IEEE Trans. on Acous., Speech and Signal Process., vol. 38,

Rated stator voltage V 380 no. 7, pp. 1084-1091, Jul. 1990.

Rated frequency Hz 50 [16] Y. Gritli, A. Stefani, C. Rossi and F. Filippetti, A. Chatti, and L. Zarri,

Rated speed rpm 1440 "Experimental Validation of Doubly Fed Induction Machine Rotor Fault

Stator phase resistance Ω 0.54 Diagnosis Based on Wavelet Analysis in Closed Loop Operations", The

Stator inductance mH 88.4 20th International Symposium on Power Electronics, Electrical Drives,

Pole pairs 2 Automation and Motion-SPEEDAM‘2010, Jun. 14-16, Pisa (Italy), 2010.

Number of rotor bars 28 [17] Y. Gritli, L. Zarri, C. Rossi, F. Filippetti, G. Capolino, and D. Casadei,

"Advanced diagnosis of electrical faults in wound rotor induction

machines," IEEE Transactions on Industrial Electronics (Accepted for

REFERENCES publication), p. 1, 2012.

[1] A.H. Bonnett, C. Yung, "Increased Efficiency Versus Increased [18] S.G. Mallat, "A Theory for Multiresolution Signal Decomposition: The

Reliability", IEEE Industry Application Magazine., Vol. 14, Issue 1, Wavelet Representation", IEEE Tran. On Pat. Ana. And Mac. Inte. Vol.

Jan./Feb. 2008. 2, N° 7, July 1989.

[2] A. Bellini, F. Filippetti, C. Tassoni, and G. A. Capolino, "Advances in [19] J. Antonino-Daviu, M. Riera-Guasp, J. Roger-Folch, and M. P. Molina,

diagnostic Techniques for induction machines", IEEE Transactions on "Validation of a new method for the diagnosis of rotor bar failures via

Industrial Electronics, Vol.55, N° 12, Dec. 2008. wavelet transformation in industrial induction machines", IEEE

[3] S.H. Kia, H. Henao, G.-A. Capolino, ''A High-Resolution Frequency Transactions on Industry Applications, vol. 42, no. 4, pp. 990–996,

Estimation Method for Three-Phase Induction Machine Fault Detection'', Jul./Aug. 2006.

978-1-4673-5549-0/13/$31.00 ©2013 IEEE 898

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Inductively Coupled PlasmaDokument8 SeitenInductively Coupled Plasmagerarjui100% (1)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Saes T 000 PDFDokument10 SeitenSaes T 000 PDFsvrao4uNoch keine Bewertungen

- All-Wheel Drive Four-Wheel Drive Systems and Strategies PDFDokument7 SeitenAll-Wheel Drive Four-Wheel Drive Systems and Strategies PDFjohn ayengahNoch keine Bewertungen

- 1088 HD Camera Operating ManualDokument46 Seiten1088 HD Camera Operating ManualSn Dayanidhi100% (1)

- TM 9 6230 210 13p Floodlight SetDokument264 SeitenTM 9 6230 210 13p Floodlight SetAdvocateNoch keine Bewertungen

- 9500 MPR Product DescriptionDokument79 Seiten9500 MPR Product DescriptionRoger Juan Gomez Ramirez100% (1)

- A Complete Ensemble Empirical Mode DecompositionDokument4 SeitenA Complete Ensemble Empirical Mode DecompositionArturo Ga PeNoch keine Bewertungen

- Induction Machine Fault Detection EnhancementDokument6 SeitenInduction Machine Fault Detection EnhancementArturo Ga PeNoch keine Bewertungen

- Reliable Detection of Induction Motor Rotor FaultsDokument9 SeitenReliable Detection of Induction Motor Rotor FaultsArturo Ga PeNoch keine Bewertungen

- A MUSIC-Based Method To Detect Broken RotorDokument4 SeitenA MUSIC-Based Method To Detect Broken RotorArturo Ga PeNoch keine Bewertungen

- A High-Resolution Frequency Estimation Method ForDokument10 SeitenA High-Resolution Frequency Estimation Method ForArturo Ga PeNoch keine Bewertungen

- Startup Current Analysis of Incipient Broken Rotor Bar in PDFDokument7 SeitenStartup Current Analysis of Incipient Broken Rotor Bar in PDFArturo Ga PeNoch keine Bewertungen

- Induction Machine Fault Detection EnhancementDokument6 SeitenInduction Machine Fault Detection EnhancementArturo Ga PeNoch keine Bewertungen

- Reliable Detection of Induction Motor Rotor FaultsDokument9 SeitenReliable Detection of Induction Motor Rotor FaultsArturo Ga PeNoch keine Bewertungen

- Broken Bar Condition Monitoring of An Induction Motor Under PDFDokument7 SeitenBroken Bar Condition Monitoring of An Induction Motor Under PDFArturo Ga PeNoch keine Bewertungen

- Fourier Methods of Spectral Estimation PDFDokument44 SeitenFourier Methods of Spectral Estimation PDFArturo Ga PeNoch keine Bewertungen

- Broken Bar Condition Monitoring of An Induction Motor Under PDFDokument7 SeitenBroken Bar Condition Monitoring of An Induction Motor Under PDFArturo Ga PeNoch keine Bewertungen

- Lecture Notes 13Dokument16 SeitenLecture Notes 13Arturo Ga PeNoch keine Bewertungen

- Ec4440 III DLDokument49 SeitenEc4440 III DLArturo Ga PeNoch keine Bewertungen

- Fourier Methods of Spectral Estimation PDFDokument44 SeitenFourier Methods of Spectral Estimation PDFArturo Ga PeNoch keine Bewertungen

- Vibration Transient DetectionDokument7 SeitenVibration Transient DetectionArturo Ga PeNoch keine Bewertungen

- Fractional Calculus Based Processing For Feature Extraction in Harmonic Polluted Fault Monitoring SystemsDokument15 SeitenFractional Calculus Based Processing For Feature Extraction in Harmonic Polluted Fault Monitoring SystemsArturo Ga PeNoch keine Bewertungen

- Random ProcessesDokument47 SeitenRandom ProcessesArturo Ga PeNoch keine Bewertungen

- InTech-Time Frequency Transforms For Classification of Power Quality DisturbancesDokument18 SeitenInTech-Time Frequency Transforms For Classification of Power Quality DisturbancesArturo Ga PeNoch keine Bewertungen

- A New Approach For Induction Motor Broken Bar Diagnosis by Using Vibration SpectrumDokument6 SeitenA New Approach For Induction Motor Broken Bar Diagnosis by Using Vibration SpectrumArturo Ga PeNoch keine Bewertungen

- Broken Rotor Bar DetBroken Rotor Bar Detection in Variableection in VariableDokument5 SeitenBroken Rotor Bar DetBroken Rotor Bar Detection in Variableection in VariableArturo Ga PeNoch keine Bewertungen

- E LBP Mcoq Mod 13.10 IfeDokument9 SeitenE LBP Mcoq Mod 13.10 IfearunNoch keine Bewertungen

- TTLDokument31 SeitenTTLLembar Firdillah KurniawanNoch keine Bewertungen

- Plano Antena Yagi Frecuencia 850 MHZDokument2 SeitenPlano Antena Yagi Frecuencia 850 MHZageroNoch keine Bewertungen

- EVE ReportDokument8 SeitenEVE ReportMARY SIRACH DELA TORRENoch keine Bewertungen

- Arno ConverterDokument3 SeitenArno ConverterFariha shaikhNoch keine Bewertungen

- E9180 PDFDokument14 SeitenE9180 PDFGlauber RodriguesNoch keine Bewertungen

- Mitsubishi Electric PURY-P YLM-A1 PURY-EP YLM A Service Manual EngDokument434 SeitenMitsubishi Electric PURY-P YLM-A1 PURY-EP YLM A Service Manual Engsantiago quinterosNoch keine Bewertungen

- A Seminar Reporton System VerilogDokument29 SeitenA Seminar Reporton System Verilograkeshcusat890% (1)

- Dual JK Negative Edge-Triggered Flip-Flop SN54/74LS114A: Low Power SchottkyDokument4 SeitenDual JK Negative Edge-Triggered Flip-Flop SN54/74LS114A: Low Power Schottkydistrict19Noch keine Bewertungen

- ATV320 Getting Started EN NVE21763 01 PDFDokument4 SeitenATV320 Getting Started EN NVE21763 01 PDFmaristele rimolo JuniorNoch keine Bewertungen

- TIL306, TIL307 Numeric Displays With LogicDokument9 SeitenTIL306, TIL307 Numeric Displays With LogicAndy ScriptorNoch keine Bewertungen

- Six-Step Troubleshooting ProcedureDokument1 SeiteSix-Step Troubleshooting ProcedureNoneya BidnessNoch keine Bewertungen

- Analog & Discrete IC Design: Dr. Ali Imran Najam 21 01 12Dokument38 SeitenAnalog & Discrete IC Design: Dr. Ali Imran Najam 21 01 12Muhammad AdnanNoch keine Bewertungen

- ABL8MEM24012: Panel Mount DIN Rail MountDokument1 SeiteABL8MEM24012: Panel Mount DIN Rail MountSebastian Alexis Muñoz PoveaNoch keine Bewertungen

- Mechanical Au 3-1Dokument10 SeitenMechanical Au 3-1Venkata Sai Kumar NunnaNoch keine Bewertungen

- ECEPurdue MOSFET Lundstrom L2.3v3bDokument22 SeitenECEPurdue MOSFET Lundstrom L2.3v3balNoch keine Bewertungen

- BS Standard-Hot Water Storage SizingDokument3 SeitenBS Standard-Hot Water Storage Sizinglijo johnNoch keine Bewertungen

- KD36XS55 Service ManualDokument211 SeitenKD36XS55 Service ManualRob MyersNoch keine Bewertungen

- Microwave ODUDokument5 SeitenMicrowave ODUImranRafiqNoch keine Bewertungen

- Datasheet Relay ENG, DS, OMI, OMIH SeriesDokument3 SeitenDatasheet Relay ENG, DS, OMI, OMIH SeriesrealaffiliateNoch keine Bewertungen

- Assignment 02Dokument10 SeitenAssignment 02Zain UL ABIDINNoch keine Bewertungen

- Filtering BasicsDokument83 SeitenFiltering BasicsDikshitJainNoch keine Bewertungen

- UPS Battery Maintenance 101 - EC&MDokument6 SeitenUPS Battery Maintenance 101 - EC&MZiad BadrNoch keine Bewertungen

- Manual Motor Starter MS132: Data SheetDokument12 SeitenManual Motor Starter MS132: Data SheetHELLOGREGNoch keine Bewertungen