Beruflich Dokumente

Kultur Dokumente

Corken-Kompressoraggregate Englisch

Hochgeladen von

LPG Equipment Consulting and ServicesOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Corken-Kompressoraggregate Englisch

Hochgeladen von

LPG Equipment Consulting and ServicesCopyright:

Verfügbare Formate

NINNELT International GmbH Filling stations for gases and liquids

Peiner Strasse 221 Conveying and transport technology

DE-38229 Salzgitter (Engelnstedt) Palletizing systems

Tel: (+49) 53 41 - 8 66 06-0 Safety breakaway couplings

Fax: (+49) 53 41 - 8 66 06-10 Pumps • Compressors

E-mail: info@ninnelt.de Fittings • Ball valves

Internet: www.ninnelt.de Repairs • Engineering

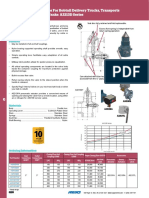

Corken Dry-running Piston Compressor Aggregates

Compressor-aggregate with oil free dry running piston type gas compressor PN 25,

type Corken/NINNELT, for stationary systems, all fittings are connected by steel piping,

aggregate with pressure gauges, oil pressure gauge, mechanical liquid separator, strainer,

4-way ball valve, drive belt clamping mechanism, drive belt, drive belt pulley for the drive motor, belt guard, Ex-

proofed three phase motor 400/690 V 50 Hz, EEx e 11 T3, IP 54, Model B 3, both erected on a rigid mounting

plate, ready for connection, fully welded, assembled, primed and painted,

with an inspection certificate 3.1.B according to EN 10 204 (DIN 50.049-3.1

Design: with type tested safety valve 19 bar in the pressure piping

Compressor cylinder and cylinder head

made of spheroid graphite iron ASTMA536

Version A = with a single piston rod seal

Version B = with a double piston rod seal (D)

Order -Nr. type Order -Nr. type

Version A Corken/ Version B Corken/

NINNELT NINNELT

63330 91 63316 D 291

63306 291 63303 D 491

63311 491 63400 D 691

21064 691 63384 D 891

Technical Data

Compressor Typs 91 D291/291 D491/491 D691/691 D891/891

Connection: Single compressor (NPT – IG) ¾“ ¾“ ¼“ ½“ 2“ANSI

Complete aggregate (flange DIN) 20 25 32 40 50

Number of cylinders 2 2 2 2 2

Piston stroke (mm) 63,5 63,5 76,2 101,6 101,6

Maximum piston displacement (m³/h) 14,1 28,0 60,3 102,3 192,0

Minimum inlet pressure (bar) 0,21 0,21 0,21 0,21 0,21

Maximum operating pressure (bar) 24,1 24,1 24,1 24,1 32,1

RPM 790 790 790 790 790

Maximum power consumption (kW) 5,6 11 11 26,1 34

Maximum outlet temperature (°C) 177 177 177 177 177

Motor capacity (kW) 2,2 5,0 10 17,5 30

Weight (kg) 140 270 400 650 900

ANSI / DIN flange option F91 F291 F491 F691 Not

deliverable

Certificate for the pressure test I starting up

Hydrostatics test 52 bar, manufacturer's certificate for single compressor

TÜV-pressure testing the pipeline system 35 bar for complete unit

Commissioning compressor unit

Additional equipment and additional monitoring and control equipment to TRB on request

Electrical control cabinet for controlling the compressor unit on request

Corken Compressor Aggregates Rev. 03.11.2011 Page 1 of 1

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Manuel Maintenance Pompes CorkenDokument88 SeitenManuel Maintenance Pompes CorkenLPG Equipment Consulting and ServicesNoch keine Bewertungen

- 120001RohrbruchvRBV EDokument1 Seite120001RohrbruchvRBV ELPG Equipment Consulting and ServicesNoch keine Bewertungen

- Chek-Lok® Excess Flow Valves 7590U and 7591U Series: ApplicationDokument1 SeiteChek-Lok® Excess Flow Valves 7590U and 7591U Series: ApplicationLPG Equipment Consulting and ServicesNoch keine Bewertungen

- Side Channel Pumps: Self-Priming, Multi-Stage TypeDokument5 SeitenSide Channel Pumps: Self-Priming, Multi-Stage TypeLPG Equipment Consulting and ServicesNoch keine Bewertungen

- Right ItemDokument1 SeiteRight ItemLPG Equipment Consulting and ServicesNoch keine Bewertungen

- Group 19 : Shut-Off Valves Bypass Valves Three-Way Valves Quick-Acting Valves Solenoid Valves Ball ValvesDokument10 SeitenGroup 19 : Shut-Off Valves Bypass Valves Three-Way Valves Quick-Acting Valves Solenoid Valves Ball ValvesLPG Equipment Consulting and ServicesNoch keine Bewertungen

- AS4012LPG M5: 9 Meters 384.000 360º ManualDokument4 SeitenAS4012LPG M5: 9 Meters 384.000 360º ManualLPG Equipment Consulting and ServicesNoch keine Bewertungen

- Fas 13Dokument6 SeitenFas 13LPG Equipment Consulting and ServicesNoch keine Bewertungen

- Group 14 : Strainers, Traps, Fine-Mesh Filters Filling Device For Methanol Drain DeviceDokument3 SeitenGroup 14 : Strainers, Traps, Fine-Mesh Filters Filling Device For Methanol Drain DeviceLPG Equipment Consulting and ServicesNoch keine Bewertungen

- Willy Resume-July .2016Dokument13 SeitenWilly Resume-July .2016LPG Equipment Consulting and ServicesNoch keine Bewertungen

- Group 15 : Relief Valves AccessoriesDokument4 SeitenGroup 15 : Relief Valves AccessoriesLPG Equipment Consulting and ServicesNoch keine Bewertungen

- Group 21 : Compressors Pumps Accessories Complete Units and PackagesDokument11 SeitenGroup 21 : Compressors Pumps Accessories Complete Units and PackagesLPG Equipment Consulting and ServicesNoch keine Bewertungen

- CD 45Dokument1 SeiteCD 45LPG Equipment Consulting and ServicesNoch keine Bewertungen

- Multipurpose Valves For Liquid Withdrawal of LP-Gas and NH Containers A8017D & A8020DDokument1 SeiteMultipurpose Valves For Liquid Withdrawal of LP-Gas and NH Containers A8017D & A8020DLPG Equipment Consulting and ServicesNoch keine Bewertungen

- Group 12 : Excess Flow Valves Back Pressure Check ValvesDokument3 SeitenGroup 12 : Excess Flow Valves Back Pressure Check ValvesLPG Equipment Consulting and ServicesNoch keine Bewertungen

- Fas 18Dokument17 SeitenFas 18LPG Equipment Consulting and ServicesNoch keine Bewertungen

- FAS Eng Catalogue - 2020 Lite FullDokument174 SeitenFAS Eng Catalogue - 2020 Lite FullLPG Equipment Consulting and ServicesNoch keine Bewertungen

- Excess Flow Valves For Flange Mounting in Container Service A3500 Series and A4500 SeriesDokument1 SeiteExcess Flow Valves For Flange Mounting in Container Service A3500 Series and A4500 SeriesLPG Equipment Consulting and ServicesNoch keine Bewertungen

- FAS NZ PumpSeriesTechnologyDokument2 SeitenFAS NZ PumpSeriesTechnologyLPG Equipment Consulting and ServicesNoch keine Bewertungen

- External "Pop-Action" Supplementary Pressure Relief Valves For Small ASME Containers and DOT Cylinders 3127 and 3129 SeriesDokument1 SeiteExternal "Pop-Action" Supplementary Pressure Relief Valves For Small ASME Containers and DOT Cylinders 3127 and 3129 SeriesLPG Equipment Consulting and ServicesNoch keine Bewertungen

- Single Check Filler Valves For Storage Tanks With Supplementary Back Check Valves 3174C, 3194C and 6584CDokument1 SeiteSingle Check Filler Valves For Storage Tanks With Supplementary Back Check Valves 3174C, 3194C and 6584CLPG Equipment Consulting and ServicesNoch keine Bewertungen

- T50 UN Portable Tank Container PDFDokument1 SeiteT50 UN Portable Tank Container PDFLPG Equipment Consulting and ServicesNoch keine Bewertungen

- Operating Instructions PumpDokument43 SeitenOperating Instructions PumpLPG Equipment Consulting and ServicesNoch keine Bewertungen

- Compressor I SeriesDokument52 SeitenCompressor I SeriesLPG Equipment Consulting and ServicesNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Bloques de Medicion MOTOR VagcomDokument32 SeitenBloques de Medicion MOTOR VagcomErnesto Patiño LeyvaNoch keine Bewertungen

- Cg47ej Cg47ej (L) Cg47ej (T) Cg47ey (T) PDFDokument156 SeitenCg47ej Cg47ej (L) Cg47ej (T) Cg47ey (T) PDFGabriel Reiriz SanchezNoch keine Bewertungen

- Eestinova MV Emi Proud: I and II: 19.95 (MM) IiiDokument1 SeiteEestinova MV Emi Proud: I and II: 19.95 (MM) IiiDPNoch keine Bewertungen

- Volvo 9 Litri - EDCDokument69 SeitenVolvo 9 Litri - EDCEdison GonsalvesNoch keine Bewertungen

- Honda ST1300 Parts FileDokument255 SeitenHonda ST1300 Parts FilelbehaegheNoch keine Bewertungen

- Cat 3116 Marine Spec Sheet AbbyDokument6 SeitenCat 3116 Marine Spec Sheet AbbyJesus CaguaNoch keine Bewertungen

- Isuzu Engine Diagnostics PDFDokument2 SeitenIsuzu Engine Diagnostics PDFJorge R RojasNoch keine Bewertungen

- MAN D2866E Manual PDFDokument64 SeitenMAN D2866E Manual PDFAleksanrd Mihailov85% (27)

- Manual VW Polo 2018+ PDFDokument326 SeitenManual VW Polo 2018+ PDFCarlos Nuñez100% (2)

- Yamaha Dynamic Spark Tester Special Tool Ym-34487 90890-06754 PDFDokument5 SeitenYamaha Dynamic Spark Tester Special Tool Ym-34487 90890-06754 PDFDr DNoch keine Bewertungen

- Fiddle II 125 Aw12w PDFDokument182 SeitenFiddle II 125 Aw12w PDFPablo Aimar100% (1)

- Havoc 300 Engine Service ManualDokument72 SeitenHavoc 300 Engine Service ManualJohannes Du PlessisNoch keine Bewertungen

- Turbine Heat Rate CalculationDokument2 SeitenTurbine Heat Rate Calculationkaruna34650% (2)

- Fuel SystemDokument16 SeitenFuel SystemGovea HeduNoch keine Bewertungen

- M52TU Throttle Valve CodesDokument3 SeitenM52TU Throttle Valve Codeswicka3Noch keine Bewertungen

- Aircraft System Prelim Module 3 Induction System RevisedDokument31 SeitenAircraft System Prelim Module 3 Induction System RevisedGertrudeshane IletoNoch keine Bewertungen

- Wartsila 20121 PDFDokument53 SeitenWartsila 20121 PDFDan Alin Mircea100% (1)

- Doosan Infracore Diesel Engine Current Models: Marine PropulsionDokument4 SeitenDoosan Infracore Diesel Engine Current Models: Marine PropulsionTrevor BurnettNoch keine Bewertungen

- Maxima Z FL UG LPG & Petrol SPCDokument66 SeitenMaxima Z FL UG LPG & Petrol SPCErik R. AraúzNoch keine Bewertungen

- DYNAJ05CENGREPAIRMANUALDR137EDokument154 SeitenDYNAJ05CENGREPAIRMANUALDR137ERowan Cornelius0% (1)

- Manual de Motos Honda Crf450x (2005-2012) (EN)Dokument83 SeitenManual de Motos Honda Crf450x (2005-2012) (EN)Jose David HNoch keine Bewertungen

- Ee6504 Electrical MachinesDokument2 SeitenEe6504 Electrical MachinesanbuelectricalNoch keine Bewertungen

- Kubota Diesel 3.6L Engine: PART NO. 4053146 0600 SRM 1579Dokument112 SeitenKubota Diesel 3.6L Engine: PART NO. 4053146 0600 SRM 1579Gabriela PurcenaNoch keine Bewertungen

- Manual Motor 721-821e Parte 1Dokument50 SeitenManual Motor 721-821e Parte 1Diego ResendeNoch keine Bewertungen

- Piaggio Xevo 250ie EN PDFDokument312 SeitenPiaggio Xevo 250ie EN PDFedutadNoch keine Bewertungen

- Fault Code SpreadsheetBTPDokument2 SeitenFault Code SpreadsheetBTPM. Shaat100% (1)

- Internal Combustion Engine: Induction TuningDokument39 SeitenInternal Combustion Engine: Induction TuningSudhakar SpartanNoch keine Bewertungen

- Safety Recall: Service BulletinDokument4 SeitenSafety Recall: Service BulletincycojadNoch keine Bewertungen

- Ae Unit-2Dokument23 SeitenAe Unit-2Dolly PhaniNoch keine Bewertungen

- Detroit Diesel Miami SERIES 60 Parts CatalogDokument16 SeitenDetroit Diesel Miami SERIES 60 Parts CatalogÖnder Büyükişcan100% (3)