Beruflich Dokumente

Kultur Dokumente

Tome Service

Hochgeladen von

jorge n m silvaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Tome Service

Hochgeladen von

jorge n m silvaCopyright:

Verfügbare Formate

Cranex Tome

and

Cranex Tome Ceph

Dental X-ray Units

Service Manual

Medical Device Directive

93/42/EEC

April 1999

Document code - 8200629

Manufactured by:

SOREDEX

P.O. Box 250

00031 Helsinki, Finland

Doc. code 8200629 I

Soredex endeavours to produce product documentation that is accurate

and up to date. However, our policy of continual product development

may result in changes to products that are not reflected in the product

documentation. Therefore, this document should not be regarded as an

infallible guide to current product specifications.

Soredex maintains the right to make changes and alterations without

prior notice.

II Cranex Tome Service Manual

General Contents

1. General

Contents ........................................................................................................... 1-i

Introduction ...................................................................................................... 1-1

Associated documentation ............................................................................... 1-1

Warnings and precautions ............................................................................... 1-1

Unauthorized Modifications .............................................................................. 1-4

Disclaimer ........................................................................................................ 1-4

2. Unit Description

Contents ........................................................................................................... 2-i

The Cranex Tome ............................................................................................ 2-1

Mechanical description .................................................................................... 2-6

Operating the unit ............................................................................................ 2-8

Electrical description ........................................................................................ 2-9

How the unit works ........................................................................................ 2-25

Symbols, markings that appear on the unit .................................................... 2-29

3. Covers and cover removal

Contents ........................................................................................................... 3-i

The unit covers ................................................................................................ 3-1

Removing the covers ....................................................................................... 3-4

4. Circuit boards

Contents ........................................................................................................... 4-i

N100 Connector Unit 1 (CU1) ....................................................................... 4-1-1

N200 Auxiliary Voltage Supply (AVS) ............................................................ 4-2-1

N300 Z-Motor Controller (ZMC) ................................................................... 4-3-1

N600 Imaging controller (IMC) ..................................................................... 4-4-1

N650 RAM Memory Module (RMM) ............................................................. 4-5-1

N660/N665 Flash Memory Modules (FMMA/FMMAB) ................................. 4-6-1

N700 Motor Controller (MC) ......................................................................... 4-7-1

N800 External Connectors Interface (ECI) ................................................... 4-8-1

N900 Connector Unit (CU2) .......................................................................... 4-9-1

X-Ray Generator ........................................................................................ 4-10-1

N1000 High Voltage Supply (HVS) .............................................................. 4-11-1

N1100 High Voltage Controller (HVC) ......................................................... 4-12-1

N1200 Cassette Head Controller (CHC) ..................................................... 4-13-1

N1400 Tubehead Controller (THC) ............................................................. 4-14-1

N1500 Tubehead (TH) and N1550 Diode Hybride (DH) .............................. 4-15-1

N1600 Display and Keyboard Interface (DKI) ............................................. 4-16-1

N1700 Ceph Interface (CI) ......................................................................... 4-17-1

N1800 Ceph Filter Position Indicators (CFPI) ............................................. 4-18-1

N1900/1901/2200/2201 Ceph Cassette Sensors (CCS1/2) ....................... 4-19-1

Doc. code 8200629 III

N2000 Line Interface Unit (LIU) .................................................................. 4-20-1

N2100 Top/Bottom Sensor (TBS) ............................................................... 4-21-1

N2300 Rotation Position Sensor (RPS) ...................................................... 4-22-1

N2400 Cassette Type Sensor (CTS) .......................................................... 4-23-1

N2500 Opto-Sensor X, Y, C (OS) .............................................................. 4-24-1

N2600 Vertical Position Sensors (VPS) ...................................................... 4-25-1

5. Service Codes

Contents ........................................................................................................... 5-i

Introduction ...................................................................................................... 5-1

Code types ...................................................................................................... 5-1

Using Service Codes ....................................................................................... 5-2

List of Service Codes ...................................................................................... 5-9

Factory and installation setups ...................................................................... 5-10

Service Code Descriptions ............................................................................ 5-11

Movement and alignment codes .................................................................... 5-72

6. Using a PC with the Cranex Tome

Contents ........................................................................................................... 6-i

Introduction ...................................................................................................... 6-1

PC requirements .............................................................................................. 6-1

Connecting the PC to the Tome ....................................................................... 6-1

Down loading information from the Tome ......................................................... 6-2

7. Trouble Shooting

Contents ........................................................................................................... 7-i

Warnings and precautions ............................................................................... 7-1

Trouble shooting principles .............................................................................. 7-2

Problems during start-up ............................................................................... 7-11

Problems during use ...................................................................................... 7-21

Other problems that may occur during use .................................................... 7-47

Blown fuses ................................................................................................... 7-49

Generator problems ...................................................................................... 7-67

8. Mechanical Parts

Contents ........................................................................................................... 8-i

Replacing the tube head .................................................................................. 8-1

9. Annual Service

Contents ........................................................................................................... 9-i

Annual tests and inspections ............................................................................ 9-1

Appendix A. Technical Specifications

Apendix B Installation and set-up manual

IV Cranex Tome Service Manual

1. General

1. General

Contents

Introduction ........................................................................................................ 1-1

Associated documentation ............................................................................... 1-1

Warnings and precautions ................................................................................ 1-1

General precautions ........................................................................................ 1-1

Radiation Safety .............................................................................................. 1-2

Mechanical safety ............................................................................................ 1-2

Electrical Safety .............................................................................................. 1-2

Electrostatic discharge .................................................................................... 1-3

Explosion Hazard ............................................................................................. 1-3

Unauthorized Modifications .............................................................................. 1-4

Disclaimer ........................................................................................................... 1-4

Doc. code 8200629 1-i

1. General

1 - ii Cranex Tome Service Manual

1. General

Introduction

This manual describes how to service the Cranex Tome

and Cranex Tome Ceph. The manual includes servicing

information for all versions of the Cranex Tome and Tome

Ceph, the Gendex ORALIX multiscan and multiscan ceph

and the Satelec X-mind and X-mind ceph.

Associated documentation

The Cranex Tome User's manual.

The Cranex Tome Installation manual.

The Cranex Tome Spare-parts manual.

Servicing warnings and precautions

General precautions

Only Soredex trained and approved service personnel

are allowed to service the Cranex Tome and Tome Ceph.

Before attempting to service the unit make sure that you

know how to operate it. Read the Cranex Tome user's

manual.

Only use original Soredex spare parts when repairing the

unit or replacing parts.

The unit is factory set to operate using a 230VAC power

supply. If the unit is to be used with a 115VAC power

supply jumpers must be attached to the N200 and N1000

boards. Information on how to install theses jumpers is

given in the Cranex Tome installation manual.

Before a new unit can be operated cassette sensitivity

stickers must be attached to all the panoramic cassettes

that will be used with the unit, and the unit calibrated to

work with these cassettes. Refer to the user's manual,

section "Setting up a new unit", for information on how to

do this.

Doc. code 8200629 1-1

1. General

Radiation Safety

Before servicing the unit familiarise yourself with local and

national radiation safety standards and requirements

relating to dental x-ray equipment.

If you need to take test exposures you MUST take ad-

equate steps to protect yourself from radiation. Use a

lead apron or by stand behind a suitable radiation shield.

In addition, when taking an exposure stand at least two

metres (six feet) from the unit.

Mechanical safety

Switch the main power supply off before repairing or

replacing mechanical parts.

Be careful when operating the unit not to get body parts or

clothing trapped between moving parts.

The aperture plate in the collimator is made of lead (Pb)

which is a toxic material. Do not touch it with your bare

hands.

DO NOT open the tube head.

There are no serviceable parts, mechanical or electrical,

inside the tube head.

Electrical Safety

Switch the main power supply off before repairing or

replacing parts.

Live electrical terminals are deadly.

Be sure that power switch is OFF and that precautions

have been taken before opening access doors, removing

enclosures and panels, or attaching accessories.

This equipment should be used only in areas that are

provided with a protective earth connection to ensure an

equipotential ground connection.

Before cleaning or disinfecting the unit switch the main

power supply off.

1-2 Cranex Tome Service Manual

1. General

Electrostatic discharge

Electrostatic Discharge (ESD) can damage or destroy

electronic components.

A static electricity charge builds up in everyone. The build

up is due to movement, humidity, the person's clothing

and the conductivity of the floor. If anyone charged with

static electricity touches a electronic component the static

electricity will discharge through the component and can

damage or destroy it. Note that components damaged by

electrostatic discharge can fail at a later date.

When servicing the unit take proper precautions to avoid

electrostatic build up and discharge (ESD). Follow the

recommendations for the prevention of ESD that are

used in the country in which you are working. If no recom-

mendations are available follow the guide lines below.

Before handling any electrical parts or components make

sure that any static electricity charge that has built up in

you body is discharged.

When handling electrical parts or components use an

elasticated wrist wrap which is connected to a ground

point through a 1 Mohm current limiting cable. For a

ground point use water pipes, radiators or other objects

that are known to be connected to the ground. Also use a

cable to connect the unit to the same ground potential as

the wrist wrap.

If an antistatic mat is used, connect the wrist wrap to the

carpet and the carpet to the ground potential.

Wash the wrist wrap and check that it is good condition

frequently.

Explosion Hazard

Certain disinfectants and cleaning agents may vaporize

to form an explosive vapour. If such chemicals are used

the vapour should be allowed to disperse before switch-

ing the unit on.

Doc. code 8200629 1-3

1. General

Operating warnings and precautions

The Soredex Cranex Tome x-ray unit must only be used to

take dental, TMJ and cephalometric (optional) x-ray

exposures. It must not be used for any other purpose.

The unit or its accessories must not be modified, altered

or remanufactured in any way. Repairing shall be per-

formed by Soredex authorized service only.

WARNING:

The x-ray unit may be dangerous to both patient and

operator unless safe exposure values are used and

correct operating procedures are observed.

When taking exposures operators must protect them-

selves from radiation by using a lead apron or by stand-

ing behind a suitable radiation shield.

When taking exposures operators must stand at least two

metres (six feet) from the patient.

Operators must be able to see and hear the patient dur-

ing an exposure.

Operators must be able to see the exposure warning

lights and hear the exposure warning signal during expo-

sures. If the X-ray unit is located in such a position that the

operator cannot see the exposure warning lights, an

external exposure warning light must be used.

As radiation safety and protection requirements vary from

country to country and state to state it is the responsibility

of the operator to ensure that all local and national radia-

tion safety and protection requirements are met.

Never leave cassettes open in daylight.

Avoid taking exposures of pregnant women.

The use of ACCESSORY equipment not complying with

the equivalent safety requirements of this equipment may

lead to a reduced level of safety of the resulting system.

1-4 Cranex Tome Service Manual

1. General

Consideration relating to the choice shall include:

– use of the accessory in the PATIENT VICINITY

– evidence that the safety certification of the ACCES-

SORY has been performed in accordance to the

appropriate IEC 601-1 or IEC 950 and/or IEC 601-1-

1 harmonized national standard.

– only RS-232C serial interface cable, provided by the

manufacturer shall be used.

Unauthorized Modifications

Unauthorized changes or modifications to any part of the

unit or its equipment can have hazardous consequences.

Changes or modifications must not be made unless

specifically authorized by Soredex.

When properly assembled with a compatible beam-

limiting device, the diagnostic source assembly will fully

meet the United States of America Federal Performance

Standards for Diagnostic X-Ray Systems and Their

Components (C21FR 1020. 30-32) provided no compo-

nents or parts are removed from the unit and no unauthor-

ized adjustments are made to the beam-limiting device or

tube housing assembly.

Never remove or remanufacture any part of the tube

housing assembly or beam-limiting device.

Never adjust any part of the beam-limiting device unless

under the direction of Soredex or their authorized distribu-

tor.

Doc. code 8200629 1-5

1. General

Disclaimer

Soredex shall have no liability for consequential dam-

ages, personal injury, loss, damage or expense directly or

indirectly arising from the use of its products. No agent,

distributor or other party is authorized to make any war-

ranty or other liability on behalf of Soredex with respect to

its products.

1-6 Cranex Tome Service Manual

2. Unit Description

2. Unit Description

Contents

The Cranex Tome .............................................................................................. 2-1

The main parts and assemblies of the Tome Pan ............................................ 2-3

The main parts and assemplies of the Tome Pan/ceph .................................... 2-4

Identifying the unit version ............................................................................... 2-5

Mechanical description ..................................................................................... 2-6

Movement axes and moving assemblies .......................................................... 2-7

Operating the unit ............................................................................................. 2-8

Electrical description ......................................................................................... 2-9

Tome circuit boards ......................................................................................... 2-9

Circuit board location ..................................................................................... 2-10

Power supply ................................................................................................. 2-13

Unit control - Serial Peripheral Interface (SPI) ............................................... 2-14

Motors and motor control .............................................................................. 2-16

Position control .............................................................................................. 2-17

Diagram showing board location on the wiring diagrams ............................... 2-18

Wiring diagram - sheet 1 ............................................................................... 2-19

Wiring diagram - sheet 2 ............................................................................... 2-20

Wiring diagram - sheet 3 ............................................................................... 2-21

Wiring diagram - sheet 4 ............................................................................... 2-22

Wiring diagram - sheet 5 ............................................................................... 2-23

Power supply and grounding diagram ............................................................ 2-24

How the unit works .......................................................................................... 2-25

Unit functions during use ................................................................................ 2-26

Main functions during the program selection state ......................................... 2-26

Main functions during the patient positioning state ......................................... 2-27

Main functions during the exposure state ....................................................... 2-28

Symbols, markings that appear on the unit .................................................. 2-29

Doc. code 8200629 2-i

2. Unit Description

2 - ii Cranex Tome Service Manual

2. Unit Description

The Cranex Tome

The Soredex Cranex Tome is an extra-oral x-ray unit

designed to take exposures of the dento-maxillofacial

region. It cannot be used to take x-ray exposures of any

other part of the human anatomy.

Two main versions of the Cranex Tome are available:

- Cranex Tome Pan

This version takes panoramic, scanographic and

tomographic images

- Cranex Tome Pan/Ceph

This version takes panoramic, scanographic , tomo-

graphic and cephalographic images.

There are several OEM versions of the units:

- Gendex Oralix multiscan

Equivalent to the Cranex Tome Pan

- Gendex Oralix multiscan ceph

Equivalent to the Cranex Tome Pan/Ceph

- Satelec x-mind Tome

Equivalent to the Cranex Tome Pan

- Satelec x-mind Tome ceph

Equivalent to the Cranex Tome Pan/Ceph

The OEM versions are mechanically and electrically the

same as the Soredex Cranex Tome. The only differences

between the versions are the product name labels and

stickers.

The panoramic version of the unit uses standard flat 15

cm x 30 cm panoramic cassettes.

Doc. code 8200629 2-1

2. Unit Description

Cephalometric units for three different film sizes are

available

- Standard metric

Uses 18 x 24 cm cassette to take symmetric vertical

(SV), asymmetric vertical (AV) and asymmetric hori-

zontal (AH) exposures.

Uses 24 x 30 cm cassette to take asymmetric verti-

cal (AV) exposures.

- Large metric

Uses 24 x 30 cm cassette to take asymmetric vertical

(AV), symmetric vertical (SV) and asymmetric hori-

zontal (AH) exposures.

- Inch

Uses 8 x 10 in cassette to take asymmetric vertical

(AV), symmetric vertical (SV) and asymmetric hori-

zontal (AH) exposures.

Pan/ceph units can be supplied with the ceph arm

mounted on either the left- or right-hand side of the col-

umn.

The ceph arm is also available as a retrofit kit that can be

installed to a pan unit that was not originally fitted with a

ceph arm.

All units are factory set to operate using a 230 VAC

power supply. For countries where the power supply is

115 VAC, a 115 VAC conversion kit is supplied with the

unit to convert it to that voltage.

For information on how to instal the 115 VAC conversion

kit, refer to the installation and setup manual.

2-2 Cranex Tome Service Manual

2. Unit Description

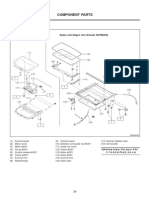

The main parts and assemblies of the Tome Pan

Support arm Sliding assembly Head support

Rotating

assembly

C-arm

Rotating unit

On/off switch

Tube head

C-arm

Cassette head assembly

Control panel

Patient support mechanism

Moving column

Fixed column

Doc. code 8200629 2-3

2. Unit Description

The main parts and assemplies of the Tome Pan/ceph

Ceph head support Ceph arm

Cassette holder

Soft tissue filter knob

2-4 Cranex Tome Service Manual

2. Unit Description

Identifying the unit version

The unit type/serial number label is located at the rear of

the unit, on the right-hand side, above the main power

cable. The type number allows the version of the unit to be

identified.

Product identification

Country or language code

00 General (English) 07 Russia

01 UK only 08 Italy

02 German 09 Spain

03 USA 10 Portugal

04 Australia 2X OEM version

05 France 3X OEM version

06 Finland and Sweden

X-ray tube version

0 OPX/105

1 DE 100/15ö

2 D-051

3 XL 90

Indicates unit version

0 No cephalometric unit

1 Left-hand ceph - standard metric cassettes

2 Left-hand ceph - large metric cassettes

3 Left-hand ceph - inch size cassettes

4 Right-hand ceph - standard metric cassettes

5 Right-hand ceph - large metric cassettes

6 Right-hand ceph - inch size cassettes

Reserved for future options

The production version

Doc. code 8200629 2-5

2. Unit Description

Mechanical description

The Cranex Tome comprises a two part column, a sup-

port arm, a sliding assembly and rotating unit. The lower

part of the two-part column, the fixed column, is attached

to the wall and floor. The upper part of the column, the

moving column, is able to slide up and down (Z-axis) over

the fixed column. The support arm is located at the top of

the moving column.

Attached to the underside of the support arm is the sliding

assembly and attached to this is the rotating unit. The

rotating unit comprises the rotating assembly and the C-

arm assembly. The sliding unit is able to slide along the

support arm and allows the rotating unit to move towards

or away from the column (Y-axis). The rotating unit is able

to rotate (R-axis) and slide to the left and right (X-axis).

The C-arm assembly, which comprises the C-arm, the

tube head assembly and the cassette head assembly, is

able to tilt (V-axis). The cassette carriage is also able to

move (C-axis) during exposures.

The x-ray tube is a fixed tungsten anode type with focal

spot of 0.4 - 0.5mm, depending on tube type. The maxi-

mum anode voltage is 85kV and maximum current is

10mA. X-ray beam filtration is 2.7 mm Al minimum. Addi-

tional gadolinium filtration is used for tomography

imaging programs.

The patient's head is held in position with a four-point

holding system. The head support holds the temples and

the forehead and the patient support assembly supports

the chin or lips.

The unit can be supplied with an optional ceph unit that

can be mounted either on the left or right-hand side of the

column. The side must be specified when the unit is

ordered.

The unit is normally attached to a wall, but a stand (pt. no.

9801755) is available if the unit needs to be free stand-

ing.

2-6 Cranex Tome Service Manual

2. Unit Description

Movement axes and moving assemblies

Doc. code 8200629 2-7

2. Unit Description

Operating the unit

The on/off switch is located on the left-hand side of the

column above the control panel.

The unit is operated by pressing keys on the control panel

and by carrying out manual operations.

Control panel operations include:

- procedure and program selection

- kV selection

- patient size selection

- exposure time selection (ceph units only)

- focal trough positioning (arrow keys)

- height adjustment (arrow keys)

Manual operations include:

- aperture selection (pan, tomo, ceph)

- chin rest position (up or down)

- cassette shield position (narrow beam or wide beam)

- mirror position (open or closed)

- cassette head position (pan or ceph exposures)

- cephalometric soft tissue filter adjustment

Information on the display tells users what to do and

warns them if they make mistakes. If the user selects a

wrong setting the unit cannot be used until the correct

setting is selected.

For information on how to operate the unit refer to the

user's manual.

2-8 Cranex Tome Service Manual

2. Unit Description

Electrical description

A complete description of all the circuit boards is given in

the section "Circuit boards".

Tome circuit boards

Number Name Quantity

N100 CU1 Connector Unit 1 1

N200 AVS Auxiliary Voltage Supply 1

N300 ZMC Z-motor Controller 1

N400 RBI Remote Box Interface 1 Optional

N600 IMC Imaging Controller 1

N650 RMMRam Memory Module 1 On N600

N660 FMMA Flash Mem Module (Mem A) 1 On N600

N665 FMMAB Flash Mem Module (Mem Ab) 2 On N600

(N665 is the same as N660 but with four flash memory chips)

N700 MC Motor Controller 1

N800 ECI External Connectors Interface 1

N900 CU2 Connector Unit 2 1

N1000-2 HVS High Voltage Supply 1

N1100-1 HVC High Voltage Controller 1

N1200 CHC Cass Head Controller 1

N1400 THC Tubehead Controller 1

N1500 TH Tubehead 1 Inside tubehead

N1550 DH Diode Hybrid 7 Inside tubehead

N1600 DKI Display And Keyboard Interface 1

N2000 LIU Line Interface Unit 1

N2100 TBS Top/Bottom Sensor 2

N2300 RPS Rotation Position Sensor 1

N2400 CTS Cassette Type Sensor 1

N2500 OS Opto Sensor (X/Y/C) 3

N2600 VPS Vertical Position Sensors 1

Ceph unit circuit boards

N1700 CI Ceph Interface 1 Ceph Metric/Inch

N1800 CFPI Ceph Filter Position Indicators 1 Ceph Metric/Inch

N1900 CCS1M Ceph Cass Sensors 1 Metric 1 Ceph Metric

N1901 CCS1I Ceph Cass Sensors 1 Inch 1 Ceph Inch

N2200 CCS2M Ceph Cass Sensors 2 Metric 1 Ceph Metric

N2201 CCS2I Ceph Cass Sensors 2 Inch 1 Ceph Inch

Doc. code 8200629 2-9

2. Unit Description

Circuit board location

2 - 10 Cranex Tome Service Manual

2. Unit Description

Doc. code 8200629 2 - 11

2. Unit Description

2 - 12 Cranex Tome Service Manual

2. Unit Description

Power supply

Power is supplied to the unit through the N2000 board

(Line interface unit). From N2000 power is routed to the

N200 board (Auxiliary voltage supply) which is a switched

mode power supply. This board generates low-voltage

operating powers, +9V, ±19V and +28V, for all the

boards in the unit. The low-voltage powers are distributed

via N100 (Connector unit 1) and N900 (Connector unit 2).

The N200 board also supplies high voltage, 230V (115V),

directly to the x-ray generator. The x-ray generator com-

prises N1000 (High voltage supply), N1100 (High voltage

controller), N1400 (Tube head controller) and N1500

(Tubehead). Note that the N1500 board is located inside

the tubehead and cannot be accessed.

A detailed power supply and grounding diagram is on

page 2.24.

Simplified power supply diagram

Doc. code 8200629 2 - 13

2. Unit Description

Unit control - Serial Peripheral Interface (SPI)

The unit is controlled by a microprocessor on the N600

board (Imaging controller) that continually monitors and

controls the operation of the unit. A serial peripheral

interface communication protocol (SPI - RS485) is used

to monitor most of the unit functions.

The microprocessor:

- monitors optosensors and microswitches

- monitors panel keys

- controls unit movements during exposures

- starts, controls and stops x-ray generation

- guides and controls user actions

- monitors safety.

The necessary unit settings and parameters for all the

imaging programs are stored on the MEM boards (N660/

N665 memory modules) which are located on the N600

board.

2 - 14 Cranex Tome Service Manual

2. Unit Description

Unit block diagram

Doc. code 8200629 2 - 15

2. Unit Description

Motors and motor control

There are five stepper motors and one DC-motor in the

unit. The stepper motors drive the unit in the X, Y, R, V

and C directions.

During exposure these motors are controlled by N600

through the N700 board (Motor controller).

During program selection and patient positioning the

motors are activated by N1600 (Display and keyboard

interface) and controlled by N600 through N700.

Note that if the C-arm or cassette carriage are moved

during exposure setup they will automatically return to the

PIO position. This automatic return feature can be

switched off. Refer to service code 9700.

The DC-motor is used to adjust the height of the unit, Z

direction, and this motor is activated directly by N1600

and controlled by N300 (Z-motor controller).

2 - 16 Cranex Tome Service Manual

2. Unit Description

Position control

The positions of the mechanical assemblies are moni-

tored by optosensors and microswitches.

The optosensors only respond to start or stop positions

and do not control unit movements. (N600 controls move-

ment duration and speed). The optosensors ensure that

the mechanical assemblies are in the correct PIO (Patient

in/out) or start position for the required exposure.

The statuses of the optosensors are monitored continually

by N600.

Cassette type and cassette carriage position are moni-

tored, via the N1200 board (Cassette head controller), by

optosensors on the N2400 board (Cassette type sen-

sors) and the N2500 board (Cassette carriage sensors)

respectively.

The position of the primary aperture (the selected slot) is

monitored, via connector units N100 and N900, by sen-

sors mounted on the N1400 board (Tubehead controller).

The C-arm rotation position is monitored by optosensors

on the N2300 board (Rotation sensors) and the angle of

the C-arm by the N2600 board (Vertical sensors). The

upper and lower height limits of the unit are monitored by

optosensors on two N2100 boards (Top/bottom sensors).

The positions of the mirror, the chin rest, the cassette

shields and the cassette carriage (pan or ceph) are all

monitored by microswitches.

In the cephalostat the position and orientation of the

different ceph cassettes are monitored by microswitches

on the cephalometric cassette sensor boards via the

N1700 board (Ceph interface). The board used will de-

pend on whether the ceph unit is mounted on the left or

right and whether the unit is for metric or inch cassettes.

The boards are:

- N1900 - left metric

- N1901 - left inch

- N2200 - right metric

- N2201 - right inch

Doc. code 8200629 2 - 17

2. Unit Description

Diagram showing board location on the wiring

diagrams

The dashed areas indicate the sheets of the wiring dia-

gram on which the boards appear.

2 - 18 Cranex Tome Service Manual

2. Unit Description

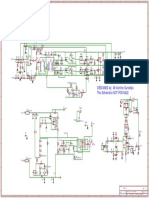

Wiring diagram - sheet 1

Doc. code 8200629 2 - 19

2. Unit Description

Wiring diagram - sheet 2

2 - PB Cranex Tome Service Manual

2. Unit Description

Wiring diagram - sheet 3

Doc. code 8200629 2 - 21

2. Unit Description

Wiring diagram - sheet 4

2 - PB Cranex Tome Service Manual

2. Unit Description

Wiring diagram - sheet 5

Doc. code 8200629 2 - 23

2. Unit Description

Power supply and grounding diagram

2 - PB Cranex Tome Service Manual

2. Unit Description

How the unit works

The user presses control panel keys to select an imaging

program. The microprocessor (N600) monitors the keys

pressed and "identifies" the selected program from the

program information that is stored in the program mod-

ules (N650 and N660).

The program information includes all the settings that the

unit must be set to for the particular exposure program

selected.

The microprocessor then compares the existing unit

settings with the required program parameter settings for

the exposure program selected. If an existing setting is

not the same as the program parameter setting an infor-

mation message will be sent to the display so the user

knows what setting has to be changed.

For example, if the chin rest is in the upper position and

the program selected requires the chin rest to be in the

lower position, the microprocessor will "detect" that the

chin rest is in the wrong position and send an information

message to the display telling the user to change the

position.

When the exposure button is pressed to take an expo-

sure, the microprocessor activates and then controls the

stepper motors so that the unit moves correctly for the

program selected. All information on stepper motor move-

ment duration, speed and direction is included in the

program parameters.

Doc. code 82006290 2 - 25

2. Unit Description

Unit functions during use

The functions and operations of the boards and SPI vary

according to the state in which the unit is in.

Main functions during the program selection state

2 - 26 Cranex Tome Service Manual

2. Unit Description

Main functions during the patient positioning state

Doc. code 82006290 2 - 27

2. Unit Description

Main functions during the exposure state

2 - 28 Cranex Tome Service Manual

2. Unit Description

Symbols, markings that appear on the unit

On (power)

Power on symbol

Off (power)

Power off symbol

Radiographic control

Exposure button symbol

Stand-by or preparatory state for a part of equipment

Exposure button enabled (unlocked) symbol

"Off" only for a part of equipment

Exposure button disabled (locked) symbol

Hand-held switch

This symbol identifies the connector for the exposure

switch.

This symbol identifies the connector for an external expo-

sure warning device.

Attention, consult accompanying documents

The RS232C connector for a PC. See also the section

"Warnings and precautions"

This symbol and the letter R (Return) identify the return

button. Press this button to drive the C-arm to the patient

in/out (PIO) position.

Ionizing radiation

Radiation symbol. Appears on the display during an

exposure when radiation is generated.

Connection point for the neutral conductor on permanently

installed equipment.

Connection point for the live conductor on permanently

installed equipment.

Doc. code 82006290 2 - 29

2. Unit Description

Alternating current

Protective earth (ground)

Earth (ground)

Dangerous voltage

Type B equipment

CE (0537) symbol

MDD 93/42/EEC

UL Classification Symbol

DENTAL X-RAY EQUIPMENT MODEL SRC1

CLASSIFIED BY UNDERWRITERS

LABORATORIES INC.

WITH RESPECT TO ELECTRIC

SHOCK, FIRE, MECHANICAL AND

OTHER SPECIFIED HAZARDS ONLY

IN ACCORDANCE WITH UL 2601-1 AND

CAN/CSA C22.2 NO 601.1 - M90

5D42

The enter (E) key. Press this key to drive the C-arm to the

patient in/out (PIO) position.

The clear (C) key. Press this key to remove information

from the display

The up and down arrows are on the height adjusting keys

and indicate the direction of travel.

The left and right arrows are on the focal trough position-

ing keys and indicate the direction of travel.

2 - 30 Cranex Tome Service Manual

2. Unit Description

Symbols that appear on the aperture labels

Standard metric version

1 Normal height narrow beam aperture

2 Reduced height narrow beam aperture

3 Low filtration tomograph aperture

4 High filtration tomograph aperture

5 Asymmetric vertical aperture for 18 x 24 cm film.

6 Asymmetric horizontal aperture for 18 x 24 cm film.

7 Symmetric vertical aperture for 18 x 24 cm film.

8 Asymmetric vertical aperture for 24 x 30 cm film.

Large metric version

1 Normal height narrow beam aperture

2 Reduced height narrow beam aperture

3 Low filtration tomograph aperture

4 High filtration tomograph aperture

5 Symmetric vertical aperture for 24 x 30 cm film.

6 Asymmetric vertical aperture for 24 x 30 cm film.

7 Asymmetric horizontal aperture for 24 x 30 cm film.

Doc. code 82006290 2 - 31

2. Unit Description

Inch version

1 Normal height narrow beam aperture

2 Reduced height narrow beam aperture

3 Low filtration tomograph aperture

4 High filtration tomograph aperture

5 Asymmetric vertical aperture for 8 x 10 in film.

6 Symmetric vertical aperture for 8 x 10 in film.

7 Asymmetric horizontal aperture for 8 x 10 in film.

2 - 32 Cranex Tome Service Manual

3. Covers and cover removal Contents

3. Covers and cover removal

Contents

The unit covers .................................................................................................. 3-1

Panoramic Covers ........................................................................................... 3-1

Cephalostat Covers ......................................................................................... 3-3

Removing the covers ........................................................................................ 3-4

Removing the top cover ................................................................................... 3-4

Removing the front cover ................................................................................. 3-4

Removing the front column cover ..................................................................... 3-5

Removing the column covers ........................................................................... 3-6

Removing the outer covers from the C-arm ..................................................... 3-8

Removing the cassette head covers ................................................................ 3-9

Removing the inner covers from the C-arm.................................................... 3-11

Removing the tubehead cover ....................................................................... 3-12

Removing the cephalostat covers .................................................................. 3-13

Doc. code 8200629 3-i

Contents 3. Covers and cover removal

3 - ii Cranex Tome Service Manual

3. Covers and cover removal

The unit covers

To repair and replace parts the unit covers must be re-

moved. This section lists the covers and describes how to

remove and replace them.

Panoramic Covers

Top cover

Cover plate

Front cover

Upper cover

Rotating assembly cover C-arm covers

Lower cover

Tube head cover

Control panel cover Cassette head - outer cover

Column cover - rear

Front column cover

Left-hand column cover

Base cover

Doc. code 8200629 3-1

3. Covers and cover removal

Support cover

Cover plate

Rotating assembly cover

Patient support cover

Right-hand column cover

Cassette head - upper cover

Cassette head - inner cover

3-2 Cranex Tome Service Manual

3. Covers and cover removal

Cephalostat Covers

Cephalostat cover

Ceph cassette holder cover

Doc. code 8200629 3-3

3. Covers and cover removal

Removing the covers

Removing the top cover

The cover is held in place with

twelve screws, ten on top and

two at the rear.

Removing the front cover

Cover plates

Remove the two cover plates from the

rear of the sliding unit and then remove

the front cover.

Front cover

3-4 Cranex Tome Service Manual

3. Covers and cover removal

Removing the front column cover

Patient support cover

Remove the patient support cover. It

is held in position by a long screw in

the underside of the patient posi-

tioning assembly

Screw

Loosen these

screws

Patient support assembly

Remove the two screws from the

underside of the front column cover

and then loosen the two screws that

hold the cover to the patient support

assembly.

Front column cover

Screws

Doc. code 8200629 3-5

3. Covers and cover removal

Removing the column covers

The instructions describe the removal of the left-hand

column cover. The right-hand cover is removed in the

same way except that the side is reversed and there is no

frankfort light.

Slide the orange warning light cover Warning light cover

from the top of the column cover.

Remove the two screws that hold the

frankfort light cover (rear of column

cover) in position and remove the cover.

Column cover

Frankfort light cover

(Left-hand side only)

3-6 Cranex Tome Service Manual

3. Covers and cover removal

Front cover

Loosen screw

Front cover screw

Remove the front column cover (see previ-

ous page).

Remove left-hand screw from the front

cover and loosen the right-hand screw.

Remove the screw from the bottom front of

the column cover.

Column cover screw

Inner screw

Rear screws

Remove the three screws from the rear of

the column cover and the single screw from

inside the cover.

Doc. code 8200629 3-7

3. Covers and cover removal

Removing the outer covers from the C-arm

The left and right C-arm covers are identical.

Remove the two screws from

the top of the cover and then

pull the cover out slightly.

Screws

Cover

Holding prong

Lift the cover up to disengage

the holding prongs from support

bar and then remove the cover.

Support bar

3-8 Cranex Tome Service Manual

3. Covers and cover removal

Removing the cassette head covers

To remove the outer cover from the cassette head,

remove the four holding screws, two at the top and

two at the bottom, and then disconnect the ready

button cable (J1210) from the N1200 board.

Outer cover

Ready button cable

Holding screws

Doc. code 8200629 3-9

3. Covers and cover removal

To remove the inner cover from the cassette head,

first remove the upper cover. It is held in place with

two screws. Note that a long allen key will be

required to remove them.

Upper cover

Remove the four screws, two at the top and two at the

bottom, that hold the inner cover in position. Note that

the cassette shield mechanism is attached to the inner

cover. The shield position microswitches must be

removed from the top of the inner cover before the

cover can be removed.

Inner cover

Microswitch

3 - 10 Cranex Tome Service Manual

3. Covers and cover removal

Removing the inner covers from the C-arm

First remove the support cover and

then the two C-arm cover halves.

Support cover C-arm cover halves

Doc. code 8200629 3 - 11

3. Covers and cover removal

Removing the tubehead cover

If the unit is a pan/ceph pull off the soft tissue filter knob.

Remove the aperture selection knob. It is held in place

with one screw.

Remove the four screws that hold the tubehead cover in

position and remove the cover.

Tubehead cover

Soft tissue filter knob

Aperture selection knob

Pan/ceph unuts only

3 - 12 Cranex Tome Service Manual

3. Covers and cover removal

Removing the cephalostat covers

Cephalostat cover

Ceph cassette holder cover

Doc. code 8200629 3 - 13

3. Covers and cover removal

3 - 14 Cranex Tome Service Manual

4. Circuit Boards Contents

4. Circuit Boards

Contents

N100 Connector Unit 1 (CU1) ........................................................................... 4-1-1

N200 Auxiliary Voltage Supply (AVS) ................................................................ 4-2-1

N300 Z-Motor Controller (ZMC) ........................................................................ 4-3-1

N600 Imaging controller (IMC) .......................................................................... 4-4-1

N650 RAM Memory Module (RMM) ................................................................. 4-5-1

N660/N665 Flash Memory Modules (FMMA/FMMAB) ...................................... 4-6-1

N700 Motor Controller (MC) ............................................................................. 4-7-1

N800 External Connectors Interface (ECI) ........................................................ 4-8-1

N900 Connector Unit (CU2) .............................................................................. 4-9-1

X-Ray Generator ............................................................................................ 4-10-1

N1000 High Voltage Supply (HVS) .................................................................. 4-11-1

N1100 High Voltage Controller (HVC) ............................................................. 4-12-1

N1200 Cassette Head Controller (CHC) ......................................................... 4-13-1

N1400 Tubehead Controller (THC) .................................................................. 4-14-1

N1500 Tubehead (TH) and N1550 Diode Hybride (DH) ................................... 4-15-1

N1600 Display and Keyboard Interface (DKI) ................................................. 4-16-1

N1700 Ceph Interface (CI) ............................................................................. 4-17-1

N1800 Ceph Filter Position Indicators (CFPI) ................................................. 4-18-1

N1900/1901/2200/2201 Ceph Cassette Sensors (CCS1/2) ............................ 4-19-1

N2000 Line Interface Unit (LIU) ...................................................................... 4-20-1

N2100 Top/Bottom Sensor (TBS) ................................................................... 4-21-1

N2300 Rotation Position Sensor (RPS) .......................................................... 4-22-1

N2400 Cassette Type Sensor (CTS) .............................................................. 4-23-1

N2500 Opto-Sensor X, Y, C (OS) ................................................................... 4-24-1

N2600 Vertical Position Sensors (VPS) .......................................................... 4-25-1

Doc. code 8200629 4-i

Contents 4. Circuit Boards

4 - ii Cranex Tome Service Manual

4. Circuit Boards N100 Connector Unit 1

N100 Connector Unit 1 (CU1)

Location

In top of support arm.

To access, remove top cover.

Field replaceable parts

None.

Description

The N100 Connector Unit 1 (CU1) board serves as a

connector for boards in the rotating unit, the column and, if

installed, the cephalostat. The stepper motors for X- and

Y-movements of the C-arm and the sensor boards

(N2500) that control these movements are also

comnected to this board. Supply voltages from the Auxil-

iary Voltage Supply (N200) to the other boards pass

through N100.

Data from the X and Y sensors goes via the internal SPI

bus to the Image Controller (N600) in serial format. This

differential bus uses the RS485 protocol in the master/

slave configuration. The slave communicates with the

master (N600) using SLVSEL0-3 address signals, the

asyncronous clock is defined with signals SCLK and

SCLKB, which are also differential RS485 signals. The

signals that transfer data from the master to the slave are

called MOSIA and MOSIB (RS485) and from the slave to

the master MISOA and MISOB (RS485).

The green LEDs on the board indicate the supply

voltages. All the LEDs must be on if the unit is to operate

correctly. The yellow LED indicates that there is SPI

communication between the slave (N100) and the master

(N600).

Doc. code 8200629 4-1-1

N100 Connector Unit 1 4. Circuit Boards

Indicator LEDs

LED Colour Indicates

D1 green +28V1 on

D2 yellow SPI communication active

D3 green -19V1 on

D4 green +19V1 on

D5 green +5V on

D8 green +28V2 on

D9 green +9V1 on

D10 green +9V2 on

D11 green +19V2 on

D12 green -19V2 on

Test Points

Number Value

TP2 +5V

TP3 SLVSEL3

TP4 SLVSEL2

TP5 SLVSEL1

TP6 SLVSEL0

TP7 INT_MISO

TP9 SCLK1

TP10 SLV5*

TP11 MRESET*

Connector J101

Pin Signal Description

1 +28V1 -

4 POWGND -

Connector J102

Pin Signal Description

1 +28V2 -

4 POWGND -

4-1-2 Cranex Tome Service Manual

4. Circuit Boards N100 Connector Unit 1

Connector J103

Pin Signal Description

1,2 +9V2 -

3-5 GND2 -

6 +9V1 -

7,8 GND1 -

9 +19V2 -

10 +19V1 -

11,12 ANGND2 -

13 -19V2 -

14 -19V1 -

15,16 ANGND1 -

17 (SYNC) Not used

18 PFAIL* Too low or high +28V supply voltage

19 NETV Analog signal which is proportional to mains voltage

20,21 SREF1,2 Analog signal to control up/down z-movement

22,23 (ON1,2) Not used

24 TOP Column at highest position

25 BOTTOM* Column at lowest position

26 EXPLIGHT* Exposure lights on

Connector J104

Pin Signal Description

1 + 9V1 Supply voltage (logic)

2 GND1 Gnd (logic)

3 MOSIA Differential RS485 signal (Master Out/Slave In)

4 MOSIB Differential RS485 signal (Master Out/Slave In)

5 MISOA SPI tranmission differential RS485 signal

(Master In/Slave Out)

6 MISOB SPI tranmission differential RS485 signal

(Master In/Slave Out)

7 SCLKA Differential RS - 485 clock signal from IMC

8 SCLKB Differential RS - 485 clock signal from IMC

9 -12 SLVSEL0 - 3 SPI address (Slave selection 0 - 3) from IMC

13 MRESET* Master Reset

14 +19V1 Analog supply voltages

15 -19V1 -

16 ANGND1 Analog Gnd

Doc. code 8200629 4-1-3

N100 Connector Unit 1 4. Circuit Boards

Connector J105

Pin Signal Description

1 POWGND1 Power supply GND

2 + 28 V1 Power supply voltage

3 POWGND1 Power supply GND

4 + 28 V1 -

5 POWGND1 Power supply GND

6 - Not used

7 EXPC* Exposure command from IMC and exposure button

8 ( SYNC ) Not used

Connector J106

Pin Signal Description

1-4 RSTEP0 - 3 Phases 0-3 to rotation stepper motor

5-8 VSTEP0 - 3 Phases 0-3 to vertical stepper motor

9 - 12 CSTEP0 - 3 Phases 0-3 to cassette carriage stepper

motor

Connector J107

Pin Signal Description

1, 3, 5, 7 AGND -

2, 4 +19V -

6 -19V -

8, 9, 11,

13, 15, 16 GND -

10, 12, 14 +9V -

17-18 MOSI_A, MOSI_B SPI diff. RS485 signal (Master Out/Slave In)

19-20 MISO_A, MISO_B SPI diff. RS485 signal (Master In/Slave Out)

21-22 SCLK_A, SCLK_B Differential RS - 485 clock signal

23-26 SLVSEL0-3* SPI address (Slave selection 0 - 3)

27 MRESET* Master reset

28 PFAIL* Too low or high +28V supply voltage

29 EXPC* Exposure command from IMC button

30 EXPLGHT* Exposure lights on

31 TOP Column at highest position

32 BOTTOM* Column at lowest position

33-34 SREF1, SREF2 Analog signal to control up/down z-movement

35, 36 ON1, ON2 Not used

37 NETV Analog signal which is proportional to mains

voltage

38 HEADSIZE Not used

39 CEPHAUTO Not used

42, 44, 46,

48, 50 POWGND -

43, 45,

47, 49 +28V -

4-1-4 Cranex Tome Service Manual

4. Circuit Boards N100 Connector Unit 1

Connector J108

Pin Signal Description

1-4 XSTEP0-3 Phases 0-3 to x-move stepper motor

5-8 YSTEP0-3 Phases 0-3 to y-move stepper motor

9-12 - Not used

Connector J109

Pin Signal Description

1-4 RSTEP0-3 Phases 0-3 to rotation stepper motor

5-8 VSTEP0-3 Phases 0-3 to vertical stepper motor

9-12 CSTEP0-3 Phases 0-3 to cassette stepper motor

Connector J110

Pin Signal Description

1 SENSPOW Supply voltage for sensors

3 2XSENS1* X-sensor 1 data

4 GND2 -

Connector J111

Pin Signal Description

1 SENSPOW Supply voltage for sensors

2 YSENS1* Y-sensor1 data

3 YSENS2* Y-sensor2 data

4 GND2

Connector J112

Pin Signal Description

1-4 XSTEP0-3 Phases 0-3 to x direction stepper motor

Connector J113

Pin Signal Description

1-4 YSTEP0-3 Phases 0-3 to y-direction stepper motor

Doc. code 8200629 4-1-5

N100 Connector Unit 1 4. Circuit Boards

Connector J114

Pin Signal Description

1 +9V2 +9V supply voltage to be regulated to +5V

3 +9V2 -

2 GND2 Gnd (+5V)

4 GND2 -

16 GND2 -

5 MOSIA Differential RS485 signal (Master Out/Slave In)

6 MOSIB Differential RS485 signal (Master Out/Slave In)

7 MISOA SPI tranmission differential RS485 signal

(Master In/Slave Out)

8 MISOB SPI tranmission differential RS485 signal

(Master In/Slave Out)

9 SCLKA Differential RS - 485 clock signal from IMC

10 SCLKB Differential RS - 485 clock signal from IMC

11 MRESET* Master Reset

12-15 SLVSEL0-3 Slave Select 0-3.

17 (CEPHAUTO) Not used

18 SREF2 Analog signal to control up/down z-movement

19 (ON2) Not used

20 (CEPHMAG) Not used

4-1-6 Cranex Tome Service Manual

4. Circuit Boards N100 Connector Unit 1

Doc. code 8200629 4-1-7

N100 Connector Unit 1 4. Circuit Boards

4-1-8 Cranex Tome Service Manual

4. Circuit Boards N100 Connector Unit 1

Doc. code 8200629 4-1-9

N100 Connector Unit 1 4. Circuit Boards

4 - 1 - 10 Cranex Tome Service Manual

4. Circuit Boards N200 Auxiliary Voltage Supply

N200 Auxiliary Voltage Supply (AVS)

Location

In top of support arm.

To access, remove the top cover.

Field replaceable parts

- Jumpers for voltage conversion.

They MUST be installed if the unit is used with a 115 VAC

mains voltage. Refer to the "Installation and set-up

manual" for information on how to instal the jumper.

- Fuse F1 - 5 AT, 250 VAC

- Fuse F2 - 2 AT, 250 VAC

- Fuse F3 - 1 AT, 250 VAC

- Fuse F4 - 3.2 AT, 250 VAC

- Fuse F5 - 3.2 AT, 250 VAC

- Fuse F6 - 10 AT, 250 VAC

- Fuse F7 - 3.2 AT, 250 VAC @ 230 VAC mains

6.3 AT, 250 VAC @ 115 VAC mains

All fuses are 6.3 mm x 32 mm.

WARNING

Replace only with the same type and rating of fuse.

- Cooling fan 24 VDC. Part number 4800955.

Description

The N200 Auxiliary Voltage Supply board produces all the

low power supply voltages for the unit. From the mains

voltage it generates +28 VDC, +9VDC and +- 19VDC

low power supply voltages.

The mains voltage (115 or 220-240 VAC) is supplied to a

full bridge rectifier, D58, through RF-filter, RF1. Trans-

former T4 monitors the mains voltage for two reasons, to

generate the supply voltage to start the PWM and to

detect low mains voltage.

If the unit is used with a 115 VAC mains voltage a special

jumpers MUST be installed. A second jumper must also

be connected to N1000.

If the unit is used with a 220-240 VAC mains voltage the

jumpers MUST NOT be used. Refer to the "Installation

and set-up manual" for information on how to instal the

jumpers.

Doc. code 8200629 4-2-1

N200 Auxiliary Voltage Supply 4. Circuit Boards

Transformer T1 is the mains voltage switching trans-

former with one primary and four secondary windings.

Rectified mains voltage (between DC+ and DC-) is

switched with transistors TR1 and TR2 through T1 to

produce correct output voltages. Transformer T3 switches

the transistors on and off according to the signal

PWMOUT. The current through the transistors is moni-

tored by transformer T2 and its current feedback signal is

used to control the current mode PWM (IC1) circuit.

Indicator LED’s

Led Colour Indicates

D11 green +9V on

D12 green -19V on

D13 green +19V on

D14 green +28V on (before fuses F4-F6)

D24 green +28V1 on

D25 green +28V2 on

D26 green +28V3 on

D45 green PWM is switching

D57 yellow High voltage (350 VDC on)

Test points

Pin Signal Description

TP1 GND 1,2,3 Ground for +9V

TP2 +9V -

TP3 ANGND Gnd for ±19V

TP4 -19V -

TP5 +19V -

TP6 +28V_FB +28V putput of T1 (before fuses F4-F6)

TP7 POWGND Gnd for +28V

TP8 +22V PWM supply voltage

TP9, 20 SIGGND Signal gnd

TP10 COMP PWM error amplifier output

TP11 CT PWM frequency (about 132 kHz)

TP12 CUR_SENS Current feedback signal

TP14 +5V1 +5V supply voltage for AVS

TP16 NETV Signal proportional to mains voltage

TP18 Under or over voltage detection (mains)

TP19 VREF Reference voltage of PWM

TP21 DC+ Rectified mains voltage

TP22 DC0 -

TP23 DC- Rectified mains voltage

4-2-2 Cranex Tome Service Manual

4. Circuit Boards N200 Auxiliary Voltage Supply

Connector J201

AC1 mains voltage in

Connector J202

AC2 mains voltage in

Connector J203

Pin Signal Description

1,2 - AC1 mains voltage to HVS

5,6 - AC2 mains voltage to HVS

Connector J204

Pin Signal Description

1 +28V1 -

4 POWGND -

Connector J205

Pin Signal Description

1 +28V2 -

4 POWGND -

Connector J206

Pin Signal Description

1, 2 +9V2 -

3-5 GND2 -

6 +9V1 -

7, 8 GND1 -

9 +19V2 -

10 +19V1 -

11, 12 ANGND2 -

13 -19V2 -

14 -19V1 -

15, 16 ANGND1 -

17 (SYNC) Not used

18 PFAIL* Too low or high +28V supply voltage

19 NETV Voltage which is proportional to mains voltage

20, 21 SREF1,2 Analog signal to control up/down z-movement

22, 23 (ON1,2) Not used

Doc. code 8200629 4-2-3

N200 Auxiliary Voltage Supply 4. Circuit Boards

Connector J207

Pin Signal Description

1, 2, 3 +28V3 -

6, 7, 8 POWGND -

24 TOP Z-Movement Top Limit

25 BOTTOM* Z-Movement Bottom Limit

26 EXPLGHT* Signal Which Activates Exposure Lights

Connector J208

Pin Signal Description

1, 2 +9 V Logic supply voltage

3, 4 GND Logic gnd

5, 7 +/- 19 V Logic supply voltage

6 ANGND Not used

8 SREF1 Z - motor control in panoramic mode

10 ON1 Not used

9 SREF2 Z - motor control in cephalo mode

SREFN Z-movement direction

<1.7V down

2.5V stopped

>3.5V up

11 ON2 Not used

12 TOP Z-movement top limit

13 BOTTOM* Z-movement bottom limit

14 EXPLGHT* Signal which activates exposure lights.

4-2-4 Cranex Tome Service Manual

4. Circuit Boards N200 Auxiliary Voltage Supply

Doc. code 8200629 4-2-5

N200 Auxiliary Voltage Supply 4. Circuit Boards

4 - 2 - PB Cranex Tome Service Manual

4. Circuit Boards N200 Auxiliary Voltage Supply

Doc. code 8200629 4-2-7

N200 Auxiliary Voltage Supply 4. Circuit Boards

4 - 2 - PB Cranex Tome Service Manual

4. Circuit Boards N300 Z-Motor Controller

N300 Z-Motor Controller (ZMC)

Location

In top of support arm.

To access, remove top cover.

Field replaceable parts

None.

Description

The N300 Z-Motor Controller board receives control

signals from the up/down keys on the control panel and

the side of the cephalostat, and the N2100 Top/bottom

sensors. These signals come through the N600, N100

and the N200 boards.

The N300 board has a microprocessor which can inde-

pendently control the speed of z-motor in both directions

and the motor acceleration (0-2 seconds) and

deacceleration (0-1 second) sequences. The N300 board

also switches the exposure lights on.

Reset circuitry

If the microprocessor supply voltage is too low or the

microprocessor stops operating during z-motor move-

ment, a RESET* signal is generated by IC 6. The thresh-

old voltage for the RESET operation is 4.6 V +10 mV with

a 500ns delay.

PWM control signal D/A conversion

The pulsed signal at pin TCMP (compare pin) on proces-

sor IC1 is called SREF_OUT. Its frequency is 357 Hz and

its duty cycle varies between 46.0 - 82.6 %. R3/C8 con-

vert this signal to an analog voltage. This analog voltage

controls the PWM IC4 pulse rate (output PWMOUT*)

which controls the acceleration and deacceleration ramps

of the z-motor.

The internal frequency of the PWM is about 20 kHz.

PAL circuit

The PAL circuit IC 5 protects the processor and prevents

z-motor movement if microprocessor is not functioning

according to the software. It also makes sure that the z-

motor stops if either the TOPLIMIT or BOTLIMIT signal is

generated (the unit has reached its maximum or minimum

height). IC 5 also controls the rotation speed of the z-

motor.

Doc. code 8200629 4-3-1

N300 Z-Motor Controller 4. Circuit Boards

Power drive

The z-motor drive consists of two power drivers IR2110

(IC 7, IC 8) and four power FET transistors IRFZ44 (TR3-

TR6). When channels A and D are active, the z-motor

rotates and drives the unit up. When channels B and C

are active, it rotates and moves the unit down. Thermal

switch SW1 is connected so that it measures the tem-

perature of FETs. If temperature becomes too high, an

OVERTEMP* signal will be generated causing the proc-

essor to decrease the motor speed to 1/4 of the normal

speed. Voltage across R48-R50 is used to monitor the

current through the motor. If motor current exceeds 16 A

the PWM pin COMP will be forced to ground thus disa-

bling the PWM output pulses. The z-motor will then stop.

Indicator LEDs

Led Colour Indicates

D1 green +5 V:n on

D2 yellow Z-MOTOR is on when LED is on. If LED flashes,

1/4 speed only possible (FETs temperature too

high)

D15 green +15 V ON

D16 green +28 V ON

Test pins

Pin Signal

TP1, TP4, TP17, TP18 GND

TP15 POWGND

TP2 +5 V

TP16 +28 V

TP8 SREF_1

TP9 SREF_2

TP10 EXPLIGHT*

TP11 EL1- Exposure light test point

TP12 Low voltage RESET*

TP5 SREF_OUT

TP3 MOT CUR, current limit

TP7 SREF3 = PWM pin COMP

TP6 PWMOUT*

TP13 ZM2, motor connection ( J303 / 4 )

TP14 ZM1, motor connection ( J303 / 1 )

4-3-2 Cranex Tome Service Manual

4. Circuit Boards N300 Z-Motor Controller

Connector J301

Pin Signal Description

1, 2, 3 +28V3 -

6, 7, 8 POWGND -

Connector J302

Pin Signal Description

1, 2 +9 V Logic supply voltage

3, 4 GND Logic gnd

5, 7 +/- 19 V Not used

6 ANGND Not used

8 SREF1 Z-motor control in panoramic mode

10 ON1 Z-motor enable in panoramic mode

9 SREF2 Z-motor control in cephalo mode

SREF Z-movement direction

<1.7V down

2.5V stopped

>3.5V up

11 ON2 Z-motor enable in cephalo mode.

12 TOP Z-movement top limit

13 BOTTOM* Z-movement bottom limit

14 EXPLGHT* Signal which activates exposure lights.

Processor signals (IC1)

Pin Signal Description

10 CPU_OK Processor is in control

9 DOWN Driving down

8 UP Driving up

7 STOP Drive stopped

6 SHUTDOWN PWM and thus the z-motor is disabled

24 SREF_OUT PWM control and speed up/slow down ramp

generation.

Doc. code 8200629 4-3-3

N300 Z-Motor Controller 4. Circuit Boards

Z-Motor controller (ZMC) N300

4-3-4 Cranex Tome Service Manual

4. Circuit Boards N300 Z-Motor Controller

Doc. code 8200629 4-3-5

N300 Z-Motor Controller 4. Circuit Boards

4-3-6 Cranex Tome Service Manual

4. Circuit Boards N300 Z-Motor Controller

Doc. code 8200629 4-3-7

N300 Z-Motor Controller 4. Circuit Boards

4-3-8 Cranex Tome Service Manual

4. Circuit Boards N600 Imaging controller

N600 Imaging controller (IMC)

Location

In front of moving column.

To access, remove the front column cover.

Field serviceable parts

Battery CR2032.

NOTE

The battery must be replaced with one of the same type

(UL recognised).

Description

Imaging Controller and Display Driver (IMC) consist of the

main processor (IC1), which controls all the main func-

tions of the unit, the driver for the electro luminescent

display (IC15), a real time clock, an A/D converter, +12V

flash EPROM programming electronics and an I/O con-

troller (IC16).

The I/O controller has several functions, to serve as a

Master RESET controller for the peripheral circuits, to

decode the slave addresses (SPI communication), to

verify that the real time clock remains under processor

control, to control the SPI master communication and to

control all those input/output signals that are not micro-

processor signals.

Doc. code 8200629 4-4-1

N600 Imaging controller 4. Circuit Boards

The Display Driver and I/O Controller have been imple-

mented using programmable LCA circuits which are

programmed in the following way. At start up IC 15 con-

figuration is loaded from flash EPROMs on N660. IC 15

is configuration from IC16 in serial format (daisy chain).

Indicator LEDs

LED Colour Indicates

D4 yellow Flash memory +12V programming voltage on (Not

used)

D5 red Motor control reset

D6 red Master reset

D7 yellow LCA’s configured

D8 green +5V ok

Test points

Pin Signal Description

TP1 EL+9V -

TP2 EL+19V -

TP3, TP16, -

TP17, TP34, -

TP39-43 GND -

TP4 +9V -

TP5 MISO_1 Master In / Slave Out signal

TP8 PROGRAM* LCA programming control at start up

TP9 DONE LCA’s are configured

4-4-2 Cranex Tome Service Manual

4. Circuit Boards N600 Imaging controller

TP10 R/W* Internal bus read/write control

TP11 WRL* Write low

TP12 WRH* Write high

TP13 RDL* Read low

TP14 RDH* Read high

TP15 RESET* CPU reset

TP18 EXPC* Exposure on control

TP20 DONE* LCA’s are configured

TP21-33 Internal bus signals

TP35 Filtered EXP*

TP36 EXPC_1* Exposure enable from processor

TP37 HALT CPU halted

TP38 CLKOUT CPU clock signal

TP44 +5V -

Connector J601

Pin Signal Description

1, 3, 5, 7 AGND -

2, 4 +19V -

6 -19V -

8, 9, 11,

13, 15, 16 GND -

10, 12, 14 +9V -

17-18 MOSI_A, MOSI_B SPI diff. RS485 signal (Master Out/Slave

In)

19-20 MISO_A, MISO_B SPI diff. RS485 signal (MasterIn /Slave

Out)

21-22 SCLK_A, SCLK_B Differential RS - 485 clock signal

23-26 SLVSEL0-3* SPI address (Slave selection 0 - 3)

27 MRESET* Master reset

28 PFAIL* Too low or high +28Vsupply voltage

29 EXPC* Exposure command from IMC button

30 EXPLGHT* Exposure lights on

31 TOP Column at highest position

32 BOTTOM* Column at lowest position

33-34 SREF1, SREF2 Analog signal to control up/down z-movement

35, 36 ON1, ON2 Not used

37 NETV Voltage which is proportional to mains voltage

38 HEADSIZE Not used

39 CEPHAUTO Not used

42, 44,

46, 48, 50 POWGND -

43, 45,

47, 49 +28V -

Doc. code 8200629 4-4-3

N600 Imaging controller 4. Circuit Boards

Connector J602

Pin Signal Description

1, 3, 5 AGND -

2 +19V -

4 -19V -

6, 8, 10, 16, 25 GND -

7,9 +9V -

11 STEP1CLK Stepping clock for x-movement

12 STEP2CLK Stepping clock for y-movement

13 STEP3CLK Stepping clock for rotation movement

14 STEP4CLK Stepping clock for vertical movement

15 STEP5CLK Stepping clock for cassette movement

17-21 MC_DATA0-4 5-bit databus for registers

22-24 MC_ADDR0-2 Register select/address signals

26 MCLATCH Register write signal

27 MOTPOWON Switches main power of stepping motor drivers

on and off

28 MVOK* Signal from N700, main motor power is high

enough, and LCA devices are configured

properly

29 LIGHTSON Patient positioning lights on

30 MCRESET* Master reset for N700

32, 34, 36,

38, 40 POWGND -

33, 35, 37, 39 +28V -

Connector J603

Pin Signal Description

1 VDATA Display data

2,4,6,8, -

9,10,12,13 GND -

3 VCLK Display clock

5 HS Horizontal sync

7 VS Vertical sync

11 BLANK/NC Not used

14,17,18 ANGND -

15,16 EL+19V Electroluminance display power +19V

20 SREF1 Analog signal to control up/down z-movement

4-4-4 Cranex Tome Service Manual

4. Circuit Boards N600 Imaging controller

Connector J604

Pin Signal Description

1-8 KEYCOL7-1* Keyboard columns

9-13 KEY_ROW4-0 Keyboard rows

14, 17, 18 GND -

15, 16 EL+9V Electroluminance sidplay power +9V

19 SPEAKER Speaker output signal

20 LAYER Y- motor control:

out 3.7V

in 1.3V

stop 2.5V

Connector J605

Pin Signal Description

1 EXP* Exposure button signal

2 RDYL Ready for exposures

3, 6, 14 GND -

4 TXD Transmit data (RS232C)

5 RXD Receive data (RS232C)

7 MRESET* Master reset

8 MOSI Differential RS485 signal (Master Out/Slave In)

9 MISO SPI differential RS485 signal (Master In/SlaveOut)

10 SCLK Differential RS - 485 clock signal

11 SLVSEL7* SPI address (Slave selection 0 - 3)

15 +28V -

16 POWGND Gnd for +28V electronics

Connector J606

Pin Signal Description

1 SENSPOW Supply voltage to sensors

2 TOP Column at top sensor

4 GND

Connector J607

Pin Signal Description

1 SENSPOW Supply voltage to sensors

2 BOTTOM* Column at bottom sensor

4 GND

Doc. code 8200629 4-4-5

N600 Imaging controller 4. Circuit Boards

Connector J608

Pin Signal Description

1 CRUP* Chin rest up

2 GND -

Connector J609

Pin Signal Description

1 CRDOWN* Chin rest down

2 GND -

Connector J610

Pin Signal Description

1 MIRLOCK* Patient mirror locked

2 GND -

Connector J611

Pin Signal Description

2 SREF1 Analog signal to control up/down Z-movement

4 GND -

Connector J612

Pin Signal Description

2 LAYER Not used

3 LAYERON Not used

4 GND -

4-4-6 Cranex Tome Service Manual

4. Circuit Boards N600 Imaging Controller

Doc. code 8200629 4-4-7

N600 Imaging Controller 4. Circuit Boards

4-4-8 Cranex Tome Service Manual

4. Circuit Boards N600 Imaging Controller

Doc. code 8200629 4-4-9

N600 Imaging Controller 4. Circuit Boards

4 - 4 - 10 Cranex Tome Service Manual

4. Circuit Boards N600 Imaging Controller

Doc. code 8200629 4 - 4 - 11

N600 Imaging Controller 4. Circuit Boards

4 - 4 - 12 Cranex Tome Service Manual

4. Circuit Boards N600 Imaging Controller

Doc. code 8200629 4 - 4 - 13

N600 Imaging Controller 4. Circuit Boards

4 - 4 - 14 Cranex Tome Service Manual

4. Circuit Boards N650 RAM Memory Module

N650 RAM Memory Module (RMM)

Location

Plugged into N600.

To access, remove the front column cover.

Field serviceable parts

None

Description

Although the N650 RAM Memory Module (RMM) is a

separate board it is a functional part of N600. On the

N650 board there are the RAM memories that the micro-

processors require.