Beruflich Dokumente

Kultur Dokumente

Cemflor MBS

Hochgeladen von

Amirul ShamOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Cemflor MBS

Hochgeladen von

Amirul ShamCopyright:

Verfügbare Formate

(CM13/07/16)

CEMFLOR MBS

EPOXY BASED MODIFIED CEMENT WATER BARRIER / UNDERLAYMENT

DESCRIPTION

Substrate

CEMFLOR MBS is a 3 component, water based epoxy

Cemflor MBS

cement screed with specially selected high crushing

Cemflor MBS

strength, chemical inert aggregates. CEMFLOR MBS does

not requires primer and is compatible for over-coating

with a wide range of CEMKRETE epoxy coating systems.

USES

CEMFLOR MBS is designed to use as vapor barrier layer

for epoxy and polyurethane coating. Ideally suited for

wet and dry areas such as engineering plants, oil refiner-

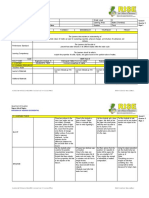

ies,paint workshops, dairies, foods industries, breweries TYPICAL CEMFLOR MBS WATER BARRIER SYSTEM

etc., that are continuously exposed to washing. Product

also can be used as an underlayment for vinyl tiles laying.

BENEFITS

• Waterbased

• User friendly

• Moisture tolerant

• Effective vapor barrier layer

• Excellent adhesion and high compressive strength

COLORS

Amber Grey

Technical Data :

No. of Components 3

No. of Coats Recommended 1 or 2

Recommended Dry Film Thickness 2-3mm

Mixing Ratio (By Weight) A : B : C : water = 3.0 : 1.75 : 20.6 : 5.0 to 6.0 kg by weight

Pot Life 20-30 min at 30ºC

Curing Time Over Coating - 24-48 hours depending on room temperature and relative humidity

Full Cure - 7 days depending on room temperature and relative humidity

Estimated Coverage 2kg/m²/mm

Bond Strength 1 day: 2.0N/mm2 3 days: 2.5N/mm2 7 days : 2.8N/mm2

Compressive Strength 1 day: 25.0N/mm2 3 days: 40.0N/mm2 7 days: 48.0N/mm2

Tensile Strength 3 days: 6.0N/mm2 7 days: 10.0N/mm2

Light Traffic 24 hours @ 10ºC 16 hours @ 20ºC

Storage & Shelf life Unopened in dry conditions at 25ºC / 12 months

Cleaner Water

Packaging 25.35kg/set

The information given in this data sheet is to the best of our knowledge true and accurate; but as we have no control over where or how the product is applied, there are no warranties expressed

or implied regarding the product’s use or performance. Customers are advised to thoroughly test before adapting them to their own use. It is strongly recommended to trial on small area before

large scale application.

WEBSITE TELEPHONE FAX EMAIL

www.cemkrete.com.my +603-8062 4478 +603-8061 5877 enquiry@cemkrete.com.my

(CM13/07/16)

CEMFLOR MBS

EPOXY BASED MODIFIED CEMENT WATER BARRIER / UNDERLAYMENT

SUBSTRATE CONDITION APPLICATION

SUBSTRATE REQUIREMENT The mixed material is poured onto the prepared substrate and

Floor to receive CEMFLOR MBS should be preferably Grade 20 spread to the required thickness with a steel trowel; alternatively, a

concrete or above and preferably waterproofed that when measured serrated trowel can be used. The resin floor should not be

with moisture meter, its reading should not exceed 5%. Cracks, joints overworked but spread slowly and evenly. Immediately after spread-

if there is must be treated accordingly by normal concrete repair ing, the floor should be firmly rolled with a spike roller to help release

procedures. any entrapped air in the material and level any slight trowel marks.

The floor should now self smoothen to an even colored, dense,

SURFACE PREPARATION impervious floor. CEMFLOR MBS shall not be applied over the

Laitance and other foreign materials are to be removed by grinding, existing expansion joints on the substrate.

grit blasting or scarification depending on the profile and depth of

removal required. All residues must be removed to provide a dry, dust Over-Coating

free open textured surface and porous substrates (high air cavities) Surface of CEMFLOR MBS may be top coated with CEMKRETE

may need to be primed to cosolidate it’s surface before applying flooring systems. For this, CEMFLOR MBS must be at least 3 days

CEMFLOR MBS. old and high spots such as cold joints and trowel marks rubbed

down. However, at temperature below 30OC and at RH above 60%,

MIXING there is a possibility of delay in setting of CEMFLOR MBS. In such

It is important that CEMFLOR MBS is mixed correctly. A suitable circumstance, the over coating should be done only after 7 days. All

forced action mixer such as a paddle fitted to a heavy duty, slow tools and equipment should be cleaned immediately after use with

speed electric hand drill or screed mixer is recommended for mixing. water or cleaning thinner.

Base and hardener are poured into a container and mixed thoroughly

until homogeneous for 30 seconds.

Add clean water 5.0 to 6.0 liters to mixed resin then stir thoroughly TEMPERATURE

until milky white, then slowly add the Part C aggregate to the mixture. CEMFLOR MBS should not be applied on substrate with tempera-

Continue mixing for further 2-3 minutes until all the component are ture <10ºC and >30ºC.

thoroughly blended. Care must be taken to avoid air incorporation

into the mixture. Once mixed, the materials must be used within the

specified pot life period, after this time, unused materials will have HEALTH & SAFETY

stiffened and should be discarded. Although CEMFLOR MBS is a water based product, some of the

components may be hazardous during mixing and application.

THINNING Always use with suitable protective gears and adequate ventilation.

On normal substrate, CEMFLOR MBS must be thinned with 20 - 25% Please read the relevant Health & Safety Data Sheet, available on

of clean portable water on total weight after Part A and B are request.

thoroughly mixed.

Make sure water is added only after mixing Part A and Part B and FURTHER INFORMATION

continue mixing product until homogenous before application. CEMKRETE SDN BHD is the leading manufacturer of Polymer

Flooring System and we have many years of hands on experinces not

limited to car park only. Our core business besides flooring, we are

also known supplier of protective coatings, water proofing, concrete

repair products, cementitious / Epoxy / PU grouts, fire proofing, tank

lining and surface preparation equipment. For a complete technical

solution, make CEMKRETE your partner today! Contact CEMKRETE

hotline NOW!

The information given in this data sheet is to the best of our knowledge true and accurate; but as we have no control over where or how the product is applied, there are no warranties expressed

or implied regarding the product’s use or performance. Customers are advised to thoroughly test before adapting them to their own use. It is strongly recommended to trial on small area before

large scale application.

WEBSITE TELEPHONE FAX EMAIL

www.cemkrete.com.my +603-8062 4478 +603-8061 5877 enquiry@cemkrete.com.my

Das könnte Ihnen auch gefallen

- Cera Polymortar: Single Component Micro Fiber Enriched Cementitious Repair MortarDokument3 SeitenCera Polymortar: Single Component Micro Fiber Enriched Cementitious Repair Mortaranandhan boobalanNoch keine Bewertungen

- DS - 645 - Pro Anticarb HB Elastomeric CoatingDokument2 SeitenDS - 645 - Pro Anticarb HB Elastomeric CoatingRay EngineeringNoch keine Bewertungen

- Cempatch HM PDFDokument2 SeitenCempatch HM PDFharish14586Noch keine Bewertungen

- Sikagrout 215 M Pds enDokument3 SeitenSikagrout 215 M Pds enfikryh_2Noch keine Bewertungen

- Boscoflex: Flexible Cementitious Waterprofing MembraneDokument2 SeitenBoscoflex: Flexible Cementitious Waterprofing MembraneCLENTH FLORentinoNoch keine Bewertungen

- Hydroblocker Superelastic: Liquid MembraneDokument2 SeitenHydroblocker Superelastic: Liquid MembraneSemir SpahicNoch keine Bewertungen

- Cera MicroconcreteDokument2 SeitenCera MicroconcreteSindhe SwethaNoch keine Bewertungen

- TDS Weberfloor 620 PMB PlusDokument3 SeitenTDS Weberfloor 620 PMB PlusBurak AkyazıNoch keine Bewertungen

- iKOTE CM 30R (TDS) 02-APRIL-2024Dokument2 SeiteniKOTE CM 30R (TDS) 02-APRIL-2024nguyen hoang AnhNoch keine Bewertungen

- Repair Morters Cicogrout MCDokument2 SeitenRepair Morters Cicogrout MCSharookhan ShajahanNoch keine Bewertungen

- Sikagrout FM - Pds en PDFDokument3 SeitenSikagrout FM - Pds en PDFANDI SETIAWANNoch keine Bewertungen

- E Ds Vandex BB 75Dokument2 SeitenE Ds Vandex BB 75Oscar GuerreroNoch keine Bewertungen

- Sikagrout 215 New - Pds en PDFDokument3 SeitenSikagrout 215 New - Pds en PDFDeny Anarista SitorusNoch keine Bewertungen

- Tamseal SBR - V3in - July 2018 - TdsDokument2 SeitenTamseal SBR - V3in - July 2018 - TdsBharat Pest Control ServicesNoch keine Bewertungen

- TDS Consol Grout 600 MFDokument2 SeitenTDS Consol Grout 600 MFPEP GUDANGNoch keine Bewertungen

- MAJOON WRF Data SheetDokument2 SeitenMAJOON WRF Data SheetChristos LeptokaridisNoch keine Bewertungen

- Sikagrout® 215 (New) : Product Data SheetDokument3 SeitenSikagrout® 215 (New) : Product Data SheetWan Fikri DarmawanNoch keine Bewertungen

- PDS SikaGrout-215P PDFDokument3 SeitenPDS SikaGrout-215P PDFDeny PutraNoch keine Bewertungen

- How To Avoid Screed Failure: Contact The Flooring SpecialistDokument7 SeitenHow To Avoid Screed Failure: Contact The Flooring SpecialistSamuel WooNoch keine Bewertungen

- 6823 Sigmacover 410Dokument4 Seiten6823 Sigmacover 410Chiller jnglNoch keine Bewertungen

- Comfort: Cement-Based Joint Mortar For 1 To 8mmDokument2 SeitenComfort: Cement-Based Joint Mortar For 1 To 8mmVaittianathan MahavapillaiNoch keine Bewertungen

- 00 - 6823 SigmaCover 410Dokument4 Seiten00 - 6823 SigmaCover 410Mohammed AdilNoch keine Bewertungen

- DR - Fixit Pidigrout 10 MDokument3 SeitenDR - Fixit Pidigrout 10 MBijaya RaulaNoch keine Bewertungen

- Extract Page 1Dokument1 SeiteExtract Page 1SebastianAnNoch keine Bewertungen

- Sikagrout 280 Hs Pds enDokument3 SeitenSikagrout 280 Hs Pds enDimas SaputraNoch keine Bewertungen

- Corrofill VE DatasheetDokument2 SeitenCorrofill VE DatasheettienNoch keine Bewertungen

- Abe Construction Chemicals Duraflex DatasheetDokument2 SeitenAbe Construction Chemicals Duraflex DatasheetEthanNoch keine Bewertungen

- Smartcare Epdm Membrane: Single Ply Elastomeric MembraneDokument2 SeitenSmartcare Epdm Membrane: Single Ply Elastomeric MembranePankaj ShirkeNoch keine Bewertungen

- Aac Block Adhesive: Product DescriptionDokument2 SeitenAac Block Adhesive: Product DescriptionmaznahNoch keine Bewertungen

- Fairmate Waterproofing - PunjabDokument128 SeitenFairmate Waterproofing - PunjabAyush GoyalNoch keine Bewertungen

- Flowcoat: Pumacoat WDDokument2 SeitenFlowcoat: Pumacoat WDDan George IonescuNoch keine Bewertungen

- Ikote CM 50X TDS (02-April-2024) V1.3Dokument2 SeitenIkote CM 50X TDS (02-April-2024) V1.3nguyen hoang AnhNoch keine Bewertungen

- DR - Fixit Micro ConcreteDokument3 SeitenDR - Fixit Micro ConcreteKiran KumarNoch keine Bewertungen

- Sika Raintite: Liquid Membrane Waterproofing SystemDokument2 SeitenSika Raintite: Liquid Membrane Waterproofing SystemMoatz HamedNoch keine Bewertungen

- iKOTE CM 40X (TDS) 02-APRIL-2024Dokument2 SeiteniKOTE CM 40X (TDS) 02-APRIL-2024nguyen hoang AnhNoch keine Bewertungen

- SdadsadasDokument3 SeitenSdadsadasTwink Arcane 9Noch keine Bewertungen

- Abe DIY BookletDokument89 SeitenAbe DIY BookletPula ConsultantsNoch keine Bewertungen

- Costar 2K: Cementitious Waterproof MembraneDokument2 SeitenCostar 2K: Cementitious Waterproof MembranePearl GbolahanNoch keine Bewertungen

- Polyhard: Mineral Based Dry Shake Floor HardenerDokument2 SeitenPolyhard: Mineral Based Dry Shake Floor HardenerAlexi ALfred H. TagoNoch keine Bewertungen

- SikaTop 121 - Fiber Reinforced Polymer Modified Repair Mortar PDFDokument3 SeitenSikaTop 121 - Fiber Reinforced Polymer Modified Repair Mortar PDFJames Jatmiko OetomoNoch keine Bewertungen

- Recommendations Annexure 2Dokument13 SeitenRecommendations Annexure 2Structform ConsultantNoch keine Bewertungen

- CONCRESIVE 2200 - v1Dokument2 SeitenCONCRESIVE 2200 - v1VaishamNoch keine Bewertungen

- MAJOON WRB Data SheetDokument2 SeitenMAJOON WRB Data SheetChristos LeptokaridisNoch keine Bewertungen

- TDS CP 1 CapaStuccoDokument3 SeitenTDS CP 1 CapaStuccoMearg NgusseNoch keine Bewertungen

- IKOTE CM 31 TDS (11-Oct-2023)Dokument2 SeitenIKOTE CM 31 TDS (11-Oct-2023)nguyen hoang AnhNoch keine Bewertungen

- Nafufill: Corrosion Protection Coat and Bond CoatDokument2 SeitenNafufill: Corrosion Protection Coat and Bond CoatRichard AmoahNoch keine Bewertungen

- SikaTop Seal-107 Standard PB ENGDokument4 SeitenSikaTop Seal-107 Standard PB ENGJoshua WijayaNoch keine Bewertungen

- Sikagrout - 215 NewDokument3 SeitenSikagrout - 215 NewAlex Tri WijayantoNoch keine Bewertungen

- Sikagrout®-215 (New) : Product Data SheetDokument3 SeitenSikagrout®-215 (New) : Product Data SheetWahyu MahaendraNoch keine Bewertungen

- Sikagrout - 215 NewDokument3 SeitenSikagrout - 215 NewPeralatan Divisi3Noch keine Bewertungen

- Sikagrout - 215 NewDokument3 SeitenSikagrout - 215 Newmanuel rgNoch keine Bewertungen

- Pds Epilux 218 VocDokument2 SeitenPds Epilux 218 VocmuthukumarNoch keine Bewertungen

- Roof Construction Dr. Fixit Newcoat PDFDokument1 SeiteRoof Construction Dr. Fixit Newcoat PDFRishabh VijayNoch keine Bewertungen

- MasterProtect 1891Dokument2 SeitenMasterProtect 1891SHAIK ASIMUDDINNoch keine Bewertungen

- RAF026-SiKA QUARTZTOPDokument11 SeitenRAF026-SiKA QUARTZTOPEmil ElkinNoch keine Bewertungen

- Tribology of Polymeric Nanocomposites: Friction and Wear of Bulk Materials and CoatingsVon EverandTribology of Polymeric Nanocomposites: Friction and Wear of Bulk Materials and CoatingsNoch keine Bewertungen

- Atmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionVon EverandAtmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionNoch keine Bewertungen

- Fastener Drive System: For Threaded Fastener TestingDokument2 SeitenFastener Drive System: For Threaded Fastener TestingAmirul ShamNoch keine Bewertungen

- Low Noise Microphone: Use of Model 378A04Dokument2 SeitenLow Noise Microphone: Use of Model 378A04Amirul ShamNoch keine Bewertungen

- 394C06 - Handheld ShakerDokument2 Seiten394C06 - Handheld ShakerAmirul ShamNoch keine Bewertungen

- Low Noise Microphone: Use of Model 378A04Dokument2 SeitenLow Noise Microphone: Use of Model 378A04Amirul ShamNoch keine Bewertungen

- The First Handheld Sound Camera For EveryoneDokument2 SeitenThe First Handheld Sound Camera For EveryoneAmirul ShamNoch keine Bewertungen

- Extreme: Featured ProductsDokument3 SeitenExtreme: Featured ProductsAmirul ShamNoch keine Bewertungen

- Page 1000169313 PDFDokument1 SeitePage 1000169313 PDFAmirul ShamNoch keine Bewertungen

- To Be Supplied LaterDokument1 SeiteTo Be Supplied LaterAmirul ShamNoch keine Bewertungen

- Page 1000169313 PDFDokument1 SeitePage 1000169313 PDFAmirul ShamNoch keine Bewertungen

- Contract Seal Diagram: Straight Through Applicable To: FORDokument2 SeitenContract Seal Diagram: Straight Through Applicable To: FORAmirul ShamNoch keine Bewertungen

- Page 1000169313 PDFDokument1 SeitePage 1000169313 PDFAmirul ShamNoch keine Bewertungen

- Spring Energized Seal Guide: Brought To You byDokument28 SeitenSpring Energized Seal Guide: Brought To You byZorghNoch keine Bewertungen

- Item Part #QTY Description: NS Not Shown - AR As Requested - NU Not Used - SL Separate ListDokument1 SeiteItem Part #QTY Description: NS Not Shown - AR As Requested - NU Not Used - SL Separate ListAmirul ShamNoch keine Bewertungen

- Page 590-369-201 PDFDokument1 SeitePage 590-369-201 PDFAmirul ShamNoch keine Bewertungen

- Item Part #QTY Description: NS Not Shown - AR As Requested - NU Not Used - SL Separate ListDokument1 SeiteItem Part #QTY Description: NS Not Shown - AR As Requested - NU Not Used - SL Separate ListAmirul ShamNoch keine Bewertungen

- Item Part #QTY Description: NS Not Shown - AR As Requested - NU Not Used - SL Separate ListDokument1 SeiteItem Part #QTY Description: NS Not Shown - AR As Requested - NU Not Used - SL Separate ListAmirul ShamNoch keine Bewertungen

- Item Part #QTY Description: NS Not Shown - AR As Requested - NU Not Used - SL Separate ListDokument1 SeiteItem Part #QTY Description: NS Not Shown - AR As Requested - NU Not Used - SL Separate ListAmirul ShamNoch keine Bewertungen

- Item Part #QTY Description: NS Not Shown - AR As Requested - NU Not Used - SL Separate ListDokument1 SeiteItem Part #QTY Description: NS Not Shown - AR As Requested - NU Not Used - SL Separate ListAmirul ShamNoch keine Bewertungen

- Page 590-369-201Dokument1 SeitePage 590-369-201Amirul ShamNoch keine Bewertungen

- Page 1000169313 PDFDokument1 SeitePage 1000169313 PDFAmirul ShamNoch keine Bewertungen

- Rulmenti Precizie Inalta NACHI PDFDokument49 SeitenRulmenti Precizie Inalta NACHI PDFNicu TruicaNoch keine Bewertungen

- Kemet 48 Model: Features & BenefitsDokument2 SeitenKemet 48 Model: Features & BenefitsAmirul ShamNoch keine Bewertungen

- CPG Management of Heart Failure (3rd Edition) 2014Dokument8 SeitenCPG Management of Heart Failure (3rd Edition) 2014Atiqah HudaaNoch keine Bewertungen

- Item Part #QTY Description: NS Not Shown - AR As Requested - NU Not Used - SL Separate ListDokument1 SeiteItem Part #QTY Description: NS Not Shown - AR As Requested - NU Not Used - SL Separate ListAmirul ShamNoch keine Bewertungen

- Item Part #QTY Description: NS Not Shown - AR As Requested - NU Not Used - SL Separate ListDokument1 SeiteItem Part #QTY Description: NS Not Shown - AR As Requested - NU Not Used - SL Separate ListAmirul ShamNoch keine Bewertungen

- IOM - H-CE High Performance Coplanar Reduced Movement Couplings PDFDokument12 SeitenIOM - H-CE High Performance Coplanar Reduced Movement Couplings PDFJhon SanabriaNoch keine Bewertungen

- Lap & Polish Carriers: PR Hoffman Machine ProductsDokument2 SeitenLap & Polish Carriers: PR Hoffman Machine ProductsAmirul ShamNoch keine Bewertungen

- EP 1039184 A1 20000927 (EN) : Title (En) Title (De) Title (FR) Publication Application Priority Abstract (En)Dokument1 SeiteEP 1039184 A1 20000927 (EN) : Title (En) Title (De) Title (FR) Publication Application Priority Abstract (En)Amirul ShamNoch keine Bewertungen

- Root Cause & Corrective Action (RCCA)Dokument30 SeitenRoot Cause & Corrective Action (RCCA)AAKIL AHAMEDNoch keine Bewertungen

- MAXCLEAN WIPER-600 S4ff7987c7ba99Dokument2 SeitenMAXCLEAN WIPER-600 S4ff7987c7ba99Amirul ShamNoch keine Bewertungen

- 6.03 How Do Externalities Affect YouDokument1 Seite6.03 How Do Externalities Affect YouNiyanthri Ramaswamy Naresh PrabhuNoch keine Bewertungen

- Republic Act 00003 FinalDokument9 SeitenRepublic Act 00003 FinalNombs NomNoch keine Bewertungen

- 1.4.1 Drainage Requirement: CET 3414 Irrigation and DrainageDokument2 Seiten1.4.1 Drainage Requirement: CET 3414 Irrigation and DrainagentirugiribambeNoch keine Bewertungen

- Khairul's Advanced Math (Pipe&cistern) PDFDokument35 SeitenKhairul's Advanced Math (Pipe&cistern) PDFGolden Apex100% (1)

- Optimization of A Novel Mixed-Salt CO Capture Process Using OLI Flowsheet ESP V10Dokument4 SeitenOptimization of A Novel Mixed-Salt CO Capture Process Using OLI Flowsheet ESP V10kglorstadNoch keine Bewertungen

- Clinoptilolite (Natural Zeolite)Dokument4 SeitenClinoptilolite (Natural Zeolite)Hamed HpNoch keine Bewertungen

- Waste Water Treatment ProposalDokument6 SeitenWaste Water Treatment ProposalSalvador IINoch keine Bewertungen

- Metal Finishing Processes Best PracticesDokument44 SeitenMetal Finishing Processes Best PracticesHoang TanNoch keine Bewertungen

- Thermodynamic Analysis of Rajby Industries Power and Boiler HouseDokument20 SeitenThermodynamic Analysis of Rajby Industries Power and Boiler HouseSyed AhmedNoch keine Bewertungen

- Group 6 - The Role of Gravitational Force As A Driver For Waterfall Power Plants - Scientific JournalsDokument5 SeitenGroup 6 - The Role of Gravitational Force As A Driver For Waterfall Power Plants - Scientific JournalsANANDA ALIP JANWAR 2021Noch keine Bewertungen

- Crude Oil DesaltingDokument25 SeitenCrude Oil DesaltingNaumanNoch keine Bewertungen

- DWLP Science Week 6 Quarter 1Dokument12 SeitenDWLP Science Week 6 Quarter 1amiel riveraNoch keine Bewertungen

- Topics For DebateDokument5 SeitenTopics For DebateTariq AzizNoch keine Bewertungen

- CLEXTRAL Preconditioner Plus EN PDFDokument2 SeitenCLEXTRAL Preconditioner Plus EN PDFÁrpád OrbánNoch keine Bewertungen

- Energetically-Optimized-Concentration of Fruit JuicesDokument6 SeitenEnergetically-Optimized-Concentration of Fruit JuicesBarat NiloyNoch keine Bewertungen

- 631 Progress On Wastewater Treatment 2018Dokument40 Seiten631 Progress On Wastewater Treatment 2018hdsNoch keine Bewertungen

- W2-SITUATION ANALYSIS CLJIP 2023-25 Barangay MangagoyDokument4 SeitenW2-SITUATION ANALYSIS CLJIP 2023-25 Barangay MangagoySammy CoderaNoch keine Bewertungen

- General Considerations in Plant Design PartDokument29 SeitenGeneral Considerations in Plant Design PartArvee Galor Olvido100% (1)

- Smart Water Quality Monitoring System Based On Iot: Journal Critical ReviewsDokument6 SeitenSmart Water Quality Monitoring System Based On Iot: Journal Critical ReviewsrajyamgarNoch keine Bewertungen

- MCQDokument13 SeitenMCQJitendra Singh RathoreNoch keine Bewertungen

- AFRISO Watchdog en 05-14 PDFDokument8 SeitenAFRISO Watchdog en 05-14 PDFb400013Noch keine Bewertungen

- List of Dams and Reservoirs in India - Wikipedia, The Free EncyclopediaDokument14 SeitenList of Dams and Reservoirs in India - Wikipedia, The Free EncyclopediaHemant PandeyNoch keine Bewertungen

- Fijiidp (EquilibriaDokument13 SeitenFijiidp (EquilibriazibaNoch keine Bewertungen

- The Causes of Floods.Dokument5 SeitenThe Causes of Floods.Delmy Elizabeth Fuentes NuñezNoch keine Bewertungen

- As Biology Core Practical SummaryDokument2 SeitenAs Biology Core Practical Summaryjoelleb100% (1)

- EIA Report MBS Isd Peshawar Morr NIIA - CompressedDokument288 SeitenEIA Report MBS Isd Peshawar Morr NIIA - CompressedMuhammad Waqas AhmedNoch keine Bewertungen

- Division of Negros Occidental: The Learners Demonstrate An Understanding ofDokument39 SeitenDivision of Negros Occidental: The Learners Demonstrate An Understanding ofRAMIR BECOYNoch keine Bewertungen

- Homemade Liposomal CDokument8 SeitenHomemade Liposomal CDennis LipterNoch keine Bewertungen

- S T P DesignDokument70 SeitenS T P DesignvijaykumarlambaNoch keine Bewertungen