Beruflich Dokumente

Kultur Dokumente

ENGRO Cement CEM 1

Hochgeladen von

Amariah JuliahCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ENGRO Cement CEM 1

Hochgeladen von

Amariah JuliahCopyright:

Verfügbare Formate

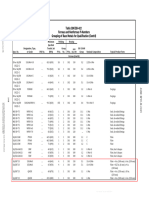

CEM I

Portland Cement, Strength Class 42.5 N a n d 5 2 . 5 N – Complying with SS EN 197-1: 2014

SPECIFICATIONS

Typical Composition, % EnGro CEM I

EnGro Portland Cement meets or exceeds all applicable SiO2 20 - 25

chemical and physical requirements of SS EN 197-1:2014. Al2O3 5-6

Certificate of Analysis is available upon request. Fe2O3 2-3

CaO 60 - 65

MgO 1-2

Na2O 0.2 – 0.3

K2O 0.4 – 0.5

Free Lime as CaO 0.5 – 1.0

C3A 5 - 10

SS EN 197-1

Chemical EnGro

Requirements

Analysis CEM I

(42.5N, 52.5N)

% Loss on

≤ 5.0 % 2-3

Ignition

% Insoluble

≤ 5.0 % 0.1 – 0.5

Residue

EnGro Portland Cement is used in concrete, precast, and % Sulphate

≤ 3.5 % 2 – 2.5

as SO3

masonry products for a multitude of construction projects

% Chloride as

≤ 0.1 % 0.01 – 0.02

including high-rise office buildings, roadway bridges and Cl-

pavements, residential foundations and driveways, water BCA Recommendation

collection and treatment facilities, and airport structures. % Alkali Max 0.6 0.3 – 0.6

It consists of Portland cement clinker finely ground together SS EN 197-1

Compressive Requirements EnGro

with calcium sulfate compound, which is needed as a setting Strength CEM I

(42.5 N) (52.5N)

regulator. The optimized production process ensures a high

2 Days ≥ 10 ≥ 20 20 - 25

degree of uniformity of the cement.

28 Days ≥ 42.5 ≤ 62.5 ≥ 52.5 54 - 56

USE AND LIMITATIONS

EnGro products are all in accordance with strict quality control PACKAGING

procedures to ensure optimum product performance and EnGro CEM I is available in bag (50-kg) and bulk forms.

uniformity. However, there are many variables that affect

concrete performance that are beyond the control of EnGro. PRECAUTIONS

Skilled persons should use these products with special Freshly mixed cement, mortar, grout or concrete may cause

attention given to formwork, batching, mixing, placing, minor skin irritations. Avoid direct contact with skin and eyes

finishing and curing. In most applications, quality aggregates, and if contacted, wash exposed areas promptly with water.

admixtures and additives should be utilized. For detailed Refer to the applicable EnGro product SDS prior to use which

information, contact your EnGro sales office. may be obtained by contacting EnGro sales office.

STORAGE

Cements are sensitive to moisture and should therefore be

stored in a dry place and protected from moisture. With

proper storage, this cement is guaranteed for a period of 12

months from loading date.

EnGro Corporation Limited

29 International Business Park Tel : +65 6561 7978

#08-05/06 Acer Building Tower B Fax: +65 6561 9770

Singapore 609923 www.engro-global.com

Das könnte Ihnen auch gefallen

- Irjet V5i6236Dokument4 SeitenIrjet V5i6236PRAVEEN KUMARNoch keine Bewertungen

- Çimsa Eco White TDS (EN)Dokument1 SeiteÇimsa Eco White TDS (EN)Babu NysemereNoch keine Bewertungen

- Lafarge Fondu Spec SheetDokument5 SeitenLafarge Fondu Spec SheetpankajmandloiNoch keine Bewertungen

- Lead Free MLCC, Chip-R, MLCI SMA Application GuidelineDokument4 SeitenLead Free MLCC, Chip-R, MLCI SMA Application GuidelineBru MNoch keine Bewertungen

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardsDokument1 SeiteMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardschetanNoch keine Bewertungen

- Eni Geum ID 540-840Dokument1 SeiteEni Geum ID 540-840Muhammad RipandiNoch keine Bewertungen

- Test Certificate: Counto Microfine Products Private LimitedDokument1 SeiteTest Certificate: Counto Microfine Products Private LimitedSiddhesh Kamat MhamaiNoch keine Bewertungen

- Material Product Data Sheet Zirconia - Polymer Ceramic Abradable PowdersDokument4 SeitenMaterial Product Data Sheet Zirconia - Polymer Ceramic Abradable PowderskerbaubiruNoch keine Bewertungen

- Specification for Pre Cast Chamber MaterialsDokument6 SeitenSpecification for Pre Cast Chamber MaterialsTai ChoonNoch keine Bewertungen

- WABCO Specification for Passivation of Al AlloysDokument3 SeitenWABCO Specification for Passivation of Al AlloysAbothe35Noch keine Bewertungen

- Phosphogypsum Based CementDokument17 SeitenPhosphogypsum Based CementChaitanya ChintaNoch keine Bewertungen

- Semen 2Dokument30 SeitenSemen 2TotoIswantoMuhammadTohirNoch keine Bewertungen

- AGCO Beauvais Engineering: General Specification For Cast IronsDokument8 SeitenAGCO Beauvais Engineering: General Specification For Cast IronsRafa Lopez PuigdollersNoch keine Bewertungen

- Tds l170 White Primer Chrome Free McilDokument1 SeiteTds l170 White Primer Chrome Free McilSajib Chandra RoyNoch keine Bewertungen

- Counto Microfine GGBS 4000 Test CertificateDokument1 SeiteCounto Microfine GGBS 4000 Test CertificateSiddhesh Kamat MhamaiNoch keine Bewertungen

- DSM-0289.1 AM NiCrMo SuperalloyDokument3 SeitenDSM-0289.1 AM NiCrMo SuperalloyApichitNoch keine Bewertungen

- DSM-0260.1 20YO ZrODokument3 SeitenDSM-0260.1 20YO ZrORangaswamy DoraiswamyNoch keine Bewertungen

- Inspection Certificate AnalysisDokument2 SeitenInspection Certificate AnalysisInspectorNoch keine Bewertungen

- NT COMPANY PROFILE عربي10Dokument12 SeitenNT COMPANY PROFILE عربي10Hisham BerrasaliNoch keine Bewertungen

- Cracking EvaluationDokument17 SeitenCracking Evaluationهوا عجلون-المهندسNoch keine Bewertungen

- NT COMPANY PROFILE 10 x1Dokument13 SeitenNT COMPANY PROFILE 10 x1Hisham BerrasaliNoch keine Bewertungen

- Shell Morlina S2 B 220 - TDSDokument4 SeitenShell Morlina S2 B 220 - TDSFandemen AdintaNoch keine Bewertungen

- DSMTS-0084.3 Al2O3 13TiO2 PDFDokument4 SeitenDSMTS-0084.3 Al2O3 13TiO2 PDFJosua Cavin WijayaNoch keine Bewertungen

- Gazpromneft Reductor CLP industrial gear oilsDokument2 SeitenGazpromneft Reductor CLP industrial gear oilsJonathan HansenNoch keine Bewertungen

- 8215Dokument2 Seiten8215diuska13Noch keine Bewertungen

- Reuse of Fly Ash and Dredging Marine Sediments On Self-Compacting BackfillsDokument10 SeitenReuse of Fly Ash and Dredging Marine Sediments On Self-Compacting BackfillsfoufouNoch keine Bewertungen

- Effect of Cement Type On The Resistance of Concrete Against Rapid Chloride PermeabilityDokument8 SeitenEffect of Cement Type On The Resistance of Concrete Against Rapid Chloride PermeabilityMuhammad YaseenNoch keine Bewertungen

- Characteristics (Typical Figures) Eni I-Sigma Universal ID SAE Grade 15W-40 20W-50Dokument2 SeitenCharacteristics (Typical Figures) Eni I-Sigma Universal ID SAE Grade 15W-40 20W-50AdeAryadewanataNoch keine Bewertungen

- ARTICULODokument7 SeitenARTICULOAnonymous Km4MhaeQNoch keine Bewertungen

- DSMTS 0026.7 - Self Fluxing PDFDokument6 SeitenDSMTS 0026.7 - Self Fluxing PDFRemco van den BergNoch keine Bewertungen

- Section 67 En3 PDFDokument18 SeitenSection 67 En3 PDFKarina CastroNoch keine Bewertungen

- Specification For Marker PostsDokument5 SeitenSpecification For Marker PostsTai ChoonNoch keine Bewertungen

- TOP SPEED 4T: High-Performance Synthetic Oil for 4-Stroke MotorcyclesDokument1 SeiteTOP SPEED 4T: High-Performance Synthetic Oil for 4-Stroke MotorcyclesĆerimovićDooNoch keine Bewertungen

- Mae 1153 Concrete Applications & Mix DesignDokument23 SeitenMae 1153 Concrete Applications & Mix DesignMohammad AL HaririNoch keine Bewertungen

- Test Certificate: Counto Microfine Products Private LimitedDokument1 SeiteTest Certificate: Counto Microfine Products Private LimitedSiddhesh Kamat MhamaiNoch keine Bewertungen

- DSM-0283.1 NiAl HoneycombDokument3 SeitenDSM-0283.1 NiAl HoneycombApichitNoch keine Bewertungen

- Cross Power 2T - enDokument1 SeiteCross Power 2T - enKarankawakahlaNoch keine Bewertungen

- Carboguard 890 EF PDS 9-06Dokument2 SeitenCarboguard 890 EF PDS 9-06Ckaal74Noch keine Bewertungen

- Comparison Between Sinocem & Lafarge CementDokument4 SeitenComparison Between Sinocem & Lafarge CementNidDouNoch keine Bewertungen

- Granulated Wool CatalogueDokument5 SeitenGranulated Wool CatalogueRaihan AhmedNoch keine Bewertungen

- Commander chassis - Drive axle - Shell Spirax ADME 75W90Dokument3 SeitenCommander chassis - Drive axle - Shell Spirax ADME 75W90xhdsnsxyqsNoch keine Bewertungen

- Mobil ATF 220: Automatic Transmission FluidDokument2 SeitenMobil ATF 220: Automatic Transmission Fluidzaidan hadiNoch keine Bewertungen

- Appropriate Selection of Materials For Making Durable Self Compacting Concrete For Using in Underground StructuresDokument10 SeitenAppropriate Selection of Materials For Making Durable Self Compacting Concrete For Using in Underground StructuresIJRASETPublicationsNoch keine Bewertungen

- Shell Morlina s2 B 320Dokument4 SeitenShell Morlina s2 B 320Aep HidayatNoch keine Bewertungen

- Attachment #1. ASME IX (2019)Dokument2 SeitenAttachment #1. ASME IX (2019)dung05n2Noch keine Bewertungen

- Enersyn MP-S RangeDokument2 SeitenEnersyn MP-S RangecarmaNoch keine Bewertungen

- DSMTS 0021 2 NiGraphiteDokument8 SeitenDSMTS 0021 2 NiGraphitemgharba123Noch keine Bewertungen

- High load industrial gear lubricants - Tauro REPSOL 220 & 320Dokument1 SeiteHigh load industrial gear lubricants - Tauro REPSOL 220 & 320randiNoch keine Bewertungen

- SF-0015.1 IGT HPT Abradables ENDokument8 SeitenSF-0015.1 IGT HPT Abradables ENThanaraj SanmughamNoch keine Bewertungen

- Snow CreteDokument2 SeitenSnow CreteAndrew PiNoch keine Bewertungen

- Lightweight Aggregates For Structural ConcreteDokument3 SeitenLightweight Aggregates For Structural ConcreteFRANZ RICHARD SARDINAS MALLCONoch keine Bewertungen

- Isododecane and Ldpe ProductionDokument6 SeitenIsododecane and Ldpe ProductionjaveddilberNoch keine Bewertungen

- Protect Your Engine with Total Quartz INEO ECOB 5W-20 OilDokument2 SeitenProtect Your Engine with Total Quartz INEO ECOB 5W-20 OilVelibor KaranovicNoch keine Bewertungen

- Diamondspark 52 MC: Seamless Metal-Cored WireDokument2 SeitenDiamondspark 52 MC: Seamless Metal-Cored WireDavid RodriguesNoch keine Bewertungen

- Mix Design Report for Dry Lean ConcreteDokument9 SeitenMix Design Report for Dry Lean ConcreteSanjay Constructions100% (1)

- Zircon - Patch 150Dokument1 SeiteZircon - Patch 150Jorge MermNoch keine Bewertungen

- AGIP ROTRA JD/F Multi-Purpose Tractor LubricantDokument2 SeitenAGIP ROTRA JD/F Multi-Purpose Tractor LubricantJan HendriksNoch keine Bewertungen

- Effect of Silica Fume On The Properties of Concrete: (Ijerat)Dokument5 SeitenEffect of Silica Fume On The Properties of Concrete: (Ijerat)Ohnmar OmNoch keine Bewertungen

- Fossil Hydrocarbons: Chemistry and TechnologyVon EverandFossil Hydrocarbons: Chemistry and TechnologyBewertung: 3 von 5 Sternen3/5 (1)

- Astm C1260 07Dokument5 SeitenAstm C1260 07Amariah JuliahNoch keine Bewertungen

- MALAYSIAN STANDARDS FOR ELECTRICAL ENGINEERING AND ELECTRONICSDokument46 SeitenMALAYSIAN STANDARDS FOR ELECTRICAL ENGINEERING AND ELECTRONICSrwaz3535100% (2)

- 15 Materials and WorkmanshipDokument55 Seiten15 Materials and WorkmanshipAmariah JuliahNoch keine Bewertungen

- TP541Dokument7 SeitenTP541Amariah JuliahNoch keine Bewertungen

- Revised COP For Road Opening - Ed7 - 31mar08Dokument84 SeitenRevised COP For Road Opening - Ed7 - 31mar08Amariah JuliahNoch keine Bewertungen

- TP541Dokument7 SeitenTP541Amariah JuliahNoch keine Bewertungen

- CALCULATION OF REPEATABILITY AND REPRODUCIBILITY FOR QUALITATIVE DATADokument13 SeitenCALCULATION OF REPEATABILITY AND REPRODUCIBILITY FOR QUALITATIVE DATAhandoyo_eko20017573Noch keine Bewertungen

- CALCULATION OF REPEATABILITY AND REPRODUCIBILITY FOR QUALITATIVE DATADokument13 SeitenCALCULATION OF REPEATABILITY AND REPRODUCIBILITY FOR QUALITATIVE DATAhandoyo_eko20017573Noch keine Bewertungen

- 310 Ta PDFDokument8 Seiten310 Ta PDFVincent GomuliaNoch keine Bewertungen

- Yoga Nidra MethodDokument13 SeitenYoga Nidra MethodPrahlad Basnet100% (2)

- In-Vitro Anti-Lipase and Antioxidant Activity of Polyherbal AyurvedicDokument9 SeitenIn-Vitro Anti-Lipase and Antioxidant Activity of Polyherbal AyurvedicErvi DyahNoch keine Bewertungen

- Behavior Intervention PlanDokument6 SeitenBehavior Intervention Planapi-308475283Noch keine Bewertungen

- A1 Tuv Dosimetry Application Form For Email (Effective 25 October 2019) 3Dokument2 SeitenA1 Tuv Dosimetry Application Form For Email (Effective 25 October 2019) 3Shaira May Flores PalmaNoch keine Bewertungen

- SIDCSDokument8 SeitenSIDCSsakshi suranaNoch keine Bewertungen

- DaloDokument2 SeitenDalojosua tuisawauNoch keine Bewertungen

- Fermenting For Health - Pip MagazineDokument2 SeitenFermenting For Health - Pip MagazinePip MagazineNoch keine Bewertungen

- Coffee Master Program Flashcards - QuizletDokument23 SeitenCoffee Master Program Flashcards - QuizletmuuayliiNoch keine Bewertungen

- 4front Projects: BbbeeDokument12 Seiten4front Projects: BbbeeBrand Media OfficeNoch keine Bewertungen

- Smartphone Technician Cum App Tester: Trade PracticalDokument218 SeitenSmartphone Technician Cum App Tester: Trade PracticalF ZaidiNoch keine Bewertungen

- DepEd Region I Summative Test in Cookery 9Dokument2 SeitenDepEd Region I Summative Test in Cookery 9Jessel Mejia OnzaNoch keine Bewertungen

- AC7101.1 Rev G 2Dokument37 SeitenAC7101.1 Rev G 2Namelezz ShadowwNoch keine Bewertungen

- Eng & FLS Standards Rev.1 (Dec. 2018)Dokument72 SeitenEng & FLS Standards Rev.1 (Dec. 2018)Nalan BAHCEKAPILINoch keine Bewertungen

- SPR MAN 4 14 ET Operating ManualDokument24 SeitenSPR MAN 4 14 ET Operating ManualJason WeeksNoch keine Bewertungen

- Meditation ProjectDokument2 SeitenMeditation Projectapi-411448305Noch keine Bewertungen

- 'S Outfits and Emergency Escape Breathing Devices (Eebd)Dokument11 Seiten'S Outfits and Emergency Escape Breathing Devices (Eebd)Thurdsuk NoinijNoch keine Bewertungen

- Tracking SARDO StudentsDokument2 SeitenTracking SARDO StudentsLean ABNoch keine Bewertungen

- Venkateshwara Institute of MedicalDokument10 SeitenVenkateshwara Institute of Medicalbolhari070Noch keine Bewertungen

- Photodegradation and Photoprotection of Wood SurfaceDokument14 SeitenPhotodegradation and Photoprotection of Wood Surfaceichsan hakimNoch keine Bewertungen

- DQ RMGDokument23 SeitenDQ RMGDhaval ChaplaNoch keine Bewertungen

- Escala de Violencia e Índice de SeveridadDokument11 SeitenEscala de Violencia e Índice de SeveridadpsiserviciosprofesioNoch keine Bewertungen

- Food Sample Test For Procedure Observation InferenceDokument2 SeitenFood Sample Test For Procedure Observation InferenceMismah Binti Tassa YanaNoch keine Bewertungen

- Prof Educ 2: Foundation of Special and Inclusive EducationDokument12 SeitenProf Educ 2: Foundation of Special and Inclusive EducationNerissa Custosa BastoNoch keine Bewertungen

- Employment Law Lubs 3915Dokument4 SeitenEmployment Law Lubs 3915ogunsatoNoch keine Bewertungen

- History of Medicine - Alexander WilderDokument555 SeitenHistory of Medicine - Alexander WilderMark R. JaquaNoch keine Bewertungen

- A Humanistic Approach To Medical PracticeDokument3 SeitenA Humanistic Approach To Medical PracticeFilipos ConstantinNoch keine Bewertungen

- Physical Therpay Protocols For Conditions of Neck RegionDokument74 SeitenPhysical Therpay Protocols For Conditions of Neck Regionjrpsaavedra4599Noch keine Bewertungen

- Bill 192: An Act To Ensure Student Health and Safety in The Classroom by Regulating Ambient Air Quality in SchoolsDokument8 SeitenBill 192: An Act To Ensure Student Health and Safety in The Classroom by Regulating Ambient Air Quality in SchoolsCtv MontrealNoch keine Bewertungen

- Un Primer Acercamiento A La Escritura Científica: OPI LabDokument66 SeitenUn Primer Acercamiento A La Escritura Científica: OPI LabLolaNoch keine Bewertungen