Beruflich Dokumente

Kultur Dokumente

SAIC A 1005 Compaction Test

Hochgeladen von

Abdul HannanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SAIC A 1005 Compaction Test

Hochgeladen von

Abdul HannanCopyright:

Verfügbare Formate

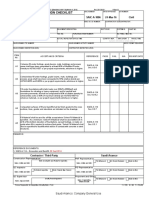

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.

00 30-Jun-16

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Compaction Testing SAIC-A-1005 15-Nov-17 MAH-SA-C-5140

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

HAWAIYAH & HARADH DEVELOMENT SATELLITE GAS COMPRESSION 10 - 01996 / 0007 MOFARREH ALHARBI & PARTNERS

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

N/A N/A N/A N/A D-82

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

N/A

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SATIP-A-114-01 3.4

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

W W

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Note: To verify that the area/ material being inspected was tested by

SA approved third party testing agency, the test results attached with

this RFI shall be verified by the relevant PID inspection unit if copy of

the test results had been received directly from the third party lab. If

not available in the PID Inspection Unit, the inspector shall contact .

the third party laboratory representative and request for an

explanation. If the explanation is not reasonable, NCR shall be

issued to the third party lab through the Batch Plant and Civil Testing

Group.

Contractor's testing agency shall be a Saudi ARAMCO-approved SAES-A-114

A1 .

independent civil testing agency. Sec. 5.1.1

One Modified Proctor Test per ASTM D1557 with corresponding

SAES-A-114

A2 Proctor curve shall be performed for each type of fill material or .

Sec. 6.4.1.1

where there is a change in the type or the source of material.

For cohesionless free draining soils, ASTM D4253 Maximum Index

Density and Unit Weight of Soils Using a Vibratory Table and ASTM

D4254 Minimum Index Density and Unit Weight of Soil and SAES-A-114

A3 .

Calculation of Relative Density shall also be performed for each type Sec. 6.4.1.1

of cohesionless, free draining material or where there is a change in

the type or the source of material..

In-place density shall be determined using one of the following:

ASTM D-1556 Sand Cone Method;

SAES-A-114

A4 ASTM D-2167 Rubber Balloon Method; .

Sec. 6.4.2.1

ASTM D-6938 Nuclear Method;

or ASTM D-2937 Drive-cylinder.

Acceptance testing of in-place density and moisture content (field

density testing) on compacted fill will be performed at the following

rates:

1. Under all foundations - one test every 1077 ft² (100 m²) of each lift.

2. Under area paving - one test every 2153 ft² (200 m²) of each lift. SAES-A-114

A5 .

3. Road base and sub-base - one test every 2153 ft² (200 m²) of Sec. 6.4.2.3

base or sub-base.

4. Backfill of trenches - one test for every 50 linear ft (15 m) of each

lift.

5. General fill - one test every 5382 ft² (500 m²) of each lift.

As a minimum, at least one in-place density test must be performed

SAES-A-114

A6 on every lift of fill and further placement shall not be allowed until the .

Sec. 6.4.2.4

required density has been achieved.

Nuclear density gauges, when used, shall have a valid calibration SAES-A-114

A7 .

certificate per the requirement of ASTM D6938, Sec. 8. Sec. 3.2

Fill or backfill placed beneath footings, grade beams, mats, buildings

SAES-A-114

A8 or process areas shall be compacted to at least 90% of the maximum .

Sec. 6.3.6.1

Modified Proctor density as determined by ASTM D1557.

For cohesionless free draining soils, 70% relative density as

SAES-A-114

A9 determined by ASTM D4253 and ASTM D4254 shall be achieved .

Sec. 6.3.6.4

under footings, grade beams, mats, buildings or process areas.

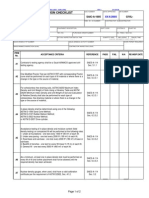

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.00 30-Jun-16

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Compaction Testing SAIC-A-1005 15-Nov-17 MAH-SA-C-5140

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

HAWAIYAH & HARADH DEVELOMENT SATELLITE GAS COMPRESSION 10 - 01996 / 0007 MOFARREH ALHARBI & PARTNERS

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

N/A N/A N/A N/A D-82

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

N/A

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SATIP-A-114-01 3.4

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

W W

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Under foundations with static loads over 320kPa and foundations for

vibrating or heavy machinery and pavements, 85% of relative density

SAES-A-114

A10 (ASTM D4253/ASTM D4254) for cohesionless soils or 95% of of the .

Sec. 6.3.6.2

maximum density as determined by ASTM D1557 for cohesive

materials.

When the backfill material cannot clearly be classified as cohesive or

cohesionless both relative density and Proctor density tests must be SAES-A-114

A11 .

performed. The backfill shall then be compacted to the greater Sec. 6.4.1.1

density.

The compaction requirement for base coarse shall not be less than

SAES-Q-006

A12 98% of the maximum laboratory dry density as determined by ASTM .

Sec. 5.2.2.2

D1557 or AASHTO T180..

The compaction requirement for subbase shall not be less than 95%

SAES-Q-006

A13 of the maximum laboratory dry density as determined by ASTM .

Sec. 5.2.2.2

D1557 or AASHTO T180..

Compacted surfaces of fill and backfill shall be finish graded to the

SAES-A-114

A14 cross sections, lines, grades, and elevations as indicated on the .

Sec. 6.3.7

drawings.

The depth of the test holes shall be no greater than 300mm (12 SAES-A-114

A15 .

inches) deep. (ASTM D 2922, Sec. 1.1) Sec. 6.4.2

REMARKS:

REFERENCE DOCUMENTS:

1- SAES-A-114 -- Excavation and Backfill, 30 September , 2014

2- SAES-Q-006 -- Asphalt Concrete Pavement, 26 November 2014

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

Mr. Tahir Muhammad

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

Mr.hedayat Ullah khan MR. REYNOLD CASIDSID

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Mr.Muhammed Zubair Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.00 30-Jun-16

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Compaction Testing SAIC-A-1005 15-Nov-17 MAH-SA-RFI#C057

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

HAWAIYAH & HARADH DEVELOMENT SATELLITE GAS COMPRESSION 10-01996/0007 MOFARREH ALHARBI & PARTNERS

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

For cohesionless free draining soils, 70% relative density as

SAES-A-114

A9 determined by ASTM D4253 and ASTM D4254 shall be achieved

Sec. 6.3.6.4

under footings, grade beams, mats, buildings or process areas.

Under foundations with static loads over 320kPa and foundations for

vibrating or heavy machinery and pavements, 85% of relative density

SAES-A-114

A10 (ASTM D4253/ASTM D4254) for cohesionless soils or 95% of of the

Sec. 6.3.6.2

maximum density as determined by ASTM D1557 for cohesive

materials.

When the backfill material cannot clearly be classified as cohesive or

cohesionless both relative density and Proctor density tests must be SAES-A-114

A11

performed. The backfill shall then be compacted to the greater Sec. 6.4.1.1

density.

The compaction requirement for base coarse shall not be less than

SAES-Q-006

A12 98% of the maximum laboratory dry density as determined by ASTM

Sec. 5.2.2.2

D1557 or AASHTO T180..

The compaction requirement for subbase shall not be less than 95%

SAES-Q-006

A13 of the maximum laboratory dry density as determined by ASTM

Sec. 5.2.2.2

D1557 or AASHTO T180..

Compacted surfaces of fill and backfill shall be finish graded to the

SAES-A-114

A14 cross sections, lines, grades, and elevations as indicated on the

Sec. 6.3.7

drawings.

The depth of the test holes shall be no greater than 300mm (12 SAES-A-114

A15

inches) deep. (ASTM D 2922, Sec. 1.1) Sec. 6.4.2

REMARKS:

REFERENCE DOCUMENTS:

1- SAES-A-114 -- Excavation and Backfill, 30 September , 2014

2- SAES-Q-006 -- Asphalt Concrete Pavement, 26 November 2014

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

Das könnte Ihnen auch gefallen

- Multi-Engine Oral Exam Guide: The comprehensive guide to prepare you for the FAA checkrideVon EverandMulti-Engine Oral Exam Guide: The comprehensive guide to prepare you for the FAA checkrideBewertung: 5 von 5 Sternen5/5 (4)

- Saic A 1005Dokument2 SeitenSaic A 1005Ansar Ali VemmullyNoch keine Bewertungen

- Saic A 1005Dokument3 SeitenSaic A 1005Naushad AlamNoch keine Bewertungen

- Saic A 1005Dokument2 SeitenSaic A 1005Rauf ChaudharyNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument2 SeitenSaudi Aramco Inspection ChecklistMuhammadNoch keine Bewertungen

- Saic A 1005.Dokument5 SeitenSaic A 1005.Fazal HaqNoch keine Bewertungen

- Saic A 1005Dokument2 SeitenSaic A 1005munibbarcaNoch keine Bewertungen

- Saic-A-1005 Compaction TestingDokument2 SeitenSaic-A-1005 Compaction TestingZia ur RehmanNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument3 SeitenSaudi Aramco Inspection ChecklistJagdishNoch keine Bewertungen

- Saic A 1005Dokument2 SeitenSaic A 1005pradeepthalava97Noch keine Bewertungen

- Saic A 1005Dokument2 SeitenSaic A 1005Niel TanedoNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 29-Jun-17Dokument2 SeitenSaudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 29-Jun-17Zia ur RehmanNoch keine Bewertungen

- SAUDI ARAMCO COMPACTION INSPECTION CHECKLISTDokument3 SeitenSAUDI ARAMCO COMPACTION INSPECTION CHECKLISTkarthi51289Noch keine Bewertungen

- Saic A 1005Dokument3 SeitenSaic A 1005mohammadNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 31-Nov-2019 CivilDokument2 SeitenSaudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 31-Nov-2019 CivilyazNoch keine Bewertungen

- Saudi Aramco Compaction Testing ChecklistDokument3 SeitenSaudi Aramco Compaction Testing ChecklistJeffrey Lipata Jr.Noch keine Bewertungen

- Saic A 1005Dokument2 SeitenSaic A 1005Son AbanadorNoch keine Bewertungen

- Compaction Testing Inspection ChecklistDokument3 SeitenCompaction Testing Inspection ChecklistShazab NawazNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 1-Nov-09 CivilDokument2 SeitenSaudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 1-Nov-09 CivilNaushad AlamNoch keine Bewertungen

- SAIC A 1005 Compaction TestingDokument2 SeitenSAIC A 1005 Compaction TestingwalidNoch keine Bewertungen

- Saic A 1005Dokument2 SeitenSaic A 1005Afzal HussainNoch keine Bewertungen

- Saic A 1005Dokument2 SeitenSaic A 1005Hussain Nasser Al- Nowiesser0% (1)

- Saudi Aramco Inspection ChecklistDokument3 SeitenSaudi Aramco Inspection ChecklistZia ur RehmanNoch keine Bewertungen

- Saic A 1001Dokument3 SeitenSaic A 1001Ansar Ali VemmullyNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 8-Nov-15 CivilDokument3 SeitenSaudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 8-Nov-15 CivilAhsaan MughalNoch keine Bewertungen

- Saic A 1001Dokument3 SeitenSaic A 1001Shazab NawazNoch keine Bewertungen

- SAUDI ARAMCO FILL PLACEMENT INSPECTION CHECKLISTDokument2 SeitenSAUDI ARAMCO FILL PLACEMENT INSPECTION CHECKLISTyazNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 24-Mar-16 CivilDokument3 SeitenSaudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 24-Mar-16 CivilSajid ShaikhNoch keine Bewertungen

- Saic A 1001Dokument3 SeitenSaic A 1001Rauf ChaudharyNoch keine Bewertungen

- SAUDI ARAMCO SOIL TESTING CHECKLISTDokument2 SeitenSAUDI ARAMCO SOIL TESTING CHECKLISTMuhammadNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 8-Nov-15 CivilDokument3 SeitenSaudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 8-Nov-15 CivilAhsaan MughalNoch keine Bewertungen

- Saudi Aramco: Soil Sampling ChecklistDokument2 SeitenSaudi Aramco: Soil Sampling ChecklistyazNoch keine Bewertungen

- Saic A 1004Dokument2 SeitenSaic A 1004usmanNoch keine Bewertungen

- Saic A 1004Dokument2 SeitenSaic A 1004Son AbanadorNoch keine Bewertungen

- SAIC-Q-1036 Raw Materials Sampling, Testing & Asphalt Mix Design ReviewDokument7 SeitenSAIC-Q-1036 Raw Materials Sampling, Testing & Asphalt Mix Design ReviewAbdul HannanNoch keine Bewertungen

- Saic A 1001Dokument3 SeitenSaic A 1001QCI MYOUSIFNoch keine Bewertungen

- Saic A 1004Dokument3 SeitenSaic A 1004Ansar Ali VemmullyNoch keine Bewertungen

- Saic A 1001Dokument3 SeitenSaic A 1001ansar aliNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 30-Apr-17 CivilDokument3 SeitenSaudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 30-Apr-17 Civilkarthi51289Noch keine Bewertungen

- Saudi Aramco Soil Sampling ChecklistDokument3 SeitenSaudi Aramco Soil Sampling ChecklistTayyab KhanNoch keine Bewertungen

- Saic A 1004Dokument2 SeitenSaic A 1004pradeepthalava97Noch keine Bewertungen

- Saic A 1004Dokument3 SeitenSaic A 1004Rauf ChaudharyNoch keine Bewertungen

- Saic A 1004Dokument3 SeitenSaic A 1004Saragadam DilsriNoch keine Bewertungen

- Saic A 1001Dokument2 SeitenSaic A 1001pradeepthalava97Noch keine Bewertungen

- SAIC-Q-1036 Raw Materials Sampling, Testing & Asphalt Mix Design ReviewDokument8 SeitenSAIC-Q-1036 Raw Materials Sampling, Testing & Asphalt Mix Design ReviewAbdul HannanNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 30-Apr-13 CivilDokument3 SeitenSaudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 30-Apr-13 CivilJeffrey Lipata Jr.Noch keine Bewertungen

- Saic A 1004Dokument2 SeitenSaic A 1004Hussain Nasser Al- Nowiesser0% (1)

- SAIC-Q-1043 Asphalt Core Density Testing InspectionDokument3 SeitenSAIC-Q-1043 Asphalt Core Density Testing InspectionAbdul HannanNoch keine Bewertungen

- Saic A 1001Dokument2 SeitenSaic A 1001Son AbanadorNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Geotechnical Field Works Inspection SAIC-A-1008 15-Nov-17 CivilDokument8 SeitenSaudi Aramco Inspection Checklist: Geotechnical Field Works Inspection SAIC-A-1008 15-Nov-17 CivilAbdul HannanNoch keine Bewertungen

- Refractory Installation Qualification ChecklistDokument3 SeitenRefractory Installation Qualification ChecklistSUNIL RAJPUTNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument4 SeitenSaudi Aramco Inspection ChecklistMainuddin AliNoch keine Bewertungen

- Quality control of foamed stabilized materialsDokument3 SeitenQuality control of foamed stabilized materialsWaleed MedhatNoch keine Bewertungen

- Saic A 1006Dokument1 SeiteSaic A 1006Saragadam DilsriNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Cast-In-Place Concrete Grade & Site Preparation SAIC-Q-1011 15-Nov-17 MAH-SA-RFI-C2626Dokument3 SeitenSaudi Aramco Inspection Checklist: Cast-In-Place Concrete Grade & Site Preparation SAIC-Q-1011 15-Nov-17 MAH-SA-RFI-C2626Abdul HannanNoch keine Bewertungen

- Saic A 1008Dokument4 SeitenSaic A 1008Naushad AlamNoch keine Bewertungen

- Saic A 1011Dokument4 SeitenSaic A 1011mohammadNoch keine Bewertungen

- Saudi Aramco Vibro Replacement ChecklistDokument4 SeitenSaudi Aramco Vibro Replacement ChecklistNaushad AlamNoch keine Bewertungen

- Saic A 1006Dokument1 SeiteSaic A 1006munibbarcaNoch keine Bewertungen

- SAIC-A-1005 Rev 3 Compaction TestingDokument2 SeitenSAIC-A-1005 Rev 3 Compaction Testingimrankhan22Noch keine Bewertungen

- RFI HPR FORM - 12E-C01-CE-0084 - 3rd LAYER BACFILLING AT PROJECT F 9 AROUND OFFICE AND LAY DOWN AREADokument4 SeitenRFI HPR FORM - 12E-C01-CE-0084 - 3rd LAYER BACFILLING AT PROJECT F 9 AROUND OFFICE AND LAY DOWN AREAAbdul Hannan100% (1)

- 01 Samss 012 2014Dokument10 Seiten01 Samss 012 2014lhanx2Noch keine Bewertungen

- 12e-C01 Rfis & Hprs Log Updated 28-Jan-2024Dokument30 Seiten12e-C01 Rfis & Hprs Log Updated 28-Jan-2024Abdul HannanNoch keine Bewertungen

- 12e-C01 Rfis & Hprs Log Updated 28-Jan-2024Dokument30 Seiten12e-C01 Rfis & Hprs Log Updated 28-Jan-2024Abdul HannanNoch keine Bewertungen

- 01-SAMSS-017 Auxiliary Piping For Mechanical EquipmentDokument13 Seiten01-SAMSS-017 Auxiliary Piping For Mechanical EquipmentAbdul HannanNoch keine Bewertungen

- Saes A 005 PDFDokument32 SeitenSaes A 005 PDFAdnanAtifNoch keine Bewertungen

- Saes Z 008Dokument47 SeitenSaes Z 008nadeemNoch keine Bewertungen

- RFI HPR FORM - 12E-C01-CE-0084 - 3rd LAYER BACFILLING AT PROJECT F 9 AROUND OFFICE AND LAY DOWN AREADokument4 SeitenRFI HPR FORM - 12E-C01-CE-0084 - 3rd LAYER BACFILLING AT PROJECT F 9 AROUND OFFICE AND LAY DOWN AREAAbdul Hannan100% (1)

- Saep 13 PDFDokument25 SeitenSaep 13 PDFAnonymous 4IpmN7OnNoch keine Bewertungen

- Saes A 010Dokument32 SeitenSaes A 010hyderabadNoch keine Bewertungen

- Saes Z 004Dokument40 SeitenSaes Z 004nadeem100% (1)

- 01 Samss 010Dokument12 Seiten01 Samss 010Ahmed Shaban KotbNoch keine Bewertungen

- Saes Z 010Dokument16 SeitenSaes Z 010nadeemNoch keine Bewertungen

- Saes A 102Dokument22 SeitenSaes A 102nadeemNoch keine Bewertungen

- Saes A 100Dokument6 SeitenSaes A 100nadeemNoch keine Bewertungen

- Saes A 011 PDFDokument20 SeitenSaes A 011 PDFcywahaNoch keine Bewertungen

- 09-SAMSS-060 Packaging Requirements For CoatingsDokument4 Seiten09-SAMSS-060 Packaging Requirements For CoatingsAbdul HannanNoch keine Bewertungen

- Saes A 007 PDFDokument29 SeitenSaes A 007 PDFsindalisindiNoch keine Bewertungen

- 02 Samss 010Dokument7 Seiten02 Samss 010balajiNoch keine Bewertungen

- Samss 023Dokument10 SeitenSamss 023Subin RoshanNoch keine Bewertungen

- 01 Samss 005 PDFDokument5 Seiten01 Samss 005 PDFjojo_323Noch keine Bewertungen

- 01-SAMSS-016 Qualification of Plates For Storage Tanks and Pressured Equipment For Resistance To Hydrogen-Induced CrackingDokument14 Seiten01-SAMSS-016 Qualification of Plates For Storage Tanks and Pressured Equipment For Resistance To Hydrogen-Induced CrackingJoni Carino SuniNoch keine Bewertungen

- 01 Samss 010Dokument12 Seiten01 Samss 010Ahmed Shaban KotbNoch keine Bewertungen

- 01 Samss 005 PDFDokument5 Seiten01 Samss 005 PDFjojo_323Noch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument3 SeitenSaudi Aramco Inspection ChecklistAbdul HannanNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument1 SeiteSaudi Aramco Inspection ChecklistAbdul HannanNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 15-Nov-17 MechDokument5 SeitenSaudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 15-Nov-17 MechAbdul HannanNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument2 SeitenSaudi Aramco Inspection ChecklistAbdul HannanNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Final Inspection of Intumescent Fireproofing Application SAIC-B-2010 15-Nov-17 MechDokument2 SeitenSaudi Aramco Inspection Checklist: Final Inspection of Intumescent Fireproofing Application SAIC-B-2010 15-Nov-17 MechAbdul HannanNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 15-Nov-17 MechDokument2 SeitenSaudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 15-Nov-17 MechAbdul HannanNoch keine Bewertungen

- CE 581 Reinforced Concrete Structures: Lecture 4: Axial LoadingDokument36 SeitenCE 581 Reinforced Concrete Structures: Lecture 4: Axial LoadingCelil OrakNoch keine Bewertungen

- POLIOMYELITISDokument26 SeitenPOLIOMYELITISIzhra Margate100% (1)

- Ub40 LyricsDokument76 SeitenUb40 LyricsJose Lucio Flores SantosNoch keine Bewertungen

- Digital B&W Copiers (D154/D155-NA) Parts CatalogDokument118 SeitenDigital B&W Copiers (D154/D155-NA) Parts Catalogkhoi vuNoch keine Bewertungen

- CSC-1321 Gateway User Guide: Downloaded From Manuals Search EngineDokument48 SeitenCSC-1321 Gateway User Guide: Downloaded From Manuals Search EngineKislan MislaNoch keine Bewertungen

- The Grey Nomads Guide To AustraliaDokument3 SeitenThe Grey Nomads Guide To AustraliaFreerangecamping60% (5)

- Khasi Community of MeghalayaDokument3 SeitenKhasi Community of MeghalayaMidhat FatimaNoch keine Bewertungen

- Tyfo SDokument2 SeitenTyfo SAndi AsNoch keine Bewertungen

- Coloi Eeml Disease: Original ArticlesDokument67 SeitenColoi Eeml Disease: Original ArticlesLuisAngelPonceTorresNoch keine Bewertungen

- LIST Real Estate Contacts ListDokument4 SeitenLIST Real Estate Contacts ListChauhan Harshit100% (1)

- GMsetDokument8 SeitenGMsetdilo001Noch keine Bewertungen

- Earthing Substation Earthing Guide Central NetworksDokument12 SeitenEarthing Substation Earthing Guide Central Networksshahkhan552000100% (1)

- Tennis BiomechanicsDokument14 SeitenTennis BiomechanicsΒασίλης Παπατσάς100% (1)

- 5s OfficeDokument10 Seiten5s OfficeTechie InblueNoch keine Bewertungen

- Crimson Holdings Fact Sheet As of April 14Dokument3 SeitenCrimson Holdings Fact Sheet As of April 14WDIV/ClickOnDetroitNoch keine Bewertungen

- Specs Mantilla UV BT8800 Oct 2014Dokument2 SeitenSpecs Mantilla UV BT8800 Oct 2014Julio MendezNoch keine Bewertungen

- ADDC Construction QuestionairesDokument19 SeitenADDC Construction QuestionairesUsman Arif100% (1)

- Applying Value Engineering to Improve Quality and Reduce Costs of Ready-Mixed ConcreteDokument15 SeitenApplying Value Engineering to Improve Quality and Reduce Costs of Ready-Mixed ConcreteayyishNoch keine Bewertungen

- AOAC 2012.11 Vitamin DDokument3 SeitenAOAC 2012.11 Vitamin DPankaj BudhlakotiNoch keine Bewertungen

- Basler Electric 87T - Great InfoDokument3 SeitenBasler Electric 87T - Great InfoMrNoch keine Bewertungen

- State of The Art Penelitian - Chat GPT 2023Dokument137 SeitenState of The Art Penelitian - Chat GPT 2023restyNoch keine Bewertungen

- Kuffner Final PresentationDokument16 SeitenKuffner Final PresentationSamaa GamalNoch keine Bewertungen

- 4 Ideal Models of Engine CyclesDokument23 Seiten4 Ideal Models of Engine CyclesSyedNoch keine Bewertungen

- Year 5:: NUMBERS TO 1 000 000Dokument47 SeitenYear 5:: NUMBERS TO 1 000 000Rusehaiza Bin Md DarusNoch keine Bewertungen

- Product:: Electronic, 2 C #18 STR TC, PE Ins, OS, PVC JKT, CMDokument2 SeitenProduct:: Electronic, 2 C #18 STR TC, PE Ins, OS, PVC JKT, CMAnonymous XYAPaxjbYNoch keine Bewertungen

- Schaeffler - Account Insights - Mar 2020Dokument13 SeitenSchaeffler - Account Insights - Mar 2020mohit negiNoch keine Bewertungen

- Common Herbs and Foods Used As Galactogogues PDFDokument4 SeitenCommon Herbs and Foods Used As Galactogogues PDFHadi El-MaskuryNoch keine Bewertungen

- Goat Milk Marketing Feasibility Study Report - Only For ReferenceDokument40 SeitenGoat Milk Marketing Feasibility Study Report - Only For ReferenceSurajSinghalNoch keine Bewertungen

- Ericsson Microwave Outlook 2021Dokument16 SeitenEricsson Microwave Outlook 2021Ahmed HussainNoch keine Bewertungen

- GT ĐỀ 04Dokument39 SeitenGT ĐỀ 04Cao Đức HuyNoch keine Bewertungen