Beruflich Dokumente

Kultur Dokumente

Operation and Cleaning of Glass Lined Reactor

Hochgeladen von

DrVishwanatha HNCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Operation and Cleaning of Glass Lined Reactor

Hochgeladen von

DrVishwanatha HNCopyright:

Verfügbare Formate

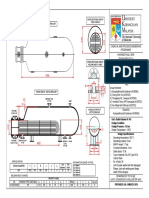

Operation and Cleaning of Glass Lined Reactor ( Capacity –

3KL )

Purpose : To provide a documented procedure for operation and cleaning of Glass

Lined Reactor

Objective : To provide a guide line for safe operation and cleaning of Glass Lined Reactor

Scope : This SOP is applicable for operation and cleaning of Glass Lined Reactor

4.0 Responsibility :

Primary: Production chemist.

Secondary: Production officer.

5.0 Procedure:

Safety Precaution.

The area of operation should be well ventilated.

There should be no open flame in adjacent areas.

A continuous watch should be kept on reactions, which are 1) Exothermic, 2)

involving highly reactive compounds etc.

If found necessary, concrete /steel barricades should be built around

the apparatus.

The Reactor is manufactured out of glass, coated on Mild Steel.. Hence chemicals of corrosive

nature with Glass should not be used in the apparatus.

Operation:

Opening the Reactor for charging / discharging:

The glass Lined reactor is in assembled condition with all accessories.

Open the manhole, first open the vent valve to release the internal pressure if any.

Remove the nut/bolts of the manhole and slide to the side.

Check that the reactor is cleaned as per SOP. Charge the material in the Reactor. Solid Material to be

charged from the manhole and liquid materials to be charged through charging line under negative

pressure.

Closing the Reactor for operation:

Examine whether all fittings and body pickings are in good condition and correct

position.

Place the manhole in right position after charging the material.

Tightened nut bolt by fix spanner only and never use a wrong spanner otherwise

the nut/bolt will deform.

Now switch on the stirrer and stir the content as per requirement. To stop stirring push the RED button of

the Main Switch and stirring stops.

Cleaning of the Reactor:

Check that the Reactor is empty and bottom valve is closed.

Flush the Reactor with plenty of water so as to remove any adhering material.

If required use Scrapper to remove the adhering material. Scrap inner walls, Thermo well, Baffles etc.

Flush the reactor with plenty of water and open the bottom valve of the reactor and drain out water.

Close the bottom valve of the Reactor and charge Methanol, Make stirring ON and start heating, heat the

content to reflux and reflux for 1hr. and distil out methanol about 40%.

Apply Cooling and cool the content to About 30ºC to 35ºC.

Unload the Solvent from the Reactor and Flush The Reactor with methanol,

Collect 250ml flushed methanol from Reactor and send to QC with Test Request to check absence of

previous product on TLC.

Result: COMPLIES / DOES NOTCOMPLIES.

If Result Complies, dry the Reactor by applying steam and vacuum in the Reactor for 30 min.

Update Status Board of the Equipment as CLEANED and update Equipment usage Log Book.

Method of cleaning and quantity of Methanol has given in Equipment cleaning record.

6.0 Reference Document :

Equipment Cleaning Record, ECR (Format No. F/PR/001)

Equipment usage log book

Equipment Cleaning Record Equipment ID.

Sr. Date Stage No. Batch Time Product Activity Done by Checked by Remarks

No. No.

From To

Format No. F/PR/002

Das könnte Ihnen auch gefallen

- DM Plant CommissioningDokument10 SeitenDM Plant CommissioningSANTRANoch keine Bewertungen

- Chemical Cleaning MethodsDokument71 SeitenChemical Cleaning MethodsDonatas Bertasius100% (1)

- SOP For Compressed Air SystemDokument14 SeitenSOP For Compressed Air SystemAbeer arif100% (1)

- Catalyst Loading Work InstructionDokument4 SeitenCatalyst Loading Work Instructionvishal bailurNoch keine Bewertungen

- INTRO TO COLUMN INTERNALSDokument7 SeitenINTRO TO COLUMN INTERNALSamitNoch keine Bewertungen

- Vacuum Drying MethodsDokument28 SeitenVacuum Drying MethodsJoann HowardNoch keine Bewertungen

- SAES-B-062 Editorial Revision-16 March 2023Dokument22 SeitenSAES-B-062 Editorial Revision-16 March 2023Faheem Khan100% (1)

- SOP For FBDDokument3 SeitenSOP For FBDAshok KumarNoch keine Bewertungen

- Standard Operation ProcedureDokument66 SeitenStandard Operation Procedureved847100% (2)

- Ek GeneralDokument24 SeitenEk GeneralPRASHANT SAWANTNoch keine Bewertungen

- Cat Loading by Sock Method in Inert AtmosphereDokument5 SeitenCat Loading by Sock Method in Inert Atmospherevishal bailurNoch keine Bewertungen

- Rev3 SOP Boiler Alkali Boil Out Pertamina Balongan PWJ IFIR1Dokument8 SeitenRev3 SOP Boiler Alkali Boil Out Pertamina Balongan PWJ IFIR1nbagarNoch keine Bewertungen

- SOP For Passivation 1 Scope:: FM/VD/04/R0Dokument3 SeitenSOP For Passivation 1 Scope:: FM/VD/04/R0Nishar BalkavadeNoch keine Bewertungen

- Remove Boiler Tube Coatings with Alkaline SolutionDokument32 SeitenRemove Boiler Tube Coatings with Alkaline Solutionsekhar_ntpcNoch keine Bewertungen

- DepVAPOR290409 PDFDokument8 SeitenDepVAPOR290409 PDFltrevino100Noch keine Bewertungen

- Skimming Job GeneralDokument5 SeitenSkimming Job Generalvishal bailurNoch keine Bewertungen

- Rock Drill & SluDokument36 SeitenRock Drill & SluElizabeth Octagon100% (2)

- Chemical CleaningDokument40 SeitenChemical CleaningPiyush Singh100% (1)

- CLEANING STEAM LINES CHECKING CLEANLINESSDokument8 SeitenCLEANING STEAM LINES CHECKING CLEANLINESSm_ganesh1983Noch keine Bewertungen

- Mindray BS-200 - User ManualDokument253 SeitenMindray BS-200 - User ManualGustavo Meneo64% (11)

- Catalyst Loading ProcedureDokument9 SeitenCatalyst Loading ProcedureMidha Neer0% (1)

- Chemical Cleaning ReportDokument8 SeitenChemical Cleaning ReportSandeep KottaryNoch keine Bewertungen

- Alkaline Boil-out Chemical Cleaning Procedure for Ambarli Power Plant BoilerDokument11 SeitenAlkaline Boil-out Chemical Cleaning Procedure for Ambarli Power Plant BoilerAdnan Doğan50% (2)

- Standard For RO Water AnalysisDokument2 SeitenStandard For RO Water AnalysisSathish GlNoch keine Bewertungen

- Catalyst Loading MethodDokument3 SeitenCatalyst Loading Methoderwan_exe0% (1)

- Sneha IndustriesDokument13 SeitenSneha IndustriesDrVishwanatha HNNoch keine Bewertungen

- Chemical Boiling Out Procedure Boiler BDFB 350-1004. Rev.00Dokument7 SeitenChemical Boiling Out Procedure Boiler BDFB 350-1004. Rev.00Ari Puji Hidayatullah0% (1)

- Catalyst Loading by Dense Method Multi Bed Reactor Inert AtmosphereDokument7 SeitenCatalyst Loading by Dense Method Multi Bed Reactor Inert Atmospherevishal bailurNoch keine Bewertungen

- Loading and Commissioning of Ion Exchange ResinsDokument5 SeitenLoading and Commissioning of Ion Exchange ResinsSANTRANoch keine Bewertungen

- Dokumen - Tips Inspection Checklist Distillation ColumnDokument5 SeitenDokumen - Tips Inspection Checklist Distillation ColumnSaidFerdjallah100% (1)

- Cross Sectional View of Tube Bundles in Kettle ReboilerDokument1 SeiteCross Sectional View of Tube Bundles in Kettle ReboilerNursyarafina Binti Sulaiman100% (1)

- Cooling Water Treatment PDFDokument2 SeitenCooling Water Treatment PDFvjNoch keine Bewertungen

- Catalyst Loading by Sock Method Single Bed Reactor Normal AtmosphereDokument5 SeitenCatalyst Loading by Sock Method Single Bed Reactor Normal Atmospherevishal bailurNoch keine Bewertungen

- SOP For WTPDokument3 SeitenSOP For WTPMurthy VvnNoch keine Bewertungen

- Catalyst Loading by Dense Method (SingleBed) in Inert AtmosphereDokument5 SeitenCatalyst Loading by Dense Method (SingleBed) in Inert Atmospherevishal bailurNoch keine Bewertungen

- Iso Iec 25020 2007 (E)Dokument24 SeitenIso Iec 25020 2007 (E)AngélicaNoch keine Bewertungen

- Operating Instructions and Maintain EdiDokument119 SeitenOperating Instructions and Maintain EdiPhạm Quang HuyNoch keine Bewertungen

- SPEC TECH SPEC BRINE CHILLER 0°CDokument17 SeitenSPEC TECH SPEC BRINE CHILLER 0°Cdhanu_lagwankar100% (1)

- Reactor Loading - Dense or Sock Loading PDFDokument11 SeitenReactor Loading - Dense or Sock Loading PDFvictorvikramNoch keine Bewertungen

- POWER PLANT MAINTENANCE EQUIPMENT CLEANINGDokument25 SeitenPOWER PLANT MAINTENANCE EQUIPMENT CLEANINGMariusDragoescuNoch keine Bewertungen

- Pradeep 11th Physics Guide DownloadDokument2 SeitenPradeep 11th Physics Guide DownloadSandeep Kaswan33% (3)

- Amit Udgirkar PRAJ PDFDokument38 SeitenAmit Udgirkar PRAJ PDFjpsingh75Noch keine Bewertungen

- Steam Blowing Steam Blowing Procedure PDFDokument11 SeitenSteam Blowing Steam Blowing Procedure PDFAdelAbdElhamidNoch keine Bewertungen

- Catalyst Loading ProcedureDokument3 SeitenCatalyst Loading ProcedureNaresh SamalaNoch keine Bewertungen

- Technical Service Bulletin: Commissioning Procedure For HydracapDokument10 SeitenTechnical Service Bulletin: Commissioning Procedure For HydracapValesh MonisNoch keine Bewertungen

- Boiler Acid CleaningDokument5 SeitenBoiler Acid CleaningKumar RNoch keine Bewertungen

- Boiler DescalingDokument2 SeitenBoiler DescalingAngshuman DuttaNoch keine Bewertungen

- DM Plant Operation SopDokument3 SeitenDM Plant Operation Sopvel muruganNoch keine Bewertungen

- Chemical Cleaning Report of Hydrogen Makeup Compressor.Dokument9 SeitenChemical Cleaning Report of Hydrogen Makeup Compressor.Engr Mohammad FarhanNoch keine Bewertungen

- Vacuum DistillationDokument1 SeiteVacuum Distillationzephyr_2090Noch keine Bewertungen

- Boiler Boil OutDokument1 SeiteBoiler Boil Outgshori2000Noch keine Bewertungen

- Sop MeeDokument5 SeitenSop MeeYogesh Dhekale100% (4)

- De Scaling Plate Heat ExchangersDokument2 SeitenDe Scaling Plate Heat ExchangersKiran DuggarajuNoch keine Bewertungen

- Boiler Cleaning+Procedure+Rev+00Dokument10 SeitenBoiler Cleaning+Procedure+Rev+00Govarthanan Gopalan100% (1)

- Whrs ManualDokument41 SeitenWhrs ManualAKHLESH JHALLARENoch keine Bewertungen

- Cleaning Cooling Tower Project: Technical Proposal ofDokument6 SeitenCleaning Cooling Tower Project: Technical Proposal ofIqbal Safirul BarqiNoch keine Bewertungen

- The Acid Function of Platforming Catalyst Is Provided by Support Promoted With ChlorideDokument2 SeitenThe Acid Function of Platforming Catalyst Is Provided by Support Promoted With ChloriderawadNoch keine Bewertungen

- Chemical Cleaning of Carbon and Stainless Steel PipingDokument3 SeitenChemical Cleaning of Carbon and Stainless Steel PipingMohamed100% (1)

- Procedure of Boiler Acid Cleaning: and Flushing & PassivationDokument4 SeitenProcedure of Boiler Acid Cleaning: and Flushing & PassivationSteve Wan100% (2)

- Boiler PassivationDokument3 SeitenBoiler PassivationAhemadNoch keine Bewertungen

- 3M™ Activated Carbon Filters - Data Sheet (PDF 670.8 K) PDFDokument2 Seiten3M™ Activated Carbon Filters - Data Sheet (PDF 670.8 K) PDFshwethakunjilna100% (1)

- Exp 1Dokument9 SeitenExp 1zackwanNoch keine Bewertungen

- Ek GeneralDokument24 SeitenEk GeneralCadet ABDUL REHMANNoch keine Bewertungen

- Bio Reactor 2016Dokument7 SeitenBio Reactor 2016asim zeshanNoch keine Bewertungen

- Pre OperationDokument2 SeitenPre OperationHưng NguyễnNoch keine Bewertungen

- Laksh Fine Chem PVT LTD.: Standard Operating Procedure Operation of Reactor Sop No: RO 02 Issue Number: 02Dokument1 SeiteLaksh Fine Chem PVT LTD.: Standard Operating Procedure Operation of Reactor Sop No: RO 02 Issue Number: 02ncubepharmaNoch keine Bewertungen

- Content For Moringa Powder Product Label DesignDokument2 SeitenContent For Moringa Powder Product Label DesignDrVishwanatha HNNoch keine Bewertungen

- CH 6503 Cet IiDokument66 SeitenCH 6503 Cet IiDrVishwanatha HNNoch keine Bewertungen

- Distillation PlantDokument3 SeitenDistillation PlantDrVishwanatha HN100% (1)

- Vitamin CDokument3 SeitenVitamin CDrkrishnasarma pathyNoch keine Bewertungen

- Is 6608 2004Dokument13 SeitenIs 6608 2004DrVishwanatha HNNoch keine Bewertungen

- CalculationDokument5 SeitenCalculationDrVishwanatha HNNoch keine Bewertungen

- Sarshika CostingDokument3 SeitenSarshika CostingDrVishwanatha HNNoch keine Bewertungen

- Chapter - Vii: Moringa Oleifera Seed PowderDokument18 SeitenChapter - Vii: Moringa Oleifera Seed PowderDrVishwanatha HNNoch keine Bewertungen

- Ideal Non Ideal SolutionDokument6 SeitenIdeal Non Ideal SolutionDrVishwanatha HNNoch keine Bewertungen

- 10 1 1 529 7411 PDFDokument39 Seiten10 1 1 529 7411 PDFDrVishwanatha HNNoch keine Bewertungen

- TT RCT: No - TC I/2 /2 /2Dokument3 SeitenTT RCT: No - TC I/2 /2 /2DrVishwanatha HNNoch keine Bewertungen

- Fertilizer, Micronutrients, Biopesticieds and Bio FertilizersDokument6 SeitenFertilizer, Micronutrients, Biopesticieds and Bio FertilizersDrVishwanatha HNNoch keine Bewertungen

- 987 PDFDokument5 Seiten987 PDFDrVishwanatha HNNoch keine Bewertungen

- Production of Non-Edible Oils and CakesDokument3 SeitenProduction of Non-Edible Oils and CakesDrVishwanatha HNNoch keine Bewertungen

- 987 PDF PDFDokument5 Seiten987 PDF PDFDrVishwanatha HNNoch keine Bewertungen

- ReviewDokument1 SeiteReviewDrVishwanatha HNNoch keine Bewertungen

- Chapter02 PDFDokument20 SeitenChapter02 PDFDrVishwanatha HNNoch keine Bewertungen

- Effective Utilization of ZincDokument1 SeiteEffective Utilization of ZincDrVishwanatha HNNoch keine Bewertungen

- Material BalanceDokument2 SeitenMaterial BalanceDrVishwanatha HNNoch keine Bewertungen

- Introduction to Chemical Engineering Textbook CompanionDokument138 SeitenIntroduction to Chemical Engineering Textbook CompanionDrVishwanatha HN0% (1)

- Packing TechnologyDokument5 SeitenPacking TechnologyDrVishwanatha HNNoch keine Bewertungen

- Effective Utilization of ZincDokument1 SeiteEffective Utilization of ZincDrVishwanatha HNNoch keine Bewertungen

- FluorideDokument63 SeitenFluorideSuresh SinghNoch keine Bewertungen

- BIS Specification Updation 2015Dokument10 SeitenBIS Specification Updation 2015DrVishwanatha HNNoch keine Bewertungen

- PFA-Act & RulesDokument216 SeitenPFA-Act & RulesSougata Pramanick100% (2)

- Partitioning Studies of A-Lactalbumin in Environmental Friendly Poly (Ethylene Glycol) - Citrate Salt Aqueous Two Phase SystemsDokument7 SeitenPartitioning Studies of A-Lactalbumin in Environmental Friendly Poly (Ethylene Glycol) - Citrate Salt Aqueous Two Phase SystemsDrVishwanatha HNNoch keine Bewertungen

- Introduction to Chemical Engineering Textbook CompanionDokument138 SeitenIntroduction to Chemical Engineering Textbook CompanionDrVishwanatha HN0% (1)

- Informatics Practices Class 12 Record File CbseDokument22 SeitenInformatics Practices Class 12 Record File CbseShubham Kushwaha68% (31)

- Nikola Tesla BiographyDokument6 SeitenNikola Tesla BiographyDavid CristianNoch keine Bewertungen

- Studio Iso Booth Console Monitors: Record Plant Ssl-1 SpecificationsDokument1 SeiteStudio Iso Booth Console Monitors: Record Plant Ssl-1 Specificationssoulboy01Noch keine Bewertungen

- K6856099 GLOBAL JL PHEV BATT - 10 11 21 - No Recycler Info - (English) - Trans - Doc (En-Ko)Dokument4 SeitenK6856099 GLOBAL JL PHEV BATT - 10 11 21 - No Recycler Info - (English) - Trans - Doc (En-Ko)Nader chazliNoch keine Bewertungen

- Cryptography CS 555: Topic 16: Key Management and The Need For Public Key CryptographyDokument21 SeitenCryptography CS 555: Topic 16: Key Management and The Need For Public Key Cryptographycrazz1Noch keine Bewertungen

- SIP Report PDFDokument31 SeitenSIP Report PDFAnushka MadanNoch keine Bewertungen

- Prooccore Traınıng5Dokument13 SeitenProoccore Traınıng5ErkinNoch keine Bewertungen

- Manual CMB2 BubenzerDokument25 SeitenManual CMB2 BubenzerJosé Ramos100% (2)

- GUT EIM Compro - 0114 - A4 - 2014-02-06Dokument19 SeitenGUT EIM Compro - 0114 - A4 - 2014-02-06Bronoz GrypenNoch keine Bewertungen

- Indian Oil Corporation Limited: Vendor Code:........................Dokument6 SeitenIndian Oil Corporation Limited: Vendor Code:........................dheeraj1993Noch keine Bewertungen

- 1k BolcfgDokument34 Seiten1k BolcfgTrader 20Noch keine Bewertungen

- PIO and Interrupt StudentsDokument12 SeitenPIO and Interrupt StudentsLê Đình TiếnNoch keine Bewertungen

- Installing The TCD To FID Series Connector: 4890, 5890, 6890 Gas Chromatographs Accessory 19232CDokument10 SeitenInstalling The TCD To FID Series Connector: 4890, 5890, 6890 Gas Chromatographs Accessory 19232C신지훈Noch keine Bewertungen

- Data Analytics VsDokument3 SeitenData Analytics VsJoel DsouzaNoch keine Bewertungen

- Preparing and Interpreting Technical DrawingDokument20 SeitenPreparing and Interpreting Technical DrawingAriel Santor EstradaNoch keine Bewertungen

- Engineering EMBRAER DAY 2007Dokument37 SeitenEngineering EMBRAER DAY 2007Juan Sebastian Camero CartagenaNoch keine Bewertungen

- Mmantc ProfileDokument4 SeitenMmantc ProfileKaran SharmaNoch keine Bewertungen

- Bca Syllabus 2021 2022Dokument45 SeitenBca Syllabus 2021 2022Bible YTNoch keine Bewertungen

- Case KarenDokument2 SeitenCase KarenНаталя ДуткевичNoch keine Bewertungen

- Sonata™: Dual Pulse OutputDokument2 SeitenSonata™: Dual Pulse OutputPra YugoNoch keine Bewertungen

- Specification of Electric Actuator - DZWDokument5 SeitenSpecification of Electric Actuator - DZWĐình ThếNoch keine Bewertungen

- Binary Tree and BSTDokument48 SeitenBinary Tree and BSTsri aknthNoch keine Bewertungen

- Group Project GuidelinesDokument3 SeitenGroup Project GuidelinesAmer IkhwanNoch keine Bewertungen

- Zip HydroTap G4 BC PI enDokument8 SeitenZip HydroTap G4 BC PI enRicardoNoch keine Bewertungen

- Stub Loss Correction Table For Coated ElectrodesDokument1 SeiteStub Loss Correction Table For Coated ElectrodesTAMILNoch keine Bewertungen