Beruflich Dokumente

Kultur Dokumente

PFD SUPER FINAL Production of Phenol PDF

Hochgeladen von

John Philip AyoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PFD SUPER FINAL Production of Phenol PDF

Hochgeladen von

John Philip AyoCopyright:

Verfügbare Formate

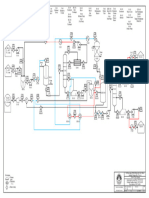

PROCESS FLOW DIAGRAM FOR PHENOL PLANT

P – 102 A/B E – 101 R – 102 H – 102 H – 103 E – 102 D – 101 P– 104 A/B D – 102 H – 104 D – 103 E – 105 D – 104 E – 107 D – 105 E – 109 C – 102 A/B

NaOH Pump Vent Gases Condenser Cleavage Heat Heat Condenser Distillation Pump Distillation Heat Exchanger Distillation Condenser Distillation Condenser Distillation Condenser Hydrogen

Reactor Exchanger Exchanger Column 1 Column 2 Column 3 Column 4 Column 5 Compressor

V – 101 P– 103 A/B P– 105 A/B P– 106 A/B P– 107 A/B R - 103

P – 101 A/B R – 101 E– 104

Phase Reflux Reflux Reflux Reflux Pre - Purification

Feed Pump Oxidation Reactor Reboiler

Separator Pump Pump Pump Pump Reactor

C – 101 A/B E– 106 E– 108 E– 110

E– 103

Air Compressor Reboiler Reboiler Reboiler

Reboiler

H – 101

Heat

Exchanger

Acetone

LEGEND: 97%

83

TEMPERATURE ( oC ) 2.11

PRESSURE ( atm )

Acetone 65 %

76

0.23

91%

145

0.58

a - methylstyrene

19 21

Vent Gases 12

H2SO4 Hydrogen

100

6 atm 115 24

0.34

25

7 Organic 1 atm

5 Stream 17

25 128 150

6 atm 0.47 0.47

NaOH Pump

14 16

1

NaOH

10

2

Cumene

25 25

1 atm 6 atm

3 6 9 11 22

Air 30

30 25 80

1 atm

6 atm 6 atm 1 atm

4

100 13

6 atm

8 25

20

110 Aqueous 152

6 atm Stream 110 0.57

2.45

15

18

152 152

0.68 1 atm

23

PHENOL

175

0.81

180

0.92

95%

25

1 atm

Das könnte Ihnen auch gefallen

- 1 PEAB ZC311 Assignment IDokument2 Seiten1 PEAB ZC311 Assignment IM Helmy Aditya100% (1)

- Pap (Design of Distillation Column)Dokument26 SeitenPap (Design of Distillation Column)MambaulkNoch keine Bewertungen

- PD2055E1 MEP Multi Effect Plate DistillerDokument4 SeitenPD2055E1 MEP Multi Effect Plate Distillergochi bestNoch keine Bewertungen

- Topsoe Sec Ref Cat RKS 2Dokument5 SeitenTopsoe Sec Ref Cat RKS 2Vo Duc Minh MinhNoch keine Bewertungen

- SCORE Furnace Erection SequenceDokument12 SeitenSCORE Furnace Erection SequenceAleem QureshiNoch keine Bewertungen

- 2nd Part of CalculationDokument26 Seiten2nd Part of CalculationLohith NatarajNoch keine Bewertungen

- Fluid Catalytic Cracking Unit (FCCU)Dokument1 SeiteFluid Catalytic Cracking Unit (FCCU)Billy BlinksNoch keine Bewertungen

- Topsoe High Flux Steam Reform - AshxDokument6 SeitenTopsoe High Flux Steam Reform - AshxAgam HanasichulaNoch keine Bewertungen

- Correctly Modeling and Calculating Combustion Efficiencies in Fired EquipmentDokument23 SeitenCorrectly Modeling and Calculating Combustion Efficiencies in Fired Equipmentfawmer61Noch keine Bewertungen

- Ben FieldDokument10 SeitenBen FieldashmitharajaNoch keine Bewertungen

- Divided Wall Column 496Dokument6 SeitenDivided Wall Column 496GeorgeNoch keine Bewertungen

- Sablin Alpha Raab FDokument3 SeitenSablin Alpha Raab Fsk281Noch keine Bewertungen

- Comparison of Several Packings For CO2 Chemical Absorption in A Packed ColumnDokument7 SeitenComparison of Several Packings For CO2 Chemical Absorption in A Packed ColumnianphilanderNoch keine Bewertungen

- A Design Adn Rating Method For Shell and Tube Heat ExchangerDokument8 SeitenA Design Adn Rating Method For Shell and Tube Heat Exchangerhuynhthanhtamga1981100% (1)

- Sist de Alivio Icm1200Dokument66 SeitenSist de Alivio Icm1200Fabian GomezNoch keine Bewertungen

- Simultaneous Optimization of Pump and Cooler Networks in A Cooling Water SystemDokument9 SeitenSimultaneous Optimization of Pump and Cooler Networks in A Cooling Water SystemFillipe BystekaNoch keine Bewertungen

- Dehydration Plant Twenty Years PaperDokument5 SeitenDehydration Plant Twenty Years Papersejerson07Noch keine Bewertungen

- PED 5 Heat ExchangersDokument74 SeitenPED 5 Heat ExchangersoperationmanagerNoch keine Bewertungen

- Heat Exchanger DesignDokument19 SeitenHeat Exchanger DesignRankhamb ShubhamNoch keine Bewertungen

- Fouling Factor 1-2 ExchangerDokument7 SeitenFouling Factor 1-2 ExchangerNaresh SamalaNoch keine Bewertungen

- Nicholas Oligomerization PDFDokument16 SeitenNicholas Oligomerization PDFTanase DianaNoch keine Bewertungen

- Uop Par-Isom Process: Nelson A. CusherDokument6 SeitenUop Par-Isom Process: Nelson A. CusherBharavi K S100% (1)

- Steam Cracking of Naphtha in Packed Bed ReactorsDokument6 SeitenSteam Cracking of Naphtha in Packed Bed Reactorscandidater100% (1)

- STRATCO AlkylationTechnologyImprovementsDokument23 SeitenSTRATCO AlkylationTechnologyImprovementsAli YousefNoch keine Bewertungen

- Energy Efficiency Improvement in An Ethylene PlantDokument5 SeitenEnergy Efficiency Improvement in An Ethylene Plantshubham bobdeNoch keine Bewertungen

- Assignment NO 3:: Question 1: Define Cracking. Classify Cracking OperationsDokument6 SeitenAssignment NO 3:: Question 1: Define Cracking. Classify Cracking OperationsMilan MoradiyaNoch keine Bewertungen

- Dee CDokument15 SeitenDee CAnderson David ValenciaNoch keine Bewertungen

- Condution Holman 10th-Ed PDFDokument167 SeitenCondution Holman 10th-Ed PDFLizbeth Abril100% (1)

- Heat Transfer Equipment 1. Heat Exchangers: Chemical Engineering DesignDokument45 SeitenHeat Transfer Equipment 1. Heat Exchangers: Chemical Engineering DesignMuthuNoch keine Bewertungen

- Coke Tower DesignDokument14 SeitenCoke Tower DesignMahendra Rathore100% (1)

- Cooling Tower IntroductionDokument27 SeitenCooling Tower Introductiondinesh babuNoch keine Bewertungen

- Fired Heaters - Fired Capital Equipment Key Plant ComponentsDokument4 SeitenFired Heaters - Fired Capital Equipment Key Plant ComponentsReyes SanchezNoch keine Bewertungen

- Operation of A Distillate Hydrot UnitDokument18 SeitenOperation of A Distillate Hydrot UnitFranklin RevillNoch keine Bewertungen

- PFD - Nitrogen Plant UTL Plaju (Cold Box)Dokument1 SeitePFD - Nitrogen Plant UTL Plaju (Cold Box)Arga YudhaNoch keine Bewertungen

- BTX SeparationDokument21 SeitenBTX Separationhhhhosh100% (2)

- Ethylene 2520oxide Methods 2520of 2520productionDokument25 SeitenEthylene 2520oxide Methods 2520of 2520productionmartin_2104Noch keine Bewertungen

- TOTAL Modeling and Optimization of Fluid Catalytic Cracking UnitsDokument19 SeitenTOTAL Modeling and Optimization of Fluid Catalytic Cracking Unitssaleh4060Noch keine Bewertungen

- PFD PrintDokument1 SeitePFD PrintAgung PrabowoNoch keine Bewertungen

- SEPURAN® Noble - Membrane Technology For Efficient Hydrogen Generation PDFDokument6 SeitenSEPURAN® Noble - Membrane Technology For Efficient Hydrogen Generation PDFHabli MawardiNoch keine Bewertungen

- Energy and Material BalanceDokument158 SeitenEnergy and Material BalanceUmer FarooqNoch keine Bewertungen

- Designing A Divided Wall ColumnDokument12 SeitenDesigning A Divided Wall ColumnArash AbbasiNoch keine Bewertungen

- L - 17 Catalyst Deactivation: Prof. K.K.Pant Department of Chemical Engineering IIT DelhiDokument23 SeitenL - 17 Catalyst Deactivation: Prof. K.K.Pant Department of Chemical Engineering IIT DelhiMehul VarshneyNoch keine Bewertungen

- Catacarb Section, Dawood Hercules Fertilizers LimitedDokument16 SeitenCatacarb Section, Dawood Hercules Fertilizers LimitedMuddassar Sultan100% (1)

- HSFCCDokument22 SeitenHSFCCdonald55555100% (1)

- Furnace Heater DesignDokument7 SeitenFurnace Heater DesignAaAaA_88Noch keine Bewertungen

- Part 1: Design, Modeling and Simulation of Post-Combustion CO Capture Systems Using Reactive SolventsDokument24 SeitenPart 1: Design, Modeling and Simulation of Post-Combustion CO Capture Systems Using Reactive SolventsBenjamin F ZavalaNoch keine Bewertungen

- Hot High Pressure SeparatorDokument2 SeitenHot High Pressure SeparatorKhai NguyenNoch keine Bewertungen

- Development of Highly Selective Process For Mono-Ethylene Glycol Production From Ethylene Oxide Via Ethylene Carbonate Using Phosphonium Salt CatalystDokument5 SeitenDevelopment of Highly Selective Process For Mono-Ethylene Glycol Production From Ethylene Oxide Via Ethylene Carbonate Using Phosphonium Salt CatalystirfanNoch keine Bewertungen

- Model 10 10fb 11 Carbon HousingsDokument4 SeitenModel 10 10fb 11 Carbon HousingsrezNoch keine Bewertungen

- Engr. MariamDokument130 SeitenEngr. MariamMariam AsgharNoch keine Bewertungen

- Process Heat Transfer Hof MasterDokument327 SeitenProcess Heat Transfer Hof MastersdrtfgNoch keine Bewertungen

- Refining Process-AlkylationDokument20 SeitenRefining Process-AlkylationTusenkrishNoch keine Bewertungen

- Definition & Types of Reboilers - A. Thermosiphon - : Reboiler CircuitsDokument2 SeitenDefinition & Types of Reboilers - A. Thermosiphon - : Reboiler CircuitsWade ColemanNoch keine Bewertungen

- PFD Ano & Reni A3 - Sidang 2Dokument1 SeitePFD Ano & Reni A3 - Sidang 2Andriano Suryawan UtamaNoch keine Bewertungen

- PFD X Hysys Act 2 Modif Buat 4DDokument1 SeitePFD X Hysys Act 2 Modif Buat 4DMasterNoch keine Bewertungen

- Gas Phase RealDokument2 SeitenGas Phase RealJULIA REESE REYESNoch keine Bewertungen

- Pra-Rancangan Pabrik Produksi Etilen Dari Gas Alam Berkapasitas 400.000 TON/TAHUNDokument1 SeitePra-Rancangan Pabrik Produksi Etilen Dari Gas Alam Berkapasitas 400.000 TON/TAHUNiknaiw27Noch keine Bewertungen

- PFD X Hysys Act 2 Modif Buat 4CDokument1 SeitePFD X Hysys Act 2 Modif Buat 4CMasterNoch keine Bewertungen

- 10 1080@01614947208076867Dokument42 Seiten10 1080@01614947208076867John Philip AyoNoch keine Bewertungen

- Checal 2 Midterm ExamDokument1 SeiteChecal 2 Midterm ExamJohn Philip AyoNoch keine Bewertungen

- Experiment On DiffusionDokument7 SeitenExperiment On DiffusionJohn Philip AyoNoch keine Bewertungen

- Experiment On DiffusionDokument7 SeitenExperiment On DiffusionJohn Philip AyoNoch keine Bewertungen

- Gas AbsorptionDokument9 SeitenGas AbsorptionJohn Philip AyoNoch keine Bewertungen

- Diffusion Uops2Dokument8 SeitenDiffusion Uops2John Philip AyoNoch keine Bewertungen

- CHE501 - Lecture 6Dokument35 SeitenCHE501 - Lecture 6John Philip AyoNoch keine Bewertungen

- Diffusion Uops2Dokument7 SeitenDiffusion Uops2John Philip AyoNoch keine Bewertungen

- Ammonia Stripping TowerDokument4 SeitenAmmonia Stripping TowerArvind KushwahaNoch keine Bewertungen

- Class X Test Electrolysis and MetullargyDokument4 SeitenClass X Test Electrolysis and MetullargyToshiGMaheshwariNoch keine Bewertungen

- Cluster Chemistry Chapter 4 PDFDokument48 SeitenCluster Chemistry Chapter 4 PDFGax AllebNoch keine Bewertungen

- 2.3 External Mass Transfer EffectsDokument19 Seiten2.3 External Mass Transfer EffectsAstra BeckettNoch keine Bewertungen

- Experimental Determination of Organic StructuresDokument11 SeitenExperimental Determination of Organic StructuresJochebed MirandaNoch keine Bewertungen

- Food Technology TrendDokument56 SeitenFood Technology TrendBambang NurhadiNoch keine Bewertungen

- Topical Mock Chemistry QuestionsDokument294 SeitenTopical Mock Chemistry QuestionsMichael Mike100% (1)

- Demand Defrost Strategies in Supermarket Refrigeration SystemsDokument33 SeitenDemand Defrost Strategies in Supermarket Refrigeration SystemsHoàngViệtAnhNoch keine Bewertungen

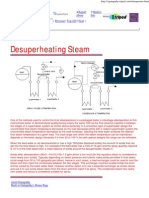

- Desuperheating Steam: The Web TripodDokument1 SeiteDesuperheating Steam: The Web Tripodhappale2002Noch keine Bewertungen

- ST, ViscosityDokument26 SeitenST, ViscosityAyush SrivastavNoch keine Bewertungen

- European Patent Specification C23F 11/10, C02F 5/12: Printed by Jouve, 75001 PARIS (FR)Dokument11 SeitenEuropean Patent Specification C23F 11/10, C02F 5/12: Printed by Jouve, 75001 PARIS (FR)mini2018Noch keine Bewertungen

- Use The Table Below To Answer The Questions That Follow.: A. Multiple-Choice and Bimodal QuestionsDokument13 SeitenUse The Table Below To Answer The Questions That Follow.: A. Multiple-Choice and Bimodal QuestionsHUY NGUYỄN PHƯƠNG PHÚCNoch keine Bewertungen

- Structure of Atoms and IonsDokument34 SeitenStructure of Atoms and IonsChristineNoch keine Bewertungen

- Offshore Hydrate Engineering HandbookDokument255 SeitenOffshore Hydrate Engineering HandbookreninbabaskiNoch keine Bewertungen

- Particle Size Effect On The Hydrophobicity and The Natural Floatability of MolybdeniteDokument105 SeitenParticle Size Effect On The Hydrophobicity and The Natural Floatability of MolybdeniteAgustín F. Correa100% (1)

- Quantum Mechanics de - Broglie Matter WavesDokument16 SeitenQuantum Mechanics de - Broglie Matter Wavesvivek patelNoch keine Bewertungen

- One Dimensional Steady State Conduction: By: Taz 1Dokument52 SeitenOne Dimensional Steady State Conduction: By: Taz 1Adam AndualemNoch keine Bewertungen

- Numerical Study of Second Harmonic GenerDokument473 SeitenNumerical Study of Second Harmonic GenerUniversity classesNoch keine Bewertungen

- Sergey Vulfson PHD (Author) - Molecular Magnetochemistry (1998)Dokument492 SeitenSergey Vulfson PHD (Author) - Molecular Magnetochemistry (1998)EUGENNoch keine Bewertungen

- Module1 EC NotesDokument25 SeitenModule1 EC NotesTriveni M KNoch keine Bewertungen

- LPG Standards PDFDokument115 SeitenLPG Standards PDFhandoyo_eko20017573Noch keine Bewertungen

- Fator de Watson KW Ie50312a018Dokument5 SeitenFator de Watson KW Ie50312a018Luiz Roberto TerronNoch keine Bewertungen

- Experiment 5 - Double Indicator TitrationDokument16 SeitenExperiment 5 - Double Indicator TitrationJoemer Absalon Adorna67% (6)

- THERMO1 - 1 Introductory Concepts and Definition - Sample Problems PDFDokument25 SeitenTHERMO1 - 1 Introductory Concepts and Definition - Sample Problems PDFEdmark AldeaNoch keine Bewertungen

- TAMU Compressor SelectionDokument8 SeitenTAMU Compressor SelectionAdnan RajkotwalaNoch keine Bewertungen

- Tifr 2011 PhysicsDokument8 SeitenTifr 2011 PhysicsAbhrajit MahapatraNoch keine Bewertungen

- Hebat Sains Form 2 Changes of MatterDokument4 SeitenHebat Sains Form 2 Changes of MatterHalizah RamthanNoch keine Bewertungen

- Journal of The Taiwan Institute of Chemical Engineers: Tawfik A. Saleh, Gaddafi I. DanmalikiDokument9 SeitenJournal of The Taiwan Institute of Chemical Engineers: Tawfik A. Saleh, Gaddafi I. DanmalikiPrativa BeheraNoch keine Bewertungen

- Chemistry Lab ManualDokument8 SeitenChemistry Lab ManualKritin ReddyNoch keine Bewertungen

- DLP For ObservationDokument7 SeitenDLP For ObservationElvie CristobalNoch keine Bewertungen