Beruflich Dokumente

Kultur Dokumente

18 Maintenance TTP

Hochgeladen von

Rao Ahsan AttaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

18 Maintenance TTP

Hochgeladen von

Rao Ahsan AttaCopyright:

Verfügbare Formate

Department of Chemical Engineering Batch 18

Maintenance Engineering & Risk Assessment Term 5th `

Course Outline Page No 1 of 2

COURSE CODE:

COURSE NAME: Maintenance Engineering & Risk Assessment

CREDIT HOURS: Theory =2

Practical =0

Total =2

PREREQUISITE: None

MODE OF TEACHING: Two hours of lecture per week 100 %

Course Outline:

Types of maintenance, Preventive, predictive, break down and total productive maintenance. Individual

versus group replacement; Internal versus external maintenance. Scheduling of maintenance. Computerized

Maintenance. Organization of maintenance force. Design considerations; Layout and construction

maintenance of rotary and stationery equipment, inspection techniques. Non-destructive testing techniques,

basic of rigging and lifting. Lubrication and lubricants.

Hazard, Risk assessment and Management. Importance of safety with increased productivity. Overall safety

of plant and personnel; Accident and loss statistics. Accident analysis and prevention. Types of accidents in

chemical industry. Govt. regulations for industrial safety. Difference between accident and incident. Accident

rate calculations and economics of accident prevention. Safety management.. Accident investigation and case

history. Fires and explosions. Fire triangles. Flammability characteristics. Safety equipment, firefighting

equipment’s and their uses. Occupational diseases related to chemical industry.

RELEVANT PROGRAM LEARNING OUTCOMES (PLOs):

The course is assigned so that students will achieve the PLOs:

1 Engineering Knowledge: 7 Environment and Sustainability: ☐

2 Problem Analysis: ☐ 8 Ethics: ☐

3 Design/Development of Solutions: ☐ 9 Individual and Team Work:

4 Investigation: ☐ 10 Communication: ☐

5 Modern Tool Usage: 11 Project Management:

6 The Engineer and Society: ☐ 12 Lifelong Learning: ☐

COURSE LEARNING OUTCOMES:

Upon successful completion of the course, the student will demonstrate competency by being

able to:

CLOs Description Taxonomy Level PLOs

1 Categorize the different kinds of maintenance activities. C4 1

2 Explain hazards, risk assessment and safety management related to C2 9, 11

both plant and personnel.

3 Use of firefighting equipment’s in case of different types of fire C3 5

TOPICS COVERED WITH THEIR CONTRIBUTION TO PLOs:

Department of Chemical Engineering Batch 18

Maintenance Engineering & Risk Assessment Term 5th `

Course Outline Page No 2 of 2

Theory:

S. No Contents No. of

lectures

1 Introduction To Maintenance Engineering 01

2 Types Of Maintenance 02

3 Individual vs Group Replacement 01

4 Computerized Maintenance System 01

5 Scheduling Of Maintenance 02

6 Design Considerations; Layout & Construction of Equipment’s 02

7 Inspection Techniques ; Non Destructive Testing 01

8 Basics Of Rigging & Lifting 02

9 Lubrication & Lubricants 02

10 Hazard, Risk assessment and Management 01

11 Importance of safety with increased productivity 02

12 Overall safety of plant and personnel 02

13 Accident and loss statistics. Accident analysis and prevention. Types of 02

accidents in chemical industry

14 Govt. regulations for industrial safety. Difference between accident and 02

incident. Accident investigation and case history

15 Fires and explosions. Fire triangles 01

16 Flammability characteristics 01

17 Safety equipment, firefighting equipment’s and their uses 02

18 Occupational diseases related to chemical industry 01

Total Lectures 28

TEXTBOOKS AND MATERIALS:

1. Maintenance Manager’s Standard Manual by Thom as A. Wester-Kamp, Prentice-Hall.

2. A Guide to Effective Industrial Safety by Jack W. Boley, Gulf Publishing Company

Prepared By Name with Sign Rao Ahsan Atta

(Instructor) Date 21 October 2019

Reviewed By Sign

(OBE-Committee) Date

Approved By Sign

(Dean/ HoD)

Date

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

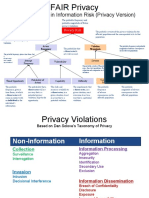

- Factor Analysis in Information Risk (Privacy Version)Dokument8 SeitenFactor Analysis in Information Risk (Privacy Version)Otgonbayar TsengelNoch keine Bewertungen

- Program BCNA (English)Dokument1 SeiteProgram BCNA (English)Oliver HoadleyNoch keine Bewertungen

- Austria vs. NLRCDokument2 SeitenAustria vs. NLRCJenilyn EntongNoch keine Bewertungen

- AI Sample SyllabusDokument3 SeitenAI Sample SyllabusArvin F. VillodresNoch keine Bewertungen

- Beauchamp Thomas Understanding Teacher IdentityDokument16 SeitenBeauchamp Thomas Understanding Teacher IdentityOswaldo Cabrera100% (1)

- Sarahdhobhany Resume PDFDokument1 SeiteSarahdhobhany Resume PDFAnonymous Uz535ScEMVNoch keine Bewertungen

- 2.1 Understanding REACH: How Does REACH Work?Dokument3 Seiten2.1 Understanding REACH: How Does REACH Work?xixixoxoNoch keine Bewertungen

- Planning - Emerging TheoriesDokument84 SeitenPlanning - Emerging TheoriesEarl Schervin CalaguiNoch keine Bewertungen

- Pereka Online Registration ManualDokument7 SeitenPereka Online Registration ManualaxnoobxisNoch keine Bewertungen

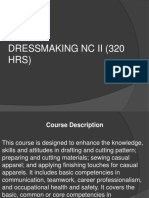

- Dressmaking NC Ii (320 HRS)Dokument8 SeitenDressmaking NC Ii (320 HRS)Amir Hasan Nicko BaidanNoch keine Bewertungen

- Whitehead and BiosemioticsDokument22 SeitenWhitehead and BiosemioticsJ PNoch keine Bewertungen

- Sai Vidya Institute of Technology: Department of Civil EngineeringDokument9 SeitenSai Vidya Institute of Technology: Department of Civil EngineeringSrinivasNoch keine Bewertungen

- Student - Marksheet - OpticsDokument7 SeitenStudent - Marksheet - OpticsNguyệt PhươngNoch keine Bewertungen

- Activity in Law Related StudiesDokument7 SeitenActivity in Law Related StudiesJames Bryan M. PrimaNoch keine Bewertungen

- Research ProposalDokument6 SeitenResearch Proposalanon-48724100% (3)

- Translation Review What Is TranslationDokument5 SeitenTranslation Review What Is TranslationJinNoch keine Bewertungen

- Level 1 - Revenue Management Distance Training ProposalDokument9 SeitenLevel 1 - Revenue Management Distance Training ProposalGurprit Singh JauraNoch keine Bewertungen

- An Analysis of Students' Ability in Distinguishing Perfect TenseDokument103 SeitenAn Analysis of Students' Ability in Distinguishing Perfect TenseThủy NguyễnNoch keine Bewertungen

- Lesson 1 and 2 Summary On LANGUAGE, CULTURE & SOCIETYDokument4 SeitenLesson 1 and 2 Summary On LANGUAGE, CULTURE & SOCIETYJasper RoqueNoch keine Bewertungen

- John Hankinson AffidavitDokument16 SeitenJohn Hankinson AffidavitRtrForumNoch keine Bewertungen

- MCQ On Smart GridDokument4 SeitenMCQ On Smart GridJoshi RohitNoch keine Bewertungen

- IELTS Advantage Speaking and Listening SkillsDokument122 SeitenIELTS Advantage Speaking and Listening SkillsAlba Lucía Corrales Reina100% (8)

- JMC CV UpdatedDokument2 SeitenJMC CV UpdatedJoy100% (2)

- RADIO COMMUNICATIONS OF THE PHILIPPINES, INC. (RCPI), Petitioner, Vs - ALFONSO VERCHEZDokument4 SeitenRADIO COMMUNICATIONS OF THE PHILIPPINES, INC. (RCPI), Petitioner, Vs - ALFONSO VERCHEZVenus Jane FinuliarNoch keine Bewertungen

- Political Law NotesDokument186 SeitenPolitical Law NotesDaneva AnticamaraNoch keine Bewertungen

- Accident Reporting and Investigation: A. GeneralDokument7 SeitenAccident Reporting and Investigation: A. Generalwaseemyounis123Noch keine Bewertungen

- Learn With Facebook - Digital-Skills-Modules-Combined-04-24 PDFDokument182 SeitenLearn With Facebook - Digital-Skills-Modules-Combined-04-24 PDFMostesareNoch keine Bewertungen

- Doku - Pub Zach Weinersmith Polystate v7Dokument73 SeitenDoku - Pub Zach Weinersmith Polystate v7TommyNoch keine Bewertungen

- MoodleTMB 2019-20 Seminar 4 Relative GroundsDokument36 SeitenMoodleTMB 2019-20 Seminar 4 Relative GroundsJohn SheldonNoch keine Bewertungen

- Passed CGPA-7.2: Rohit Kumar Singh At-Plot-28 Vasundhara Vihar Society Iit Gate Kalyanpur Kanpur PIN-208017 (U.P)Dokument2 SeitenPassed CGPA-7.2: Rohit Kumar Singh At-Plot-28 Vasundhara Vihar Society Iit Gate Kalyanpur Kanpur PIN-208017 (U.P)Rohit Singh100% (1)