Beruflich Dokumente

Kultur Dokumente

Squiler

Hochgeladen von

muhyideen6abdulganiyOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Squiler

Hochgeladen von

muhyideen6abdulganiyCopyright:

Verfügbare Formate

Soldering could be a joining process wont to join differing kinds of metals together.

Solder could

be a metal alloy usually made from tin and lead which is melted employing a hot iron. The iron is

heated to temperatures above 600 degrees fahrenheit which then cools to form a powerful bond.

This article is one amongst a series of TWI commonly asked questions (FAQs). How it Works

Solder is melted by using heat from an iron connected to a temperature controller. it's hot to

temperatures beyond its freezing point at around 600 degrees fahrenheit which then causes it to

melt, which then cools creating the soldered joint. As well as creating strong electrical joints

solder may also be removed employing a desoldering tool. Solder could be a metal alloy wont to

create strong permanent bonds; like copper joining in circuit boards and copper pipe joints. It may

also be supplied in two differing kinds and diameters, lead and lead free and can also be between .

032” and .062”. Inside the solder core is that the flux, a fabric wont to strengthen and improve its

mechanical properties. What Metals are Used? Tin, lead, brass or silver are the metals utilized in

solder for soldering joints. Which Flux may be Used for Soldering? Occasionally at the location of

the joint, there are impurities like oil, dirt or oxidation, the flux helps prevent oxidation and may

sometimes chemically clean the metal. The flux used is rosin flux which helps the mechanical

strength and tangency of electrical joints. Sometimes it's also possible to use a ‘wetting agent’ to

cut back the physical phenomenon. Types of Soldering There are three sorts of soldering which

use increasingly higher temperatures, which successively produce progressively stronger joints:

Soft soldering (90 °C - 450 °C) - This process has the bottom filler metal freezing point of all the

soldering types at but around 400°C these filler metals are usually alloys, often containing lead

with liquidus temperatures under 350°C. due to the low temperatures utilized in soft soldering it

thermally stresses components the smallest amount but doesn't make strong joints and is then

therefore unsuitable for mechanical load-bearing applications. it's also not suited to hot

temperature use as this kind of solder loses strength and melts. Hard (silver) soldering (>450 °C) –

Brass or silver is that the bonding metal utilized in this process, and requires a blowtorch to attain

the temperatures at which the solder metals. Brazing (>450 °C) – this kind of soldering uses a

metal with a far higher freezing point than those utilized in hard and soft soldering. However,

similarly to hard soldering, the metal being bonded is heated as against being melted. Once both

the materials are heated sufficiently, you'll be able to then place the soldering metal between them

which melts and acts as a bonding agent. Uses of a hand tool A hand tool could be a tool wont to

heat solder, usually from an electrical supply at high temperatures above the freezing point of the

metal alloy. this permits for the solder to flow between the workpieces eager to be joined. This

soldering tool is created from an insulated handle and a heated pointed metal iron tip. Although

the hand tool has engineering uses, it may be utilized in other contexts. What is a Soldering Gun

Used For? Soldering guns are used for applications where more heat is required as irons use lower

power. This tool is employed for joining glass, light flat solid and heavy electronic soldering work.

after you must solder intermittently, the soldering gun is far more practical because it cools much

quicker.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Invisible CitiesDokument14 SeitenInvisible Citiesvelveteeny0% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Volvo BL 71 ManualDokument280 SeitenVolvo BL 71 ManualAlberto G.D.100% (2)

- 7Dokument6 Seiten7Joenetha Ann Aparici100% (1)

- Friday 21st October 2022 No 48Dokument4 SeitenFriday 21st October 2022 No 48muhyideen6abdulganiyNoch keine Bewertungen

- How Lodge ComplaintsDokument3 SeitenHow Lodge Complaintsmuhyideen6abdulganiyNoch keine Bewertungen

- Chapter Three 1Dokument30 SeitenChapter Three 1muhyideen6abdulganiyNoch keine Bewertungen

- Customer StatementDokument18 SeitenCustomer Statementmuhyideen6abdulganiyNoch keine Bewertungen

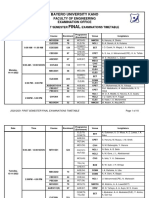

- 1st Semester 2020 2021 Final Examination TTDokument18 Seiten1st Semester 2020 2021 Final Examination TTmuhyideen6abdulganiyNoch keine Bewertungen

- Lubricating System (MEC5303)Dokument5 SeitenLubricating System (MEC5303)muhyideen6abdulganiyNoch keine Bewertungen

- Past QuestionDokument19 SeitenPast Questionmuhyideen6abdulganiyNoch keine Bewertungen

- Retail Genral Enterprises and Marchandise Business PlanDokument6 SeitenRetail Genral Enterprises and Marchandise Business Planmuhyideen6abdulganiyNoch keine Bewertungen

- Beans Sheller Machine SynopsisDokument4 SeitenBeans Sheller Machine Synopsismuhyideen6abdulganiyNoch keine Bewertungen

- Fuel System Assignment 4-5-1Dokument5 SeitenFuel System Assignment 4-5-1muhyideen6abdulganiy100% (1)

- Gas Distribution MechanismDokument6 SeitenGas Distribution Mechanismmuhyideen6abdulganiyNoch keine Bewertungen

- Cost of Capital and Investment CriteriaDokument9 SeitenCost of Capital and Investment Criteriamuhyideen6abdulganiyNoch keine Bewertungen

- Engineering Management: 1.0 Engineering Management, Also Referred To As Industrial Engineering, Operations ManagementDokument5 SeitenEngineering Management: 1.0 Engineering Management, Also Referred To As Industrial Engineering, Operations Managementmuhyideen6abdulganiyNoch keine Bewertungen

- Irjet V7i5215Dokument3 SeitenIrjet V7i5215muhyideen6abdulganiyNoch keine Bewertungen

- Class 2 - Death & Day of JudgementDokument15 SeitenClass 2 - Death & Day of Judgementmuhyideen6abdulganiyNoch keine Bewertungen

- Thermo LabDokument2 SeitenThermo Labmuhyideen6abdulganiyNoch keine Bewertungen

- New Doc 2018-10-08Dokument1 SeiteNew Doc 2018-10-08muhyideen6abdulganiyNoch keine Bewertungen

- Education: Year of Award Degree Type InstitutionDokument1 SeiteEducation: Year of Award Degree Type Institutionmuhyideen6abdulganiyNoch keine Bewertungen

- Practicing Truthfulness in Every Aspect of LifeDokument14 SeitenPracticing Truthfulness in Every Aspect of Lifemuhyideen6abdulganiyNoch keine Bewertungen

- Generation III Sonic Feeder Control System Manual 20576Dokument32 SeitenGeneration III Sonic Feeder Control System Manual 20576julianmataNoch keine Bewertungen

- Mcdaniel Tanilla Civilian Resume Complete v1Dokument3 SeitenMcdaniel Tanilla Civilian Resume Complete v1api-246751844Noch keine Bewertungen

- G2 Rust Grades USA PDFDokument2 SeitenG2 Rust Grades USA PDFSt3fandragos4306Noch keine Bewertungen

- Toh736 - 84000 The Dharani of Parnasavari PDFDokument24 SeitenToh736 - 84000 The Dharani of Parnasavari PDFJames LeeNoch keine Bewertungen

- Niveshdaily: From Research DeskDokument53 SeitenNiveshdaily: From Research DeskADNoch keine Bewertungen

- Mecha World Compendium Playbooks BWDokument12 SeitenMecha World Compendium Playbooks BWRobson Alves MacielNoch keine Bewertungen

- Nantai Catalog NewDokument30 SeitenNantai Catalog Newspalomos100% (1)

- PostScript Quick ReferenceDokument2 SeitenPostScript Quick ReferenceSneetsher CrispyNoch keine Bewertungen

- Ateneo de Manila University: Submitted byDokument5 SeitenAteneo de Manila University: Submitted byCuster CoNoch keine Bewertungen

- Acting White 2011 SohnDokument18 SeitenActing White 2011 SohnrceglieNoch keine Bewertungen

- Contemporary Strategic ManagementDokument2 SeitenContemporary Strategic ManagementZee Dee100% (1)

- 2201 IntGCSE (9-1) Subject Grade Boundaries V1Dokument4 Seiten2201 IntGCSE (9-1) Subject Grade Boundaries V1Fariha RahmanNoch keine Bewertungen

- Simon Ardhi Yudanto UpdateDokument3 SeitenSimon Ardhi Yudanto UpdateojksunarmanNoch keine Bewertungen

- Computer System Validation - Definition and Requirements - MustRead PDFDokument3 SeitenComputer System Validation - Definition and Requirements - MustRead PDFtraining validNoch keine Bewertungen

- The Effect of Co-Op Approach in Improving Visual Motor Integration Skills in Children With Learning DisabilityDokument7 SeitenThe Effect of Co-Op Approach in Improving Visual Motor Integration Skills in Children With Learning DisabilityIJAR JOURNALNoch keine Bewertungen

- OT Initial Assessment (OTIA) 2022-11-15Dokument2 SeitenOT Initial Assessment (OTIA) 2022-11-15funtikarNoch keine Bewertungen

- Virtual WorkDokument12 SeitenVirtual Workdkgupta28Noch keine Bewertungen

- CA21159 MG 8 Digital BookletDokument5 SeitenCA21159 MG 8 Digital BookletcantaloupemusicNoch keine Bewertungen

- ISA InTech Journal - April 2021Dokument50 SeitenISA InTech Journal - April 2021Ike EdmondNoch keine Bewertungen

- Based On PSA 700 Revised - The Independent Auditor's Report On A Complete Set of General Purpose Financial StatementsDokument12 SeitenBased On PSA 700 Revised - The Independent Auditor's Report On A Complete Set of General Purpose Financial Statementsbobo kaNoch keine Bewertungen

- RCA LCD26V6SY Service Manual 1.0 PDFDokument33 SeitenRCA LCD26V6SY Service Manual 1.0 PDFPocho Pochito100% (1)

- Alaba Adeyemi AdediwuraDokument12 SeitenAlaba Adeyemi AdediwuraSchahyda ArleyNoch keine Bewertungen

- View All Callouts: Function Isolation ToolsDokument29 SeitenView All Callouts: Function Isolation Toolsمهدي شقرونNoch keine Bewertungen

- Cobol v1Dokument334 SeitenCobol v1Nagaraju BNoch keine Bewertungen

- The Scope and Method of Economics: © 2007 Prentice Hall Business Publishing Principles of Economics 8e by Case and FairDokument36 SeitenThe Scope and Method of Economics: © 2007 Prentice Hall Business Publishing Principles of Economics 8e by Case and FairLangson phiriNoch keine Bewertungen

- Application of The Strain Energy To Estimate The Rock Load in Non-Squeezing Ground ConditionDokument17 SeitenApplication of The Strain Energy To Estimate The Rock Load in Non-Squeezing Ground ConditionAmit Kumar GautamNoch keine Bewertungen

- The Chemistry of The Colorful FireDokument9 SeitenThe Chemistry of The Colorful FireHazel Dela CruzNoch keine Bewertungen