Beruflich Dokumente

Kultur Dokumente

Incoming Inspection Standard-1

Hochgeladen von

rishi gautamOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Incoming Inspection Standard-1

Hochgeladen von

rishi gautamCopyright:

Verfügbare Formate

Doc.

No:- F/QA/01

INCOMING INSPECTION STANDARD Eff. Date:- 01/01/2019

Rev.Date/No:- 01/01/2019/00

PART NAME/NO:- ISSUE DATE:-

MATERIAL GRADE:-

SUPPLIER NAME:-

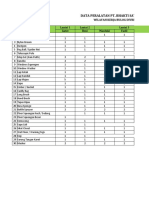

S.NO PARA. CTQ SPECIFICATION INSPECTION METHOD REACTION PLAN

REJECT THE

MATERIAL & SEND

BACK TO

SUPPLIER.

PREPARED BY:- APPROVED BY:-

Doc.No:- F/QA/01

INCOMING INSPECTION STANDARD Eff. Date:- 01/01/2019

Rev.Date/No:- 01/01/2019/00

PART NAME/NO:- COVER ISSUE DATE:-

MATERIAL GRADE:- CR SHEET

SUPPLIER NAME:- M/S VENUS METAL/AGGARWAL INDUSTRIES

Ø4.50 X04 Nos.

40.0

Ø5.0 X04 Nos.

+0.035

+0.020

Ø22.0

P C D Ø 8 0 .0

Ø10

Ø 9 6 .8 0

Ø 6 1 .0

Ø 9 5 .0

Ø23.0

1.0

LEAD HOLE

Ø16 24.50

Ø22.0

Ø61.0

Ø95.0

PCD Ø108

Ø120.0

S.NO PARA. CTQ SPECIFICATION INSPECTION METHOD REACTION PLAN

1 Dia Ø120.0 VC

2 PCD Ø108.0 VC

3 Dia Ø95.0 VC

4 Dia Ø61.0 VC

5 Dia Ø22.0 +0.020/+0.035 Air Gauge

6 Punch Dia Ø10.0 VC

7 Dia Ø96.80 VC

8 Dim. 40 DHG/VC REJECT THE

9 Lead Hole Ø16.0 VC

MATERIAL &

10 CD (LE) 24.5 DHG/VC

11 Dim. 1.0 DHG/VC

RETURN BACK TO

12 PCD Ø80.0 VC

SUPPLIER.

13 Hole Dia Ø4.50 X 04Nos. VC

14 Hole Dia Ø4.50 X 04Nos. VC

Free From Burr, Scratch,

15 Appearance Crack etc Visual

NOTE:- IN OLE COVER, LEAD HOLE SHOULD NOT BE DONE & THEN IF ANY QUIERY PLEASE CONTACT

WITH US.

CRITICAL CHARACTERISTIC:-

PREPARED BY:- Jitendra Gupta APPROVED BY:- Yogendra

Doc.No:- F/QA/01

INCOMING INSPECTION STANDARD Eff. Date:- 01/01/2019

Rev.Date/No:- 01/01/2019/00

PART NAME/NO:- COVER (FOR BEARING Ø22) ISSUE DATE:-

MATERIAL GRADE:- CR SHEET

SUPPLIER NAME:- M/S VENUS METAL/AGGARWAL INDUSTRIES

0.20

Sq.(5.0X5.0)-04 Nos. 32.0

+0.035

+0.020

Ø22.0

Ø107.50/107.55

Ø51.0

11.0

Ø10.0

19.50

PCD Ø100.0

1.30

S.NO PARA. CTQ SPECIFICATION INSPECTION METHOD REACTION PLAN

1 ID Ø107.50/107.55 VC

2 PCD Ø100.0 VC

3 Dia Ø51.0 VC

4 SQ. HOLE (5X5)-04NOS. VC

5 Dia Ø22.0 +0.020/+0.035 Air Gauge

6 Punch Dia Ø10.0 VC

7 SH. THICK 1.30±0.10 VC

8 HEIGHT 32 DHG/VC

9 Lead Hole Ø11.0 -02NOS. VC REJECT THE

10 CD (LE) 19.50 DHG/VC MATERIAL &

11 DEPTH 11.0 DHG/VC RETURN BACK TO

12 DIA R/O

0.20 DG WITH FIXTURE

SUPPLIER.

13 FACE R/O

Free From Burr, Scratch,

14 Appearance

Crack etc

Visual

NOTE:- IN OLE COVER, LEAD HOLE SHOULD NOT BE DONE & THEN IF ANY QUIERY PLEASE CONTACT

WITH US.

CRITICAL CHARACTERISTIC:-

PREPARED BY:- Jitendra Gupta APPROVED BY:- Yogendra

Doc.No:- F/QA/01

INCOMING INSPECTION STANDARD Eff. Date:- 01/01/2019

Rev.Date/No:- 01/01/2019/00

PART NAME/NO:- COVER(FOR BEARING Ø32) ISSUE DATE:-

MATERIAL GRADE:- CR SHEET

SUPPLIER NAME:- M/S VENUS METAL/AGGARWAL INDUSTRIES

0.20

Sq.(5.0X5.0)-04 Nos. 34.0-0.50

+0.032

+0.020

Ø32.0

Ø107.50/107.55

Ø64.50

Ø16.50

15.0

19.50

1.30

PCD Ø100.0

S.NO PARA. CTQ SPECIFICATION INSPECTION METHOD REACTION PLAN

1 ID Ø107.50/107.55 VC

2 PCD Ø100.0 VC

3 Dia Ø64.50 VC

4 SQ. HOLE (5X5)-04NOS. VC

5 Dia Ø32.0 +0.020/+0.035 Air Gauge

6 Punch Dia Ø16.50 VC

7 SH. THICK 1.30±0.10 VC

8 HEIGHT 34.0-0.50 DHG/VC

9 Lead Hole Ø11.0 -02NOS. VC REJECT THE

10 CD (LE) 19.50 DHG/VC MATERIAL &

11 DEPTH 15.0 DHG/VC RETURN BACK TO

12 DIA Con.

0.20 DG WITH FIXTURE

SUPPLIER.

13 FACE Con.

Free From Burr, Scratch,

14 Appearance

Crack etc

Visual

NOTE:- IN OLE COVER, LEAD HOLE SHOULD NOT BE DONE & THEN IF ANY QUIERY PLEASE CONTACT

WITH US.

CRITICAL CHARACTERISTIC:-

PREPARED BY:- Jitendra Gupta APPROVED BY:- Yogendra

Doc.No:- F/QA/01

INCOMING INSPECTION STANDARD Eff. Date:- 01/01/2019

Rev.Date/No:- 01/01/2019/00

PART NAME/NO:- Rotor/ G1102, G1103 ISSUE DATE:- 18/02/2019

MATERIAL GRADE:- AL+ CRC

SUPPLIER NAME:- M/S TR METALS

0.05

SKEW BAR :- 1.50 BAR

*21.0±0.50

Ø8.15/8.20

* Ø59.51/59.47

Ø57.40 Typ.

5.70 Ref.

S.NO PARAMETER CTQ SPECIFICATION INSPECTION METHOD REACTION PLAN

1 OD Ø59.51/59.47 Comp. Stand

2 Concetricity 0.050 Dial Gauge

3 Length X±0.50 Varnier caliper

4 Skew bar 1.50 Bar Visualy With Scale

5 Dia Ø8.15/8.20 Air Gauge

6 Angle 5° Bevel Projector

7 Endring Dia Ø57.40 (2X) Varnier caliper

8 Dim. 5.70 DHG/VC

Free From unfilling,

REJECT THE

9 Appearance crack, burr & other Visual MATERIAL & SEND

Machining defects

BACK TO

SUPPLIER.

Note:-

1. Rotor should be check as per Specification.

2. For part No.-G1102, d=8.15/8.20 &

X=21.0 3.

For part No.-G1103, d=8.15/8.20 & X=19.0

PREPARED BY:- Jitendra Gupta APPROVED BY:- Yogendra

Doc.No:- F/QA/01

INCOMING INSPECTION STANDARD Eff. Date:- 01/01/2019

Rev.Date/No:- 01/01/2019/00

PART NAME/NO:- ROTOR-J1343 ISSUE DATE:- 18/02/2018

MATERIAL GRADE:- AL+ CRC

SUPPLIER NAME:- M/S TR METALS

0.05

SKEW BAR :- 1.50 BAR

*24.0 ±0.50

Ø8.0

* Ø61.97/62.02

Ø57.40 Typ.

5.70 Ref.

S.NO PARAMETER CTQ SPECIFICATION INSPECTION METHOD REACTION PLAN

1 DIA Ø61.97/62.02 Comp. Stand

2 Concetricity 0.050 Dial gauge

3 Length 24.0 ±0.50 Varnier caliper

4 Skew bar 1.50 Bar Visualy With Scale

5 Dia Ø8.0 Air Gauge

6 Angle 5° Bevel Projector

7 Endring Dia Ø57.40 (2X) Varnier caliper

8 Dim. 5.70 DHG/VC

Free From unfilling, REJECT THE

9 Appearance crack, burr & other Visually

Machining defects MATERIAL & SEND

BACK TO

SUPPLIER.

PREPARED BY:- Jitendra Gupta APPROVED BY:- Yogendra

Doc.No:- F/QA/01

INCOMING INSPECTION STANDARD Eff. Date:- 01/01/2019

Rev.Date/No:- 01/01/2019/00

PART NAME/NO:- Rotor ISSUE DATE:- 18/02/2019

MATERIAL GRADE:- AL+ CRC

SUPPLIER NAME:- M/S TR METALS

0.05

SKEW BAR :- 1.50 BAR

*X ±0.50

Ød

* Ø61.97/62.02

Ø57.40 Typ.

5.70 Ref.

S.NO PARAMETER CTQ SPECIFICATION INSPECTION METHOD REACTION PLAN

1 OD Ø59.51/59.47 Comp. Stand

2 Concetricity 0.050 Dial Gauge

3 Length X±0.50 Varnier caliper

4 Skew bar 1.50 Bar Visualy With Scale

5 Dia Ød Air Gauge

6 Angle 5° Bevel Projector

7 Endring Dia Ø57.40 (2X) Varnier caliper

8 Dim. 5.70 DHG/VC

Free From unfilling,

9 Appearance crack, burr & other Visual

Machining defects

Note:- REJECT THE MATERIAL

1. Rotor should be check as per Specification. & SEND BACK TO

2. For part No.-J1340, d=8.0 & X=25.50 SUPPLIER.

3. For part No.-J1342, d=8.0 & X=21.0

4. For part No.-J11151, d=12.70 & X=28.0

5. For part No.-J11143, d=12.70 & X=32.0

6. For part No.-J11161, d=12.70 &

X=38.0

7. For part No.-J11139, d=12.70 & X=41.0

8. For part No.-J1302/1305, d=8.0 & X=21.0

9. For part No.-J1301, d=8.0 & X=21.0

10.For part No.-J1334, d=8.0 & X=24.0

11.For part No.-

J1138, d=12.70 & X=21.0 12.For part No.-

J1170, d=12.70 & X=24.0

13. For part No.-J1136, d=12.70 & X=24.0

PREPARED BY:- Jitendra Gupta APPROVED BY:- Yogendra

Doc.No:- F/QA/01

INCOMING INSPECTION STANDARD Eff. Date:- 01/01/2019

Rev.Date/No:- 01/01/2019/00

PART NAME/NO:- Shaft ISSUE DATE:- 19/02/2019

MATERIAL GRADE:- EN-8

SUPPLIER NAME:- M/S TR METALS

A±0.20

Dia. Ø8.00/8.005

W/o Phospated

C±0.20

6.80±0.10

D±0.50 G±1.0

Ø5.0 1.1/1.20

B±1.0

3.50

E±0.20

1.1/1.20

2.0 F±0.20

7.0-0.50

Ø6.50±0.10

Ø8.15/8.20

S.NO PARAMETER CTQ SPECIFICATION INSPECTION METHOD REACTION PLAN

1 Flat Dim 6.80±0.10 Varnier caliper

2 Total Length A±0.20 HG/VC

3 B' Dim. B±1.0 Varnier caliper

4 C' Dim. C±0.20 Varnier caliper

5 D' Dim. D±0.50 Varnier caliper

6 E' Dim. E±0.20 Varnier caliper

7 F' Dim F±0.20 Varnier caliper

8 G' Dim G±1.0 Varnier caliper

9 Gr. Dia 7.0 Varnier caliper

10 Gr. Dia 6.50±0.10 (2X) Blade Micrometer

11 Gr. Distt. 1.10/1.20 (2X) VC/Slip

12 Dimple Dia Ø5.0 Varnier caliper

13 Gr. Distt. 2.0 Varnier caliper

14 Run Out 0.050 Dial Gauge

15 Dimple Depth 3.500 Varnier caliper

16 Knurling Dia Ø8.15/8.20 Varnier caliper

REJECT THE MATERIAL

17 Dim. 7.0-0.50 Varnier caliper

& SEND BACK TO

18 W/o phosphated Dia Ø8.00/8.005 Air Gauge

SUPPLIER.

19 Plunge Dia. Ø7.955/7.985 Air Gauge

Free From unfilling,

9 Appearance crack, burr & other Visual

Machining defects

Note:-

4. 136.0 22.0 58.30 35.50 30 17.0 20.0 G1102

3. 134.0 25.0 60.0 35.50 30 14.0 20.0 J1302BB

2. 158.0 25.0 60.0 46.50 7.50 14.0 20.0 J1301BB

1. 140.5 22.0 58.30 35.50 30. 17.0 20.0 G1103

S.No. A B C D E F G PART NO.

PREPARED BY:- Jitendra Gupta APPROVED BY:- Yogendra

Doc.No:- F/QA/01

INCOMING INSPECTION STANDARD Eff. Date:- 01/01/2019

Rev.Date/No:- 01/01/2019/00

PART NAME/NO:- Shaft Touch 20/35 ISSUE DATE:- 19/02/2019

MATERIAL GRADE:- EN-8

SUPPLIER NAME:- M/S TR METALS

132.0±0.20

36.50±0.20 83.30±0.20

35.50±0.20

Ø12.700

Ø12.665

/12.705

/12.670

61.50±0.20

6.0±0.2 9.50±0.10

30.0 19.0±1.0

1.10/1.20

3.0

Ø5

1.0X45°

6.80±0.10

Ø7.93/7.94

Ø10.80±0.10

10.0

08 NOS. ST. KNURLING

1.20/1.10

AFTER KNURLING

Ø12.91/12.86

S.NO PARAMETER CTQ SPECIFICATION INSPECTION METHOD REACTION PLAN

1 Flat Dim 6.80±0.10 Varnier caliper

2 Total Length 132.0±0.20 HG/VC

3 Dim. 83.30±0.20 Varnier caliper

4 Dim. 61.50±0.20 Varnier caliper

5 Knurling Length 30.0±1.0 Varnier caliper

6 Dim. 19.0±0.20 Varnier caliper

7 Dia Ø7.93/7.94 Varnier caliper

8 Gr. Dia 10.80±0.10 (2X) Blade Micrometer

9 Gr. Distt. 1.10/1.20 (2X) VC/Slip

10 Dimple Dia Ø5.0 Varnier caliper

11 Step Distt. 10.0 Varnier caliper

12 Run Out 0.050 Dial Gauge

REJECT THE MATERIAL

13 Dimple Depth 3.00 Varnier caliper

& SEND BACK TO

14 Knurling Dia Ø12.91/12.86 Varnier caliper

SUPPLIER.

15 Flat Length 35.50±0.20 Varnier caliper

16 Dim. 36.50±0.20 Varnier caliper

17 Dimple Dim. 6.0±0.20 Varnier caliper

18 phosphated Dia Ø12.700/12.705 Air Gauge

19 Plunge Dia. Ø12.665/12.670 Air Gauge

Free From unfilling,

20 Appearance crack, burr & other Visual

Machining defects

PREPARED BY:- Jitendra Gupta APPROVED BY:- Yogendra

Doc.No:- F/QA/01

INCOMING INSPECTION STANDARD Eff. Date:- 01/01/2019

Rev.Date/No:- 01/01/2019/00

PART NAME/NO:- Shaft-J11182 ISSUE DATE:- 19/02/2019

MATERIAL GRADE:- EN-8

SUPPLIER NAME:- M/S TR METALS

141.50±0.50

Ø12.665/12.670

Ø11.70±0.10

84.50±0.20

Ø11.50±0.10

65.0±0.20

35.50±0.50 9.50±0.10

28.0 19.0±1.0

30.0±0.50

2.0

Ø10.80±0.10

10.0

12.700/12.705

08 NOS. ST. KNURLING

1.20/1.10

AFTER KNURLING

Ø12.91/12.86

20.0

S.NO PARAMETER CTQ SPECIFICATION INSPECTION METHOD REACTION PLAN

1 Flat Dim 11.50±0.10 Varnier caliper

2 Total Length 141.50±0.50 HG/VC

3 Dim. 84.50±0.20 Varnier caliper

4 Dim. 65.0±0.20 Varnier caliper

5 Knurling Length 28.0±1.0 Varnier caliper

6 Dim. 19.0±1.0 Varnier caliper

7 Gr. Dia Ø11.70±0.10 Varnier caliper

8 Gr. Dia 10.80±0.10 (2X) Blade Micrometer

9 Gr. Distt. 1.10/1.20 (2X) VC/Slip

10 Dimple Dia Ø5.0 Varnier caliper

11 Step Distt. 10.0 Varnier caliper REJECT THE MATERIAL

12 Run Out 0.050 Dial Gauge & SEND BACK TO

13 Dimple Depth 3.50 Varnier caliper SUPPLIER.

14 Knurling Dia Ø12.91/12.86 Varnier caliper

15 Flat Length 35.50±0.50 Varnier caliper

17 Dimple Dim. 30.0±0.50 Varnier caliper

18 phosphated Dia Ø12.700/12.705 Air Gauge

19 Plunge Dia. Ø12.665/12.670 Air Gauge

Free From unfilling,

20 Appearance crack, burr & other Visual

Machining defects

PREPARED BY:- Jitendra Gupta APPROVED BY:- Yogendra

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- IN-PROCESS INSPECTION SHEET (Version 1)Dokument1 SeiteIN-PROCESS INSPECTION SHEET (Version 1)rishi gautamNoch keine Bewertungen

- IQC ChartDokument1 SeiteIQC Chartrishi gautamNoch keine Bewertungen

- F-HR-01 Master List of EmployeeDokument20 SeitenF-HR-01 Master List of Employeerishi gautamNoch keine Bewertungen

- 23.sop - HRDDokument4 Seiten23.sop - HRDrishi gautamNoch keine Bewertungen

- 4list of DocumentsDokument2 Seiten4list of Documentsrishi gautam100% (1)

- F-PD-14 Suggestion and Kaizen FormDokument2 SeitenF-PD-14 Suggestion and Kaizen Formrishi gautamNoch keine Bewertungen

- Guide-Floor MarkingDokument24 SeitenGuide-Floor Markingrishi gautamNoch keine Bewertungen

- 5S Organization ChartDokument1 Seite5S Organization Chartrishi gautam100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1091)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Data PeralatanDokument2 SeitenData PeralatanSaeful BahriNoch keine Bewertungen

- Equipment List Engine 9M32C: Devices Sensors and ActuatorsDokument6 SeitenEquipment List Engine 9M32C: Devices Sensors and ActuatorsJezrell JaravataNoch keine Bewertungen

- 4 Lecture Notes Turning ProcessDokument23 Seiten4 Lecture Notes Turning ProcessAkun SayaNoch keine Bewertungen

- Crown Catalog Eu 2024 WebDokument60 SeitenCrown Catalog Eu 2024 WebRiadh BouzidiNoch keine Bewertungen

- 8999 5589 00 Diagrams and Drawings S1D AGDDokument100 Seiten8999 5589 00 Diagrams and Drawings S1D AGDAbdul Zapata100% (1)

- Room Air Conditioner: Service ManualDokument80 SeitenRoom Air Conditioner: Service ManualNyiNyiNoch keine Bewertungen

- How To Make A Zip Gun - 12 Steps (With Pictures) - Wikihow PDFDokument10 SeitenHow To Make A Zip Gun - 12 Steps (With Pictures) - Wikihow PDFalex0% (1)

- Micrometer Screw GaugeDokument15 SeitenMicrometer Screw GaugeDeen Zakaria100% (1)

- Studor Technical ManualDokument46 SeitenStudor Technical ManualZ-Spiro-Noch keine Bewertungen

- ZRN Aluminum O Flute Speed Chart v6Dokument1 SeiteZRN Aluminum O Flute Speed Chart v6sneakbubbaNoch keine Bewertungen

- Tormek Sharpening 2017Dokument11 SeitenTormek Sharpening 2017Tommy TiplerNoch keine Bewertungen

- Cera Caliper Checker Mitutoyo PDFDokument12 SeitenCera Caliper Checker Mitutoyo PDFArzillo SalvatoreNoch keine Bewertungen

- Milling Machine Report DelyDokument10 SeitenMilling Machine Report DelyFazdly Azilan0% (2)

- What Are Air Handlers or AHUDokument24 SeitenWhat Are Air Handlers or AHUTushar PatilNoch keine Bewertungen

- Af WF Doc 001 PDFDokument19 SeitenAf WF Doc 001 PDFArjun S Rana100% (1)

- Valvula Contrabalance Insertable CeDokument7 SeitenValvula Contrabalance Insertable CeSamuel Lopez BenitesNoch keine Bewertungen

- Wood Magazine - 3 in One Bed For All Ages Part 1Dokument4 SeitenWood Magazine - 3 in One Bed For All Ages Part 1clnieto2450% (2)

- Basic Hydraulics - Accessory ComponentsDokument7 SeitenBasic Hydraulics - Accessory ComponentsmkNoch keine Bewertungen

- AC Tanpa HeaterDokument1 SeiteAC Tanpa HeaterZulfikarNoch keine Bewertungen

- Machine ToolsDokument48 SeitenMachine ToolsPrabhu VNoch keine Bewertungen

- Grinding-Machine - HTML: Dear Tom, Thank You For Your Inquiry. Hereby The Prices and Some Technical Information. PME12-VDokument2 SeitenGrinding-Machine - HTML: Dear Tom, Thank You For Your Inquiry. Hereby The Prices and Some Technical Information. PME12-VTom GoodladNoch keine Bewertungen

- RL4 Series Relief Valve Adjustment and Seal Replacement Instructions (MS-CRD-0055 Rev - C en-US Maintenance)Dokument2 SeitenRL4 Series Relief Valve Adjustment and Seal Replacement Instructions (MS-CRD-0055 Rev - C en-US Maintenance)Tuan TranNoch keine Bewertungen

- MINELAYINGNOV06Dokument60 SeitenMINELAYINGNOV06Kiran Moy Mandal100% (1)

- Air Rifles EssayDokument2 SeitenAir Rifles EssayMaruri LonesNoch keine Bewertungen

- List Sparepart KobelcoDokument1 SeiteList Sparepart Kobelcoargya AwangNoch keine Bewertungen

- Operation Manual TT1800SY PDFDokument268 SeitenOperation Manual TT1800SY PDFGriffin Armament SuppressorsNoch keine Bewertungen

- Ac Push Control ModuleDokument2 SeitenAc Push Control ModuleJorge Martínez CoralNoch keine Bewertungen

- Interlocks SM6Dokument3 SeitenInterlocks SM6Ben DavisNoch keine Bewertungen

- Pipe Support Sleeve PEDokument2 SeitenPipe Support Sleeve PEkiki270977Noch keine Bewertungen

- Coupling Alignment: Code Word/ ClientDokument3 SeitenCoupling Alignment: Code Word/ ClientFernando AguilarNoch keine Bewertungen