Beruflich Dokumente

Kultur Dokumente

Method Statement Rev.1

Hochgeladen von

Fuzail AyazOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Method Statement Rev.1

Hochgeladen von

Fuzail AyazCopyright:

Verfügbare Formate

Construction of Service Road (Extension)

at Showroom Zone in Duqm

CONSTRUCTION OF SERVICE ROAD (EXTENSION) AT

SHOWROOM ZONE IN DUQM

METHOD STATEMENT

SUBMISSION DATE: Tuesday, 23-07-2019

METHOD STATEMENT PAGE 1 of 23

Construction of Service Road (Extension)

at Showroom Zone in Duqm

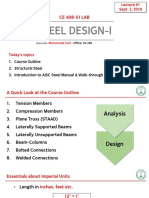

TABLE OF CONTENTS

1 GENERAL INFORMATION AND SCOPE ....................................................................... 3

1.1 PROJECT LOCATION ............................................................................................................. 3

1.2 PROJECT DESCRIPTION ....................................................................................................... 4

1.3 TIMELINE .............................................................................................................................. 4

1.4 SCOPE OF W ORKS .............................................................................................................. 4

1.5 TYPICAL DRAWINGS ............................................................................................................. 5

1.5.1 Site plan .......................................................................................................................... 5

1.5.2 Roads Cross Section .................................................................................................... 5

1.5.3 Roundabout Cross Section .......................................................................................... 6

1.6 MAIN QUANTITIES................................................................................................................. 7

2 CONSTRUCTION STRATEGY AND METHODOLOGY ................................................. 8

2.1 SEQUENCING AND PLANNING, MATERIALS AND WORK FRONTS ........................................ 8

2.2 ROADWORKS METHODOLOGY ............................................................................................. 9

2.2.1 The Workfronts and Assumed Productivities ............................................................ 9

2.2.2 Earthworks...................................................................................................................... 9

2.2.3 Subgrade Construction ............................................................................................... 11

2.2.4 Aggregate Base Course ............................................................................................. 12

2.2.5 Bituminous Pavement ................................................................................................. 13

2.3 PIPE CULVERT ................................................................................................................... 16

2.3.1 Foundation Prepration and Bedding ........................................................................ 16

2.3.2 Pipe Laying................................................................................................................... 16

2.3.3 Backfilling for Structures ............................................................................................ 16

2.4 ROAD LIGHTING AND ELECTRICAL INSTALLATION .............................................................. 17

2.4.1 Installation of Lighting Poles and Earthing .............................................................. 17

2.5 UTILITY WORK .................................................................................................................... 18

2.5.1 Sequence of Work Zones .......................................................................................... 18

2.6 SIDEWALKS ........................................................................................................................ 19

2.7 ROAD FURNITURE .............................................................................................................. 21

2.7.1 Road Marking............................................................................................................... 21

2.7.2 Road Signs ................................................................................................................... 22

2.8 SITE INSTALLATION AREA (OFFICE, STORAGE) .................................................................. 23

2.8.1 Labour Resources ....................................................................................................... 23

2.8.2 Equipment Resources ................................................................................................ 23

2.8.3 Material Procurement and Logistics ......................................................................... 23

2.9 SUBCONTRACTORS ........................................................................................................... 23

METHOD STATEMENT PAGE 2 of 23

Construction of Service Road (Extension)

at Showroom Zone in Duqm

1 GENERAL INFORMATION AND SCOPE

1.1 PROJECT LOCATION

METHOD STATEMENT PAGE 3 of 23

Construction of Service Road (Extension)

at Showroom Zone in Duqm

1.2 PROJECT DESCRIPTION

The project is in Governorate of Duqm of Al-Wusta Region. SEZAD has recently completed construc-

tion of a part of internal roads network at Airport Showroom Zone in Duqm. It is now intention of

the Client to extend the aforementioned road near SEZAD Headquarter in both directions

1.3 TIMELINE

The overall completion period is eight (8) months which includes mobilization period. The Period of

Commencement from the Engineer’s order to commence is thirty (30) days. The Period of Mainte-

nance is three hundred and sixty-five (365) days, or one (1) year.

1.4 SCOPE OF WORKS

The project consists of extension of newly constructed road R4A-1. The length of service road ex-

tension is 1.09 km on southern end and 1.77 km on northern end. The overall extended length of

the service road will be approx. 2.86 Km.

The project involves construction of two (2) roundabouts, each at start and end of project, one (1)

Floodway at station 3+700, drainage ditch, embankment protection along right side of the embank-

ment, and other protection works

■ Site clearance, including removal of existing structure wherever required

■ Removal of existing pavement wherever required

■ Earthwork (excavation and embankment)

■ Concrete construction for pipe culverts

■ Sub-grade preparation

■ Aggregate base course construction

■ Bituminous base course

■ Loose riprap works

■ Reinforced concrete slope protection

■ Sidewalk (precast curb and tile works)

■ Road Signs and Pavement Markings and Road studs

■ Road lighting works

METHOD STATEMENT PAGE 4 of 23

Construction of Service Road (Extension)

at Showroom Zone in Duqm

1.5 TYPICAL DRAWINGS

1.5.1 Site plan

1.5.2 ROADS CROSS SECTION

METHOD STATEMENT PAGE 5 of 23

Construction of Service Road (Extension)

at Showroom Zone in Duqm

1.5.3 ROUNDABOUT CROSS SECTION

METHOD STATEMENT PAGE 6 of 23

Construction of Service Road (Extension)

at Showroom Zone in Duqm

1.6 MAIN QUANTITIES

Activity Quantity UoM Remarks

Clearing and Grubbing 49,500 m2

Unclassified Excavation 15,000 m3

Borrow Excavation 73,500 m3

Subgrade Preparation in cut 10,000 m2

Aggregate Base Course 8,395 m3

Bituminous Base Course 2,516 m3

Pipe Culvert 100 Lin.m

Loose Riprap 2,700 m3

Precast Curb 15,900 Lin.m

Precast Concrete Block 11,652 m2

Reinforced Concrete Slope Protection 1,100 m3

Electrical Cables for Road Lighting 12,000 Lin.m

Road Lighting Luminaries & Columns 115 No.

METHOD STATEMENT PAGE 7 of 23

Construction of Service Road (Extension)

at Showroom Zone in Duqm

2 CONSTRUCTION STRATEGY AND METHODOLOGY

Construction will be managed by STRABAG and sub-contractors under STRABAG’s supervision.

2.1 SEQUENCING AND PLANNING, MATERIALS AND WORK

FRONTS

One important aim of sequencing is to provide as early as possible a parallel working space for po-

tential works.

Works will be organized as such that major activities are started immediately with the award of

contract.

The site activities sequence shown as:

METHOD STATEMENT PAGE 8 of 23

Construction of Service Road (Extension)

at Showroom Zone in Duqm

2.2 ROADWORKS METHODOLOGY

2.2.1 THE WORKFRONTS AND ASSUMED PRODUCTIVITIES

Description of Work Quantities Unit Teams/ Production/ Production/day

day Team

Clearing and Grubbing 49,500 m2 1 7,000 7,000

Unclassified Excavation 15,000 m3 1 1,000 1,000

Borrow Excavation 73,500 m3 1 1000 1000

Aggregate Base Course 8,385 m3 1 800 800

Bituminous Base Course 2,516 m3 1 350 350

2.2.2 EARTHWORKS

The key staff and equipment dedicated for proceeding these works will be as follows:

■ Site personnel

▪ Site supervisor-Responsible for this activity

▪ Earthwork foreman-Responsible for this activity

▪ Land surveyors-Responsible for boundary limits, level of excavation, thickness of layers of

subgrade, subbase etc.

▪ Chainman- Assist the surveyors

▪ Lab technician

▪ Laboratory assistant

▪ Operators/drivers-Operate the equipment

▪ Helpers- Assist the equipment operator

■ Survey instruments

▪ Total station

▪ GPS

▪ Auto level

■ Plant, Machinery and Vehicles

▪ Grader

▪ Wheel loader

▪ Excavators

▪ Tipper Trucks 10m³

▪ Tipper Trucks 18m³

▪ Compactors

▪ Vibratory Rollers 24 Tons

▪ Mobile crusher plant

▪ Water tankers

METHOD STATEMENT PAGE 9 of 23

Construction of Service Road (Extension)

at Showroom Zone in Duqm

2.2.2.1 SITE CLEARANCE

Before excavation, we will clear all work areas of rubbish, vegetation and unsuitable materials.

When clearing, the sequence of operations depends on the type of trees, the terrain, and planned

construction. After establishing the boundaries of the clearing, select spoil areas for disposal of all

cleared material based on the shortest haul, a downgrade slope, effective camouflage, and general

accessibility. Start clearing at the disposal area and move in each direction away from it. These ma-

terials will be loaded onto trucks by wheeled loaders and disposed at a location approved by the

Engineer.

2.2.2.2 EXCAVATION AND FILL

Excavation will be carried out by teams of wheel loader and excavators. The size of equipment will

be chosen by the Contractor to suit the ambient conditions.

2.2.2.2.1 Sources of Materials for embankment fill

STRABAG owns a quarry in Duqm which is located about 50 km from beginning of project.

There are private wells in the vicinity of the project site from where water for construction can be

obtained.

The working drawings for excavation will be submitted for approval for individual sites or each loca-

tion prior to start of the excavation. Referring to the approved construction drawings, the excava-

tion layout will be marked w.r.t. the grids and axis lines as the case may be as per the site condition.

■ All material transported to site will undergo a quality control verification process;

■ All materials transported away from the site will be accounted for with tally sheets;

■ If a material needs to be stockpiled it will be in the area where required and if not required it

will be moved offsite.

METHOD STATEMENT PAGE 10 of 23

Construction of Service Road (Extension)

at Showroom Zone in Duqm

2.2.2.3 DISPOSAL OF UNSUITABLE/SURPLUS MATERIAL

The Contractor will dispose unsuitable material to areas out of right of way on both sides of the

alignment, the possible disposal area is about 20 km away from the project .

2.2.3 SUBGRADE CONSTRUCTION

As per the QA/QC report of our laboratory, existing material after crushing and screening can be

used for the preparation of subgrade as it is suitable. It will be then watered to achieve the opti-

mum moisture content and compacted by using smooth vibrating rollers.

■ Wheel loaders and excavators will be used for excavation and graders prepare the embank-

ment layers and sub-grade.

METHOD STATEMENT PAGE 11 of 23

Construction of Service Road (Extension)

at Showroom Zone in Duqm

■ If top soil exists this will be cleaned and material will be scrapped away.

■ Prior to excavation adjacent to existing underground services, as built drawings will be made

in order to determine the exact location and for record of existing utilities.

■ Site testing of compaction will be to be carried as mentioned in the specifications.

■ Construction of the next course will only commence after the previous course has been ap-

proved by the Engineer.

2.2.4 AGGREGATE BASE COURSE

Equipment dedicated for proceeding these works will be as follows:

■ Finisher

■ Steel drum roller

■ Grader or Paver

We plan to deploy One (1) crew each having the productivity of 800-900 m3 per day

■ The layer will be compacted using 10-15 ton vibrating rollers.

■ Our standard work method for these works is to place the first layer using graders and placing

of second layer with a finisher. This method is adjusted to suit local conditions.

■ The site supervisor will be responsible for applying the required number of passes by equip-

ment for the compaction.

■ Materials is available from the proposed borrow pit locations.

METHOD STATEMENT PAGE 12 of 23

Construction of Service Road (Extension)

at Showroom Zone in Duqm

2.2.5 BITUMINOUS PAVEMENT

We will prepare asphalt mix designs before beginning the work. A copy of calibration certificates for

the batching plant, laboratory equipment and material test result will be provided.

We plan to deploy one (1) crew for asphalt each having the productivity of 350 m3 per day. We

have foreseen for setup our own asphalt plant on site.

The key staff and equipment dedicated for proceeding these works will be as follows:

■ Site personnel

▪ Site engineer-Responsible for these works

▪ Lab technician-Responsible for testing of asphalt

▪ Site supervisor

▪ Asphalt foreman

▪ Asphalt workers

▪ Helpers

▪ Land surveyors-Responsible for layout and thickness of pavement layers

▪ Chainman- Assist the surveyors

▪ Operators/drivers-Operate the equipment

▪ Helpers- Assist the equipment operator

▪ Asphalt plant operator

▪ Helpers asphalt plant

■ Survey instruments

▪ GPS

▪ Total station

▪ Auto level

■ Plant, Machinery and Vehicles

▪ Asphalt finisher

▪ Bitumen sprayer capacity 5000 liters or 8000 litres

▪ Trucks

METHOD STATEMENT PAGE 13 of 23

Construction of Service Road (Extension)

at Showroom Zone in Duqm

▪ Tandem Rollers e.g BW 161 AD, BW 174 AD4

▪ Pneumatic tyre rollers 218 Tons

▪ Asphalt plant

▪ Core cutters

■ Before laying of each course a notice will be given to the Engineer to inform about the coming

works.

2.2.5.1 BITUMINOUS PRIME COAT

After preparing the surface, the prime coat will be applied through bitumen distributors.

2.2.5.2 BITUMINOUS BASE COURSE

We plan to deploy one (1) crew for asphalt paving. Each paving crew will be assigned for asphalt

paving to achieve 400m3 per crew on average.

■ Each Civil Engineer will be responsible for construction of the bituminous base course in-

cluded in his Section under supervision of the Project Manager.

■ The bituminous Base Course will be laid through the paver.

■ The paving width will be determined depending on the total width of the road.

■ Asphalt base course will be transported to site by trucks.

■ The mix will be delivered to the site at temperature between 140 to 170 Celsius.

■ The trucks will be covered with tarpaulin to retain the temperature and prevent oxidation.

■ The compaction first pass by tandem roller without vibration and PTR will compact the mix

close to the paver.

■ During laying levels are checked to control the screed and if required, to adjust it.

■ During and after final rolling, the evenness, levels and thickness will be checked.

■ In case of longitudinal joints, old asphalt will be cut with a cutting wheel or a disk cutter.

Transverse joints are carried out by cutting with a jackhammer to achieve good bonding with

the existing pavement.

METHOD STATEMENT PAGE 14 of 23

Construction of Service Road (Extension)

at Showroom Zone in Duqm

■ Materials and work testing will be performed by the Lab technician in accordance with the

Standard Specifications for Road & Bridge Construction, June 2010 and the Special Specifica-

tion in the Site’s Laboratory.

METHOD STATEMENT PAGE 15 of 23

Construction of Service Road (Extension)

at Showroom Zone in Duqm

2.3 PIPE CULVERT

2.3.1 FOUNDATION PREPRATION AND BEDDING

Foundation will be most likely involved with excavation; the most important excavation limitations

are trench width and depth. As excavation progresses, trench grades should be continuously

checked against the elevations established in culvert profile.

After the foundation prepared, aggregate bedding material shall be laid to receive the pipe culvert.

Bedding thickness of no less than the specification. The width of the bedding material should equal

the width of the pipe (span plus twice the wall thickness) and the length of the bedding material

should equal the length of the pipe.

2.3.2 PIPE LAYING

Placement of pipe culvert should start at the outlet end of the line of pipe sections. The bell end

should point upstream and the spigot or tongue should point downstream. Unless otherwise ap-

proved by the engineer, loads from construction equipment transferred to a pipe section before,

during, or after fill placement, either directly or through the fill, should not be greater than the

loads assumed in the design.

2.3.3 BACKFILLING FOR STRUCTURES

Only selected granular material that will produce a stable, dense, backfill will be used for structure.

Transport of the material will be made by tipper trucks and placing by excavators, small sized wheel

loaders or by hand depending on the depth, location and quantity of fill to be placed.

Structure will not be subject to the pressure of backfilling until the strength of the concrete has

been achieved.

At pipe culverts and storm sewers the backfill will be completed around the culvert as specified

level of the original ground line.

METHOD STATEMENT PAGE 16 of 23

Construction of Service Road (Extension)

at Showroom Zone in Duqm

2.4 ROAD LIGHTING AND ELECTRICAL INSTALLATION

Street lighting involves the installation of lighting poles, lighting fixtures, relative cabling and the

earth bonding of the poles.

■ The street lighting works will be performed in conjunction with sub-contractors.

■ Material will be approved prior to ordering.

■ Street lighting poles will be as approved.

■ The height of the street lighting poles will be as per drawings.

■ The axis of each lighting pole will be located by co-ordinates.

2.4.1 INSTALLATION OF LIGHTING POLES AND EARTHING

■ The lighting poles will be installed by crane, including brackets, cut-outs, luminaire, flexible

cable and termination.

METHOD STATEMENT PAGE 17 of 23

Construction of Service Road (Extension)

at Showroom Zone in Duqm

2.5 UTILITY WORK

The work of this project features substantial amount of utility installations mentioned below.

■ Specialized works will be performed by qualified sub-contractors.

2.5.1 SEQUENCE OF WORK ZONES

The utility works will start first where no roadwork is foreseen and as soon as the material (pipes,

cable, ducts) has been approved and procured.

A technical report accompanied by drawing will recognize findings and difficulties encountered on

site. Photographs illustrating the progress and any problems encountered will be included in the

monthly report for the Employee’s reference and comments.

METHOD STATEMENT PAGE 18 of 23

Construction of Service Road (Extension)

at Showroom Zone in Duqm

The major activities to be adopted for these utilities works are following:

■ Pipe laying

■ Duct laying

■ cable laying

The pipe laying works, which we consider can be started even before subgrade construction

because in general the excavation depths for these pipe laying are below existing ground.

2.6 SIDEWALKS

The works for sidewalk interlocks and curb stones will be executed as per the approved drawings.

The key staff and equipment dedicated for proceeding these works will be as follows:

■ Site personnel

▪ Site supervisor-Responsible for these works

▪ Foremen

▪ Helpers

METHOD STATEMENT PAGE 19 of 23

Construction of Service Road (Extension)

at Showroom Zone in Duqm

▪ Land surveyors-Responsible for layout and levels

▪ Chainman- Assist the surveyors

▪ Operators/drivers-Operate the equipment

▪ Helpers- Assist the equipment operator

■ Survey instruments

▪ GPS

▪ Total station

▪ Auto level

▪ Measuring tape

▪ Straight edge

■ Plant, Machinery and Vehicles

▪ Mobile cranes 30 Tons

▪ Water tankers

▪ Trucks 25.5 Hp

▪ Plate compactors 70 kg

▪ Small wheel loader

■ Before execution of the work, testing for the quality and the size of material will be done.

■ All tests and results will be submitted to the Engineer for approval.

■ The material and the size of the interlock tiles and the curb stones will be as per the drawings

and standard specifications.

■ Execution will be done under the supervision of the responsible site engineer.

■ Proper compaction and preparation of the subgrade beneath the sidewalk is essential.

METHOD STATEMENT PAGE 20 of 23

Construction of Service Road (Extension)

at Showroom Zone in Duqm

2.7 ROAD FURNITURE

The key staff and equipment dedicated for proceeding these works will be as follows:

■ Site personnel

▪ Site engineer-Responsible for these works

▪ Road marking foremen

▪ Helpers

▪ Land surveyors-Responsible for setting out

▪ Chainman- Assist the surveyors

▪ Operators/drivers-Operate the equipment

▪ Helpers- Assist the equipment operator

■ Survey Instruments

▪ GPS

▪ Total station

■ Plant, Machinery and Vehicles

▪ Mobile crane 30 Tons

▪ Road marking machine

2.7.1 ROAD MARKING

■ After setting out of main axis, road marking will be done by our specific road marking unit as

per standards and specifications under the supervision of the responsible site engineer.

■ The material for the road marking will be approved by the Engineer.

METHOD STATEMENT PAGE 21 of 23

Construction of Service Road (Extension)

at Showroom Zone in Duqm

2.7.2 ROAD SIGNS

■ Before ordering the material, a sample will be provided to the Engineer to allow assessment

of the quality of material, size and type of the signs.

■ After the approval work will be executed.

METHOD STATEMENT PAGE 22 of 23

Construction of Service Road (Extension)

at Showroom Zone in Duqm

2.8 SITE INSTALLATION AREA (OFFICE, STORAGE)

The offices will be portable buildings of the Portacabin™ type or prefabricated buildings sandwich

panel type.

We foresee to use our existing camp at SIDRA Quarry approx. 50 km form the project location.

2.8.1 LABOUR RESOURCES

Our major works in Oman are in completion stage and we have enough resources available to con-

tinue utilizing our machinery and manpower for the this project.

As per our estimate we will require about 70 workers at peak.

2.8.2 EQUIPMENT RESOURCES

STRABAG Oman has successfully delivered projects all over the country for the last 45 years by uti-

lizing own and hired plant and equipment from the local market. In case the need arises STRABAG

can utilize resources from the affiliated companies of the Group in the region.

2.8.3 MATERIAL PROCUREMENT AND LOGISTICS

Water for the construction works will be obtained from public and private wells which are located

near the project location.

Other construction materials, as far available on the local market, will be procured locally; other-

wise they will be imported.

2.8.3.1 LOCALLY PROCURED MATERIALS

Locally procured materials will include ducts, pipes, and steel reinforcement. Further required for

material production are cement and bitumen.

2.8.3.2 IMPORTED MATERIALS

In case we should take over the supply of imported material from subcontractors, with the award of

contract Material Approval Sheet (MAS) will be submitted to Engineer and once approved, material

will be ordered accordingly so that there is no delay in construction.

2.9 SUBCONTRACTORS

Major subcontractors will be required for the following works:

■ Street light works

METHOD STATEMENT PAGE 23 of 23

Das könnte Ihnen auch gefallen

- Reference Guide Employer Incident Investigations rg5 PDF enDokument64 SeitenReference Guide Employer Incident Investigations rg5 PDF enAjiwuri100% (2)

- BAPCO Question Interview QC - 2021Dokument10 SeitenBAPCO Question Interview QC - 2021Fuzail AyazNoch keine Bewertungen

- InvDokument11 SeitenInvKannan JaganNoch keine Bewertungen

- Air India Web Booking Eticket (HR6C8) - AyazDokument2 SeitenAir India Web Booking Eticket (HR6C8) - AyazFuzail AyazNoch keine Bewertungen

- Gdit 2Dokument1 SeiteGdit 2Fuzail AyazNoch keine Bewertungen

- Reservation 264 Mr. Fuzail AyazDokument1 SeiteReservation 264 Mr. Fuzail AyazFuzail AyazNoch keine Bewertungen

- Health and SafetyDokument1 SeiteHealth and SafetyFuzail AyazNoch keine Bewertungen

- Hydrogen Sulfide (H S) : 1. Purpose 2. ScopeDokument5 SeitenHydrogen Sulfide (H S) : 1. Purpose 2. ScopemuralisunNoch keine Bewertungen

- Icmr Specimen Referral Form For Covid-19 (Sars-Cov2) : (These Fields To Be Filled For All Patients Including Foreigners)Dokument2 SeitenIcmr Specimen Referral Form For Covid-19 (Sars-Cov2) : (These Fields To Be Filled For All Patients Including Foreigners)Fuzail AyazNoch keine Bewertungen

- List of Elements of HSE PlanDokument3 SeitenList of Elements of HSE PlanSRIRAM D100% (1)

- HCF List List of Approved Quarantine FacilitiesDokument6 SeitenHCF List List of Approved Quarantine FacilitiesFuzail AyazNoch keine Bewertungen

- Strabag-Resume Fuzail HseDokument3 SeitenStrabag-Resume Fuzail HseFuzail AyazNoch keine Bewertungen

- Icmr Specimen Referral Form For Covid-19 (Sars-Cov2) : (These Fields To Be Filled For All Patients Including Foreigners)Dokument2 SeitenIcmr Specimen Referral Form For Covid-19 (Sars-Cov2) : (These Fields To Be Filled For All Patients Including Foreigners)Fuzail AyazNoch keine Bewertungen

- Fuzail Ayaz Gamca ReportDokument1 SeiteFuzail Ayaz Gamca ReportFuzail AyazNoch keine Bewertungen

- Hyd Sulf-World Health OrgDokument41 SeitenHyd Sulf-World Health OrgjoebaffaNoch keine Bewertungen

- Hydrogen Sulfide (H S) : 1. Purpose 2. ScopeDokument5 SeitenHydrogen Sulfide (H S) : 1. Purpose 2. ScopemuralisunNoch keine Bewertungen

- EP India RequirementsDokument1 SeiteEP India RequirementsFuzail AyazNoch keine Bewertungen

- All Products at A GlanceDokument3 SeitenAll Products at A GlanceFuzail AyazNoch keine Bewertungen

- Emergency Number During Eid HolidaysDokument1 SeiteEmergency Number During Eid HolidaysFuzail AyazNoch keine Bewertungen

- Dräger PARAT 3200 Filtering Escape Device: Traction Grip AreaDokument6 SeitenDräger PARAT 3200 Filtering Escape Device: Traction Grip AreaFuzail AyazNoch keine Bewertungen

- 30 Minutes... To Get Your Own WayDokument60 Seiten30 Minutes... To Get Your Own WayGregório Silva NetoNoch keine Bewertungen

- AnswersDokument12 SeitenAnswersRaluca Dragomir100% (1)

- Personal Details: University & Professional Exams Entry FormDokument3 SeitenPersonal Details: University & Professional Exams Entry FormFuzail AyazNoch keine Bewertungen

- Health Safety and Environment Plan: Disposal Record of Construction Waste MaterialsDokument1 SeiteHealth Safety and Environment Plan: Disposal Record of Construction Waste MaterialsFuzail AyazNoch keine Bewertungen

- A Conversation Book 2 - English in Everyday Life, Book 2 (PDFDrive) PDFDokument30 SeitenA Conversation Book 2 - English in Everyday Life, Book 2 (PDFDrive) PDFFuzail Ayaz0% (1)

- Proefexamen Basisveiligheid VCADokument11 SeitenProefexamen Basisveiligheid VCASatayish Anjum100% (1)

- Sr. Nos. Inspection Items Yes No N/A: / HireDokument1 SeiteSr. Nos. Inspection Items Yes No N/A: / HireFuzail AyazNoch keine Bewertungen

- INSP1 MobileCraneDailyInspectionDokument1 SeiteINSP1 MobileCraneDailyInspectionFuzail Ayaz100% (1)

- Faqs - Iso 45001 Occupational Health & Safety Management SystemDokument3 SeitenFaqs - Iso 45001 Occupational Health & Safety Management SystemTatiana RiloNoch keine Bewertungen

- Encouraging Owner/Client Involvement: How To Become ExemplaryDokument2 SeitenEncouraging Owner/Client Involvement: How To Become ExemplaryFuzail AyazNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Building ConstructionDokument146 SeitenBuilding ConstructionArunKumar Chandrasekar100% (1)

- Engg 135 Design of Reinforced Concrete Structures: Bond and Bar Development Reading: Wight and Macgregor Chapter 8Dokument24 SeitenEngg 135 Design of Reinforced Concrete Structures: Bond and Bar Development Reading: Wight and Macgregor Chapter 8Manuel MirandaNoch keine Bewertungen

- Product Data Sheet - Gyproc FirelineDokument3 SeitenProduct Data Sheet - Gyproc FirelineSugumarNoch keine Bewertungen

- Pages From SAES-H-001-3Dokument1 SeitePages From SAES-H-001-3mohammed s fawabNoch keine Bewertungen

- Semester V Course No. Course Name L-T-P/S Credits Year of Introduction AR 17-55 Design of Structures - I 2-1-0 3 2017 Course ObjectivesDokument2 SeitenSemester V Course No. Course Name L-T-P/S Credits Year of Introduction AR 17-55 Design of Structures - I 2-1-0 3 2017 Course ObjectivesSuraj KumarNoch keine Bewertungen

- Case StudyDokument2 SeitenCase Studysakshi meherNoch keine Bewertungen

- REPORT On Building ConstructionDokument55 SeitenREPORT On Building ConstructionVikas Verma83% (6)

- SD - Folded Plate Structures - V1Dokument46 SeitenSD - Folded Plate Structures - V1Vedasri Racha100% (1)

- Computation D&T FormatDokument3 SeitenComputation D&T FormatSHAINE MAIKU GELERANoch keine Bewertungen

- Corle Architect ManualDokument81 SeitenCorle Architect Manualw_christopher_miller@gmail_comNoch keine Bewertungen

- ITB-2018-3561 - Annex F - Lot 1 Structural Designs and Drawings MOHDokument5 SeitenITB-2018-3561 - Annex F - Lot 1 Structural Designs and Drawings MOHhassan amiriNoch keine Bewertungen

- Equity Trading Fundamentals - Full CourseDokument26 SeitenEquity Trading Fundamentals - Full CourseKayerinna PardosiNoch keine Bewertungen

- Rough CostDokument1 SeiteRough CostKannanNoch keine Bewertungen

- Introduction:: Report On FormworkDokument7 SeitenIntroduction:: Report On FormworkMd Minaz HossainNoch keine Bewertungen

- Tutorial IIDokument2 SeitenTutorial IIBro PatilNoch keine Bewertungen

- Productivity: Prof. Dr. Md. Mamun HabibDokument11 SeitenProductivity: Prof. Dr. Md. Mamun HabibKhaled Shams AkashNoch keine Bewertungen

- Methods of Analysis and Design of Boxbeams - Maisall, RollDokument2 SeitenMethods of Analysis and Design of Boxbeams - Maisall, RollkolnabNoch keine Bewertungen

- 7369 Val Utl CR Pyramax Cs SCRDokument2 Seiten7369 Val Utl CR Pyramax Cs SCRIrfan YogaNoch keine Bewertungen

- Mecton Material Submission R3Dokument22 SeitenMecton Material Submission R3nokia6Noch keine Bewertungen

- Lec 01 - Steel and Introduction To AISC Steel ManualDokument26 SeitenLec 01 - Steel and Introduction To AISC Steel ManualbilalNoch keine Bewertungen

- Uzin Geo Final 180619 PDFDokument3 SeitenUzin Geo Final 180619 PDFDylan CazemierNoch keine Bewertungen

- Fencing Permit: Office of The Building OfficialDokument2 SeitenFencing Permit: Office of The Building OfficialJc Jüsäyän50% (2)

- Feasibility Study On Application of Ready Mix Concrete in Construction Projects in NepalDokument8 SeitenFeasibility Study On Application of Ready Mix Concrete in Construction Projects in NepalAtul JaiswalNoch keine Bewertungen

- National Institute of Technology, Patna: Submitted To:-Submitted ByDokument57 SeitenNational Institute of Technology, Patna: Submitted To:-Submitted ByVipul MishraNoch keine Bewertungen

- A Comparative Study of BNBC 1993 and 2017 Provisions For The Design of Multistoried Steel Buildings in High Wind and High Seismic ZoneDokument7 SeitenA Comparative Study of BNBC 1993 and 2017 Provisions For The Design of Multistoried Steel Buildings in High Wind and High Seismic ZoneTahmidur RahmanNoch keine Bewertungen

- Brief Presentation FOR MARAFIQ CONTRACT#7200040904: Project TitleDokument19 SeitenBrief Presentation FOR MARAFIQ CONTRACT#7200040904: Project TitleDanish HamidNoch keine Bewertungen

- Presentation - QUALITY (SCHEDULE 'Q' REQUIREMENTS)Dokument55 SeitenPresentation - QUALITY (SCHEDULE 'Q' REQUIREMENTS)kbldamNoch keine Bewertungen

- FW - 12.5mm Gypsum Board: Description Technical Data Physical PropertiesDokument2 SeitenFW - 12.5mm Gypsum Board: Description Technical Data Physical PropertiesRaghad GNoch keine Bewertungen

- Standards of Expansion Joint Manufacturers Association 9h PDFDokument239 SeitenStandards of Expansion Joint Manufacturers Association 9h PDFvmonrroy745050% (2)

- ABTS FINAL 4th Yr SppuDokument44 SeitenABTS FINAL 4th Yr Spputejas kaleNoch keine Bewertungen