Beruflich Dokumente

Kultur Dokumente

Ar 250

Hochgeladen von

Yoo KyungsikOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ar 250

Hochgeladen von

Yoo KyungsikCopyright:

Verfügbare Formate

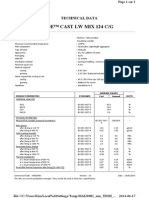

AR250-002

Okitsumo

Heat-and Acid-Resistant Paint

AR-250 date created:2012.02.03

date revised:2013.06.25

1.Application

・Inside of chimney flue

・Dust collector

2.Characteristics 3.Coating standard

Item Content Item Content

Appropriate Substrate Iron

Appearance 2 liquid type

SSPC-SP5,SSPC-SP10,SSPC-SP8,

SIS Sa3,SIS Sa2 1/2

Type of packing 4Kg set, 16Kg set Pre-treatment

(Remove the rust, old coated film, oil and water stain

(Base:Hardener=96:4) completely until the base metal is exposed.)

Color Gray Paint Preparation

Mix the hardener(Liquid part A:Hardener=96:4)

well before use, desperse uniformly

Luster Semi-gloss Potlife 4Hrs

Diluent No.50B thinner, No.100B thinner

Density(23℃) Base : 1.58±0.08 g/ml Coverage 650g/m2 840g/m2

Hardener: 0.75±0.08 g/ml Coating method Brush coating Air-less coating

Coating method

Viscosity(23℃) Liquid part A Dilution 10~15wt% 10~30wt%

BM-type viscomater 6/6

30,000mPa・s Passes to

4 pass 3 pass

spray or brush

Nonvolatile Liquid part A:76.0±2.0% Dry Film Thickness 250μ m

content

Flash point Liquid part A:11℃ Ex. Of airless coating Nozzle No:07C09(ASAHI SANAC)

Hardener:10℃ condition Pressure:8~10MPa(secondary pressure)

Ignition point Liauid part A:480℃(toluene) Temp. 5℃ 20℃ 30℃

Hardener:480℃(toluene) Drying to touch 4Hrs 2Hrs 2Hrs

to handle 24Hrs 16Hrs 16Hrs

Shelf life 6 months Note ・Depend on the air temperature or indivisual condition,

the coverage may be chagened.

・The film thickness mentioned above is supposion.

Danger sign Liauid part A: ・Regardint to the detail of specification, please refer to the

Class4 grade2 petroleum enforcement spec.

Hardener:

Class4 grade2 petroleum 4.Precautions

1) Use after mixing well until no lumps of the solids remain.

Division Liauid part A: 2) Paint after removing oil, moisture, dust on the surface.

of organic TypeⅡ organic solvent 3) Do not paint under the condition mentioned below.

Hardener: ①The day of rain and snow.

solvent TypeⅡ organic solvent ②When the air temperaure is under 5℃

③When the difference between air temp. and the

Toxic substance Liauid part A: dew point is within 3℃.

xylene ④When the relative humidity is over 85%.

ethyl benzene ⑤The day of gale.

toluene 4) Drying at room temp. only makes the paint film dried to touch.

ethylene glycol monoethyl- To cure the paint it requires baking at 180℃ for 20mins.

ether acetate 5) The coated film might become adherent temporarily and emit the smoke

when the painted machine starts up for the first time.

Hardener: But it will eventually stop smoking and soon be hardened.

toluene 6) Ensure to use the paint within the potlife after adding the hardner.

7) Regarding the general precautions for handling or others,

Note:The value mentioned above shows the standard please refer to MSDS.

and ther are some fluctuation.

Okitsumo Incorporated 1109-7 Shibade Kuramochi-cho, Nabari-city Mie 5180751 Japan

Tel:+81-595-644124 Fax:+81-595-641289

Das könnte Ihnen auch gefallen

- Tds DNT Eponics #90uc-RDokument1 SeiteTds DNT Eponics #90uc-RDocholosoNoch keine Bewertungen

- Epilux 200 Polyamide Cured Coaltar EpoxyDokument3 SeitenEpilux 200 Polyamide Cured Coaltar EpoxyIqra AngelsNoch keine Bewertungen

- 323+ Data SheetDokument5 Seiten323+ Data SheetSergioNoch keine Bewertungen

- Product Data Sheet: Topaz Matt Emulsion 588MEDokument2 SeitenProduct Data Sheet: Topaz Matt Emulsion 588MEJoseph DarwinNoch keine Bewertungen

- Pds Zincanode 690 VocDokument2 SeitenPds Zincanode 690 VocmuthukumarNoch keine Bewertungen

- 3500-00 Simathane GlossDokument3 Seiten3500-00 Simathane GlossSAEFUDDIN SAEFUDDINNoch keine Bewertungen

- TDS Zinc Rich Primer STDokument4 SeitenTDS Zinc Rich Primer STBadar MinhasNoch keine Bewertungen

- PDS Poweroil RP HPDokument2 SeitenPDS Poweroil RP HPNitant MahindruNoch keine Bewertungen

- TDS RovalDokument4 SeitenTDS RovalSyahril Fira86Noch keine Bewertungen

- Carbozinc 858 (3K)Dokument4 SeitenCarbozinc 858 (3K)DuongthithuydungNoch keine Bewertungen

- Epimastic 7200 SRDokument2 SeitenEpimastic 7200 SRqc_531040655Noch keine Bewertungen

- En GBDokument4 SeitenEn GBNithin MathaiNoch keine Bewertungen

- 3500-00 Simathane Gloss (Finish Coat)Dokument3 Seiten3500-00 Simathane Gloss (Finish Coat)Hendri Dwi cahyonoNoch keine Bewertungen

- Hempadur Zinc 17360Dokument4 SeitenHempadur Zinc 17360Noman AhmedNoch keine Bewertungen

- EPD 100 Plascotuff Epoxy Coal TarDokument2 SeitenEPD 100 Plascotuff Epoxy Coal TarAdhil RamsurupNoch keine Bewertungen

- Carboguard 880 MIO PDSDokument4 SeitenCarboguard 880 MIO PDSHerman EngelbrechtNoch keine Bewertungen

- Simathane Gloss: Product Data SheetDokument3 SeitenSimathane Gloss: Product Data SheetAkmal100% (1)

- 2401-00 Simacover EP UnicoatDokument3 Seiten2401-00 Simacover EP UnicoatSAEFUDDIN SAEFUDDINNoch keine Bewertungen

- Pds Zincanode 620 VocDokument2 SeitenPds Zincanode 620 VocmuthukumarNoch keine Bewertungen

- Kenoji Primer 59Dokument3 SeitenKenoji Primer 59erwin dimas jayaNoch keine Bewertungen

- MyPDF PDFDokument2 SeitenMyPDF PDFjeielblNoch keine Bewertungen

- Epilux 58 M.I.O.: Product DescriptionDokument2 SeitenEpilux 58 M.I.O.: Product DescriptionMoin AltafNoch keine Bewertungen

- Technical Data Sheet: Product NameDokument3 SeitenTechnical Data Sheet: Product NameAndres DelaCruzNoch keine Bewertungen

- PDS Poweroil RP CRDokument2 SeitenPDS Poweroil RP CRNitant MahindruNoch keine Bewertungen

- 1402-00 Simazinc EP PrimerDokument2 Seiten1402-00 Simazinc EP PrimerMuhammad Mulya JatiNoch keine Bewertungen

- Epimastic 4100Dokument2 SeitenEpimastic 4100Moin AltafNoch keine Bewertungen

- Product Data Sheet: Simathane GlossDokument3 SeitenProduct Data Sheet: Simathane GlossAdnan FrrNoch keine Bewertungen

- Epilux 5: Product DescriptionDokument2 SeitenEpilux 5: Product DescriptionShyam ShrishNoch keine Bewertungen

- Zincanode 620 Voc v1 Jan 2018Dokument2 SeitenZincanode 620 Voc v1 Jan 2018Moin AltafNoch keine Bewertungen

- Epilux 800Dokument2 SeitenEpilux 800anandNoch keine Bewertungen

- Acothane Spray Grade 0117Dokument2 SeitenAcothane Spray Grade 0117gregNoch keine Bewertungen

- SDZA01Dokument2 SeitenSDZA01Faisal FaizNoch keine Bewertungen

- Carboweld 11P PDSDokument4 SeitenCarboweld 11P PDS이선엽Noch keine Bewertungen

- Thor ZcepDokument2 SeitenThor Zcepazam RazzaqNoch keine Bewertungen

- Condaform 3442 E - LM - 1209 - 0Dokument1 SeiteCondaform 3442 E - LM - 1209 - 0tribolas100% (1)

- Pds Topaz WB Primer 283me En-GbDokument2 SeitenPds Topaz WB Primer 283me En-GbDipin Nediya ParambathNoch keine Bewertungen

- Carbozinc 858: Selection & Specification DataDokument4 SeitenCarbozinc 858: Selection & Specification DataNico RoisnerNoch keine Bewertungen

- Epilux 155Dokument2 SeitenEpilux 155Allana100% (1)

- Chemflake SpecialDokument5 SeitenChemflake SpecialBiju_PottayilNoch keine Bewertungen

- TDS Simacover EP Buildcoat (Intermediate)Dokument2 SeitenTDS Simacover EP Buildcoat (Intermediate)rrahardiandiasNoch keine Bewertungen

- PDS HEMPATHANE SPEED-DRY TOPCOAT 250 en-GBDokument2 SeitenPDS HEMPATHANE SPEED-DRY TOPCOAT 250 en-GBEli KhawNoch keine Bewertungen

- NP ArocoatDokument4 SeitenNP ArocoatJohn HaNoch keine Bewertungen

- Thermoplastic Road Marking Paint: Product Code: TTP 1 & TTP 2Dokument3 SeitenThermoplastic Road Marking Paint: Product Code: TTP 1 & TTP 2Veera PandiNoch keine Bewertungen

- Epimastic 5200: Product DescriptionDokument2 SeitenEpimastic 5200: Product DescriptionsreeNoch keine Bewertungen

- Phenolic Epoxy PrimerDokument3 SeitenPhenolic Epoxy PrimerSameer HyderNoch keine Bewertungen

- Rust O Cap PDFDokument1 SeiteRust O Cap PDFTitus PraveenNoch keine Bewertungen

- Carbozinc 858 PDSDokument4 SeitenCarbozinc 858 PDShuycongvuNoch keine Bewertungen

- Maestro WB Primer 28830 28830 En-GbDokument2 SeitenMaestro WB Primer 28830 28830 En-GbMohamed NouzerNoch keine Bewertungen

- PDS Adgreencoat GPσ 009Dokument1 SeitePDS Adgreencoat GPσ 009Dante KindeverNoch keine Bewertungen

- Muki Z 2001: Technical Data SheetDokument5 SeitenMuki Z 2001: Technical Data SheetIan PerdanaNoch keine Bewertungen

- DN Super Screw SeriesDokument1 SeiteDN Super Screw SeriesSadid ShahzadNoch keine Bewertungen

- Zinc Clad II (85) : Inorganic Zinc Rich CoatingDokument2 SeitenZinc Clad II (85) : Inorganic Zinc Rich CoatingANA CABRERANoch keine Bewertungen

- Hempadur Primer 1530yDokument4 SeitenHempadur Primer 1530yRodrigo CondorettyNoch keine Bewertungen

- Bar-Rust 231LV Surface Tolerant EpoxyDokument4 SeitenBar-Rust 231LV Surface Tolerant EpoxyAhmed IbrahimNoch keine Bewertungen

- 2100 Lzi Primer PDFDokument1 Seite2100 Lzi Primer PDFphillipskincaidNoch keine Bewertungen

- Jotamastic 87 MIO50Dokument5 SeitenJotamastic 87 MIO50Biju_PottayilNoch keine Bewertungen

- Pds Maestro Matt Emulsion 594me En-GbDokument2 SeitenPds Maestro Matt Emulsion 594me En-GbDipin Nediya Parambath0% (1)

- Elastomers and Rubber Compounding MaterialsVon EverandElastomers and Rubber Compounding MaterialsI FrantaBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Greenlite 23 Li Plus DsDokument2 SeitenGreenlite 23 Li Plus DsYoo KyungsikNoch keine Bewertungen

- Greenlite 23 Li G On-Line: Product DataDokument2 SeitenGreenlite 23 Li G On-Line: Product DataYoo KyungsikNoch keine Bewertungen

- Morgan Advanced Materials Thermal Ceramics Product Data Book e Version 2Dokument148 SeitenMorgan Advanced Materials Thermal Ceramics Product Data Book e Version 2Muhammad SalmanNoch keine Bewertungen

- Greenkleen - 60 PLUS: Product DataDokument2 SeitenGreenkleen - 60 PLUS: Product DataYoo KyungsikNoch keine Bewertungen

- Calde™ Gun M 60Dokument1 SeiteCalde™ Gun M 60Yoo Kyungsik100% (1)

- Fiberfrax HT Mastics ENDokument2 SeitenFiberfrax HT Mastics ENYoo KyungsikNoch keine Bewertungen

- RATHDokument12 SeitenRATHYoo KyungsikNoch keine Bewertungen

- Calde Cast LW Mix 124 CG (V13)Dokument1 SeiteCalde Cast LW Mix 124 CG (V13)Yoo Kyungsik100% (1)