Beruflich Dokumente

Kultur Dokumente

The Electrodeposition of Ternary Fe-Cr-Ni Alloys

Hochgeladen von

Mariianiita SalvatoreOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

The Electrodeposition of Ternary Fe-Cr-Ni Alloys

Hochgeladen von

Mariianiita SalvatoreCopyright:

Verfügbare Formate

Electrodeposition and Surface Treatment 367

Elsevier Sequoia S.A., Lausanne - Printed in Switzerland

T H E E L E C T R O D E P O S I T I O N OF T E R N A R Y I R O N - C H R O M I U M - N I C K E L

A L L O Y S - - A C R I T I C A L REVIEW

C. U. CHISHOLM

School of Mechanical Engineering, Robert Gordon's Institute of Technology, Aberdeen (Gt. Britain)

and R. J. G. CARNEGIE

Department of Mechanical and Production Engineering, Dundee College of Technology, Dundee

(Gt. Britain)

(Received December 17, 1972)

SUMMARY*

The potential properties of thin and thick deposits of nickel-chromium-

iron alloys are discussed. Codeposition from the baths investigated is reviewed and

results compared. The role of addition agents in the various baths is considered in

relation to deposit composition and quality. It is shown that thickness is the critical

limiting factor in all baths. The review shows that alloy compositions over a large

range are possible from the main baths. Corrosion resistance, microhardness and

structure of the more successful alloys are examined. The various deposition

mechanisms are investigated and it is shown that films on the cathode represent

the main mechanism. It is shown that the limiting factor in all baths is failure to

sustain deposition, which is associated with deterioration of deposits owing to

internal stresses and absorption/adsorption of gases. The thin alloys obtained from

the baths reviewed, in some cases, could be of considerable industrial value, but

require further development studies.

INTRODUCTION

In this highly advanced technological age, man is continually striving to

extend the frontiers of science. One major area of activity has been the development

of new materials, particularly alloys, with superior properties and better perfor-

mances than existing materials, to meet the demands of modern technology. In

particular, the development of electrodeposited alloy coatings is of great practical

interest in decorative, protective and engineering applications, mainly from the

point of view of providing an economical alternative to thermally produced wrought

and cast alloys.

This paper deals with attempts to obtain electrodeposits of ternary F e - C r -

* R6sum6 en fran~;ais b. la fin de l'article. Deutsche Zusammenfassung am SchluB des Artikels.

Electrodepos. Surface Treat., 1 (1972/73)

368 c . u . CHISHOLM,R. J. G. CARNEGIE

Ni alloys. These alloys in the wrought and cast form, in particular the stainless and

heat-resisting steels, are well recognised for the diverse combination of physical,

chemical and mechanical properties which they possess. It is quite feasible that

electrodeposited coatings of these alloys would offer similar and possibly improved

properties.

However, it is evident from a survey of previous research that the main

effort has been directed towards the production of alloy deposits having a composi-

tion approaching that of the classic highly corrosion resistant 18/8 Cr-Ni stainless

steels to the complete exclusion of other important classes of Fe-Cr-Ni alloys,

which possess other important properties such as scaling resistance and high

mechanical strength at elevated temperatures and could possibly find a wider range

of applications than the 18/8 Cr-Ni composition. In this paper, it is intended to

consider the full range of Fe-Cr-Ni alloys deposited and to critically assess the

potential value of the deposits obtained. The cast and wrought Fe-Cr-Ni alloys

can be classified accordingly to three basic groups:

1. Fe-rich alloys

This is the most important group and has two main sub-divisions, the austeni-

tic stainless and heat-resisting steels. The former contain 10-30~ Cr and 7-25%

Ni and include the widely used 300 series of austenitic stainless steels including the

basic 18/8 Cr-Ni grade. Their main attribute is their excellent corrosion resistance

in a wide variety of chemical media at room or moderate temperatures, up to

approximately 300°C. They have good mechanical and physical properties, such

as high strength and ductility, exellent wear resistance and hardness, high impact

strength, high electrical resistivity, fairly high reflectivity and possibly favourable

magnetic properties. The stainless steels find extensive applications including

corrosive service in chemical processing equipment, the food industry, the pressure

vessel industry, general engineering and the aircraft industry.

The heat resisting steels have as their most important properties high scaling

or corrosion resistance in gaseous or liquid media, either oxidising or reducing,

combined in many cases with high creep resistance at elevated temperatures in the

range 500-600 ° C. Their mechanical and physical properties are similar to those of

the stainless steels and in general these are retained to a considerable degree at high

temperatures. These steels cover a wide range of compositions, generally containing

approximately 5-30~o Cr and 7-35% Ni.

2. Cr-rich alloys

These constitute alloys with a Cr content of greater than 60~o and they

possess properties comparable with those of pure Cr. They may possibly have

improved properties over those of Cr since it is recognised that alloys usually

possess superior properties to those of the individual constituent metals owing to

favourable changes in structure. These alloys are still adequate to withstand fairly

Electrodepos. Surface Treat., 1 (1972/73)

ELECTRODEPOSITION OF F e - C r - N i ALLOYS 369

severe service conditions and find similar applications up to moderate temperatures

of 300 ° C.

3. Ni-rich alloys

The most important group of these alloys is that of the heat-resisting alloys

which contain 35-80 % Ni, 10-20 % Cr, remainder Fe. They are important because

of their superior scaling and creep resistances over the Fe-rich steels with lower Ni

contents. Their remaining mechanical and physical properties are basically equiva-

lent to those of the Cr-Ni steels, hence their applications are similar but with the

additional advantage of even higher temperature service.

The major limitation of all the above alloys in the cast or wrought iron form

is their high cost. Thus it would be highly desirable to deposit thin alloy coatings

on a cheap substrate to impart their favourable properties to the base metal and,

in so doing, provide an economical substitute for the cast and wrought alloys

without prejudice to the functional advantages.

It is interesting to note that in the absence of carbon, these electrodeposited

alloys are not expected to have an austenitic structure similar to the thermally

produced cast and wrought alloys since the austenite-stabilising action of the car-

bon would be missing. Instead a ferritic structure is anticipated, which would be

highly ferromagnetic.

Therefore such alloy deposits could have excellent potential as thin films

for use in the electronics industry for such applications as data storage in computer

memories and magnetic tapes for sound recording. The cast and wrought alloys

could not be used for such thin film applications.

Another benefit to be accrued from the absence of carbon in the alloy

deposits is the prevention of sensitisation to intergranular corrosion associated

with the austenitic steels and caused by carbide participation at and in the neigh-

bourhood of grain boundaries.

One other imt~ortant facet of the establishment of Fe-Cr-Ni codeposition

could be a single-stage plating process which would obviate the need for the two-

stage 'duplex' nickel/chromium process used at present. In addition, the mecha-

nism of deposition may be changed by such a process so that the occurrence of

cracking, associated with high internal stresses in chromium deposits, would be

prevented. Higher current densities and cathode efficiencies than those realised in

Cr deposition might also be possible.

This paper reviews and discusses previous experimental work relating to the

electrodeposition of ternary Fe-Cr-Ni alloys from aqueous electrolytes.

REVIEW

The electrodeposition of ternary Fe-Cr-Ni alloys has been reported in

reviews on Cr alloy deposition by Levy1, Spencer 2 and Brenner a. It has also been

Electrodepos. Surface Treat., 1 (1972/73)

370 c. u. CHISHOLM, R. J. G. CARNEGIE

m e n t i o n e d in general reviews on alloy deposition and electrodeposition by Saro-

j a m m a and R a m a C h a r 4, R a m a C h a r s, and K r o h n and Bohn 8. M o r e recently, a

paper by S a r o j a m m a and R a m a C h a r 7 has appeared, reviewing the electrodeposi-

tion o f 18-8 C r - N i stainless steel.

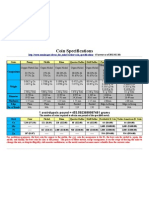

A s u m m a r y o f baths used by previous investigators is shown in Table 1, with

the o p t i m u m results obtained.

TABLE 1

THE MAJOR PLATING BATHS INVESTIGATED TO OBTAIN IRON--CHROMIUM--NICKEL ALLOY DEPOSITION

Investigators Ref. Electrolyte Operating Results

composition (g/I) conditions

Lainer and 8 Not specified. Not specified Nickel-based alloy

Kudryavtsev Based on green deposits; no informa-

modification of chro- tion on composition

mium sulphate

Kalocsay 9 Not specified. 4 Volts; 3.5 A/dm2; Stainless iron alloy

Includes addition soluble stainless iron deposits; composition

agents, in particular alloy or steel anodes not specified

citric acid

Skalozubov and 10 Chromic acid 250; 50 A/dm2; Range of alloy

Goncharova nickel sulphate 250; 60° C deposits:

ferrous sulphate 175; 44-57 ~o Ni;

boric acid 25 2 8 ~ 7 ~ Cr;

10-14~o Fe.

Poor quality plate

Brenner, 11 Not specified. Not specified. Alloy deposits. No

Burkhardt and Based on chromic Lead anodes; information on actual

Jennings acid. Ni and Fe copper deposit compositions

introduced mainly cathodes but deposits con-

in the form tained mainly Cr with

of metal very small percentages

dichromates of Ni and Fe present as

basic inclusions rather

than free metals

Machu and 12, Chromic sulphate 9-30 A/dm 2; Alloy deposits with

E1-Ghandour 13 (violet modification) 30-80 ° C; range of compositions.

265; nickel sulphate pH 2.1-2.4; 1 2 7 ~ Cr; 4 2 9 ~ Ni;

112, ferrous insoluble platinum 69-74~ Fe; including

sulphate 56; anodes; various compositions approxi-

boric acid 25; cathodes: copper, mating to 18/8 Cr-Ni

urea 180 brass, nickel, stainless steel. Good

zinc, aluminium and quality deposits up

iron to 6/~m thick

Electrodepos. Surface Treat., 1 (1972/73)

ELECTRODEPOSITION OF Fe-Cr-Ni ALLOYS 371

Table 1 (continued)

Investigators Ref. Electrolyte Operating Results

composition (g/I) conditions

Kalyuzhnaya 18 Chromium potassium (a) 15-16 A/dm2; Alloy deposits over

and alum (violet modifi- 25°C; range of composi-

Pimenova cation) 400; (b) 18-20 A/dm2; tions: 19-40~ Cr;

nickel sulphate 56; 40°C; 6 - 7 ~ Ni; 52-72~ Fe;

ferrous ammonium pH 1.6-1.8; including compositions

sulphate 39; soluble Cr 18 ~, approaching 18/8

trisubstituted sodium Ni 9 %, Ti steel Cr-Ni steel. Good

citrate 70; sodium anodes; copper and quality plate up to

fluoride 8 iron cathodes 6 #m thick

Ray and 25 Chromium sulphate 21-29 A/dm2; Alloy deposits.

Banerjee (green variety) 250; 40-58°C; Range of composi-

nickel sulphate pH 1.3-1.4; tions: 6-24% Cr;

50-120; soluble stainless 6-21 ~ Ni;

ferrous sulphate 30; steel anodes; 67-89~ Fe; including

disodium salt of brass cathodes compositions close to

EDTA 50-100; that of 18/8

boric acid 25-35 stainless steel

Takahashi, 26 Chromium trichloride 10-30 A/dm2; Alloy deposits.

Sugiyama and (green form) 133; 20-30°C; pH 2.0; Composition range:

Hayakawa nickel chloride insoluble platinum 7-25~ Cr; 5-30~ Ni;

24-71 ; ferrous anodes; copper and 63-70~ Fe. Good

chloride 20~0; nickel plated quality plate up

ammonium copper cathodes to 10~m thick

chloride 200

Mutafchiev 28 Chromic sulphate 5-60 A/dm2; Alloy deposits of

and 240-260; nickel 20-60 ° C; composition:

Marinkov sulphate 50-60; pH 1.8-2.0; 17-25 ~ Cr;

ferrous sulphate soluble 18/8 stainless 5-11~ Ni;

50-60; urea 160-180; steel anode 68-72 ~ Fe;

aluminium sulphate including composition

20-30; magnesium close to 18/8 type

sulphate 10-15 ; stainless steel

nickel chloride 10-15 ;

ammonium sulphate

35~10; ethyl alcohol

3540 ml/l

Saimanova and 32 Chromic acid 270; 8-12 A/dm2; Chromium-rich alloy

Drobantseva nickel sulphate 20-25 ° C; deposits of composi-

150-200; ferrous pH 0.2~.5; tion 9 3 ~ Cr;

sulphate 50; calcium lead or nickel anodes; I% Ni; 6 ~ Fe.

carbonate 40-60; copper and steel Good quality de-

calcium sulphate 4-10 cathodes posits up to 40btm

Electrodepos. Surface Treat., 1 (1972/73)

372 C.U. CHISHOLM, R. J. G. CARNEGIE

Table 1 (continued)

Investigators Ref. Electrolyte Operating Results

composition (g/1) conditions

Zytner, 34 Chromic chloride 35--40 A/dmZ; Alloy deposits of

Rotinyan and (green form) 250; 60-80 ° C; composition:

Fedot'ev nickel chloride pH 0.1-0.3; 5-8~o Cr; 20-25 ~ Ni;

92; ferrous soluble Cr 18 ~, 70-72 ~ Fe. Good

chloride 30; Ni 9 ~o, Ti stainless quality coatings of

trisodium steel anodes; copper 12-15/zm

citrate 70 and steel cathodes

Sarojamma 35 Chromic sulphate 4-13 Volts; Alloy deposits over

and Rama Char 132-330; 5-40 A/dm 2; range of compositions :

nickel sulphate 25-60°C; 2-30~ Cr; 3 20~ Ni;

28-168; ferrous pH 2.0; insoluble 49-85 ~ Fe; including

sulphate 14-56; platinum anode; 18/8 Cr-Ni steel

triethanolamine 149; copper-coated composition

boric acid 25 platinum cathode

Gowri, Elsie 37 Chromium sulphate 18.6 A/dm2; Alloy deposits of

and Shenoi (violet modification) 30-35°C; composition:

255-287; nickel pH 1.7-2.0; 30-35 ~ Cr;

formate 47-63; insoluble platinum 8-10 ~ Ni;

ferrous sulphate and soluble stainless 58-60 ~ Fe.

25-40; trisodium steel anodes; Satisfactory deposits

citrate 100; various cathodes: up to 15pm

ammonium sulphate copper, brass, nickel,

50-70 boric acid; 30 mild steel,

glycine 7-10; aluminium, etc.

sodium fluoride 6-8

Kudryavtsev, 40 Chromium potassium 5-12 A/dm2; Alloy deposits

Smirnova and alum 333; nickel 20°C; pH 2.0-2.2; within composition

Volkova sulphate 84; insoluble graphite range: 15-34 ~ Cr;

ferrous sulphate 56; anodes enclosed in 5-10~o Ni;

glycine 150 ceramic diaphragms 61-75 ~ Fe;

containing 0.1 N including Cr 18 ~o,

sulphuric acid Ni 9 ~ type alloy.

solution; Good quality deposits

platinum cathode up to 2-3/zm

Rotinyan, 45 Chromic chloride 25-30 A/dm2; 30°C; Alloy deposits of

Zytner and (green modification) pH 0.2-0.3; composition close

Fedot'ev 150-200; nickel nichrome (20-30~ Cr, to that of 18~ Cr,

chloride 25-50; 50-60 700Ni, 9 ~ Ni stainless

ferrous chloride 12-20; 25-30~ Fe) anode; steel, viz:

trisodium citrate copper, steel, and 20-22 ~ Cr,

50-70; aluminium copper-plated 8-10~ Ni,

chloride 130 steel cathodes 68-72 ~ Fe.

Good quality deposits

up to 25/zm

Electrodepos. Surface Treat., 1 (1972/73)

ELECTRODEPOSITION OF F e - C r - N i ALLOYS 373

Table 1 (continued)

Investigators Ref. Electrolyte Operating Results

composition (g/l) conditions

Katser, 47 Chromic sulphate 5-10 A/dm2; Alloy deposits over

Petrova and (green modification) 20-30 ° C; range of

Vitkin 160; nickel sulphate pH 1.4-1.6; compositions:

56-84; ferrous graphite anode 18-35 ~ Cr;

sulphate 29-43; (insoluble); copper 4-12~ Ni;

sulphamic acid and steel cathodes; 61-70 YoFe.

220-250 anode separated from Satisfactory deposits

cathode space by a up to 25 btm

ceramic diaphragm

Vitkin, 49 Chromium sulphate 5-10 A/dm~; Satisfactory alloy

Katser and 222; nickel 20-30° C; deposits in composi-

Petrova sulphamate 50-76; pH 1.4-1.9 tion range:

ferrous sulphamate 16-36 ~ Cr;

26-39; glycine 20--40 4-12~ Ni;

6o-72 % Fe

Kudryavtsev, 50 Chromium fluoroborate 25-30 A/dm 2; Alloy deposits

Tsupak, 217-260; nickel 45-47 oC; range of

Rashinskaya fluoroborate 47-70; insoluble anodes compositions:

and Gulyaeva ferrous fluoroborate in IN hydrofluoroboric 12-18% Cr;

29-34; free acid solution 8-18~ Ni;

hydrofluoroboric acid separated from 60-74 ~ Fe

189-198; aluminium cathodic compartment

chloride 40-45 by a porous

diaphragm

Chisholm 51 Chromium fluoroborate 8-60 A/dm2; Alloy deposits:

40-100; nickel 25-75°C; composition not

fluoroborate 100-300; pH 1.0-3.0; specified

iron fluoroborate insoluble anodes of

100-500 platinum-group metals:

titanium, graphite or

platinum;

copper cathode

Firoiu and 52 Chromium 10-20 A/dmZ; Alloy deposits in

Ionescu ammonium sulphate 45°C; pH 2.5; composition range:

350; nickel platinum anode; 36~8% Cr;

sulphate 50; copper cathode 13-18% Ni;

ferrous sulphate 50; 36-49 % Fe.

boric acid 30; Satisfactory deposits,

glycine 5; EDTA 4-5 btm thick

(disodium salt) 250

Electrodepos. Surface Treat., 1 (1972/73)

374 C. U. CHISHOLM~ R. J. G. CARNEGIE

Table 1 (continued)

Investigators Ref. Electrolyte Operating Results

composition (g/l) conditions

Chisholm and 53 Chromic chloride 10-50 A/din'2; Alloy deposits over

Carnegie (green form) 75; 40°C; pH 0.5-1.0; range of compositions:

nickel chloride 25; anodes: platinum 0-20~ Cr;

ferrous chloride 20; 18~o Cr, 8~o Ni 5-51 ~ Ni;

disodium salt of stainless steel, and 45-90.5 ~ Fe.

EDTA 25 Brightray B alloy including composi-

(65~ Ni, 15-20~ Cr, tion approaching

remainder Fe) 18 ~o Cr, 8 ~ Ni

cathodes: copper, steel. Good quality

steel, and copperplated deposits up to

steel 20/~m thick

Ternary F e - C r - N i alloy deposition was first reported as late as 1938 by

Lainer and Kudryavtsev s but the results presented were of a very vague nature.

A year later, Kalocsay 9 patented a bath to produce stainless iron deposits.

Only an abstract of this work was available and this lacked detail. No in-

formation was given on bath composition or the quality and composition of the

resultant deposits.

Skalozubov and Goncharova 1° reported results of a more fundamental

nature. They obtained alloy deposits from a chromic acid based bath, Information

was given on the effects of operating conditions on deposit composition and bath

performance. An increase in current density was alleged to increase the Cr and

decrease the Ni and Fe contents of the deposit. A rise in electrolyte temperature

resulted in a decrease in Cr. The cathode efficiency decreased with increasing

temperature and current density. The deposits were found to be of poor quality

and the electrolyte was reported to be unstable in operation at the working tem-

perature. No information was given on the thickness of deposits but the maximum

current yield was reported as 1 5 ~ and with optimum operating conditions only

approximately 10~o. Brenner et a l. l l also claimed deposition from a chromic acid

bath. The results were of limited value since deposits were obtained with only very

small percentages of Fe and Ni present as basic inclusions rather than as free metals.

The first detailed investigations in this field were conducted by Machu and

El Ghandour in 1960 when they published three papers 1z--14. Although their

particular interest was in alloys of the 18/8 C r - N i stainless steel composition, they

succeeded in depositing a wide range of alloy compositions from a complex metal

sulphate bath containing urea and boric acid t2. Urea was added to promote

complex formation and suppress the formation of metal oxides and hydroxides.

Boric acid prevented or at least greatly reduced cracks and flaws in the deposits.

Citric acid gave similar results. It can be seen from Table 1 that uniform deposits

of satisfactory appearance, showing some signs of pitting, were obtained up to a

Electrodepos. Surface Treat., I (1972/73)

ELECTRODEPOSITION OF Fe-Cr-Ni ALLOYS 375

thickness of about 6#m, but deposits could be obtained up to 20/zm. The maximum

current efficiency was around 2 5 ~ . Fundamental studies on the influence of work-

ing conditions on deposition 13 showed that the composition of the alloy deposits

was affected by changes in the concentration of the bath constituents. An increase

in Cr concentration in the bath led to a slight increase in theCrcontentinthedeposit

but decreased current efficiency. If the Fe concentration was reduced, the Fe

content of the deposit became less, while the Ni and Cr content increased but the

current efficiency dropped. If Ni concentration was increased, the Ni content rose

sharply while the current efficiency remained constant. An increase in temperature

caused a decrease in the amount of Cr in the deposit, an increase in Ni, little change

in Fe and a rise in current efficiency. At current densities of 33 A / d m 2 cracks

appeared in the deposits as well as individual 'burnt' spots and oxide formation.

At temperatures of 70-80°C smoothing of the deposit took place and led

to the disappearance of cracks and defects. Hence a high temperature and low

current density of 10 to 15 A / d m 2 were the most suitable for the formation of a

uniform deposit free from defects. The duration of electrolysis was stated to have

no effect on alloy composition but the current efficiency and brightness of the

deposits were found to decrease somewhat with increasing time. The cathode

material had no effect on the alloy composition but caused a variation in current

efficiency. Fundamental studies were also made of the mechanism of deposition 12

and it was suggested that deposition could be directly attibuted to the formation

of a chromium hydroxide diaphragm on the cathode surface which was particularly

sensitive to variations of current density, temperature and pH and that the low

current efficiency and the composition of the alloy were largely determined by this

diaphragm. It was also proposed that the three metals, Fe, Cr and Ni, mutually

impeded, or polarised, each other during their codeposition; thus the current yields

were much smaller than might be expected from the deposition of the three metals

individually. This mutual impedance was reduced if the temperature and current

density were increased. A study of the current density-cathode potential curves 12

revealed that the strongest polarisation occurred in the deposition of Cr and at

50°C with pH 2.1; the deposition potentials of the three metals and the alloy were

found almost to coincide indicating the possibility of codeposition of the three

metals.

Various organic and inorganic brightening agents were also tested 14 and in

all cases the brightening effect was much smaller than that for the individual

metals. In addition, where brightening agents were effective, current efficiencies

were reduced.

These same researchers subsequently published two further reports 15 and

filed three patents 16 on the basis of this work. The patents gave the additional

information that the metal salts could also be present as chlorides and that an

acceptable and desirable brightening agent was pyridine.

A further improvement on this bath was patented by Amchem Prods., Inc. 17,

Electrodepos. Surface Treat., 1 (1972/73)

376 C. U. CHISHOLM, R. J. G. CARNEGIE

which constituted the use of soluble hydrazine in the bath to improve the quality

and corrosion resistance of the coatings produced.

A sulphate bath containing trisodium citrate was used by Kalyuzhnaya and

Pimenova is for the deposition of a range of Fe-Cr-Ni alloys. However, although

their investigation was of a fairly fundamental nature, their main interest was in

producing alloys of the 18/8 stainless steel type. It was found, through a comparison

of soluble and insoluble anode systems, that soluble 1 8 ~ Cr, 9~o Ni, 0.68~ Ti

anodes gave the best results in regard to performance and stability of the electrolyte

and alloy quality and composition. The current efficiency obtained under the

optimum conditions reported in Table 1 was about 4 5 ~ . Alloy coatings were

claimed up to a thickness of 20-25 #m, but only uniform, and adherent, up to

6/~m. At greater thicknesses, the coatings exhibited cracking and porosity, lost

their adhesion, and peeled off the cathode surface, owing to the presence of appre-

ciable tensile stresses in the deposits. After heat treatment under vacuum at

1000°C for 5 hours, these deposits became more uniform and adhered to the

cathode. The microhardness of the deposits was found to be of the same magnitude

as that of ordinary Cr 18~, Ni 9 ~ , Ti sheet steel. Coatings up to 6 #m thick had

higher corrosion resistance in 5 ~ H2SO4 solution at 20°C than coatings 20-25/zm

thick, owing to the presence of cracks in the latter. Fundamental information was

provided on the dependence of alloy composition and current efficiency on the

operating conditions. Enrichment of the electrolyte raised the Fe content of the

alloy, but had an adverse effect on deposit quality and current efficiency. Increases

in current density caused the Cr content in the alloy to increase and the Fe content

to pass through a maximum, while the Ni showed no change. The Ni and Fe

contents increased while the Cr content dropped sharply when the temperature

was increased. Experiments were also conducted on the same electrolyte using a

diaphragm cell where the cathodes were shielded by a copper wire frame. Insoluble

lead anodes were used, with sulphuric acid. Similar deposits were obtained but the

cathode efficiency was only 18~. This work was reviewed by Domnikov 19 two

years later.

Three further papers z0-22 were published extending this basic research

work is.

In the first of these papers 20, internal stress in the deposits was studied. It

was thought that one of the probable causes of stress was the influence of hydrogen

included in the deposit and basis metal. Alternating current superimposed on d. c.

current reduced the stresses but decreased the current yield. The formation of a

thin oxide film on the cathode using sodium hydroxide solution improved deposit

quality by the oxygen in this film reacting with the hydrogen discharged at the

cathode, thus preventing hydrogen penetration into the cathode metal. The deposits

on anodised cathode surfaces had considerably lower internal stresses and satis-

factory adhesion to the basis metal. Deposits on passivated steel surfaces also

showed lower internal stresses.

Electrodepos. Surface Treat., 1 (1972/73)

ELECTRODEPOSITION OF Fe-Cr-Ni ALLOYS 377

The second paper 21 considered the rates of discharge of Fe, Cr and Ni ions

during their joint reduction through a basic study of the cathode polarisation

curves for the deposition of the alloy and the separate metals at various tempera-

tures. It was found that the rate of discharge of the ions was dependent on whether

the violet or green chromium complex was present. Electrodeposition of the alloy

from the violet modification of the Cr took place at potentials more positive than

from solutions of the green modification.

The results indicated that in solutions of the violet modification of chrome-

alum, the total polarisation curves for the deposition of the alloy were situated at

more positive potentials than the polarisation curves for the individual metals.

Deposition of Cr in the alloy was observed to take place more easily than in its in-

dividual deposition.

The third paper ~2 studied the effect of sodium citrate concentration in their

previous electrolyte la on alloy composition and quality. At very low citrate con-

centrations, a hydroxide film formed on the cathode surface, the composition and

properties of which affected the metal ion discharge. An optimum citrate addition

of about 140 g/1 decreased the Cr content, increased the Fe and Ni contents in

the alloy and also led to better quality deposits and stabilisation of the alloy com-

position.

Kvachkov and Stoicheva 2a succeeded in obtaining good, decorative, protec-

tive alloy coatings, resistant to corrosion up to 400 °C, similar in composition to

18/8 Cr-Ni stainless steel. They used the same bath and optimum operating

conditions as did Machu and EI-Ghandour lz, 13. A soluble steel anode of 18~o

C r - 9 ~ Ni permitted prolonged use of the bath without correcting its composition.

Ray published a preliminary paper 24 and later, with Banerjee, a more de-

tailed paper 25 on a successful attempt to deposit F e - C r - N i alloys from a sulphate-

EDTA (disodium salt) bath, with particular emphasis on obtaining an alloy compo-

sition approximating to 18/8 stainless steel. EDTA was added to the bath as a

complexing agent. The deposition of Cr was facilitated by its presence. Boric acid

had a particularly beneficial effect on the uniformity of the deposits by preventing

or at least reducing cracks and discontinuities in the deposits. The maximum

current efficiency obtained was 13~o for the deposition of the 18/8 Cr-Ni alloy.

A chloride electrolyte was employed by Takahashi et al. 26 for the production

of flat and continuous alloy deposits up to 10 # m thick. A chloride solution was

selected for its high electrical conductivity, high anodic dissolution efficiency, and

its capability of plating Fe-group metals at high current densities. Microscopic

cracks occurred in deposits from l0 to 15/~m thick. Heat treatment at 1000°C for

one hour followed by quenching considerably increased the corrosion resistance

of the coatings in solutions of 5 ~ HC1, 5 ~ H2SO4, and 2 0 ~ NaCl. The cathode

efficiency was maintained in the range of 30 to 4 0 ~ under the optimum conditions

shown in Table 1. A study of the effects of plating conditions on deposition showed

that the higher the chromium chloride concentration in the solution, the lower was

Electrodepos. Surface Treat., 1 (1972/73)

378 c.u. CHISHOLM, R. J. G. CARNEGIE

the current efficiency. As the current density increased, the Cr content of the de-

posits increased but the Ni content decreased. At increased temperatures, the de-

posits contained more Ni and less Cr. The Fe content remained fairly constant with

increasing current density and increased with rise in temperature. The current

efficiency remained fairly constant with current density increase and decreased with

rise of temperature. At a pH greater than 3.0, a white colloidal film formed on

the cathode surface. A decrease in current efficiency was evident after 10 minutes

plating.

Various base metals were tested. Nickel-plated copper gave good adhesion,

while wrought iron and high carbon steel led to cracks in the deposits. It was shown

that the system behaved as a regular codeposition system characterised by the

diffusion control of Fe and Ni ions. In this electrolyte, an anode of 1 8 ~ Cr, 8 ~

Ni steel was dissolved with an anode efficiency of 100~. A patent 27 was subse-

quently filed on the basis of this research.

Mutafchiev and Marinkov 28 introduced ammonium, magnesium and

aluminium sulphates, and ethyl alcohol, as additives in the basic bath described

earlier by Machu and El-Ghandour 12, a3. They obtained alloy deposits from 20

to 100 # m thick, with a network of microcracks, over a range of compositions close

to the 18/8 stainless steel composition. The average cathode efficiency was 25-30~o.

Higher amounts of ammonium sulphate improved the quality of the plate, but

caused precipitation of nickel. The presence of nickel chloride was required to

activate anode dissolution, thus maintaining a stable electrolyte composition.

These authors showed in a later paper 29 that the dissolution rates of 18/8 stainless

steel anodes was greatest at 45-55°C with an optimum chloride concentration

giving the anodic dissolution rate as equivalent to the cathodic deposition rate. The

effect of varying pH showed that the cathode efficiency reached an optimum value

at 2-2.7, with a correspondingly high anode efficiency.

Another paper 3° was published by these researchers in which they determined

a throwing power of 26.2°~, for the deposition of an F e - C r - N i alloy at 16 A/dm ~,

40°C and pH 1.8, after 15 minutes.

Saimanova and Drobantseva 31, 32 reported the deposition of a chromium-

rich alloy from a self-regulating tetrachromate electrolyte. Smooth, bright, com-

pact, non-porous deposits showing good adhesion and no cracking were deposited

up to 40 # m thick, with a microhardness of 712 kg/mm 2 compared with 480

k g / m m 2 for pure chromium deposited under similar conditions. The deposits were

compact and resistant to the action of dilute acids. A coating, 20/zm thick on steel,

showed no corrosion after 300 hours in a salt mist chamber. It was therefore

stated that the direct deposition of Cr Fe Ni alloy on steel was possible

without the use of Cu and Ni underlayers. A maximum cathode efficiency of

30~,~, was achieved but under the optimum conditions reported in Table 1 this

dropped to 16-18~. A subsequent report o n this research work was made by

Domnikov 33.

Electrodepos. Surface Treat., 1 (1972/73)

ELECTRODEPOSITIONOF Fe-Cr-Ni ALLOYS 379

The production of alloy coatings from a chloride-citrate bath was claimed

by Zytner, Rotinyan and Fedot'ev a4. A chloride solution was chosen because of

the high limiting currents for Fe and Ni deposition, which are also required for the

deposition of Cr. Trisodium citrate was employed as a complexing agent for Ni

and Fe. Good quality coatings which adhered well to the substrate, with a thick-

ness of 12-15 #m, were produced with a cathode efficiency of 2 5 - 2 7 ~ . X-Ray

diffraction showed the deposits to consist of a solid solution. Information was given

on the dependence of deposit composition and quality on plating conditions.

In 1968, a study was made by Sarojamma and Rama Char a5 of the electro-

deposition of alloys from complex sulphate-triethanolamine solutions. The boric

acid served to maintain the pH and to promote the production of adherent and

satisfactory deposits. It was found possible to obtain good deposits, varying from

dull to bright grey in appearance, over a wide range of compositions, particular

emphasis again being on the 18/8 Cr-Ni stainless steel composition. However, the

total metal content of the deposits was found to be less than 100~o, the proportion

of non-metallic constituents being approximately 3~o. The cathode efficiency

varied from 2 to 2 8 ~ . The cathode efficiency increased with increase in current

density, temperature and Fe concentration in the electrolyte. Various other addi-

tion agents were tested but in general they did not afford an improvement in the

properties of the deposits.

A subsequent paper by Rama Char and Sheth 36 reported on alloy deposi-

tion from two baths, a sulphate-urea one which was basically Machu and EI-

Ghandour's earlier bath 12, lz and the sulphate-triethanolamine bath z5 previously

described under almost the same operating conditions. The results of these studies

verified the earlier work.

Gowri, Elsie and Shenoi 37 succeeded in obtaining adherent alloy deposits

from a sulphate-citrate bath with a current efficiency of 26/0~. The hardness of the

deposit was found to be 322 kg/mm 2 compared with stainless steel at 245 kg/mm 2.

Its corrosion resistance in 5 ~ H2SO4 and 3 ~ NaCI was good. Ageing the bath for

24 hours increased the current efficiency for Cr reduction and also for the alloy.

The functions of the various addition agents were studied. Ammonium sulphate

increased the solution conductivity and improved the deposit appearance. Tri-

sodium citrate increased the pH of chromium hydroxide formation, complexed Fe

and Ni, keeping the Fe in the ferrous state in which the deposition efficiency is

high, and helped in obtaining adherent deposits. Boric acid had a profound influence

on the useful life of the bath. Glycine helped to maintain the bath pH and prevented

the pitted deposits, while sodium fluoride acted as a stress reliever. Detailed studies

were made of the effect of such variables as current density, pH and temperature

on the quality and composition of the alloy deposits. Agitation was found to in-

crease the deposit brightness, current density range and thickness. Additions of

sodium, magnesium or aluminium ammonium sulphates to the basic bath were

reported to improve the throwing power of the bath slightly, and to increase the

Electrodepos. Surface Treat., 1 (1972/73)

380 c.u. CHISHOLM, R. J. G. CARNEGIE

current density range. Aluminium ammonium sulphate also gave a better deposit

by preventing the formation of slight cracks obtained in deposits from the basic

bath. Increasing time of deposition had the detrimental effect of increasing the

cracking of deposits.

The development of these alloy coatings indicated that internal stresses were

important in relation to the cracking tendencies observed in the deposits. As a

result, these same experimenters, together with Cleghorn, conducted further work 3s

in which stress measurements were made on the alloy deposits and then correlated

to the observed cracking and spalling. The deposits showed an initial compressive

stress followed by the rapid development of a tensile stress which reached a maxi-

mum at a deposit thickness of about 0.5 to 1.0/zm and then decreased up to the

termination of electrolysis. It was suggested that this characteristic initial shape of

the stress curves might be attributed to the evolution and diffusion of hydrogen at

the substrate-deposit interface. Cracking and spalling occurred in all deposits once

the peak stresses had been reached. The stresses in the deposits were lower on electro-

polished Cu and steel than on brass and Ni substrates. Various addition agents

were tested which produced a reduction in stress without deterioration of the deposit.

The stress characteristics and crack patterns found in the deposits were similar

to those found in Cr deposits. It was suggested that if cracking problems continue,

the development of a two-layer coating system such as that used with 'duplex' Cr

deposits might be necessary.

In 1970, a slightly modified version of their earlier bath 37 was patented 39.

The main difference between the two baths was the substitution of hexamine or

formaldehyde in the later bath a9 for ammonium sulphate. The deposits obtained

after 5 minutes plating were 4 to 5 btm thick, free from basic inclusions, and

resistant to 5 ~ H 2SO4 and 3 ~ NaCI over a period of time. Their composition was

stated as 3 0 ~ Cr, 10~ Ni and 60~o Fe.

An extensive investigation by Kudryavtsev, Smirnova and Volkova 4° was

reported in which they claimed successful deposition from a sulphate-glycine bath,

their particular interest, however, being in the deposition of an alloy of the Cr

18~, Ni 9 ~ type. Smooth, bright, compact deposits of 2-3/~m were obtained,

followed by dull and matte layers of up to 50 #m, with current efficiencies of 20

to 2 6 ~ . When the coating thickness exceeded 50 btm, however, a dark precipitate

of chromium hydroxide was formed at the edges of the plates. Deposits with a Cr

content greater than 1 8 ~ showed a tendency to crack. This was suggested to be due

to a change in the nature of the internal stresses in the deposit from compressive

to tensile. The microhardness of the deposits increased with their Cr content and

reached 650 kg/mm z in a deposit containing 3 5 ~ Cr, 5 ~ Ni and 6 0 ~ Fe. The

addition of glycine to the electrolyte was reported to increase the buffering capacity

of the electrolyte, to increase the pH for the formation of chromium hydrate and

to increase the thickness of the coatings. Detailed information was given on the

influence of various factors on the deposition process. The mechanism of deposi-

Electrodepos. Surface Treat., 1 (1972/73)

ELECTRODEPOSITIONOF Fe-Cr-Ni ALLOYS 381

tion was studied using cathodic polarisation curves. From the cathodic polarisa-

tion curves it was observed that in the codeposition of the three metals, the deposi-

tion of Cr increased while that of Fe and Ni decreased. This was related to the

potential of hydrogen evolution on the F e - N i - C r alloy being more positive than

on Fe or Ni, thus causing a larger part of the current to be consumed in the evolu-

tion of hydrogen and thereby decreasing the amount of current expended in the

deposition of Fe and Ni. Increase in the glycine concentration in the electrolyte

shifted the overall polarisation curves towards more positive potentials sharply

retarding the discharge of Fe and Cr ions and facilitating theevolution of hydrogen,

with a rapid drop in cathode efficiency. This was explained by the fact that when the

glycine concentration in the electrolyte exceeded the value corresponding to the

formation of a complex cation, the presence of free glycine causes an increase in

the concentration of hydrogen ions at the cathode. This bath was subsequently

reported by Domnikov 41 and later patented 42.

Later these experimenters extended this work in two papers 4a which in-

vestigated the causes of cracking in their alloy deposits. These papers were only

available in the form of abstracts. It was discovered that internal tensile stresses

were generated in deposits with a dense network of fractures formed immediately

after electrolysis. The main cause of cracking and brittle coating formation was

proposed to be the hydrogenation of the deposit, which increased with the Cr

content in the alloy. This was verified by the fact that the amount of hydrogen in

deposits without fracture was three-fold smaller than in deposits which cracked

during electrolysis. Addition of various stress reducing agents to the bath as well as

the superposition of a.c. current on the d.c. current did not result in elimination of

deposit cracking.

A paper 44 was presented by these scientists at an international conference in

Germany in 1968. It discussed all their earlier work 40, 42, 43 and also provided

some additional information. Experiments with rotating disc electrodes showed that

the presence of chloride ion in the electrolyte was required for anode dissolution.

It was also claimed that deposits free from porosity were obtained at thick-

nesses near to 30/~m if crack-free, but the corrosion resistance of these deposits

was found to be poor.

Rotinyan, Zytner and Fedot'ev 45 attempted to improve the quality of their

earlier alloy deposits a4 using lower temperatures. Their previous work 34 had given

coatings with reduced Cr contents but of good quality at 80°C and coatings con-

taining 2 0 ~ Cr of markedly improved quality at lower temperatures. The effect of

aluminium chloride in the bath was studied using polarisation curves, X-ray

analysis and microstructural studies. They obtained high quality bright alloy

deposits showing good adhesion with compositions close to 18/9 Cr-Ni and thick-

nesses of up to 25/tm. Aluminium chloride was found to increase the quality and

Cr content of the deposit at ordinary temperatures, improve throwing power and

increase the current yield. The structure was a solid solution of a-iron type which

Electrodepos. Surface Treat., 1 (1972/73)

382 C. U. CHISHOLM, R, J. G. CARNEGIE

was magnetic. Annealing at 1100°C followed by air quenching produced a stain-

less steel structure in the electroplated alloy. The alloy possessed considerable

wear resistance with a microhardness of 580-600 kg/mm 2 and could be used as a

protective, decorative coating in corrosive atmospheres.

Annealed alloys gave, on testing, similar corrosion resistance to a Cr 18,

Ni 9, Ti-stabilised stainless steel.

The polarisation curves showed that the introduction of A1CIa to the elec-

trolyte displaced all the curves towards more negative potentials. Its addition also

retarded the discharge of hydrogen to a greater extent than the discharge of the

alloy components, thus considerably increasing the current yield.

This bath was subsequently reported by Domnikov 46.

A sulphamic acid bath was employed by Katser, Petrova and Vitkin 47 in

an attempt to reduce internal stresses in deposits. G o o d deposits of up to 25 ~m

were claimed with a current efficiency of 18 to 2 5 ~ . Temperature was found to

have a marked effect on the metal content of the alloy and the current yield. An

increase in temperature caused a rise in the Ni, but a drop in the Cr.

An increase of sulphamic acid from 50 to 250 g/l was reported as giving

higher quality deposits with no metal hydroxides. Domnikov 48 also reported on

this work.

Another paper 49 by these same scientists reported the production of deposits

of satisfactory quality from a sulphamate electrolyte at current efficiencies varying

from 17 to 2 8 ~ . Only an abstract of this work was available. The addition of gly-

cine was reported to give higher quality deposits.

A patent was filed by Kudryavtsev et al. 5o in 1969, covering the deposition of

alloy coatings from a fluoroborate electrolyte containing aluminium chloride.

Deposits up to 30 # m thick were obtained with a current yield of 30 and 5 0 ~ . The

microhardness of the deposits was reported to be 600 k g / m m 2.

Another fluoroborate bath was patented by Chisholm 5t in which 100-500

g/l of iron fluoroborate was added to a basic electrolyte for producing binary

N i - C r alloy deposits. Grey, adherent deposits were reported, with thicknesses

varying from 2.5 to 76 #m. This patent was only available in abstract form and no

other details were given.

A recent report by Firoiu and Ionescu 5~discussed the effects of current density,

temperature and pH on current yield, appearance and composition of electrode-

posited F e - C r - N i alloys obtained from a sulphate-EDTA bath with additions of

boric acid and glycine.

Using the optimum conditions reported on Table 1, deposits 4-5 # m thick,

with good adhesion, were obtained over a range of compositions at current effi-

ciencies of from 14 to 19~. The Cr content of the deposit attained a maximum

while the Fe content reached a minimum at a definite current density. Thereafter

the Cr decreased while the Fe and Ni increased. The total and partial polarisation

curves for the deposition of the alloy were also studied.

Electrodepos. Surface Treat., 1 (1972/73)

ELECTRODEPOSITION OF Fe-Cr-Ni ALLOYS 383

The most recent work in this field has been recorded by Chisholm and

Carnegie 5~ in which they investigated three baths, a sulphate-glycine bath based on

that of Kudryavtsev et ai.4o, a chloride--citrate bath based on that of Rotinyan et

al. 45, and a new chloride-EDTA bath.

The first bath differed from that of Kudryavtsev and his co-workers 40 in the

respect that a normal cell utilising platinum anodes was employed rather than a

diaphragm cell with graphite anodes. The electrolytes employed were identical.

Smooth, fine textured, bright deposits showing good adhesion and ductility were

obtained with similar compositions to those claimed by Kudryavtsev et aL 4o,

including the 18~ Cr, 8 ~ Ni stainless steel composition. All the deposits exhibited

microcracking and a spherical nodular growth which resulted in a coarsening of

surface texture. The alloys were satisfactory up to thicknesses of 10 #m but at

greater thicknesses the deposits became highly stressed and cracked.

Cathode current efficiencies did not change significantly with electrolysis

time and remained constant at around 2 0 - 2 2 ~ over the first 30 minutes of deposi-

tion.

A Brightray B alloy anode ( 6 5 ~ Ni 15-20~ Cr, remainder Fe) gave alloy

deposits up to thicknesses of 28/~m before the quality of the deposits deteriorated,

and cathode efficiencies of 19-24~. These results were of practical interest, since

such coatings were obtained directly on mild steel, thus providing a possible

corrosion-resistant coating.

Studies made on the chloride-citrate bath based on the work of Rotinyan

et al. 45 revealed a lack of reproducibility of the results. Wide variations in deposit

compositions were obtained over the narrow range of current densities employed

and although their adhesion and ductility were fairly good, only thin deposits up

to 12.5 #m thick were obtained exhibiting large amounts of microcracking.

The chloride bath containing the sodium salt of EDTA gave fine-textured

deposits showing no pitting, porosity or microcracking. The deposits exhibited a

nodular growth structure on their surface which became more severe with increased

current density.

Soluble anodes of 18~ Cr, 8 ~ Ni steel and Brightray B alloy gave rise to

satisfactory deposits, but a constant deposit composition could not be maintained

owing to differences between the anode and cathode efficiencies.

Pilot plant tests were carried out on a continuous flow plating system. This

system involved continuous circulation of a bulk quantity of electrolyte from a

central reservoir through a cylindrical plating cell.

The sulphate-glycine and chloride-EDTA electrolytes were studied and the

deposits appeared to be affected by the flow pattern of the fluid through the plating

cell.

Tests using very slow electrolyte circulation rates resulted in deposits similar

to those obtained under static conditions in the small-scale tests but no greater

thicknesses of deposit were obtained.

Electrodepos. Surface Treat., 1 (1972/73)

384 C . U . CHISHOLM, R. J. G. CARNEGIE

Initial tests using the chloride-EDTA bath at a very low circulation rate

gave rise to thicker deposits than could be obtained in the static tests. Thicknesses

of about 35 to 40/tm were possible and although the deposits exhibited coarse nodular

surface textures, they were ductile, showed good adhesion to the substrate and, in

general, exhibited no microcracking. The deposits had an average composition of

86~o Fe, 7 ~ Ni and 7~o Cr.

The tests conducted using EDTA in a chloride bath were considered to

show promise for future commercial development since microcracking appeared to

be eliminated in the deposits.

DISCUSSION

The codeposition of chromium with metals of the iron group has always

been difficult owing to the simultaneous discharge of hydrogen as a result of the

low hydrogen overpotential associated with the deposition of chromium and

chromium alloys. The low pH at which chromium hydroxide is formed also limits

the process. These factors make elucidation of the mechanism of the deposition

process difficult. Consequently, no practical commercial process exists today for

the electrodeposition of ternary iron-chromium-nickel alloys despite the many

investigations made into this system, as summarised in Table 1.

Most investigations reported success in obtaining alloy deposition, although

in much of the earlier work s, 9, 1 t the information presented was of a very vague

nature and no information was given on the composition or quality of the deposits

obtained. Several patents have been filed but only two of these 16, 17 were available

in full, giving detailed information on the processes; the remainder were only

available as abstracts 9, 27, ag, 42, 50, 51

The plating baths studied can be divided into two main groups: those based

on hexavalent chromium and those based on trivalent chromium. In the hexa-

valent baths, the chromium was present in the form of chromic acid. Two of the

chromic acid-based bathslO, 11 yielded unsatisfactory deposits but the self-regulat-

ing tetrachromate bath of Saimanova and Drobantseva 32 produced satisfactory

chromium-rich alloy deposits. However, these deposits can hardly be classed as

constituting an iron-chromium-nickel alloy because of their extremely low nickel

content. The tetrachromate electrolyte was used for its high stability in operation,

simplicity in use, and high cathode efficiency.

The trivalent baths were widely studied and gave the most successful results.

These baths were based on sulphates 12, 18, 28, 25, zs, 35-37, 40, 47, 52, 53, sulpha-

mates 49, chlorides 26, 34, 45, 5a and fluoroborates 5°, 51. Although sulphate baths

were the most frequently used, chloride baths 2~, 34, 42, ~z were sometimes preferred

for the advantage of their high electrical conductivity, high efficiency of anodic

dissolution and high limiting current densities for iron and nickel deposition. A

sulphate bath containing sulphamic acid 47 and a sulphamate bath 49 were employed

Electrodepos. Surface Treat., 1 (1972/73)

ELECTRODEPOSITION OF F e - C r - N i ALLOYS 385

in attempts to reduce internal stresses in the deposits. Fluoroborates 50, 51 were

used to give increased rates of deposition at fairly high current efficiencies.

Addition agents

The plating solutions generally contained various complexing and addition

agents in addition to the metal salts. The complexing agents used were urea 12,23,2s, 36,

trisodium citrate is, 23, 34, 37, 45, EDTA25, 52, 53, ammonium chloride 26, triethanol-

amineaS, 36, glycine40, 53, sulphamic acid 47 and hydrofluoroboric acid 5°. In

addition to promoting complex formation of the metal ions in the plating baths,

the complexing agents were beneficial from such aspects as promoting bath

stability, favourable buffering properties and improving deposit quality. Since

complexing of metal ions is recognised as a powerful method of bringing the deposi-

tion potentials of metals closer together, it is quite conceivable that this particular

mechanism was partly responsible for codeposition of the three metals in most of

the baths examined.

The most common addition agents employed were boric acid 10, 12, 25,35-37,52,

sodium fluoride TM 23, 37, ammonium sulphate 2s, 37, nickel chloride 2s, gly-

cine37, 49, 52 and aluminium chloride 45, 50

Boric acid served as a buffer and hence had a profound influence on the

useful life of the plating bath. Sodium fluoride generally acted as a stress reliever.

Ammonium sulphate increased the conductivity of the plating solution and im-

proved the quality of the plate. Nickel chloride was reported to activate anode dis-

solution, thus maintaining a consistent electrolyte composition and allowing

prolonged electrolysis. Glycine prevented pitting of the deposits and made the

deposits more uniform and compact. The introduction of aluminium chloride

improved deposit quality and increased current efficiency. Additions of sodium

sulphate, magnesium sulphate and aluminium ammonium sulphate to the sulphate-

citrate bath improved the throwing power, increased the current density range and

gave better quality crackfree deposits.

Machu and Ei-Ghandour tested various organic and inorganic brighteners

and found the most effective ones to be saccharin, pyridine, saccharin plus pyridine

and pyridine plus glucose, citric acid or tartaric acid 14. In all cases where brighten-

ing was effective, cathode efficiencies were decreased.

Thickness of deposits

The main obstacle encountered in most of the researches is the existence of a

limiting thickness of good quality deposits. In many cases, it has been shown that

good quality thin deposits can be obtained but few attempts have been made to

establish conditions for sustained deposition and the build-up of thick deposits.

Generally, this limiting thickness has a value of the order of 6/~m 13, is, 52 or

10-15/zm 26, 34. Exceptions are, however, to be found where satisfactory coatings

of up to 20-25 btm were obtained 45, 47, 53. The tetrachromate bath gave uniform,

Electrodepos. Surface Treat., l (1972/73)

386 c.u. CHISHOLM, R. J. G. CARNEGIE

pore-flee and crack-flee deposits up to 40 #m thick 32 while the sulphate-glycine

bath produced compact deposits up to 50#m thick 4°. However, these latter deposits

were smooth and bright in thin layers of 2-3/zm but dull and matte in thicker layers.

The maximum thickness of deposit reported was 100/zm but these deposits ex-

hibited a network of microcracks 2s. Kudryavtsev et al. claimed that deposits could

be obtained up to 50/~m thick and were only cracked if their chromium content

was more than 18~ 4° whereas Chisholm and Carnegie 5z found that deposits could

only be obtained up to 28 btm thick and were always microcracked regardless of their

chromium content 53. Rotinyan et al. obtained deposits of reproducible quality and

composition up to thicknesses of 25 btm without microcracking 45 while Chisholm

and Carnegie claimed a lack of reproducibility in their results and produced

cracked deposits up to only 12.5 #m thick. These contradictions are probably due

to differences in the experimental conditions employed in these researches.

The basic problem, as revealed from an examination of the literature,

appears to be the build-up of internal stresses in the deposits in the early stages of

deposition, leading to deposit embrittlement, microcracking and ultimately loss

of adhesion, spalling and exfoliation of the deposits. In this way, the thicknesses of

good quality deposits have been limited to low values.

However, this problem was solved in one instance by carrying out suitable

heat treatment on the deposits in order to reduce the stresses and improve their

adhesion to the base metal is. After this treatment, the cracked deposits were

reported to become uniform and homogeneous and adhered firmly to the substrate.

Another limitation to the build-up of thick deposits is the low cathode effi-

ciencies at which most of the baths operated. The majority of baths attained

efficiencies which did not exceed 30%. In the chloride 26, ~5 and fluoroborate 5°

baths, high efficiencies of 30 to 40~o and 30 to 5 0 ~ respectively are expected since

these types of electrolyte are well known for their high deposition efficiencies. A

sulphate Is bath gave 45 to 5 0 ~ when operated with soluble anodes.

The problem of low cathode efficiencies was further aggravated by the lower-

ing of efficiency after short deposition times. In one instance the efficiency was

reported to rise with increasing electrolysis time 18.

Internal stresses

Although most of the previous researches were of an extensive and funda-

mental nature, most of them have been restricted to theoretical studies of the

dependence of deposit quality and composition on the plating conditions, and of

the cathode polarisation curves. Few, however, have attempted to extend the exist-

ing work or endeavoured to solve the aforementioned practical problems in an

effort to develop a plating process operating at high current densities and efficien-

cies, which would give thick, crack-free deposits of good quality. These practical

aspects have, nevertheless, received some attention.

Internal stresses and cracking tendencies in deposits were studied in detail by

Electrodepos. Surface Treat., 1 (1972/73)

ELECTRODEPOSITION OF Fe-Cr-Ni ALLOYS 387

three groups of researchers 2°, as, 43. The importance of this particular problem is

emphasised by the fact that many earlier attempts to electroform stainless steel for

structural items ended in failure because the deposits became too highly stressed

and cracked 54. Kalyuzhnaya et al. reported that the most probable cause of stresses

was the occlusion 2° of hydrogen in the deposit and base metal.

Kudryavtsev et al. attributed the main cause of internal stresses and cracking

to the hydrogenation of the deposit, which increased with increase in the chromium

content of the alloy 4a.

In the chloride bath of Takahashi et al., microcracking was ascribed to

the inclusion of minute amounts of oxides in the deposits 26.

Chisholm and Carnegie suggested that the most likely reason for the failure

to sustain good quality deposition over prolonged periods of electrolysis was the

instability of the solid state film on the cathode surface associated with the deposi-

tion of chromium 53. This film may break down after deposition has progressed for

some time and thereafter the current would drive off large amounts of hydrogen

which become absorbed in the deposits, leading to a rapid drop in cathode effi-

ciency and resultant deterioration in deposit quality through the formation of

highly stressed, powdery and cracked deposits.

It was suggested that subsequent heat treatment removes hydrogen absorbed

in deposits 16 thus avoiding hydrogen embrittlement. The addition of many stress

reducing agents and the superimposition of a.c. on the d.c. current were not re-

ported to eliminate deposit cracking, although in most cases the internal stresses

were reduced 20, 38, 45

Aluminium ammonium sulphate was reported 37 as preventing the formation

of cracks in the deposits.

Chisholm and Carnegie 53 considered that the use of the sodium salt of EDTA

in their chloride bath showed promise for future commercial development in that

it ted to alloy deposits showing no microcracking.

Future development

From an examination of the literature, the most successful plating baths in

terms of obtaining thicker alloy deposits of good quality and without microcrack-

ing at good current efficiencies appeared to be the chloride-citrate-aluminium

chloride 45 and chloride-EDTA 53 baths. These two baths, therefore, offer promise

for future commercial development.

Alloy compositions

The compositions produced vary over a wide range despite the fact that the

main objective of many investigations has been to obtain alloy coatings correspond-

ing in composition to 18~ Cr, 8 ~ Ni stainless steel.

Most of the deposits obtained are iron-rich alloys with compositions ap-

proaching those of austenitic stainless steels.

Electrodepos. Surface Treat., 1 (1972/73)

388 c. u. CHISHOLM,R. J. G. CARNEGIE

Deposits were produced with a lower chromium content and higher nickel

content than the 1 8 ~ Cr 8 ~ Ni alloy 34, 53. These lower chromium contents gave a

reduction in hardness and their corrosion and heat-resistant properties compared

with those of the 1 8 ~ Cr 8 ~ Ni compositions. Improved mechanical properties,

in the form of strength and ductility, were obtained with the higher nickel contents.

Alloys were also produced with higher chromium contents than those of the

18~o Cr 8 ~ Ni alloys. These deposits possessed improved corrosion resistant

properties and increased hardness. However, one of the adverse effects of the high

chromium content was the increase in the brittleness of the deposits.

Alloys with high chromium and iron and low nickel contents were also

obtained 5z giving considerably improved corrosion and heat resistance and in-

creased hardness but also a tendency to embrittlement and cracking.

It would seem from the work completed that there is need for an investiga-

tion into the properties of the deposits. Although some work has been done on

testing of deposits, it is mainly in the fields of corrosion resistance and hardness

and information on the engineering properties is severely limited.

Corrosion resistance o f alloys

Considerable information was presented on the corrosion resistance of

deposits. Corrosion tests were conducted in dilute solutions of sulphuric acid,

hydrochloric acid, nitric acid, sodium chloride and copper sulphate. Tests were also

carried out in a salt-spray chamber.

It was found that thin coatings of 6/~m possessed higher corrosion resistance

in dilute sulphuric acid solution than 20-25/zm thick coatings 18. The latter coatings

separated from the basis metal owing to attack on the base occurring through the

fine cracks in the deposits.

Heat treatment of the deposits considerably increased the corrosion resis-

tance coatings and improved their protective properties z6, 45. After heat treatment

the corrosion resistance of the deposit approached that of 18°/O Cr, 9% Ni, Ti-

stabilised stainless steel in the same corrosive media 45.

The chromium content of the deposit was found to be an important con-

sideration by Gowri et al. 37 since an alloy coating containing 30-35% Cr and

8-10°~ Ni exhibited satisfactory corrosion resistance compared with lower chro-

mium contents.

The tetrachromate bath 32 gave 20/zm thick deposits on steel substrates which

satisfactorily withstood corrosion after 300 hours in salt-spray tests. This raises the

possibility of direct deposition of an alloy on steel as a protective/decorative coat-

ing and could obviate the need for undercoats of copper and nickel.

Microhardness studies

The hardness attained a minimum value of 322 kg/mm z for deposits obtained

from the sulphate-citrate bath 37 and a maximum of 712 kg/mm z for deposits from

Electrodepos. Surface Treat., l (1972/73)

ELECTRODEPOSITION OF F e - C r - N i ALLOYS 389

the tetrachromate bath 32. Sheet steel of 18 ° / C r , 9 ~ Ni, Ti grade is reported to have

a hardness value of 321 kg/mm 2 18. The exceptionally good hardness possessed by

the latter deposits 3z was due to the high chromium content. Microhardness

increased with increasing chromium content of deposits reaching 650 kg/mm z for

an alloy containing 3 5 ~ Cr and 5 ~ Ni 4°.

Throwing power

Three attempts were made to examine throwing power 30, 37, 45. This prop-

erty becomes a very important consideration when plating objects of complex

shape and has obviously received little study.

Mutafchiev and Marinkov 3° devised a method to evaluate the throwing

power and obtained values of 26.2~ for their bath.

Addition of sodium, magnesium or aluminium ammonium sulphates to the

sulphate-citrate bath 37 and of aluminium chloride to the chloride-citrate bath 45

was found to improve the throwing power.

Structure of alloys

Deposits from the tetrachromate bath were reported to have a micro-

crystalline structure 32.

X-Ray diffraction analysis showed that the deposits consisted of a solid

solution over the entire composition range 34, 45. In the deposited condition, the

alloy was a solid solution of the three component metals with a body-centred lattice

of the a-iron type. After suitable heat treatment the deposits attained the structure

of an austenitic 18~ Cr, 8~o Ni stainless steel. The a-iron phase structure is what

could be predicted for an electrodeposited alloy as opposed to a thermally-formed

alloy a-iron phase.

Microscopic examination of the deposits from the sulphate-glycine and

chloride-EDTA baths of Chisholm and Carnegie 53 revealed a spherical nodular

growth structure on the deposit surfaces which became more pronounced with

increase in electrolysis time and current density 5a. This suggested a growth struc-

ture of the field-oriented type where the deposit grows outwards from the cathode

surface in the direction of current flow.

Deposition mechanisms

An examination of the trends obtained in the literature revealed that the

majority of the baths studied were controlled by complex plating mechanisms which

appear to be a compromise between normal and abnormal codeposition systems.

The deposition of the metals iron and chromium in the ternary alloy system follows

the trends of normal alloy deposition while nickel deposits by an abnormal plating

mechanism.

Consequently, an accurate assessment of any particular system is difficult

and can only be based on which plating mechanism predominates according to

Electrodepos. Surface Treat., 1 (1972/73)

390 C. U. CHISHOLM, R. J. G. CARNEGIE

the trends observed between the alloy composition structure and bath para-

meters.

This approach has been used to identify to which plating system a particular

bath belonged. Takahashi et al. 28 classified their deposition process as a regular

alloy plating system controlled by the diffusion of iron and nickel ions 26. A critical

examination of the results of the investigations of most of the plating baths suggests

that this mechanism is predominant.

Exceptions to this behaviour do exist. The chloride-citrate 34 and sulphate-

EDTA 5z baths exhibited a predominant tendency towards irregular codeposition

which is controlled, not simply by diffusion, but by the effect of the cathode poten-

tials.

Abnormal codeposition was shown by the tetrachromate bath where the

less noble metal chromium was deposited preferentially with respect to the more

noble metals iron and nickel.

The chloride-EDTA bath, investigated by Chisholm and Carnegie 53, gave

an indication that chromium acts as a reluctant metal during its codeposition and

was deposited in association with some form of solid state film on the cathode

surface. This plating mechanism appeared to be of the abnormal type associated

with induced codeposition where the more noble metals iron and/or nickel induce

deposition of the reluctant metal chromium. In addition, thin deposits were obtained

with a fairly high reluctant metal, chromium present, such as are associated with

induced codeposition.

Examination of the literature shows that very few attempts have been made

to analyse the possible reasons for codeposition of the three metals, in particular,

the mechanisms responsible for bringing together the deposition potentials and

promoting codeposition. Complex formation is known to be a very effective method

of bringing the deposition potentials of meta|s closer together and it is quite feasible

that this particular mechanism was partly responsible for alloy deposition in most

of the baths studied. If the complexing agents are to be effective, however, their

action would have to be predominantly on the more noble metals iron and

nickel, since it is known that the complexing of a metal ion normally causes the

deposition potential of the metal to shift in an electronegative direction. Their

action was reported to be specific to only iron and nickel in some investiga-

tions18, 34, 37

Potentiostatic studies showed that during simultaneous deposition of the

three metals, the discharge of chromium was facilitated while that of nickel and

iron was retarded relative to their individual deposition 21, 40

Film mechanisms were proposed as being responsible for alloy deposition

in two investigations. Machu and El Ghandour claimed that successful codeposi-

tion in their sulphate-urea bath 12 was due to a chromium hydroxide diaphragm

formed on the cathode surface in solutions containing urea, the presence of which

was necessary for the deposition of chromium in metallic form.

Electrodepos. Surface Treat., l (1972/73)

ELECTRODEPOSITION OF F e - C r - N i ALLOYS 391

Chisholm and Carnegie 5a postulated that chromium acts as a reluctant

metal during its codeposition with iron and nickel from their chloride-EDTA bath

and was deposited in association with some form of solid state film on the cathode

surface 53. The film mechanism suggested seems quite feasible since this type of

mechanism is generally accepted for the deposition of chromium and has also

been proposed for the deposition of chromium alloys.

Green and violet modifications of chromium salts

It is a known fact that the hydrated salts of chromium can exist as differently

coloured modifications. Thus the sulphate and chloride salts of chromium can

occur in both violet and green modifications. Studies showed that the violet

modification of chromium was the most widely preferred in the sulphate baths

whereas the green modification was reported for the chloride baths. The reasons

for these preferences were not always given. It was reported for the sulphate-

citrate bath 18 that cathode efficiencies were considerably higher using solutions

of the violet rather than the green modification. This was confirmed through a study

of the cathode polarisation curves which revealed that the alloy was electro-

deposited from solutions of the violet chromium salt at more positive potentials

than from solutions of the green salt ~1.

In violet solutions chromium was suggested as being a complex hydrated

ion. The green form was alleged to be a more mobile hexaquo ion which was hydrol-

ysed to a more stable and tightly bound complex chromium ion. Hence the green

form of chromium sulphate was more difficult to reduce than the violet form.

However, conflicting ideas were reported for the chloride bath where the

green form gave rise to easier reductions.

General conclusions

1. Satisfactory codeposition of ternary alloys of iron, chromium and nickel

can be obtained from a wide range of plating baths.

2. A wide range of deposit compositions, including the 18% Cr, 8% Ni

stainless steel composition, can be produced.

3. In general, only thin deposits of good quality could be produced, the

limiting factor being failure to sustain deposition regardless of the bath type.

4. Stressing and resultant deterioration of deposits appear to be associated

with the absorption and/or adsorption of gases, in particular hydrogen, into the

deposits and/or the base metal.

5. The development of functional deposits will involve elimination of internal

stresses and microcracking.

6. Microcracked deposits could be considered as functional deposits in con-

junction with underlayers of nickel and/or copper to obtain corrosion resistance.

7. Many of the deposits possess considerable wear resistance and could

therefore be developed as protective coatings on softer substrate materials.

Electrodepos. Surface Treat., 1 (1972/73)

392 c . u . CHISHOLM, R. J. G. CARNEGIE

8. Th e experimental results confirm the need for future studies towards the

d e v e l o p m e n t o f sustained deposition.

9. Certain c o m p l e x i n g agents offer promise for future c o m m e r c i a l develop-

ment by giving rise to thicker deposits showing no microcracking.

ACKNOWLEDGEMENTS

The authors wish to express their thanks to the G o v e r n o r s o f D u n d e e

College o f T e c h n o l o g y and R o b e r t G o r d o n ' s Institute o f T e c h n o l o g y for research

facilities provided.

Dr. C h i s h o l m wishes to express his thanks for bibliography research provided

by the staff o f the Library in R o b e r t G o r d o n ' s Institute o f Technology.

REFERENCES

I C. Levy, Metal Finishing, 57 (1959) 59, 65.

2 L. F. Spencer, Metal Finishing, 60 (1962) 48.