Beruflich Dokumente

Kultur Dokumente

Injectores S 60 PDF

Hochgeladen von

franciscoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Injectores S 60 PDF

Hochgeladen von

franciscoCopyright:

Verfügbare Formate

16 MISFIRING CYLINDER

Section Page

16.1 POOR VEHICLE GROUND ..................................................................... 16-3

16.2 AERATED FUEL ..................................................................................... 16-5

16.3 IMPROPER INJECTOR CALIBRATION SETTING (DDEC III/IV

ENGINES ONLY) ..................................................................................... 16-6

16.4 IMPROPER VALVE CLEARANCE OR INJECTOR HEIGHT, WORN OR

DAMAGED CAMSHAFT LOBES AND ROLLERS .................................. 16-9

16.5 FAULTY FUEL INJECTOR ....................................................................... 16-19

16.6 FAULTY ELECTRONIC CONTROL MODULE ......................................... 16-21

16.7 WORN OR DAMAGED VALVE OR CYLINDER KIT ................................ 16-22

(Rev. 12/05) All information subject to change without notice.

16-2 6SE660 0512 Copyright © 2005 DETROIT DIESEL CORPORATION

SERIES 60 OFF-HIGHWAY SERVICE MANUAL

16.1 POOR VEHICLE GROUND

To determine if poor vehicle ground is causing the cylinder to misÞre, perform the following steps:

1. Remove alternator belt.

2. Start the engine.

3. Run the engine through operating range.

4. Listen for engine misÞring.

[a] If the engine is not misÞring, refer to section 16.1.1. Shut down the engine.

[b] If the engine is still misÞring, check for aerated fuel; refer to section 16.2.

16.1.1 Negative Lead Repair

Perform the following steps for negative lead repair:

1. Shut down the engine.

2. Remove negative lead(s) at frame ground stud near battery box.

3. Clean ground stud; refer to OEM guidelines.

4. Clean negative lead(s) terminal lugs with low grit sandpaper.

5. Repair any loose or damaged lead(s), using the splice method or rosin core solder.

6. Install negative lead(s) to frame ground stud; refer to OEM guidelines.

7. Install alternator belt.

[a] If installing a new belt, tighten to 170 N·m (125 lb).

[b] If installing a used belt, tighten to 135 N·m (100 lb).

[c] If a belt tension gage is not available, adjust the belt tension so that a Þrm push with

the thumb, at a point midway between the two pulleys, will depress the belt 12.70

- 19.05 mm (0.500-0.750 in.).

NOTE:

When installing or adjusting an accessory drive belt, be sure the bolt at the accessory

adjusting pivot point is properly tightened, as well as the bolt in the adjusting slot.

NOTE:

Drive belts (Vee and poly-vee) should be replaced every 2,000 hours or 160,000 km

(100,000 miles).

8. Verify negative lead repair; refer to section 16.1.1.1.

All information subject to change without notice. (Rev. 12/05)

6SE660 0512 Copyright © 2005 DETROIT DIESEL CORPORATION 16-3

16.1 POOR VEHICLE GROUND

16.1.1.1 VeriÞcation of Repair for Negative Lead

Perform the following steps to determine if negative lead repair resolved the misÞring cylinder

condition:

1. Refer to section 16.1 for exhaust caution before preceding. Start engine.

2. Run engine speed up to the occurrence of the misÞring.

3. Listen for misÞring cylinder.

[a] If the engine is not misÞring, no further troubleshooting is required. Shut down

the engine.

[b] If the engine is misÞring, check for aerated fuel. Shut down the engine;

refer to section 16.2.

(Rev. 12/05) All information subject to change without notice.

16-4 6SE660 0512 Copyright © 2005 DETROIT DIESEL CORPORATION

SERIES 60 OFF-HIGHWAY SERVICE MANUAL

16.2 AERATED FUEL

To determine if aerated fuel is causing the cylinder to misÞre, perform the following steps:

1. Disconnect the fuel line return hose from the Þtting located at the fuel tank.

2. Place the opened end of fuel line into a suitable container.

3. Start the engine.

4. Run the engine at 1000 rpm.

5. Visually check to see if air bubbles are rising to the surface of the fuel within the container.

[a] If air bubbles are present, refer to section 16.2.1.

[b] If air bubbles are not present, check for improper calibration setting; refer to section

16.3. Shut down the engine.

16.2.1 Aerated Fuel Repair

Perform the following steps for air in fuel repair:

1. Shut down engine.

2. Tighten all fuel line connections between fuel tank and fuel pump; refer to OEM

guidelines.

3. Visually inspect all fuel lines between fuel tank and fuel pump for leaks.

4. Replace any damaged components; refer to appropriate service manual, fuel system

chapter.

5. Verify repair of fuel lines:

[a] If no air in the fuel return, refer to section 16.2.1.1.

[b] If air in the fuel return, locate and repair. Then refer to section 16.2.1.1.

16.2.1.1 Test the Engine with Repair for Aerated Fuel

Perform the following steps to determine if the aerated fuel repair resolved the misÞring cylinder

condition:

1. Refer to section 16.2 for exhaust caution before preceding. Start engine.

2. Run engine at 1000 rpm.

3. Listen for misÞring cylinder.

[a] If the engine is not misÞring, no further troubleshooting is required. Shut down

the engine.

[b] If the engine is misÞring, check for improper injector setting. Shut down the engine;

refer to section 16.3.

All information subject to change without notice. (Rev. 12/05)

6SE660 0512 Copyright © 2005 DETROIT DIESEL CORPORATION 16-5

16.3 IMPROPER INJECTOR CALIBRATION SETTING (DDEC III/IV ENGINES ONLY)

16.3 IMPROPER INJECTOR CALIBRATION SETTING (DDEC III/IV ENGINES

ONLY)

For troubleshooting DDEC I and DDEC II engines, refer to section 16.4.

To determine if an improper injector calibration setting is causing the cylinder to misÞre, perform

the following steps:

1. Remove the valve rocker cover(s); (one-piece two-piece, three-piece) refer to the

appropriate service manual, engine chapter.

2. Record the injector calibration code of each injector noting the cylinder number;

see Figure 16-1.

NOTE:

Injector calibration and bar codes may be absent from the load plates on Þrst-run

production DDEC III/IV injectors 5235575, 5235580, and 5235550. The correct

calibration code for these units is "01". Load plates on current DDEC III/IV injectors

include the required calibration or bar code information.

Figure 16-1 Injector Calibration Code Location

(Rev. 12/05) All information subject to change without notice.

16-6 6SE660 0512 Copyright © 2005 DETROIT DIESEL CORPORATION

SERIES 60 OFF-HIGHWAY SERVICE MANUAL

3. Turn vehicle ignition to the on position, but do not run engine.

4. Install Diagnostic Data Link (DDL) adaptor to the data cable and plug the adaptor into the

DDL connector in the vehicle; refer to OEM guidelines.

5. From the Diagnostic Data Reader (DDR) DDEC III/IV Select Menu, scroll to select

ENGINE and press the ENTER key.

6. Scroll to select FUEL INJECTOR INFO and press the ENTER key.

7. Scroll to select FUEL INJECTOR CAL and press the ENTER key.

8. Scroll to select FUEL INJECTOR CAL. Select VIEW and press the ENTER key.

9. Compare the calibration code(s) shown on the display with the two digit calibration

code(s) on the injector(s).

[a] If the calibration code on the display is different then the calibration code on the

suspect injector for that cylinder, the injector setting must be repaired, see Figure

16-1; refer to section 16.3.1.

[b] If test codes match; refer to section 16.4.

16.3.1 Improper Injector Setting Repair

Perform the following steps to recalibrate improper injector setting:

NOTICE:

Whenever a DDEC III injector is removed from the engine, it

should be reinstalled in its original location to maintain proper

cylinder balance. If reinstalled in a different cylinder head

location, injector calibration must be rechecked with the DDR

and updated. Failure to observe these steps may result in

reduced engine performance.

NOTE:

Injector calibration and bar codes may be absent from the load plates on Þrst-run

production DDEC III/IV injectors 5235575, 5235580, and 5235550. The correct

calibration code for these units is "01''. Load plates on current DDEC III/IV injectors

include the required calibration or bar code information. See Figure 16-1.

1. Scroll to select FUNCTION to return to the FUEL INJECTOR CAL menu on the DDR.

2. Scroll to select FUEL INJECTOR CAL. Select UPDATE and press the ENTER key.

3. Type the four-digit "Update Injector Calibration" password for the DDR and press the

ENTER key. If this feature is not password protected, type "0000" and press the ENTER

key.

All information subject to change without notice. (Rev. 12/05)

6SE660 0512 Copyright © 2005 DETROIT DIESEL CORPORATION 16-7

16.3 IMPROPER INJECTOR CALIBRATION SETTING (DDEC III/IV ENGINES ONLY)

4. A message will appear telling you to use the scroll keys to select the cylinder (requiring

changes) or select TYPE # (enter the numerical keys to change the CAL (calibration value).

NOTE:

An asterisk (*) will highlight the Þrst cylinder number on the list.

5. Scroll to the cylinder requiring change and type in the required two-digit injector

calibration code number. Press the ENTER key.

NOTE:

The ENTER key must be pressed before the DDR will allow selection of another cylinder

number.

6. Repeat step 5, until all changes have been made.

7. Scroll to select FUNCTION and press the ENTER key.

8. Scroll to select YES and press the ENTER key to reprogram the Electronic Control

Module (ECM) with the revised injector calibration codes.

NOTE:

Turning the ignition to the off position and waiting Þve seconds before starting the engine

is not required.

9. Disconnect the DDR; refer to OEM guidelines.

16.3.1.1 VeriÞcation of Repair for Improper Injector Setting

Perform the following steps to determine if the proper injector setting adjustment resolved the

misÞring cylinder condition:

1. Install the valve rocker cover(s); (one-piece, two piece, three piece) refer to the appropriate

service manual, engine chapter.

2. Start the engine.

3. Run the engine at 1000 rpm.

4. Listen for misÞring cylinder.

[a] If the engine is not misÞring, no further troubleshooting is required. Shut down

the engine.

[b] If the engine is misÞring, shut down the engine. Check for improper valve clearance

and injector height and damaged or worn camshaft lobes and rollers; refer to section

16.4.

(Rev. 12/05) All information subject to change without notice.

16-8 6SE660 0512 Copyright © 2005 DETROIT DIESEL CORPORATION

SERIES 60 OFF-HIGHWAY SERVICE MANUAL

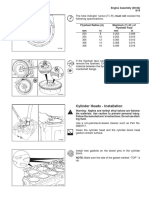

16.4 IMPROPER VALVE CLEARANCE OR INJECTOR HEIGHT, WORN OR

DAMAGED CAMSHAFT LOBES AND ROLLERS

Intake valve clearance and injector height are adjusted by means of an adjusting set screw and

locknut located at the valve (or injector) end of the rocker arm; see Figure 16-2.

1. Exhaust Valve 6. Intake Valve

2. Intake Valve 7. Fuel Injector Follower

3. Locknut 8. Valve Button

4. Adjusting Set Screw 9. Exhaust Valve

5. Exhaust Rocker Arm Assembly

Figure 16-2 Valve and Fuel Injector Height Adjustment Components

NOTE:

On engines equipped with a Jake Brake, measure valve lash and injector height before

removing any brake housings. Only remove the brake housings necessary to provide

access for adjustment.

All information subject to change without notice. (Rev. 12/05)

6SE660 0512 Copyright © 2005 DETROIT DIESEL CORPORATION 16-9

16.4 IMPROPER VALVE CLEARANCE OR INJECTOR HEIGHT, WORN OR DAMAGED CAMSHAFT LOBES

AND ROLLERS

The injector height is adjusted using the injector timing gage J–39697 (DDEC III/IV) or

J–35637–A (DDEC II and I). On engines equipped with a Jake Brake, move the handle on the

injector height gage to the alternate position, 90 degrees to the shank. A height gage pilot hole

is provided in the fuel injector body on the machined surface contacted by the injector clamp

near the solenoid; see Figure 16-3.

Figure 16-3 Timing Gauge

NOTE:

Be sure the height gage seats on the machined surface with the tip in the pilot hole.

Foreign material in the pilot hole or on the machined surface may prevent accurate

setting of the injector height.

To determine if improper valve clearance, injector height or both are causing the cylinder to

misÞre, perform the following preliminary step 1 through step 3 and repeat step 4 through step

9 for each cylinder to determine if worn or damaged lobes or rollers are causing the engine

to misÞre:

1. Disconnect starting power for engine.

2. Remove the valve rocker cover(s); (one-piece, two piece, three piece) refer to the

appropriate service manual, engine chapter.

3. Insert a 3/4 in. drive breaker bar or ratchet into the square hole in the center of the

crankshaft pulley.

(Rev. 12/05) All information subject to change without notice.

16-10 6SE660 0512 Copyright © 2005 DETROIT DIESEL CORPORATION

SERIES 60 OFF-HIGHWAY SERVICE MANUAL

4. Bar the engine over and inspect camshaft and rollers for wear or damage. Stop engine

rotation when any one of the injector followers has just begun its downward stroke;

see Figure 16-4.

1. Injector Follower 4. Injector Cam Lobe

2. Injector Rocker Arm Assembly 5. Point on the Camshaft Lobe that First Produces

Downward Motion of the Injector Follower

3. Injector Roller

Figure 16-4 Injector Followers Downward Stroke

[a] If damage is found on the camshaft lobes or rollers, stop this procedure and replace

damaged components as necessary; refer to the appropriate service manual, engine

chapter. Once complete, refer to section 16.4.1.1.

[b] If no damage was found to camshaft or rollers, continue with task.

5. Using timing chart, see Figure 16-5, determine if the intake valve clearances are acceptable

(listed in Table 16-1), by inserting a feeler gage between the tip of the intake valve stem

and the button; see Figure 16-6.

[a] If the intake valve stem clearance is between 0.127 - 0.280 mm (0.005-0.011 in.),

step 6.

All information subject to change without notice. (Rev. 12/05)

6SE660 0512 Copyright © 2005 DETROIT DIESEL CORPORATION 16-11

16.4 IMPROPER VALVE CLEARANCE OR INJECTOR HEIGHT, WORN OR DAMAGED CAMSHAFT LOBES

AND ROLLERS

[b] If the intake valve stem clearance is not between 0.127 - 0.280 mm (0.005-0.011 in.),

reset the intake valve(s) to 0.203 mm (0.008 in.); refer to section 16.4.1, step 1.

Figure 16-5 Timing Circle Chart

1. Intake Valve 4. Locknut

2. Valve Button 5. Feeler Gage

3. Intake Rocker Arm Assembly 6. Tip of Intake Valve

Figure 16-6 Intake Valve Clearance

(Rev. 12/05) All information subject to change without notice.

16-12 6SE660 0512 Copyright © 2005 DETROIT DIESEL CORPORATION

SERIES 60 OFF-HIGHWAY SERVICE MANUAL

Settings and Models Acceptable Range Recommended Setting

Injector Heights DDEC I and II

(6067GT40, 6067WT40, 6067WU40,

6067GU40, 6063WU00, 6063GU00, 77.9–78.4 mm (3.068–3.088 in.) 78.2 mm (3.078 in.)

6067WU60, 6067GU60, and

6067GU91)

Injector Heights DDEC III

(6067WK60, 6067WK28, 6067GK60,

6067GK28, 6063WK60, 6063WK28, 2.992–3.112 mm (2.992–3.112 in.) 78.8 mm (3.102 in.)

6063GK05 6063GK60, and

6063GK28)

Intake Valve Clearance 0.127 - 0.280 mm (0.005. - 0.011 in.) 0.203 mm (0.008 in.)

Exhaust Valve Clearance "U''

(6067GT40, 6067WT40, 6067WU40, 0.432 - 0.054 mm (0.017 - 0.023 in.) 0.508 mm (0.020 in.)

6067GU40, 6063WU00, 6063GU00)

Exhaust Valve Clearance 0.584 - 0.736 mm (0.023 - 0.029 in.) 0.660 mm (0.026 in.)

"H''(6067WU60, 6067GU60,

6067WK60, 6067GK60, 6067GK28,

6067WK28 6067GU91, 6063WU60,

6063GK05, 6063GK32, 6063GK60,

6063GU41, 6063GU60, 6063WK32,

6063WK60, 6063WU00, 6063WU41,

6063GU00)

Table 16-1 Valve Clearance and Injector Height Settings

6. Using timing chart, see Figure 16-5, determine if the exhaust valve clearances are

acceptable, (listed in Table 16-1) by inserting a feeler gage between the tip of the exhaust

valve stem and the button; see Figure 16-7.

[a] For exhaust valves with a machined groove between the rotator and tip, the exhaust

valve stem clearance should be between 0.584 - 0.736 mm (0.023 - 0.029 in.). If

the exhaust valve stem clearance is between 0.584 - 0.736 mm (0.023 - 0.029 in.),

proceed to step 7. For exhaust valves without a machined groove between the rotator

and tip, the exhaust valve stem clearance should be between 0.432 - 0.584 mm (0.017

- 0.023 in.). If the exhaust valve stem clearance is between 0.432 - 0.584 mm (0.017 -

0.023 in.), perform to step 7 or step 8.

[b] If the exhaust valve stem clearance is not between 0.584 - 0.736 mm (0.023 - 0.029

in.) for exhaust valves with a machined groove between the rotator and tip, reset the

valve(s) to 0.660 mm (0.026 in.); refer to step 7 or step 8.

All information subject to change without notice. (Rev. 12/05)

6SE660 0512 Copyright © 2005 DETROIT DIESEL CORPORATION 16-13

16.4 IMPROPER VALVE CLEARANCE OR INJECTOR HEIGHT, WORN OR DAMAGED CAMSHAFT LOBES

AND ROLLERS

[c] If the exhaust valve stem clearance is not between 0.432 - 0.584 mm (0.017 - 0.023

in.) for exhaust valves without a machined groove between the rotator and tip, reset

the valve(s) to 0.508 mm (0.020 in.); refer to section 16.4.1. step 2.

1. Location of IdentiÞcation Groove 5. Locknut

2. Valve Button 6. Exhaust Rocker Arm Assembly

3. Allen Wrench 7. Feeler Gage

4. Adjusting Screw 8. Tip of Exhaust Valve

Figure 16-7 Exhaust Valve Clearance

(Rev. 12/05) All information subject to change without notice.

16-14 6SE660 0512 Copyright © 2005 DETROIT DIESEL CORPORATION

SERIES 60 OFF-HIGHWAY SERVICE MANUAL

7. If troubleshooting a DDEC III/IV engine, place the small end of J–39697 in the hole

provided in the injector body, with the ßat of the gage toward the fuel injector plunger;

see Figure 16-8.

[a] If the tool is ßush against the follower, the injector height is acceptable; refer to step 9.

[b] If the tool is not ßush, adjust injector height; refer to section 16.4.1, step 3

1. Height Gage Flag 4. Adjusting Screw

2. Height Gage 5. Locknut

3. 3/16 in. Allen Wrench 6. Fuel Injector Follower

Figure 16-8 Fuel Injector Adjustment

8. If troubleshooting a DDEC I or II engine, place the small end of J–35637–A in the hole

provided in the injector body, with the ßat of the gage toward the fuel injector plunger;

see Figure 16-8.

[a] If the tool is ßush against the follower, the injector height is acceptable; refer to step 9.

[b] If the tool is not ßush, adjust injector height; refer to section 16.4.1, step 3.

9. Bar the engine over, clockwise, until the fuel injector for the next cylinder begins its

downward stroke; see Figure 16-4. Repeat step 5 through step 8 and repeat until all six

fuel injectors and sets of valves have been checked and reset as necessary. When all

cylinders have been checked, refer to section 16.4.1, step 4.

All information subject to change without notice. (Rev. 12/05)

6SE660 0512 Copyright © 2005 DETROIT DIESEL CORPORATION 16-15

16.4 IMPROPER VALVE CLEARANCE OR INJECTOR HEIGHT, WORN OR DAMAGED CAMSHAFT LOBES

AND ROLLERS

16.4.1 Improper Valve Clearance or Injector Height Repair

Perform the following steps to repair improper fuel injector height, intake valve clearance, and

exhaust valve clearance.

NOTE:

Using the steps below, it will be necessary to bar the engine over only two complete

revolutions. Three cylinders will be adjusted for valves, and three cylinders will be

adjusted for injectors on each revolution.

If required, remove Jake Brake housing necessary to provide access for repair; refer to the

appropriate service manual, engine chapter.

NOTICE:

Never set the valves and injector of the same cylinder at the

same time. Doing this will result in engine damage.

1. Adjust the intake valve clearances as follows:

[a] Insert a 0.203 mm (0.008 in.) feeler gage between the tip of one valve stem and the

valve button; see Figure 16-9.

[b] Loosen the locknut, and turn the adjusting set screw until the feeler gage produces a

snug, smooth pull between the intake valve stem and valve button; see Figure 16-9.

(Rev. 12/05) All information subject to change without notice.

16-16 6SE660 0512 Copyright © 2005 DETROIT DIESEL CORPORATION

SERIES 60 OFF-HIGHWAY SERVICE MANUAL

[c] Torque the locknut to 41 - 47 N·m (30 - 35 lb·ft) and remove the feeler gage. Reinsert

the feeler gage to ensure that the adjustment did not change when the locknut was

tightened. Readjust as necessary.

1. Intake Valve 4. Locknut

2. Valve Button 5. Feeler Gauge

3. Intake Rocker Arm Assembly 6. Tip of Intake Valve

Figure 16-9 Measurement of Intake Valve Clearance

2. Perform the following steps to adjust the exhaust valve clearances:

[a] Insert a 0.660 mm (0.026 in.) feeler gage for valves with a machined groove between

the tip of the valve stem and the valve button. Insert a 0.508 mm (0.020 in.) feeler

gage for valves without machined groove; see Figure 16-7.

[b] Loosen the locknut, and turn the adjusting set screw until the feeler gage produces a

snug, smooth pull between the exhaust valve stem and the valve button.

[c] Torque the locknut to 41 - 47 N·m (30 - 35 lb·ft) and remove the feeler gage. Reinsert

the feeler gage to ensure that the adjustment did not change when the locknut was

tightened. Readjust as necessary.

All information subject to change without notice. (Rev. 12/05)

6SE660 0512 Copyright © 2005 DETROIT DIESEL CORPORATION 16-17

16.4 IMPROPER VALVE CLEARANCE OR INJECTOR HEIGHT, WORN OR DAMAGED CAMSHAFT LOBES

AND ROLLERS

3. Perform the following steps to adjust fuel injector heights.

[a] For DDEC III/IV engines, place the small end of the timing gage (J–39697) in the

hole provided in the fuel injector body, with the ßat of the gage toward the fuel

injector plunger; see Figure 16-3 and proceed to step 3[c].

[b] For DDEC I or II engines, place the small end of the timing gage (J–35637–A) in

the hole provided in the fuel injector body, with the ßat of the gage toward the fuel

injector plunger.

[c] Loosen the locknut and turn the adjusting set screw until the extended part (ßag) of the

gage will just pass over the top of the injector follower. A snug feel is recommended.

The objective is to adjust all six injectors to the same feel; see Figure 16-9.

[d] Torque the locknut to 41 - 47 N·m (30 - 35 lb·ft).

[e] Check the adjustment with J–39697 (DDEC III/IV engines) or J–35637–A (DDEC I

or II engines), and if necessary, readjust the set screw.

4. Install the valve rocker cover(s); refer to the appropriate service manual, engine chapter.

5. Install the Jake Brakes if removed for repair; refer to the appropriate service manual,

engine chapter.

6. Reconnect starting power to the engine.

7. Verify repair of valve clearance or injector height setting. Refer to section 16.4.1.1.

16.4.1.1 VeriÞcation of Repair for Improper Valve Clearance or Injector

Height Setting

Perform the following steps to determine if valve clearance or injector height adjustment resolved

the misÞring cylinder condition:

1. Start the engine.

2. Run the engine at 1000 rpm.

3. Listen for misÞring cylinder.

[a] If the engine is not misÞring, shut down the engine. No further troubleshooting is

required.

[b] If the engine is misÞring, shut down the engine and check for faulty fuel injector;

refer to section 16.5.

(Rev. 12/05) All information subject to change without notice.

16-18 6SE660 0512 Copyright © 2005 DETROIT DIESEL CORPORATION

Das könnte Ihnen auch gefallen

- Nissan Sentra Service Manual Section Engine MechanicalDokument180 SeitenNissan Sentra Service Manual Section Engine Mechanicalvicyahoo75% (8)

- 3122 ISX CM570 CM870 CM871 Static Injection Timing MeasureDokument7 Seiten3122 ISX CM570 CM870 CM871 Static Injection Timing Measureralph aris100% (1)

- DW-K500C K501CDokument13 SeitenDW-K500C K501CPedro Falfan100% (1)

- Gen 5 DD15 Platform Workshop Manual (DDC-SVC-MAN-0215)Dokument7 SeitenGen 5 DD15 Platform Workshop Manual (DDC-SVC-MAN-0215)freddy100% (1)

- Isx 15 Fuel System WorksDokument3 SeitenIsx 15 Fuel System Workssidhu100% (2)

- 2023 Beta Xtrainer Service ManualDokument120 Seiten2023 Beta Xtrainer Service ManualPASCONoch keine Bewertungen

- Cat c15 Cylinder Head InstallationDokument7 SeitenCat c15 Cylinder Head InstallationMUHSIN MTNoch keine Bewertungen

- CalibrationListing REL 32d International 370a430HPDokument161 SeitenCalibrationListing REL 32d International 370a430HPAnonymous nhF45CNoch keine Bewertungen

- Torque Procedure Cilinder Head - MP7 EnginesDokument1 SeiteTorque Procedure Cilinder Head - MP7 Engineshamilton miranda100% (1)

- 1127 Mid Stop Counterbore CuttingDokument7 Seiten1127 Mid Stop Counterbore Cuttingralph arisNoch keine Bewertungen

- TT00041 - Injector Sleeve Installation On 2008 - 2017 Detroit DieselDokument2 SeitenTT00041 - Injector Sleeve Installation On 2008 - 2017 Detroit DieselIonut-alexandru Iordache100% (1)

- 06873E - Manual, T700 PDFDokument366 Seiten06873E - Manual, T700 PDFCharles LeiftonNoch keine Bewertungen

- Service Bulletin Trucks: Engine, ReplacementDokument29 SeitenService Bulletin Trucks: Engine, Replacementvicente456Noch keine Bewertungen

- Thermal Recirculation Valve Installation InstructionsDokument7 SeitenThermal Recirculation Valve Installation InstructionsSean DuncanNoch keine Bewertungen

- Caterpillar C10, C12Dokument8 SeitenCaterpillar C10, C12Вячеслав ШапочкаNoch keine Bewertungen

- n14 Cylinder Head InstallationDokument3 Seitenn14 Cylinder Head InstallationOumarba KamandaNoch keine Bewertungen

- No.: 04 TS-43Rev3: Detroit Diesel 13400 Outer Drive, West / Detroit, Michigan 48239-4001Dokument9 SeitenNo.: 04 TS-43Rev3: Detroit Diesel 13400 Outer Drive, West / Detroit, Michigan 48239-4001Gutierrez EfrainNoch keine Bewertungen

- Valve Lash C15 AccertDokument5 SeitenValve Lash C15 AccertDominick TalaricoNoch keine Bewertungen

- Section 1.13 Gear Case Exhaust Gas Recirculation (EGR) ModelDokument10 SeitenSection 1.13 Gear Case Exhaust Gas Recirculation (EGR) ModeldanyNoch keine Bewertungen

- Service Bulletin Trucks: Piston and Liner, ReplacementDokument11 SeitenService Bulletin Trucks: Piston and Liner, ReplacementMiller Andres ArocaNoch keine Bewertungen

- Ajuste de Valvulas PDFDokument8 SeitenAjuste de Valvulas PDFRoberto Rincon Robles100% (1)

- 1-60-04 JacobsDokument2 Seiten1-60-04 JacobsRuben Antonio Huaranca CruzNoch keine Bewertungen

- Detroit DD15 Engine: Horsepower LB-FT Torque LitersDokument10 SeitenDetroit DD15 Engine: Horsepower LB-FT Torque Litersramsi17100% (1)

- Detroit S60 SpecsDokument2 SeitenDetroit S60 Specsgrgramm50% (2)

- Service Bulletin Trucks: Timing Gears, Replacement (All)Dokument7 SeitenService Bulletin Trucks: Timing Gears, Replacement (All)Miller Andres ArocaNoch keine Bewertungen

- SPN 84/FMI 0 and SPN 84/FMI 11 Have Been AddedDokument4 SeitenSPN 84/FMI 0 and SPN 84/FMI 11 Have Been AddedHamilton mirandaNoch keine Bewertungen

- PDF - Isx MotorDokument4 SeitenPDF - Isx MotorJanier100% (1)

- ISX 871 Flywheel RunoutDokument13 SeitenISX 871 Flywheel RunoutJ.T. NoneyaNoch keine Bewertungen

- Installation Instruction: Fuel Pump Short Block Service Kit Installation InstructionsDokument4 SeitenInstallation Instruction: Fuel Pump Short Block Service Kit Installation InstructionsSean DuncanNoch keine Bewertungen

- 60.2 Installation of The 2V2-2HH Soot SensorDokument2 Seiten60.2 Installation of The 2V2-2HH Soot SensorCuong Dinh100% (1)

- Detroit: The Detroit DD5 EngineDokument2 SeitenDetroit: The Detroit DD5 Enginerichie100% (2)

- RR trts-0930Dokument400 SeitenRR trts-0930Vladimir Illich PinzonNoch keine Bewertungen

- Compresor Bendix Ba-921 P Detroit PDFDokument36 SeitenCompresor Bendix Ba-921 P Detroit PDFDenis HernandezNoch keine Bewertungen

- C11 and C13 On-Highway Truck Engines Electrical System: Right Side ViewDokument2 SeitenC11 and C13 On-Highway Truck Engines Electrical System: Right Side ViewkamalNoch keine Bewertungen

- 019-440 Aftertreatment Diesel Exhaust Fluid Dosing UnitDokument9 Seiten019-440 Aftertreatment Diesel Exhaust Fluid Dosing UnitIan WoodsNoch keine Bewertungen

- Allison AT540, 543, 545Dokument6 SeitenAllison AT540, 543, 545Gina LópezNoch keine Bewertungen

- Cylinder Head: C15 On Highway EngineDokument11 SeitenCylinder Head: C15 On Highway EngineJohan Ricardo HUANCA ESPINOZANoch keine Bewertungen

- HD BBM 2022Dokument210 SeitenHD BBM 2022CTIJRZLZTJ2022Noch keine Bewertungen

- Eaton Fuller Heavy Duty Transmission Troubleshooting Guide Trts0910 en UsDokument42 SeitenEaton Fuller Heavy Duty Transmission Troubleshooting Guide Trts0910 en Ustito del pino100% (2)

- Drive Axle PDFDokument12 SeitenDrive Axle PDFnamduong368Noch keine Bewertungen

- Trsm0940en-Us 0719Dokument263 SeitenTrsm0940en-Us 0719Wilson Yesid Perez CastañedaNoch keine Bewertungen

- Cummins IsxDokument3 SeitenCummins IsxFaudy Jonas Gonzalez CastilloNoch keine Bewertungen

- MX13 PACCAR TorqueDokument8 SeitenMX13 PACCAR TorqueMarcos Vinicius Binotto100% (1)

- 003-004 Overhead Set: General InformationDokument16 Seiten003-004 Overhead Set: General InformationIgoen YandriNoch keine Bewertungen

- Variable Valve Actuators - Inspect/Adjust: C11 and C13 Engines For Caterpillar Built MachinesDokument5 SeitenVariable Valve Actuators - Inspect/Adjust: C11 and C13 Engines For Caterpillar Built MachinesIndiNoch keine Bewertungen

- Transmision Automatizada Eaton UltrashiftDokument4 SeitenTransmision Automatizada Eaton UltrashiftDIONYBLINK100% (1)

- Delete Cancel Egr DPF SCR Adblue Regeneration SystemDokument3 SeitenDelete Cancel Egr DPF SCR Adblue Regeneration SystemScribdTranslations100% (1)

- Volvo D16, Head GasketDokument2 SeitenVolvo D16, Head GasketinduramNoch keine Bewertungen

- D12D425 VHD PDFDokument2 SeitenD12D425 VHD PDFMarco Antonio Esparza CastroNoch keine Bewertungen

- 2009 Dodge Ram 3500 SLT 6.7 ECMDokument4 Seiten2009 Dodge Ram 3500 SLT 6.7 ECMBastian CruzNoch keine Bewertungen

- Jacobs Brake 310 312 Parts Book On Caterpillar C10 C12 022040BDokument4 SeitenJacobs Brake 310 312 Parts Book On Caterpillar C10 C12 022040Bvasanth kumar100% (1)

- Calibracion Inyector n3 Ddec VDokument6 SeitenCalibracion Inyector n3 Ddec VJosue Juaniquina LucanaNoch keine Bewertungen

- Installation Instruction: Lubricating Oil Filter Bypass ValveDokument6 SeitenInstallation Instruction: Lubricating Oil Filter Bypass ValveSean DuncanNoch keine Bewertungen

- 10 Intermittentfault10Dokument94 Seiten10 Intermittentfault10libertyplusNoch keine Bewertungen

- Internal or External Leakage of The High Pressure Fuel System 2Dokument11 SeitenInternal or External Leakage of The High Pressure Fuel System 2SatooAtheiNoch keine Bewertungen

- Fuel RailDokument1 SeiteFuel RailsidhuNoch keine Bewertungen

- TRSM 1500 0413 Heavy Duty Trans RTO16915Dokument256 SeitenTRSM 1500 0413 Heavy Duty Trans RTO16915Freddy Orellana100% (1)

- Fuel Injection Pump - Install - With Electronic GovernorDokument5 SeitenFuel Injection Pump - Install - With Electronic Governoreshopmanual limaNoch keine Bewertungen

- Caution:: tm2138 - 3120, 3320, 3520 and 3720 Compact Utility Tractors Repair Manual - Injection Pump Timing-EPA EnginesDokument11 SeitenCaution:: tm2138 - 3120, 3320, 3520 and 3720 Compact Utility Tractors Repair Manual - Injection Pump Timing-EPA Enginesronald allan liviocoNoch keine Bewertungen

- Guidelines Water Pump 3 PDFDokument2 SeitenGuidelines Water Pump 3 PDFvictoverNoch keine Bewertungen

- Rcrit 20V797 0876Dokument9 SeitenRcrit 20V797 0876nobodylobuzNoch keine Bewertungen

- Cat Inspect ModulesDokument3 SeitenCat Inspect ModulesDAnielNoch keine Bewertungen

- Ficha Técnica - ElectricaDokument8 SeitenFicha Técnica - ElectricainspeccionestecnicasnfpaNoch keine Bewertungen

- (TM) Ssangyong Manual de Taller Ssangyong Actyon 2013 en Ingles (1) - 301-400Dokument100 Seiten(TM) Ssangyong Manual de Taller Ssangyong Actyon 2013 en Ingles (1) - 301-400LUIS HERNANDONoch keine Bewertungen

- 9822/0310 F630-5-1 459/10248 REVERSER CLUTCH ASSEMBLY: Marcial MilitanteDokument3 Seiten9822/0310 F630-5-1 459/10248 REVERSER CLUTCH ASSEMBLY: Marcial MilitanteMarcial Jr. MilitanteNoch keine Bewertungen

- Ficha Tecnica Motor Perkins 403d-15gDokument4 SeitenFicha Tecnica Motor Perkins 403d-15gChristian OcampoNoch keine Bewertungen

- Fluid Drives: For Diesel Engines and AC MotorsDokument4 SeitenFluid Drives: For Diesel Engines and AC MotorsHamid MojiryNoch keine Bewertungen

- Three-Phase Alternator: Prepared By: Teodoro M. de Jesus JRDokument17 SeitenThree-Phase Alternator: Prepared By: Teodoro M. de Jesus JRTeodoro De JEsusNoch keine Bewertungen

- Unit TestDokument6 SeitenUnit Testapi-312110713Noch keine Bewertungen

- Why Single Phase Induction Motor Is Not Self Starting - StudyElectrical - Online Electrical Engineering Study SiteDokument6 SeitenWhy Single Phase Induction Motor Is Not Self Starting - StudyElectrical - Online Electrical Engineering Study Siteashish palNoch keine Bewertungen

- CLUTCH - 235DTR - 267DTR - 280DTR: Renault TrucksDokument42 SeitenCLUTCH - 235DTR - 267DTR - 280DTR: Renault TrucksMax SamNoch keine Bewertungen

- J316V05 enDokument4 SeitenJ316V05 enMartin KratkyNoch keine Bewertungen

- Motor Xoay NgángDokument14 SeitenMotor Xoay NgángNguyễn Văn Hùng100% (1)

- 6403 Tractor North America Edition IntroductionDokument5 Seiten6403 Tractor North America Edition Introductionhelenio carrillo espinozaNoch keine Bewertungen

- Takeuchi Tb015 Parts ManualDokument20 SeitenTakeuchi Tb015 Parts Manuallillie100% (52)

- PMM WordDokument3 SeitenPMM WordShrey R DhanawadkarNoch keine Bewertungen

- Fuji 116 TimersDokument4 SeitenFuji 116 TimersJoe ZanterNoch keine Bewertungen

- Sds-Model EngDokument21 SeitenSds-Model EngMAZENNoch keine Bewertungen

- PSD Impt QuestionsDokument8 SeitenPSD Impt QuestionsDIPESHNoch keine Bewertungen

- Diesel Engines 8V/12V/16V 4000 M60R: For Vessels With Unrestricted Continuous Operation (1A)Dokument2 SeitenDiesel Engines 8V/12V/16V 4000 M60R: For Vessels With Unrestricted Continuous Operation (1A)Jorge Bellido100% (1)

- MDP09 - Exp. Jts With Tie RodsDokument1 SeiteMDP09 - Exp. Jts With Tie RodsEdward JulianNoch keine Bewertungen

- Sample Question PaperDokument4 SeitenSample Question PaperRajat ShrirameNoch keine Bewertungen

- ORAL Past QuestionDokument13 SeitenORAL Past QuestionhilminroziNoch keine Bewertungen

- Intelligent Cooling SystemDokument11 SeitenIntelligent Cooling SystemAnmolquick100% (3)

- Lift 1Dokument27 SeitenLift 1shelmi100% (1)

- Service Manual A10 & A12 ECDokument5 SeitenService Manual A10 & A12 ECLuisNoch keine Bewertungen

- Edrian Manzanares Resume NewDokument3 SeitenEdrian Manzanares Resume NewYcam ManzanaresNoch keine Bewertungen

- d45ks d50ks Brochure EnglishDokument12 Seitend45ks d50ks Brochure EnglishMarcelo AksteinNoch keine Bewertungen

- Advance and Ignition Timing For Better Fuel EconomyDokument9 SeitenAdvance and Ignition Timing For Better Fuel EconomySebastian BryceNoch keine Bewertungen

- 4-Stroke Diesel Engine InternshipDokument14 Seiten4-Stroke Diesel Engine InternshipBairi Rajesh100% (1)