Beruflich Dokumente

Kultur Dokumente

Ijeee Icter P103

Hochgeladen von

Thava JothiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ijeee Icter P103

Hochgeladen von

Thava JothiCopyright:

Verfügbare Formate

SSRG International Journal of Electronic and Electronics Engineering (SSRG-IJEEE) – Special Issue ICTER Mar 2019

IOT Based Sensorless Speed Control of

Induction Motor

Pradeepkumar.V1, Indhumathi.B2,Poorani.P3,Nirmala.M4,Anbarasu.L5

Ug Scholar1,2,3,4 Assistant Professor5

Department of Electrical and Electronics Engineering

Abstract

Speed sensors are required for the control of With the help of IOT through GPRS the required

induction motors and temperature sensors are speed is given as input to PWM through PIC

required to find excessive thermal stress.These microcontroller thus varying the speed of induction

sensors reduces the studiness of the system and make motor.

it expensive.Therefore a drive system without sensors Present industry is increasingly shifting towards

is required.It is usual to find single phase induction automation. Two principle components of today‟s

motor(SPIM) in several house,office,farm and industrial automations are programmable controllers

industry uses,which are become each time more and robots. In order to aid the tedious work and to

refined and requiring variable speed drives.This serve the mankind, today there is a general tendency

project presents a tender for sensorless variable to develop an intelligent operation.

speed SPIM drive based on IOT. A Spectator based

on two independent linear closed-loop control The objective of this project is to monitor and

systems provides the assessment to the rotor flux and protect if the induction motor parameters such as

speed from the measurements of the stator currents voltage , current, temperature and speed are exceed

and voltages.Variable transformation is not used in above the normal value without using any sensor.

this project in order to eliminate the asymmetry of the

stator windings of the SPIM.The performance of the Thus the proposed method has the advantage of

proposed sensorless speed control andparameters requiring a low level monitoring signal which reduces

monitoring is satisfactorily verified from computer the motor torque perturbations and additional power

simulations. losses are negligible.PIC microcontroller is the heart

of the device which handles all the sub devices

Keywords - Microcontroller, GPRS, IOT, Induction connected across it. It has flash type reprogrammable

motor, Speed, MPLAB and etc. memory. It has some peripheral devices to play this

project perform. It also provides the sufficient power

I.INTRODUCTION to inbuilt peripheral devices. We need not give

individually to all devices. The peripheral devices

General purpose of motors are increasing widely also activities as low power operation mode. These

in our surrounding from household equipments to are advantages that appear here.

machine tools in industrial applications.It is a

necessary and indispensable source of power in many

industries.In many applications the speed control

plays a vital role which can be done using many

control strategies

The purpose speed controller of a motor is to take

signal representing the demanded speed and to drive a

motor at that speed.Generally speed control of the

motor can be can be done by varying the motor

parameters of the induction motor such as

current,voltage,frequency etc.,this can be achieved by

different methods such as field control

method,armature control method etc.

II.EXISTING SYSTEM

In this project speed control is done by PWM (Pulse

Width Modulation) technique and the parameters are The objective of this project is to generate PWM

monitored and displayed in LCD by PIC frequency in PIC microcontroller to control the speed

microcontroller and shared to mobile using IOT of the single phase induction motor.In this project we

through GPRS which makes the whole system are generating frequency to control speed of single

flexible and user friendly. phase induction motor. By using the software

instruction we are generating frequency for PWM

ISSN: 2349 – 8379 www.internationaljournalssrg.org Page 10

SSRG International Journal of Electronic and Electronics Engineering (SSRG-IJEEE) – Special Issue ICTER Mar 2019

wave in the PIC microcontroller. It is the flash type by PWM technique and also the system will be

microcontroller in which we have already connected web server using Wi-Fi module. The

programmed system is designed in such a way to accept commands

from a web server. This commands are the various

The PWM pulse is given to driver circuit. Then speed. The system responds to this commands by

AC voltage is given to setup transform in order to changing the motors run speed as per the command

step up into 230V. So the output of the transformer is received.

230V AC 50Hz frequency voltage and given to

motor. The speed is monitored by proximity sensor. It

detects the metals and generates the voltage pulse.

We fixed the metal plate in the motor shaft. So

whenever metal plate is crossed, the proximity sensor

generates the pulse. The corresponding pulse signal is

given to the microcontroller.

Now the microcontrollers display the pulse rate on the

LCD display which is equal to speed of the motor.

The microcontroller compares the monitored and set

speed to regulate the speed. Here by we used the

keypad to give the set value to microcontroller.

III. PROPOSED METHOD

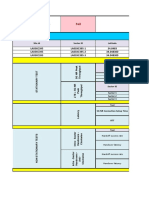

From 230V AC line PT is connected in parallel to Fig.3.1 Block diagram of proposed system

measure voltage. Precision rectifier converts AC to

DC. This is done as the PIC microcontroller works IV. INTERNET OF THINGS

only on DC not on AC. CT is connected in series to Internet of things(IOT) is the network of physical

measure current and shunt resistor is used to limit the devices, software, sensors, actuators connectivity

starting current and also current can be calculated by which enables these things to connect, collect an

measuring voltage drop. Since we know the value of exchange data.

resistor with the measured value of voltage current

can be calculated. Precision rectifier converts AC to The definition of internet of things has evolved due to

DC. PIC microcontroller receives the values of the convergence of multiple technologies, real time

parameters voltage and from CT to PT and displays it analytics, machine learning and embedded

in LCD. When current increases, torque increases and systems.The concept of a network of smart devices

speed decreases and similarly when current decreases, was discussed as early as 1982, with a modified coke

torque and speed increases. machine at Carriage Mellon University becoming the

first internet connected appliance, able to report its

With the knowledge of speed can be calculated using inventory and whether newly loaded drinks were

the relation, cold. Radio frequency identification is as essential to

Speed in rpm = HP *5250/Torque the internet of things, which would allow computers

to manage all individual things.

A SIM is inserted in the GPRS. The monitored

parameters from PIC is sent to the mobile through

GPRS. IoT app in mobile receives the parameter and

hence we can monitor the induction motor easily

whenever and whenever we want. From IOT we can

also send the required speed to control the induction

motor through GPRS to PIC microcontroller.

This value of speed is given as input to PWM which

varies the outputaccordingly which in turn drives the

control circuit (which consists of thyristor) to vary the

speed of the induction motor.

The induction motor sped is varied by varying the Fig.4.1. Internet of things

Pulse Width or Pulse Duration (frequency) can be

achieved by using relation, V. SINGLEPHASE MOTOR

Speed = 120*frequency/No. of poles However it will not self start. It may be hand

started in either direction, coming up to speed in a

The project is designed to monitor and control the

speed of induction motor. Speed control is achieved

ISSN: 2349 – 8379 www.internationaljournalssrg.org Page 11

SSRG International Journal of Electronic and Electronics Engineering (SSRG-IJEEE) – Special Issue ICTER Mar 2019

few seconds.It will only develop 2/3 of the 3-phase PROGRAM DATA DATA

power rating because one winding is not used. FLASH MEMORY EEPROM

DEVICE

PIC 8K 368 Bytes 256 Bytes

16F877

Table No. 6.1a. Specifications of PIC 16F877

I/O PORTS:

Some pin for these I/O ports are multiplexed

with an alternate function for the peripheral features

Fig.5.1. 3-phase motor from 1-phasepower on the device. In general, when a peripheral is

Types of single phase induction motor: enabled, that pin may not be used as a general

purpose I/O pin. Additional information on I/O ports

Permanent-split capacitor motor. may be found in the micro™ Mid-range Reference

Manual.

Capacitor-start induction motor.

Capacitor-run induction motor.

Resistance split phase motor.

Fig.5.2.Resistance split-phase induction motor

VI. INTRODUCTION TO PIC Fig.6.1. Pin diagram of PIC 16F887

The microcontroller that has been used for this PORT A is 16- bit wide bi-directional port. The

project is from PIC microcontroller is the first corresponding data direction register is TRIS A.

fabricatedinCMOS(Complementary Metal-Oxide Setting a bit(=1) will make the corresponding PORT

Semiconductor) that uses separate bus for instruction A pin an input, put the corresponding output driver in

and data allowing simultaneous access of program a Hi-impedance mode. Clearing a TRIS A bit (=0)

and data memory. will make the corresponding PORT A pin an

output,i.e., put the contents of the output latch on the

The main advantage of combination of CMOS and selected pin.

RISC is low power consumption resulting in a very

small chip size with a small pin count. The another

advantage of CMOS is that it has immunity to noise

than other fabrication techniques.

PIC (16F877):

Various microcontrollers offer different kinds of

memories. EEPROM, EPROM, FLASH etc., are

some of the memories of which FLASH is the most

recently developed. Technology that used in pic

Table No.6.1b. Functions of PORT A

16F877 is flash technology, so that data of retained

even when the power is switched off. Easy

PORT B is an 8-bit wide bi-directional port. The

programming and Erasing are other features of PIC

corresponding data direction register is TRIS B.

16F877.

Setting a TRIS B bit (=1) will make the

corresponding PORT B pin an input, put the

ISSN: 2349 – 8379 www.internationaljournalssrg.org Page 12

SSRG International Journal of Electronic and Electronics Engineering (SSRG-IJEEE) – Special Issue ICTER Mar 2019

corresponding output driver in a Hi- impedance advantage of PWM is that power is that power loss in

mode. Clearing a TRIS B bit (=0) will make the the switching devices is very low. When a switch off

corresponding PORT B pin an output, i, e., put the there is practically no current, and when it is on, there

content of the output latch of the selected pin. is almost no voltage drop across the switch. Power

Similarly PORT C and PORT D are operated. loss, being the product o voltage and current, is thus

in both cases close to zero. PWM also works well

Program memory with digital controls, which because of their on/off

The PIC 16F877 devices have 13-bit program nature, can easily set the needed duty cycle. PWM

counter capable of addressing 8K *14words of has also been used in certain communication systems

FLASH program memory. Accessing a location where its duty cycle has been used to convey

above the physically implemented address will cause information over a communications channel.

a wraparound. The RESET vector is at 0000h and the

interrupt vector is at 0004h. VIII. GPRS

Data memory General Packet Radio Service (GPRS) is a packet

The data memory is partitioned into multiple oriented mobile data service on the 2Gad 3G cellular

banks which contain the General Purpose Registers communication system‟s global system for mobile

and the special functions registers. Bits communications (GSM).

RP1(STSTUS<6) and RP0(STATUS>5)are the bank GPRS is a packet-based wireless data communication

selected bits. service designed to replace the current circuit-

switched services available on the second generation

Instruction set global system for mobile communications (GSM) and

All instructions are executed within the one single time division multiple access (TDMA) IS-136

instruction cycle, unless a conditional test is true or networks.

the program counter is changed as a result of an

instruction. In this case, the execution takes two The GPRS core network is the central part of the

instruction cycles with the second cycle executed as a GPRS which allows 2G, 3G and WCDMA mobile

NOP. One instruction cycle consists of four oscillator networks to transmit IP packets to external networks

periods. Thus, for an oscillator frequency of 4 MHz, such as the internet. The GPRS system is an

the normal instruction execution time is 1ms. If a integrated part of the GSM network switching sub-

conditional test is true or the program counter is system.

changed as a result of an instruction, then the

instruction execution time is 2ms. IX. PCB DESIGNING

The instruction set is highly orthogonal and is Printed Circuit Boards are form the core of

grouped into three basic categories are Byte oriented, electronic equipment domestic and industrial. The

Bit oriented, Literal and control operations. software used in our project to obtain the schematic

layout is MICROSIM. Software tools are used in tis

VII. PULSE WIDTH MODULATION (PWM) project such as MPLAB IDE is an integrated

development environment that provides development

Pulse Width Modulation (PWM) or Pulse Duration engineers with the flexibility to develop and debug

Modulation (PDM), is a commonly used technique firmware for various microchip devices. MPLAB IDE

for controlling power to inertial electrical devices, is a windows based integrated development

made practical by modern electronic power switches. environment for the microchip technology

The average value of voltage (and current) fed to the incorporated PIC microcontroller (MCU) and digital

load is controlled by turning the switch between signal microcontroller (DSC) families.

supply and load on and at fast pace. The longer

switch is on compared to the off periods, the higher

the power supplied to the load is. The PWM

switching frequency has to be much faster than what

would affect the load, which is to say device that uses

the power. Typically switches have to be done several

times a minute in an electric stove, 120Hz in a lamp

dimmer, from few kilohertz(KHz) to tens of kilohertz

for a motor drive and well into the tens or hundreds of

K Hz in audio amplifiers and computer power

supplies. The term duty cycle describes the proportion

of „on‟ time to the regular interval or „period‟ of time;

a low duty cycle corresponds to low power, because

the power is off for most of the time. Duty cycle is

expressed in percent, 100% being fully on. The main

ISSN: 2349 – 8379 www.internationaljournalssrg.org Page 13

SSRG International Journal of Electronic and Electronics Engineering (SSRG-IJEEE) – Special Issue ICTER Mar 2019

[7] “Speed control of 3-phase Induction motor by v/f method

with Arduino Uno”, Journal of Engineering Research and

Application, Ali Abdulrazzak et al 2017 vol., no.12,pp.159.

[8] “Fault detection and Protection of Induction motors using

Sensors”, IEEE Transactions on Energy Conversion,

RamazanBayindir,Ibrahim Sefallhamicolak, AslinBektas,

vol.23, n0.3, sep2008.

[9] International Journal of Scientific Research Engineering &

Technology(IJSRET) vol.2, Feb 2014,”Speed Monitoring an

Protection of Motorusingzigbee

communication”,P.E.Elavenil1, Dr.R.Kalaivani2

1M.E,Rajalaksmi Engineering college in Chennai.

[10] Young-Seol Lim et al year:2019,”Advanced Speed

Control for a Five- Leg Inverter Driving a Dual-Induction

motor System”, IEEE Transactions on Industrial Electronics,

vol.66, pp.707-716.

X. CONCLUSION

The progress in science and technology is a non-

stop process. New things and new technology are

being invented. As the technology grows day by day,

we can imagine about the future in which thing we

may occupy every place.

The proposed system based on PIC microcontroller is

found to be more compact, user friendly and less

complex, which can readily be used in order to

perform. Several tedious and repetitive task. Though

it is designed keeping in mind about the need for

industry, it can extended for other purposes such as

commercial and research applications. Due to the

probability of high technology used this “IOT

BASED SENSORLESS SPEED CONTROL OF

INDUCTION MOTOR” is fully software controlled

with less hardware circuit. The feature makes this

system is the base for future systems.

The principle of the development if science is that

“nothing is impossible”. So we all look forward to a

bright and sophisticated world.

REFERENCES

[1] “Speed control of the induction drive by temperature and light

sensors via PIC”,NadumBarsoum, ISSN:1985-9406 Online

publication June 2010.

[2] “Review on induction motor signature analysis as a medium

for fault detection”, Mohamed EI Bennbouzid, IEEE

Transactions on industrial electronics Vol.47, No.5.

[3] “Sensor less control of induction motor drives”, J.HoltzElectr.

“Wuppertal Univ., Germany.

[4] “Online sensor less induction motor temprature monitoring”,

Sonnaillan, M.O., Bisheimer,G., De Angelo, C.,Garcia, G.O.,

IEEE Transaction on Energy Conversion>2010>25>2>273-

280.

[5] “Resistance and Speed Estimation in sensor less Induction

motor D rives Using a Model With Known Regressors”,

IEEE Transactions on Industrial Electronics, vol.66,

no.4,pp.2659-2667.

[6] “Robust Speed Tracking of Induction Motors: An Arduino-

Implemented Intelligent Control Approach”, IEEE

Transactions on Industry Applications, Tan-Jan HO ID et al

2018 vol.8pp.159.

ISSN: 2349 – 8379 www.internationaljournalssrg.org Page 14

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Lesson 2Dokument22 SeitenLesson 2Queen M SANoch keine Bewertungen

- Eee 133 PDFDokument3 SeitenEee 133 PDFGracylyn Michaela AradaNoch keine Bewertungen

- SW 13 Computing - FoundationsDokument28 SeitenSW 13 Computing - FoundationsuptvirtualNoch keine Bewertungen

- HandBrake CLI GuideDokument12 SeitenHandBrake CLI GuideDavide Riboli100% (4)

- TLE JAVA First Quarter ExamDokument2 SeitenTLE JAVA First Quarter ExamRhexel ReyesNoch keine Bewertungen

- FlutterDokument2 SeitenFlutterjuniormj1Noch keine Bewertungen

- Ip Ran 2G 3G 4GDokument26 SeitenIp Ran 2G 3G 4GAnonymous 0knDANI4dNoch keine Bewertungen

- IBM System Storage DS8000 Series Architecture and ImplementationDokument590 SeitenIBM System Storage DS8000 Series Architecture and ImplementationRay CoetzeeNoch keine Bewertungen

- Install SambaDokument11 SeitenInstall SambaJhoda Louise EmbodoNoch keine Bewertungen

- Simulation of Blind Flooding Over Wireless Sensor Networks Based On A Realistic Battery ModelDokument6 SeitenSimulation of Blind Flooding Over Wireless Sensor Networks Based On A Realistic Battery ModelJúlio VérasNoch keine Bewertungen

- History of TelevisionDokument11 SeitenHistory of TelevisionGerald GavinaNoch keine Bewertungen

- GB-NetVision-operating Manual PDFDokument46 SeitenGB-NetVision-operating Manual PDFspada1975Noch keine Bewertungen

- Data Warehousing and BADokument77 SeitenData Warehousing and BAMohit NarayanNoch keine Bewertungen

- Sony Vaio VPC-W Series MBX-219 Quanta SY3 Schematic DiagramDokument44 SeitenSony Vaio VPC-W Series MBX-219 Quanta SY3 Schematic DiagramRenatoNoch keine Bewertungen

- Importance of Antivirus Software PDFDokument2 SeitenImportance of Antivirus Software PDFAlpha PublishingNoch keine Bewertungen

- MSI Motherboard ManualDokument80 SeitenMSI Motherboard ManualHamboneNoch keine Bewertungen

- XUF Card Firmware Update 8412 InfosheetDokument2 SeitenXUF Card Firmware Update 8412 InfosheetPaul MirtschinNoch keine Bewertungen

- 5G NR ATP - KPI ThresholdsDokument14 Seiten5G NR ATP - KPI ThresholdsManish Kumar50% (2)

- Solaris 10 For Experienced System Administrators Student GuideDokument434 SeitenSolaris 10 For Experienced System Administrators Student GuideKrishna KumarNoch keine Bewertungen

- Requir MentDokument6 SeitenRequir MentEstuKurniawanNoch keine Bewertungen

- Sony STR De685Dokument60 SeitenSony STR De685fernando3670Noch keine Bewertungen

- TasmDokument33 SeitenTasmvishnuhost67% (3)

- 5ESSDokument33 Seiten5ESSVTBVKJNoch keine Bewertungen

- ICT DirectoryDokument41 SeitenICT DirectoryMuhammad AzwanNoch keine Bewertungen

- Microsemi IGLOO2 FPGA Evaluation Kit User Guide UG0478Dokument57 SeitenMicrosemi IGLOO2 FPGA Evaluation Kit User Guide UG0478VishalNoch keine Bewertungen

- Bosion BX410Dokument21 SeitenBosion BX410skidamdnevnoNoch keine Bewertungen

- 04 6700 01e12Dokument2 Seiten04 6700 01e12Mohammad Seemab AslamNoch keine Bewertungen

- 11222Dokument248 Seiten11222Tariq MuhammadNoch keine Bewertungen