Beruflich Dokumente

Kultur Dokumente

4a5079e0-5819-4c52-bd56-57e568636c67

Hochgeladen von

erwin lee0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

15 Ansichten1 SeiteH20 proofing

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenH20 proofing

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

15 Ansichten1 Seite4a5079e0-5819-4c52-bd56-57e568636c67

Hochgeladen von

erwin leeH20 proofing

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

For a durable waterproof barrier on interior or exterior concrete and masonry

THOROSEAL ®

WATERPROOF CEMENT-BASED COATING CONSUMER PRODUCTS

Thorseal® is a cement based, micro-porous (breathing), seamless

coating used to fill, seal, waterproof and protect a variety of

substrates including cast-in-place and pre-cast concrete, brick,

common building and split-faced block, stucco, unglazed terra

cotta, porous stone, shotcrete, gunite and other masonry

substrates. It may be used on interior or exterior, above or below Must NOT be

grade applications on new construction or in renovation and

restoration projects. Thorseal® is highly resistant to standing

applied to

water or wind driven rain and is intended for use on vertical, painted surfaces.

overhead and non-traffic bearing horizontal surfaces.

Thorseal® is also an ideal alternative to mechanical finishing or White

rubbing of concrete. The two coat application of Thorseal® will finish

add a significant degree of protection from the deleterious Add ACRYL® 60

for peak

effects of carbonation on steel reinforced concrete. Two coats of performance

Thorseal® (40 mils) is the equivalent to 3/4” of new concrete

cover as a barrier to carbon dioxide gas. Thorseal® has also been

shown to act as a barrier to the infiltration of radon gas and can

be used on below ground structures as a barrier coating in Gray

conjunction with radon abatement systems. finish

Clean & Prepare Surface

All surfaces to be coated must be clean and structurally sound.

Chip, sand or shotblast, wet blast or high pressure water wash Application

(4,000 - 10,000 psi) to remove all foreign matter, dust, dirt, Thorseal® may be applied by spray, tampico fiber brush or

paints, oils, grease, coatings, laitance or any other surface broom. Spray application is recommended for large projects

contaminants. All static cracks or breaks, voids or honeycombing generally using a plasterer’s type spray gun, a diaphragm type or

larger than 1/32” should be cut out and repaired with rotor-stator type pump. The substrate must be completely

WATERPLUG® or a THORITE®/ACRYL® 60 mixture. Form ties dampened before application starts to prevent surface drag on

and other metal fragments must be removed and patched with a the material and eliminate flash setting. Apply the material on

THORITE®/ACRYL® 60 mixture. If any doubt exists about the the substrate filling all pores and voids. It is essential that the

suitability of a substrate to receive Thorseal®, then a bond test first coat is well brushed into the substrate even if the

should be carried out. Consult the Thorseal® technical bulletin application is by spray-gun. The first coat should be applied at 2

for further details. On block or masonry substrates, relieve excess lbs. per sq. yard (225 sq. ft./50 lb. bag at 25 mils dry film

water pressure in the substrate by tapping in weep holes at the thickness). Finish the coat with smooth horizontal strokes. Allow

base before applying Thorseal®. the material 24 hours to cure before applying second coat. The

second coat should be applied at 1 lb. per sq. yard (450 sq. ft./50

Mixing lb. bag at 15 mils dry film thickness). On block or masonry walls,

Thorseal® powder may be mixed by hand or by using a power allow 5-7 days before applying the second coat to eliminate joint

mixer fitted with a mixing paddle. Power mixing is always read through. After the second coat has hardened, plug any weep

preferable. Mix the Thorseal® powder using a solution holes using WATERPLUG® and then coat with Thorseal®. For

consisting of ACRYL 60 diluted with water, usually 1 part specific application guidelines, call 1 (440) 786-2100 or go to

ACRYL® 60 to 3 parts clean water. For improved curing, better www.thoroproducts.com

physical properties and improved bonding capability in extreme

environments or on dense or questionable surfaces, reduce the Limitations

dilution ratio to 1:2 or 1:1. A 50 lb. (22.7 kg) bag of Thorseal® Do not apply Thorseal® to surfaces that have not been properly

requires approximately 6-8 quarts of mixing liquid. Mix the cleaned or are unsound. Do not apply Thorseal® in rain or when

material until a consistency of smooth, heavy batter is achieved. rain is expected before initial set has taken place. Do not apply

Allow the mixed Thorseal®/ACRYL® 60 to rest undisturbed for a Thorseal® to frozen or frost filled surfaces or when the

minimum of 10 minutes to fully wet out all the powder. Remix the temperature is below 40°F (4.4°C) or is expected to fall below

wet material and then apply to the substrate. When remixing, a 40°F (4.4°C) within 24 hours. For additional limitations, call

small amount of mixing solution may be added for better workability. 1 (216) 839-7171 or go to www.thoroproducts.com

Thoro Consumer Products • BASF Construction Chemicals, LLC • 23700 Chagrin Blvd. • Cleveland, Ohio 44122

phone 216-839-7171 or 866-518-7171 • fx 216-839-8833 or 866-494-8833 • ThoroProducts.com

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Cobol - 400 Material by Mr. ShivakumarDokument208 SeitenCobol - 400 Material by Mr. Shivakumarchandra sekhar TippreddyNoch keine Bewertungen

- Vietnam Long Grain White Rice 5451: NameDokument3 SeitenVietnam Long Grain White Rice 5451: Nameerwin leeNoch keine Bewertungen

- Pbav 20171009 Lia Taysan R1 2Dokument1 SeitePbav 20171009 Lia Taysan R1 2erwin leeNoch keine Bewertungen

- Customer: Project Name: Cost ProposalDokument2 SeitenCustomer: Project Name: Cost Proposalerwin leeNoch keine Bewertungen

- 4storey With Roofdeck ProposalDokument2 Seiten4storey With Roofdeck Proposalerwin leeNoch keine Bewertungen

- Project V TradingDokument1 SeiteProject V Tradingerwin leeNoch keine Bewertungen

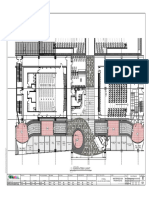

- Floor Pattern Layout 1: Masterpiece Asia Properties IncDokument7 SeitenFloor Pattern Layout 1: Masterpiece Asia Properties Incerwin leeNoch keine Bewertungen

- Requested Amount To Pay As Per Accomplishment To Date 222,183.31Dokument1 SeiteRequested Amount To Pay As Per Accomplishment To Date 222,183.31erwin leeNoch keine Bewertungen

- Mobilization / Demobilization Power Consumption Water Consumption As-Built Plan Shop Drawing Supervision CostDokument4 SeitenMobilization / Demobilization Power Consumption Water Consumption As-Built Plan Shop Drawing Supervision Costerwin leeNoch keine Bewertungen

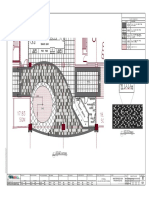

- Tile Pattern 2: Cinema HallwayDokument5 SeitenTile Pattern 2: Cinema Hallwayerwin leeNoch keine Bewertungen

- Socorro SWADokument1 SeiteSocorro SWAerwin leeNoch keine Bewertungen

- Mobilization / Demobilization Power Consumption Water Consumption As-Built Plan Shop Drawing Supervision CostDokument4 SeitenMobilization / Demobilization Power Consumption Water Consumption As-Built Plan Shop Drawing Supervision Costerwin leeNoch keine Bewertungen

- Blow Up Elevation 2: Landscape LandscapeDokument1 SeiteBlow Up Elevation 2: Landscape Landscapeerwin leeNoch keine Bewertungen

- Mobilization / Demobilization Power Consumption Water Consumption As-Built Plan Shop Drawing Supervision CostDokument4 SeitenMobilization / Demobilization Power Consumption Water Consumption As-Built Plan Shop Drawing Supervision Costerwin leeNoch keine Bewertungen

- Mobilization / Demobilization Power Consumption Water Consumption As-Built Plan Shop Drawing Supervision CostDokument4 SeitenMobilization / Demobilization Power Consumption Water Consumption As-Built Plan Shop Drawing Supervision Costerwin leeNoch keine Bewertungen

- TheNewStack Book3 Automation and Orchestration With Docker and ContainersDokument141 SeitenTheNewStack Book3 Automation and Orchestration With Docker and ContainersCristhian Rey100% (3)

- Workstation Heat and Power Usage: Lenovo ThinkStation P900 vs. Dell Precision T7910 WorkstationDokument11 SeitenWorkstation Heat and Power Usage: Lenovo ThinkStation P900 vs. Dell Precision T7910 WorkstationPrincipled TechnologiesNoch keine Bewertungen

- Automatic Ontology Creation by Extracting Metadata From The Source CodeDokument7 SeitenAutomatic Ontology Creation by Extracting Metadata From The Source CodeMadavee JinadasaNoch keine Bewertungen

- NFS Best Practice and Implement GuildeDokument178 SeitenNFS Best Practice and Implement GuildeVan LamNoch keine Bewertungen

- WEBFOCUS - ReportCaster End User's ManualDokument112 SeitenWEBFOCUS - ReportCaster End User's ManualknarravulaNoch keine Bewertungen

- 154 G4A Concealed - Quick ResponseDokument2 Seiten154 G4A Concealed - Quick Responsetedi_1999Noch keine Bewertungen

- Endian Com Fileadmin Documentation Efw Admin Guide en Efw Admin GuideDokument277 SeitenEndian Com Fileadmin Documentation Efw Admin Guide en Efw Admin GuidePaolo Brando Gavino RamosNoch keine Bewertungen

- Engineered Elastomeric Void Form: Product DescriptionDokument1 SeiteEngineered Elastomeric Void Form: Product DescriptionRajdip GhoshNoch keine Bewertungen

- Intoduction To BridgesDokument52 SeitenIntoduction To BridgesAbhishekNoch keine Bewertungen

- SD 1 AssignmentDokument17 SeitenSD 1 AssignmentAnuj Chandiwala100% (1)

- CEVNA KAPA DIN2617-Steel-butt-welding-pipe-fittings-capsDokument2 SeitenCEVNA KAPA DIN2617-Steel-butt-welding-pipe-fittings-capsBojan BučarNoch keine Bewertungen

- JBNKJDokument186 SeitenJBNKJNataliaNoch keine Bewertungen

- Hif 16011 DDokument104 SeitenHif 16011 DJuan Gutier CcNoch keine Bewertungen

- Lobby Vision BroDokument5 SeitenLobby Vision BroPearl JamNoch keine Bewertungen

- Pengertian Data LinkDokument31 SeitenPengertian Data LinkRizal Furqan RamadhanNoch keine Bewertungen

- Steps For Installing The Java Server Web Development KitDokument4 SeitenSteps For Installing The Java Server Web Development Kitjooner45Noch keine Bewertungen

- Computer System Devices and PeripheralsDokument34 SeitenComputer System Devices and PeripheralsPsyche DenNoch keine Bewertungen

- 02 CONSTRUCTION & Structural Details of Gothic Arch.Dokument13 Seiten02 CONSTRUCTION & Structural Details of Gothic Arch.AbhiNoch keine Bewertungen

- History PPT: RenaissanceDokument34 SeitenHistory PPT: Renaissancepriyanshi SharmaNoch keine Bewertungen

- Red Hat 80 VmwareDokument57 SeitenRed Hat 80 VmwareKhalid Hussain KhosoNoch keine Bewertungen

- March 2015, HONNA Quarterly NewsletterDokument40 SeitenMarch 2015, HONNA Quarterly NewsletterHistoric Old Northeast Neighborhood AssociationNoch keine Bewertungen

- Layout Arrangement ContainerDokument1 SeiteLayout Arrangement ContainerChristella Ekaristi SitorusNoch keine Bewertungen

- Raspberry Pi Command Line Audio PDFDokument8 SeitenRaspberry Pi Command Line Audio PDFSteve AttwoodNoch keine Bewertungen

- Labor Manhour EstimateDokument18 SeitenLabor Manhour EstimateCristina Dangla Cruz100% (3)

- Lec14s SecurityDokument24 SeitenLec14s SecurityPrincess Gladys Ingrid SupitNoch keine Bewertungen

- NullDokument14 SeitenNullM-NCPPCNoch keine Bewertungen

- Multiple Interrupts and Buses StructureDokument17 SeitenMultiple Interrupts and Buses Structureapi-3801329100% (2)

- 54 FT Diameter Bin: ModelsDokument168 Seiten54 FT Diameter Bin: ModelsLeonardo HutaurukNoch keine Bewertungen

- Project Titles in Mobile Ad Hoc NetworksDokument3 SeitenProject Titles in Mobile Ad Hoc NetworkssrkmattaNoch keine Bewertungen