Beruflich Dokumente

Kultur Dokumente

Spec 0132 GPS Device 09 01 2018 PDF

Hochgeladen von

Lokesh KuppiliOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Spec 0132 GPS Device 09 01 2018 PDF

Hochgeladen von

Lokesh KuppiliCopyright:

Verfügbare Formate

Page 1 of 17 Issued on : 09.01.2018 Spec. No.: RDSO/2018/EL/SPEC/0132 Rev.

‘0’

lR;eso t;rs

GOVERMENT OF INDIA

MINISTRY OF RAILWAYS

TECHNICAL SPECIFICATION OF

GPS DEVICE FOR

ELECTRIC LOCOMOTIVES

SPECIFICATION No. RDSO/2018/EL/SPEC/0132 / Rev. ‘0’

Issued on: 09.01.2018

Approved by Signature

Sr. EDSE

ELECTRICAL DIRECTORATE

RESEARCH DESIGNS AND STANDARDS ORGANISATION

LUCKNOW-226011

Prepared by Checked by Issued by

Page 2 of 17 Issued on : 09.01.2018 Spec. No.: RDSO/2018/EL/SPEC/0132 Rev. ‘0’

STATUS OF REVISION

S. N. Date of Revision Page No. Revision Reasons for Revision

1. - All 0 New

Prepared by Checked by Issued by

Page 3 of 17 Issued on : 09.01.2018 Spec. No.: RDSO/2018/EL/SPEC/0132 Rev. ‘0’

CONTENTS

S. No. Description Page no.

1. Chapter -1 General 4

2. Chapter -2 Technical details 7

3. Chapter -3 Environmental conditions 11

4. Chapter -4 Scope of supply 12

5. Chapter -5 Inspection & testing 13

Prepared by Checked by Issued by

Page 4 of 17 Issued on : 09.01.2018 Spec. No.: RDSO/2018/EL/SPEC/0132 Rev. ‘0’

SPECIFICATION OF GPS DEVICE FOR

ELECTRIC LOCOMOTIVES IN INDIAN RAILWAYS

Chapter I

GENERAL

1.0

1.1 Introduction

1.1.1 This specification covers constructional features, technical requirements and testing

procedure for GPS Device for Electric Locomotives.

1.1.2 It is proposed to install GPS device in all types of Electric locomotives for transmitting

location and speed information along with loco number and train number to a server. This

information can be accessed by authorized users through a website using

desktop/laptop/mobile.

1.2 Terminology

For the purpose of this specification, following terminology shall apply:

(i) GPS : Global Positioning System

(ii) GSM : Global System for Mobile

(iii) GPRS : General Packet Radio Service

(iv) RDSO : Research Designs and Standards Organisation

(v) API : Application Program Interface

(vi) IR : Indian Railways

(vii) SMS : Short Message Service

(viii) MMD : Maximum Moving Dimensions

(ix) AMC : Annual Maintenance Contract

(x) APN : Access Point Name

(xi) TC : Technical Circular

(xii) GNSS : Global Navigation Satellite System

(xiii) SBAS : Satellite-Based Augmentation System

(xiv) GAGAN : GPS Aided Geo Augmented Navigation

1.3 Scope Of Supply:

This specification covers design, development, manufacturing, testing, supply,

installation and commissioning of GPS device for use in 25 kV Electric locomotives. The

detailed scope of supply is given in Chapter IV.

Prepared by Checked by Issued by

Page 5 of 17 Issued on : 09.01.2018 Spec. No.: RDSO/2018/EL/SPEC/0132 Rev. ‘0’

1.4 Vendor’s Responsibility:

Vendor shall supply the equipment and depute his representatives to

CLW/Sheds/workshops for installation and commissioning of the equipment on

locomotive.

1.5 Warranty:

1.5.1 The vendor shall be responsible for carrying out improvements and modifications at

his own expense on all the equipments during the period of warranty provided such

modifications/improvements are decided to be necessary for meeting the

requirements of reliability, performance and safety etc.

1.5.2 The firm is required to give root cause analysis of all the failures and their corrective

actions. In case of any modification (hardware and software), the necessary approval

shall be obtained from RDSO.

1.5.3 For the purpose of technical decisions on improvements/modifications etc. on

equipment, the final authority from the purchaser's side will be RDSO.

1.5.4 During warranty period all charges related to server, data transfer etc. shall be paid by

vendor.

1.5.5 Charges for AMC beyond warranty period shall also be specified by the vendor and

shall include the charges related to server, data transfer etc.

1.6 Approval For Design:

The design shall be developed based on the requirements given in this specification and

sound engineering practice. Approval of design means the approval of general design

features. Notwithstanding the approval, the vendor shall be wholly responsible for the

performance and reliability of the complete system.

1.7 Documentation:

The firm shall submit following information for the design approval in printed form and

in digital format:

(a) Technical specification of GPS module, Antenna module, GSM module &

power supply module

(b) System design

(c) Schematic Circuit/Block diagram

(d) Functional Description

(e) Protection scheme

(f) BOM (Bill of Material), Data sheets for components/devices and other

equipment proposed for use.

(g) Mechanical interface diagram (Outline General Arrangement), assembly

drawings of complete unit, mounting arrangement and weight.

Prepared by Checked by Issued by

Page 6 of 17 Issued on : 09.01.2018 Spec. No.: RDSO/2018/EL/SPEC/0132 Rev. ‘0’

(h) Clause by clause compliance of specification.

(i) Test protocol with procedure of testing.

(j) Details of Backup data memory size and battery backup size along with

calculations.

1.8 Important Documents Referred In This Specification:

1. IEC-60571: General requirements and tests for electronic

2012-09 (or latest) equipment used on Rail vehicles.

2. IEC-60077-1: 1999- Railway applications – electric equipment for

10 (or latest) rolling stock

3. IEC-60529: Degrees of protection provided by enclosures (Code

2013-08 (or latest) IP)

4. IEC-61373: Railway applications – Rolling stock equipment –

2010-05 (or latest) Shock and vibration tests

5. RDSO/2018/EL/TC/0 Technical Circular for GPS device for Electric

143 Rev. „0‟ (or Locomotives in Indian Railways.

latest)

1.9 Infringement Of Patent Rights:

Indian Railway shall not be responsible for infringement of patent rights arising due to

similarity in design, manufacturing process, use of similar components used in design,

development and manufacturing of GPS device and any other factor not mentioned here

in which may cause such a dispute. The entire responsibility to settle any such

dispute/matters lies with the vendor.

Details/design/documents given by the vendors are not infringing any IPR (Intellectual

Property Rule) and they are responsible in absolute and full measures instead of Indian

Railways for any such violations. Data specifications and other IP (Intellectual Property)

as generated out of interactions with Indian Railways shall not be unilaterally used

without consent of RDSO and right of Indian railways/RDSO on such IP is acceptable to

them.

1.10 All the provisions contained in RDSOs ISO procedures laid down its Document No. QO-

D-7.1-11 dated 9.6.2017 (titled “Vendor Changes in approved status”) and subsequent

versions/ amendments thereof, shall be binding and applicable on the successful vendor/

vendors in the contracts floated by Railways to maintain quality of products supplied to

Railways.

Prepared by Checked by Issued by

Page 7 of 17 Issued on : 09.01.2018 Spec. No.: RDSO/2018/EL/SPEC/0132 Rev. ‘0’

CHAPTER II

TECHNICAL DETAILS

2.0

2.1 General technical requirements & Specification:

2.1.1 Location of installation of GPS device shall be finalized and standardized by RDSO

based on the size of GPS device developed.

2.1.2 GPS device shall include a GPS receiver, display and keyboard, two sim card

modules, power card module, battery backup module with appropriate internal or

external combo antenna for getting the GPS location information and transmitting

the data. Antenna used shall be suitable for working under 25 kV AC traction

system and shall be within MMD of the loco. External Antenna module shall have

IP 66 protection, if used.

2.1.3 GPS location information, time stamp and speed will be included in GPS data

packets along with loco number and train number.

2.1.4 The GPS device shall have position accuracy of approximately 15 meter.

2.1.5 The GPS device shall support Multi GNSS and SBAS (GAGAN).

2.1.6 Adequate provisions shall be made in the design for suppression of internal

transients, spikes and to withstand external transients, spikes and surges as per

limits laid down in IEC-60571 ed-3 or latest.

2.1.7 In the electronic equipments to be supplied to this specification, the vendors shall

use industrial grade components, backup battery and systems of high reliability,

suitable in every way for the application on rolling stock. In this connection, vendor

is advised to refer to "Rules for Electronic Equipments used on Rail Vehicles IEC

Publication 60571"

2.1.8 Minor deviations from the specification if any, can be mutually sorted out with

RDSO during development stage if supported by justification on ground of cost

and/or technical superiority.

2.1.9 All electronic components and ICs used shall be selected after proper burn in and

screening tests and shall be adequately rated to withstand the service requirements.

A quality assurance scheme shall be submitted by the vendor for approval of RDSO.

All the connecting wires, cables used on PCB in the sub units should be properly

laid out with suitable connector. The cable used inside the sub unit shall be properly

supported with stiffeners. No soldering shall be done on the PCB for inter

connection.

2.1.10 System shall have real time clock for recording date & time which is updated from

GPS system.

2.1.11 The device shall function satisfactorily under 25 kV ac electric traction. It shall not

be susceptible to malfunction due to interference from overhead traction power

supply lines or under abnormal conditions such as overloads and faults in the

electrical traction circuits of the locomotives.

Prepared by Checked by Issued by

Page 8 of 17 Issued on : 09.01.2018 Spec. No.: RDSO/2018/EL/SPEC/0132 Rev. ‘0’

2.1.12 The GPS device shall have the facility of enter the loco number and train number by

a keypad and viewed on 2 line 16 character alphanumeric LCD display. Details are

given in technical circular number TC-0143 (latest version).

2.2 Configuration parameter setting:

2.2.1 GPS device of each locomotive shall be identified by the unique locomotive

number.

2.2.2 It shall be possible to configure locomotive number associated with GPS device

through its own keypad by authorized persons.

2.2.3 IP address to which GPS devices shall transmit its data shall also be configured

through its own keypad/Over the air (OTA) by authorized persons.

2.3 Vendor Server & website:

2.3.1 Vendor shall have its own server which will located in India for safety and security

reasons with specific static IP address. There shall be flexibility in upgrading the

server configuration such that more locomotives can be added to the system as and

when more locomotives are fitted with GPS Devices. GPS device shall be

configured to communicate with the vendor server.

2.3.2 Webpage layout of the vendor server for accessing the GPS data will also be

approved by RDSO. Dashboard approach will be followed to list all the locomotives

at a glance. Filtering based on the Holding Railway/Shed and working

Railway/sheds shall be possible. Detailed information will be available after

selecting a particular locomotive. Details are given in TC-0143 (latest version).

2.3.3 Locomotive position shall also be displayed on map. Details are given in TC-0143

(latest version).

2.3.4 Webpage will have some colour coding for identifying the locomotives which are

running, stopped and in dead condition. Details are given in TC-0143 (latest

version).

2.3.5 Authorized users can access the GPS device information through internet by

connecting to vendor server through desktop/laptop/mobile devices.

2.4 Railway Server

Railway may decide to setup its own server for accessing the GPS information of

locomotives. It shall be possible to configure the GPS device to transmit data to

Railway server if required. Vendor shall provide communication protocol from GPS

device to server and other necessary details to transfer GPS data from device to Railway

server. It shall also be possible to transfer GPS data to Railway server and stopping the

data transmission to vendor server if required by Railways.

Prepared by Checked by Issued by

Page 9 of 17 Issued on : 09.01.2018 Spec. No.: RDSO/2018/EL/SPEC/0132 Rev. ‘0’

2.5 Transfer of GPS data from locomotive to server:

For transferring GPS data from device to server, device shall be equipped with APN

configured SIM cards and use 3G/4G technology for data transfer. Two SIM cards of

different operator shall be used for data transfer.

2.6 Capturing and transmission of GPS data by GPS Device

2.6.1 When Locomotive battery supply is available (HBA is in ON)

2.6.1.1 GPS data shall be captured every 05 seconds by the GPS device.

2.6.1.2 Data transfer shall be every 10 seconds or less to the server.

2.6.1.3 If due to any reason, data transfer to server is not successful, the data shall be

stored in the GPS device memory and will be transferred to the server at the

earliest opportunity.

2.6.2 When Locomotive battery supply is not available (HBA is in OFF)

2.6.2.1 GPS data shall be captured every 20 minutes by the GPS device and transferred

to the server.

2.6.2.2 If due to any reason, data transfer to server is not successful, the data shall be

stored in the GPS device memory and will be transferred to the server at the

earliest opportunity.

2.6.2.3 For the remaining period GPS device will be in sleep mode for conserving the

battery and will wake up every 20 minutes to capture and transfer GPS data.

During sleep mode GPS will be active but no data transfer shall be carried out.

2.7 Memory for the system :

2.7.1 GPS Device shall have the capacity to store GPS data for at least 30 days.

2.7.2 Vendor server shall have capacity to store GPS data for at least 90 days.

2.7.3 Calculations of data packet size to be provided by the vendor.

2.8 GPS device internal battery backup

2.8.1 Battery backup of the GPS device shall be adequate such that it can work for at least

20 days when locomotive is in dead condition (HBA in OFF condition).

2.8.2 Messages indicating battery condition shall also be transferred to server periodically

when device battery is less than 50%. These messages will be displayed on the

webpage/dashboard every hour.

2.8.3 Internal battery of GPS device shall be charged from locomotive battery when HBA

is in ON condition. Suitable protections like overvoltage, over current, short circuit,

over charge & over discharge, surge, incorrect insertion of connector, over

temperature etc. shall be provided in charging/discharging circuit.

Prepared by Checked by Issued by

Page 10 of 17 Issued on : 09.01.2018 Spec. No.: RDSO/2018/EL/SPEC/0132 Rev. ‘0’

2.9 Enclosure for GPS device

Suitable Tamper Proof, Vandal Proof and Water Proof enclosure for GPS device will be

provided.

2.10 Power supply:

2.10.1 The battery supply at 110V DC varying from 70V to 137.5V will be available in the

locomotive. Since memory storage are to be catered for, an internal battery back up

as a part of the GPS device shall also be provided.

The operating voltage of the locomotive battery is as follows:

Minimum voltage = 70 V DC

Nominal voltage = 110 V DC

Maximum Voltage = 137.5 V DC

2.10.2 The device shall be designed considering the fact that surges do appear in the

locomotive power supply. Suitable protection shall be incorporated.

2.11 Marking:

An anodized aluminium plate carrying following markings shall be fitted on the GPS

device at a suitable place:-

(i) Maker's name and trade mark

(ii) Name of the equipment

(iii) Type, Model and version of equipment

(iv) Manufacturer address with email ID.

(v) Maker's serial number and year of manufacture.

(vi) Specification No.

(vii) System Voltage.

Prepared by Checked by Issued by

Page 11 of 17 Issued on : 09.01.2018 Spec. No.: RDSO/2018/EL/SPEC/0132 Rev. ‘0’

CHAPTER III

ENVIRONMENTAL CONDITIONS

3.0

3.1 The climatic and environmental conditions prevailing in India in the area of operations

are the following:

A. Atmospheric Maximum temperature: 50 0C

temperature

Maximum touch temperature of metallic surface under the Sun: 75 0C

and in shade: 55 0C

Maximum temperature near electronic cards in un-energised condition

of locomotive standing under direct sunlight during summer: 70 0C

Maximum temperature near electronic cards in working condition of

locomotive during summer: 65 0C

Minimum temperature: - 10 0C

( Also snow fall in certain areas during winter season)

B. Solar radiation 1 kW/m2

C. Humidity 100% saturation during rainy season

D. Altitude: 1776 m above mean sea level

E. Rain fall: Very heavy in certain areas.

F. Wind speed High wind speed in certain areas, with wind pressure reaching150 kg/m2

G. Atmospheric Extremely dusty and desert terrain in certain areas. The dust

conditions concentration in air may reach a high value of 1.6 mg/m3. In many iron

ore and coal mine areas, the dust concentration is very high affecting the

filter and air ventilation system. The system shall be able to work at the

maximum specified ambient temperature inside the locomotive without

any pre-cooling requirement.

H. Coastal area Humid and salt laden atmosphere with maximum pH value of 8.5,

Sulphate of 7 mg per liter,

Maximum concentration of chlorine 6 mg per liters and

Maximum conductivity of 130 micro siemens / cm

I. Vibration & The equipment shall be designed to withstand the vibrations and shock

Shock encountered in service satisfactorily as specified in IEC -61373 (latest)

Publication for Shock & Vibration on Rolling-stock vehicle. The

vibration test shall be done as mounted in the actual operating condition.

Prepared by Checked by Issued by

Page 12 of 17 Issued on : 09.01.2018 Spec. No.: RDSO/2018/EL/SPEC/0132 Rev. ‘0’

CHAPTER IV

SCOPE OF SUPPLY

4.0

4.1 Scope of the specification is Supply, installation and commissioning of the GPS device

along with associated wiring.

4.2 Supply of two GSM SIM of commercial mobile internet provider, their activation /

registration and payment of data charges are in the scope of supply for Vendor.

4.3 Installation, commissioning and maintenance (during warranty period) are in the scope

of supply.

4.4 The following will be the scope of supply:-

Quantity

SN Items per

locomotive

GPS device along with activated two SIM

I. 01 set

Cards

Cables for connecting GPS device to loco 01 set

II.

battery

Antenna and cables for connecting Antenna 01 set

III. unit to GPS device (if applicable, in case of

external antenna).

IV. Installation & Maintenance Manual 02 set

Prepared by Checked by Issued by

Page 13 of 17 Issued on : 09.01.2018 Spec. No.: RDSO/2018/EL/SPEC/0132 Rev. ‘0’

CHAPTER V

INSPECTION & TESTING

5.0

5.1 INSPECTION:

5.1.1 The system shall be tested generally in accordance with the IEC: 60571:2012-09 (or

latest). Dry Heat test of the Electronics shall be carried out at 70º C as per IEC:

60571. All optional tests mentioned in various standards shall also be carried out.

Details shall be worked out during design approval. Type tests shall be carried out by

the vendor at his own responsibility and cost.

5.1.2 The vendor shall formulate and submit a type test protocol / plan at design approval

stage for approval of RDSO before undertaking manufacturing. It shall, however, be

open for RDSO to waive some of tests in case of equipment and sub-assemblies,

where the vendor can establish it for the requirements of this specification that such

tests have already been carried out earlier on the same equipment and where

equipment has been proved in prolonged service.

5.1.3 Modifications found necessary as a result of the tests/trials shall be incorporated by

the vendor at his own cost in the locomotives in a manner approved by the Purchaser.

Drawings incorporating the modifications found necessary, as a result of tests and

trials, shall be submitted to RDSO for final approval.

5.1.4 The vendor shall offer all the testing facilities free of charge to inspecting authority.

Testing of equipment and fittings shall, as far as possible be carried out at the works

of the vendors. Testing of bought out components may also be carried out at sub-

vendor's premises, if so required. The vendor shall provide free of charge, such

materials or fittings as may be required for testing whether at his own or his sub

vendor's premises. The test for which facilities are not available may be carried out at

RDSO or any other approved laboratory for which the testing charges shall be

payable by the vendor.

5.1.5 All the equipments and the fittings required for testing shall be selected by the

inspecting officer and the tests shall be carried out in his presence.

5.1.6 No material shall be packed or dispatched until it has been passed by the inspecting

officer but the vendor‟s responsibility for its efficiency in every way, shall remain

the same as if the work had been manufactured and tested by himself.

5.1.7 Should any part require alteration or any defect appear during the testing or trial, the

vendor shall without any extra charges make such alteration or rectify the defects to

the satisfaction of the inspecting authority.

5.1.8 Copies of Maker's test certificate, guarantee the performance of the equipment shall

be supplied in duplicated along with the delivery of each unit.

5.1.9 The inspecting authority shall:-

5.1.9.1 Visit at any reasonable time and without previous notice, either vendor‟s

works or his sub-vendor's works to inspect the vendors and the quality of

the work at any stage.

5.1.9.2 Reject any materials or fittings that does not conform to the relevant

standard/ specifications or have not been manufactured in accordance with

Prepared by Checked by Issued by

Page 14 of 17 Issued on : 09.01.2018 Spec. No.: RDSO/2018/EL/SPEC/0132 Rev. ‘0’

the approved practices. The rejected materials or fittings shall be marked in

a distinguishable manner and shall be disposed on in such manner as the

inspecting officer may direct to avoid its inadvertent use in the product

order as per this specification.

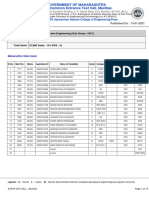

5.2 CATEGORIES OF TEST:

5.2.1 Type test:

5.2.1.1 Type test shall be carried out on equipment of the approved design. If there is

any change in design or source of supply of any components/sub-components/

assembly, units made to the changed design or from new source shall be treated

as new item for the purpose of conducting type tests.

5.2.1.2 Type tests are to be repeated in case of any major change is made. In case of

minor changes, i.e. change in type, rating of component etc., special test/tests as

agreed by user and vendor are to be conducted to ensure their suitability and

effectiveness of the modifications.

5.2.1.3 Tests will be carried out on the prototype unit as per relevant IEC specifications

or mutually agreed test program. Vendor will bear the expenses of the tests.

5.2.2 Routine test:

Routine test shall be carried out on every equipment of each order.

The tests to be carried out are given in the following table, together with the

clause number of IEC 60571 ed-3 2012-09 (or latest).

TESTS IEC ROUTI

TYPE

SN CLAUSE NE

TEST

NO. TEST

I. Visual Inspection 12.2.2

II. Performance test 12.2.3

III. Voltage variation test 12.2.3 --

IV. Cooling Test (Cold Start Test) 12.2.4 --

V. Temperature rise test (Dry heat) 12.2.5 --

VI. Temperature rise 12.2.6 --

(damp heat cyclic)

VII. Supply over voltage test 12.2.7 --

VIII. Surges test 12.2.8.1 --

IX. Insulation test 12.2.10.2

X. Voltage withstand (Dielectric) 12.2.10.3

test

XI. Vibration and shock test 12.2.12 --

XII. Water tightness test for external 12.2.13

antenna, if provided.

Prepared by Checked by Issued by

Page 15 of 17 Issued on : 09.01.2018 Spec. No.: RDSO/2018/EL/SPEC/0132 Rev. ‘0’

5.2.3 DETAILS OF TESTS:

5.2.3.1 VISUAL INSPECTION:

The object of visual inspection is to check that the equipment is free from

defects and the equipment is as per approved drawing. Bill of materials will be

submitted. The make, rating of equipment, subassemblies will be checked with

the details as per approved design document. If a change is needed in make or

rating of important equipment, sub-assemblies, it should be intimated and

should have proper approval of RDSO. GPS device with modified equipment,

subassemblies will be given separate revision number. All the important

dimensions will be measured and should be in permissible tolerance. Visual

inspection is to mainly verify cable marking, cable clearance, creepage distance

etc. Bill of material is also to be verified.

5.2.3.2 PERFORMANCE TEST:

Measurements shall be carried out at the ambient temperature.

The performance test shall consist of a comprehensive series of measurements of

the characteristics of the equipment to check that its performance is in

accordance with the functional requirements of the particular equipment

concerned, including any special requirements of its individual specification, and

general requirements of this standard. Performance test procedure will be

submitted by the vendor for approval.

These tests are carried out to check and ensure that the performance of the

equipment is in order.

5.2.3.3 VOLTAGE VARIATION TEST:

This test shall be carried out as per clause 12.2.3 of IEC 60571. During the test,

system voltage shall be as per clause 2.10.

5.2.3.4 COOLING TEST:

This test shall be carried out as per clause 12.2.4 of IEC 60571. Bring down the

temperature of the equipment to -10 ºC± 2 and keep it at the temperature for 2

hours. In this test equipment shall be in energised condition and the working of

the system will be checked. Insulation test, Dielectric test at 85% voltage of the

previous test and performance test will be carried out after the recovery period

of 3 hrs.

Prepared by Checked by Issued by

Page 16 of 17 Issued on : 09.01.2018 Spec. No.: RDSO/2018/EL/SPEC/0132 Rev. ‘0’

5.2.3.5 TEMPERATURE RISE TEST (DRY HEAT):

This test shall be carried out as per clause 12.2.5 of IEC 60571.The temperature

of the equipment will be raised to 70 ºC at the rate of 1º c at 1.5 minute and to be

kept at that temperature for 6 hours. In this test equipment shall be in energised

condition and working of the system will be checked. Insulation test, Dielectric

test at 85% voltage of the previous test and performance test will be carried out

after the recovery period of 3 hrs.

5.2.3.6 TEMPERATURE RISE (DAMP HEAT):

This test shall be carried out as per clause 12.2.6 of IEC 60571. Damp heat test

shall be done keeping the equipment in de-energised condition. It is to be ensured

that the RH of the oven should be between 80 to 100% during the above test. The

temperature of the equipment is to be raised from ambient to 55ºC in 2 hours and

kept at that temperature for 6 hours. The temperature of the equipment 55ºC

should be brought down to ambient (recovery period) in 3 hours. The cycle is to

be repeated at least two times and carry out insulation test, Dielectric test at 85%

voltage of the previous test and performance test.

5.2.3.7 SUPPLY OVER VOLTAGE & SURGES TEST:

The test shall be conducted as per IEC-60571 latest.

5.2.3.7.1 OVER VOLTAGE TEST:

The test shall be conducted as per clause 12.2.7 of IEC-60571.

5.2.3.7.2 SURGE TEST:

The test shall be conducted as per clause 12.2.8.1 of IEC-60571. The surge pulse

shall be 2 kV, 1.2/50 micro Second.

5.2.3.8 INSULATION TEST:

This test shall be carried out as per clause 12.2.10 of IEC-60571. Insulation

resistance shall be measured with megger of 500V.

The time of the meggering shall not be less than 60 Sec.

5.2.3.9 Voltage Withstand Test (DIELECTRIC TEST):

The test shall be carried out as per clause 12.2.10.3 of IEC-60571. Applied

voltage shall be of sine wave, 50 or 60 Hz for one minute between the terminals

that interface with locomotive short circuited and the metallic frame of the

assembly box.

Prepared by Checked by Issued by

Page 17 of 17 Issued on : 09.01.2018 Spec. No.: RDSO/2018/EL/SPEC/0132 Rev. ‘0’

5.2.3.10 VIBRATION AND SHOCK TEST

The test is to be carried out as per clause 12.2.12 of IEC-60571.

Random vibration & shock test is recommended as per IEC 61373 for rolling

stock application

The vibration and shocks tests shall be carried out as per category 1, class B of

IEC 61373 latest for rolling stock equipment for Railway application. The

following test should be carried out.

a) Functional random test as per clause no. 8.0 of IEC 61373.

b) Simulated long life testing as per clause no. 9.0 of IEC 61373.

c) Shock testing as per clause no. 10.0 of IEC 61373.

After the test there shall be no resulting damage, abnormality in the operation of

equipment. After completion of mechanical endurance test, vibration and shock

tests, the equipment shall again be subjected to dielectric test and performance

test.

5.2.3.11 WATERTIGHTNESS TEST:

This test will be done for external antenna (if provided) of GPS device as per

IEC-60529.

Prepared by Checked by Issued by

Das könnte Ihnen auch gefallen

- Ventilator (5 Nos.) : 2764788, 2764188 or 0483-273294 or Through EmailDokument4 SeitenVentilator (5 Nos.) : 2764788, 2764188 or 0483-273294 or Through EmailLokesh KuppiliNoch keine Bewertungen

- Uttar Pradesh Medical Supplies Corporation Limited: Signature Not VerifiedDokument1 SeiteUttar Pradesh Medical Supplies Corporation Limited: Signature Not VerifiedLokesh KuppiliNoch keine Bewertungen

- Government of Kerala: No - Gmckkd/1602/2020-S3 Dated:03.06.2020Dokument1 SeiteGovernment of Kerala: No - Gmckkd/1602/2020-S3 Dated:03.06.2020Lokesh KuppiliNoch keine Bewertungen

- O o o o o o o o 9.: VentilatorDokument2 SeitenO o o o o o o o 9.: VentilatorLokesh KuppiliNoch keine Bewertungen

- Superspecialty Procedures Under DR YSR Aarogyasri - PC - 13.08.2019 - 001finalDokument18 SeitenSuperspecialty Procedures Under DR YSR Aarogyasri - PC - 13.08.2019 - 001finalLokesh KuppiliNoch keine Bewertungen

- Tendernotice 1Dokument64 SeitenTendernotice 1Lokesh KuppiliNoch keine Bewertungen

- Amendment 05 Dated 27Dokument4 SeitenAmendment 05 Dated 27Lokesh KuppiliNoch keine Bewertungen

- Uttar Pradesh Medical Supplies Corporation LimitedDokument1 SeiteUttar Pradesh Medical Supplies Corporation LimitedLokesh KuppiliNoch keine Bewertungen

- Current Rating of Conventional Loco TMDokument2 SeitenCurrent Rating of Conventional Loco TMLokesh KuppiliNoch keine Bewertungen

- Haulage Capacity Wag-7Dokument6 SeitenHaulage Capacity Wag-7Lokesh KuppiliNoch keine Bewertungen

- Puzzles To Puzzle YouDokument136 SeitenPuzzles To Puzzle Youshahisk100% (1)

- Nijam PDFDokument2 SeitenNijam PDFLokesh KuppiliNoch keine Bewertungen

- Telugu Kathalu - Telugu Sahityam - Read Telugu Books Online - Telugu AudioDokument2 SeitenTelugu Kathalu - Telugu Sahityam - Read Telugu Books Online - Telugu AudioLokesh KuppiliNoch keine Bewertungen

- Sahaayam PDFDokument3 SeitenSahaayam PDFLokesh KuppiliNoch keine Bewertungen

- MTR Handout 03.07.18Dokument8 SeitenMTR Handout 03.07.18Lokesh KuppiliNoch keine Bewertungen

- Paapam Todelu PDFDokument2 SeitenPaapam Todelu PDFLokesh KuppiliNoch keine Bewertungen

- Telugu Kathalu - Telugu Sahityam - Read Telugu Books Online - Telugu AudioDokument2 SeitenTelugu Kathalu - Telugu Sahityam - Read Telugu Books Online - Telugu AudioLokesh KuppiliNoch keine Bewertungen

- Iec 61287-1Dokument55 SeitenIec 61287-1Lokesh Kuppili100% (2)

- Mba ProjectDokument431 SeitenMba ProjectLokesh KuppiliNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- STM32 ADC Tutorial Complete Guide With ExamplesDokument18 SeitenSTM32 ADC Tutorial Complete Guide With Examplessuper_faca100% (1)

- Middle School Activities To Celebrate International Day of EducationDokument63 SeitenMiddle School Activities To Celebrate International Day of Educationgabrielapecher84Noch keine Bewertungen

- MC860-CX2633 MM Rev1Dokument391 SeitenMC860-CX2633 MM Rev1RoboNoch keine Bewertungen

- OOP - S2021 - Mid Term ExamDokument2 SeitenOOP - S2021 - Mid Term ExamMalik RavelNoch keine Bewertungen

- 6145 - JSPM'S Jaywantrao Sawant College of Engineering, PuneDokument13 Seiten6145 - JSPM'S Jaywantrao Sawant College of Engineering, PuneRushikesh KaleNoch keine Bewertungen

- Assignment No 1-2020-FEA Intro PDFDokument2 SeitenAssignment No 1-2020-FEA Intro PDFTinashe ErwinNoch keine Bewertungen

- MC Afee Anti-Virus: Mcafee Total ProtectionDokument3 SeitenMC Afee Anti-Virus: Mcafee Total ProtectionJoylene Dayao DayritNoch keine Bewertungen

- TwinCAT TimersDokument6 SeitenTwinCAT TimersveithungengNoch keine Bewertungen

- Project Synopsis: MycityDokument3 SeitenProject Synopsis: MycityPranam RaiNoch keine Bewertungen

- If Else, - Nested If, If - Else Ladder - Switch Statement - Goto StatementDokument30 SeitenIf Else, - Nested If, If - Else Ladder - Switch Statement - Goto StatementDeep Kumar 21BCE5341Noch keine Bewertungen

- SDN and OpenFlow - The Harsh RealityDokument271 SeitenSDN and OpenFlow - The Harsh RealityPrashantPatilNoch keine Bewertungen

- Autosar Complete ReferenceDokument55 SeitenAutosar Complete ReferenceSureshNoch keine Bewertungen

- How To Get IPC MJPEG Stream Via HTTP CommandsDokument3 SeitenHow To Get IPC MJPEG Stream Via HTTP CommandsИнж.Стефан ЧавдаровNoch keine Bewertungen

- SM6-20190522 - 01 - Déclaration Design According To StandardsDokument1 SeiteSM6-20190522 - 01 - Déclaration Design According To StandardsRafael ZabotNoch keine Bewertungen

- Literature Review of JewelleryDokument8 SeitenLiterature Review of Jewelleryfvjawjkt100% (1)

- Creo Parametric 4.0 Quick ReferenceDokument14 SeitenCreo Parametric 4.0 Quick Referencemszlazak4179Noch keine Bewertungen

- Cloud Computing Customer Relationship MaDokument4 SeitenCloud Computing Customer Relationship MaslimshadesNoch keine Bewertungen

- 19-3-2019-BscNetwork-Engineering2017 2Dokument13 Seiten19-3-2019-BscNetwork-Engineering2017 2alaamabood6Noch keine Bewertungen

- Global Calling Card User Guide: Calling From Within Australia Calling From OverseasDokument1 SeiteGlobal Calling Card User Guide: Calling From Within Australia Calling From OverseasFarahaina IdrisNoch keine Bewertungen

- DEFCON 23 Lin Huang Qing Yang GPS SpoofingDokument55 SeitenDEFCON 23 Lin Huang Qing Yang GPS SpoofingEdson KitaniNoch keine Bewertungen

- Exercise 2 OSPFv2 - MUHAMMAD IZWAN BIN NAZRI - CS2555ADokument7 SeitenExercise 2 OSPFv2 - MUHAMMAD IZWAN BIN NAZRI - CS2555Aezone8553Noch keine Bewertungen

- SIM7020 Series HTTP Application Note V1.02Dokument11 SeitenSIM7020 Series HTTP Application Note V1.02Vinicius BarozziNoch keine Bewertungen

- Digsilent Powerfactory: Relay Model DescriptionDokument18 SeitenDigsilent Powerfactory: Relay Model DescriptionBra BicabaNoch keine Bewertungen

- UNIT 2 IRS UpDokument42 SeitenUNIT 2 IRS Upnikhilsinha789Noch keine Bewertungen

- Jidoka 1Dokument38 SeitenJidoka 1Lander Aspajo100% (1)

- Python RequestsDokument18 SeitenPython RequestsKlever StyleNoch keine Bewertungen

- Casio FX 82ZA PLUS CheatsheetDokument11 SeitenCasio FX 82ZA PLUS CheatsheetQuinton DuvenageNoch keine Bewertungen

- Audio, Data and Contacts Over IPDokument4 SeitenAudio, Data and Contacts Over IPprakistaoNoch keine Bewertungen

- T24 VersionsDokument26 SeitenT24 VersionsCHARLES TUMWESIGYE100% (1)

- Iba Pang Teknik at Estratehiya Sa PagtuturoDokument5 SeitenIba Pang Teknik at Estratehiya Sa PagtuturoEzekiel RabadonNoch keine Bewertungen