Beruflich Dokumente

Kultur Dokumente

Belarbi2010 PDF

Hochgeladen von

Sani NursopwanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Belarbi2010 PDF

Hochgeladen von

Sani NursopwanCopyright:

Verfügbare Formate

Effect of Contamination on Reinforcing Bar-Concrete Bond

Abdeldjelil Belarbi, P.E., F.ASCE1; David N. Richardson, P.E., M.ASCE2;

Matthew K. Swenty, P.E., M.ASCE3; and Lawrence H. Taber, P.E.4

Abstract: Current specifications require the removal of reinforcing bar contaminants that reduce bond prior to placing concrete. This

study focused on the interactions of contaminant type, bar size, epoxy coating, concrete strength, and test method 共beam and direct

pullout兲. The majority of the beam tests showed the bond strength was not significantly affected, with certain exceptions. However, the

Downloaded from ascelibrary.org by University Of Ulster AT on 06/15/15. Copyright ASCE. For personal use only; all rights reserved.

direct pullout tests revealed a significant reduction of bond strength in most situations. Although the bond strength was still greater than

that required by code, it is recommended that specifications for removal of contaminants should not be relaxed until further study is

performed.

DOI: 10.1061/共ASCE兲CF.1943-5509.0000091

CE Database subject headings: Bonding; Construction management; Specifications; Reinforced concrete; Bars; Contaminant.

Author keywords: Bond strength; Construction specifications; Reinforced concrete; Reinforcing bars; Reinforcing bar placement;

Contaminants; Slippage; Splatter.

Introduction 408 关American Concrete Institute 共ACI兲 1966兴; Kemp et al. 1968;

Goto 1971; Orangun et al. 1977; Bazant and Sener 1988; Darwin

A good bond between reinforcing bars and concrete is crucial for et al. 1994; Castro 1996; Mo and Chan 1996; Fu and Chung

structural strength and serviceability performance. Reinforcement 1998兲.

may become contaminated in a variety of ways during the con- The objectives of this study were to examine the effects of

struction process. Specifications and guidelines such as ACI 301- three common contaminants 共water-based bond breaker, water-

05, ACI 318–08, and ACI 311-07 关American Concrete Institute based release agent, concrete splatter兲 on bond strength of rein-

共ACI兲 2005, 2007, 2008兴 require or recommend that the reinforc- forced concrete for two bar sizes, two levels of concrete strength,

ing bar be cleaned of bond-reducing contaminants prior to placing and for uncoated and epoxy coated conditions. Additionally, two

test methods 共beam and direct pullout兲 were evaluated.

the concrete. Presently, the inspector has to exercise judgment as

to the perceived significance of any bond reduction. Contamina-

tion removal is time consuming, costly, and may be unnecessary Principle of Bond between Reinforcing Bar and

共Suprenant and Malisch 1998兲. Concrete

Research has shown that bond strength typically increases

with increases in concrete cover, cover-to-bar size 共C / db兲, bar Bond behavior involves bond stresses, transfer mechanisms, and

size-to-embedment length 共db / le兲, concrete compressive strength, the failure mode. Bond strength is attributed to four factors: 共1兲

optimum bar rib characteristics, concrete consolidation, and de- chemical adhesion of the concrete to the steel; 共2兲 friction at the

creases in bar size. Epoxy coating tends to lower bond strength. bar-concrete interface from mill scale, rust, and other surface ir-

The effect of rust, up to a certain degree, has been shown to not regularities; 共3兲 bearing against the rib faces; and 共4兲 shear acting

significantly reduce bond strength; subsequently, specifications along a cylindrical concrete surface between adjacent ribs. As

regarding rust have been relaxed 共Johnston and Cox 1940; ACI force is applied to a deformed bar, the adhesion will break and

friction will act where adhesion has failed. However, the primary

1 resistance at this point will come from the presence of the ribs.

Chair and Hugh Roy and Lillie Cranz Cullen Distinguished Profes-

Setting aside issues of concrete cover over the bar, if the rib

sor, Dept. of Civi and Environmental Engineering, Univ. of Houston,

4800 Calhoun Road, N127 Engineering Bldg. 1, Houston, TX 77204- height-to-rib spacing ratio is greater than about 0.10–0.15, the

4003 共corresponding author兲. E-mail: abelarbi@uh.edu shearing action on the cylindrical concrete surface between ribs

2

Associate Professor, Dept. of Civil, Architectural, and Environmental will govern and the bar will pull out. If the ratio is less than the

Engineering, Missouri Univ. of Science and Technology, CE126 1870 critical value, the concrete will be crushed in front of the rib,

Miner Circle, Rolla, MO 65409. E-mail: richardd@mst.edu sometimes forming a wedge. The uncrushed concrete may ride

3

Ph.D. Candidate, Dept. of Civil and Environmental Engineering, over the wedge, contributing to splitting failure of the surround-

Virginia Tech Univ., 102 Patton Hall, Blacksburg, VA 24061. ing concrete, or, with sufficient cover, the bar may pull through

4

Lead Structural Engineer, Black & Veatch Corporation, Kansas City, the concrete. Also, secondary cracks may open at the rib tips.

MO.

When deformed bars are subjected to tension, the reactive

Note. This manuscript was submitted on March 13, 2009; approved

on October 2, 2009; published online on November 6, 2009. Discussion

force at the ribs acts at an angle that is primarily a function of the

period open until November 1, 2010; separate discussions must be sub- rib configuration. The force that is transmitted to the concrete has

mitted for individual papers. This paper is part of the Journal of Perfor- two components. One acts parallel to the bar and is responsible

mance of Constructed Facilities, Vol. 24, No. 3, June 1, 2010. ©ASCE, for breaking the adhesion resistance and overcoming the frictional

ISSN 0887-3828/2010/3-206–214/$25.00. resistance at the bar surface, crushing the concrete against the

206 / JOURNAL OF PERFORMANCE OF CONSTRUCTED FACILITIES © ASCE / MAY/JUNE 2010

J. Perform. Constr. Facil. 2010.24:206-214.

222

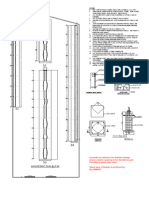

db LVDT

Bonded

51 Area

7.5 db

15 db Fig. 2. Beam test specimen

PVC Tubing with a smaller clear cover. During the test, both the reinforcing

Downloaded from ascelibrary.org by University Of Ulster AT on 06/15/15. Copyright ASCE. For personal use only; all rights reserved.

LVDT bar and concrete are in tension. The RILEM beam test 共Fig. 2兲

305 involves a simply supported beam with a gap in the middle, al-

Rebar

lowing for easy calculations of the tension force and average

bond stress.

Because of the differences in the testing methods and effects

of the two methods, both direct pullout and flexure testing meth-

Fig. 1. Direct pullout test specimen ods were chosen for this study. One of the primary purposes of

using the RILEM beam method was to investigate practical ap-

plications. This flexural test simulates the conditions in a beam or

ribs, and shearing the concrete between the ribs at a plane be- slab that have a relatively small clear cover as commonly seen in

tween the tops of the ribs. The perpendicular component is re- practice

sponsible for creation of circumferential stress. If the clear cover In the second phase of the program, bond strength was tested

is smaller than the zone of significant circumferential stress, the using the RILEM 7-II-128 direct pullout test. Overall, failure by

cracks will reach the concrete member surface and the bond will both direct pullout and flexure provided a basis for making a

fail by splitting. If there is sufficient cover to prevent splitting, comparison between the effects of the contaminants under differ-

and/or if the rib spacing is relatively short, then the cylindrical ent failure conditions as encountered in different types of struc-

shearing mode of failure may govern, causing a shearing type of tures. The purpose of the research was to study the effects of

failure rather than splitting. contaminants on bond stress and bar slip. The stipulated embed-

Both types of failure are progressive in nature, starting at the ment lengths in the RILEM test method were used because they

loaded end where stress is highest and moving toward the free prevent excessive bar stresses. Bar stress was not a variable under

end. After primary cracks are formed, bond stress adjacent to the study. Additionally, the RILEM methods keep db / le constant, so le

crack will increase, causing the concrete to pull away from the was not a variable in this study.

steel 共adhesion failure兲, again creating a perpendicular component

which induces circumferential stress in a zone around the bar.

Thus, there is an interplay between concrete strength, bar size, Experimental Program

and concrete cover 共ACI 408 关American Concrete Institute 共ACI兲

1966兴; Kemp et al. 1968; Goto 1971; Park and Paulay 1975; Four common variables were studied: surface coating condition

Orangun et al. 1977; Bazant and Sener 1988; Setareh and Darvas 共epoxy coated and uncoated兲, reinforcing bar size 关13 mm 共#4兲

2007兲. and 22 mm 共#7兲兴, concrete compressive strength 关28 MPa 共4,000

psi兲 and 48 MPa 共7,000 psi兲兴, and contaminant type 共release

agent, bond breaker, and concrete splatter兲. Instead of the 48 MPa

Bond Test Methods

共7,000 psi兲 concrete strength, a 70 MPa 共10,000 psi兲 strength level

When testing the steel-concrete bond strength, several methods would have provided a better indication of the effect of concrete

are commonly used. One method is the direct pullout test speci- strength. However, to maintain both strength and workability with

fied in RILEM 7-II-128 共RILEM 1994b兲. This test uses moder- the materials used, admixtures would have been necessary. To

ately large clear cover around the bar and ultimately gives direct avoid any possible unforeseen chemical interactions with the con-

measurement of bond strength excluding any cover failure. Other taminates, no admixtures were used. A limited survey of the con-

types of pullout tests 共Suprenant and Malisch 1998兲 have given struction industry identified the three common contaminants used

way to these newer anchorage methods because of concerns with in this study.

additional confinement provided by the reaction plate used in the The first phase of the test program consisted of 32 beam tests,

test. As shown in Fig. 1, the reinforcing bar is only bonded to the with three replicate specimens per test for a total of 96 specimens.

top one-half of the specimen in the RILEM test. A PVC tube is The contaminants were applied along the entire bar embedment

placed around the reinforcing bar to eliminate the issue of the length, simulating the worst-case situation. The specimens were

confining pressure provided by the frictional restraint at the reac- batched in groups of 12 with the type of contaminant being the

tion plate. This type of test is performed to evaluate direct bond only variable per batch.

strength and does not represent the stress conditions of a reinforc- The second phase of the program consisted of direct pullout

ing bar in a flexural beam or slab. However, it is useful for com- tests with the same variables as the flexure test phase with one

parative purposes. exception. Concrete splatter was only used on the 48 MPa 共7,000

A beam test avoids adding confinement and better simulates psi兲 concrete cases because the results of the first testing phase

the embedment in the tension zone of concrete beams or slabs showed that the effects of splatter were insignificant at the lower

JOURNAL OF PERFORMANCE OF CONSTRUCTED FACILITIES © ASCE / MAY/JUNE 2010 / 207

J. Perform. Constr. Facil. 2010.24:206-214.

strength. Thus, 28 tests of three rectangular prisms per test were respectively. “P” denotes the force applied. The size of the beam,

made for a total of 84 specimens. The specimens were batched in casting position, concrete cover, and additional reinforcement was

sets of nine and 12 for the lower and higher strength concrete as specified by RILEM, as noted earlier and in Fig. 2. The speci-

mixtures, respectively. Again, the only variable per batch was the mens were cast on their sides in three even layers of concrete. The

contaminant type, and the contaminants were applied to the entire specimens were cured for 72 h under plastic, then for 25 days at

embedment length. 60% relative humidity and 20⫾ 2 ° C, in accordance with the

The specimen identification code consists of four characters. RILEM test method.

The first character is the surface coating condition, either epoxy

coated 共C兲 or uncoated 共U兲. The second character is the reinforc-

Materials

ing bar size, either four for 13 mm 共#4兲 or seven for 22 mm 共#7兲.

The third character is the nominal 28-day compressive strength, All concrete mixtures consisted of Type I portland cement, 14.3

either four for 28 MPa 共4,000 psi兲 or seven for 48 MPa 共7,000 mm 共9/16 in.兲 nominal maximum size, clean, crushed limestone,

psi兲. The fourth character is the type of contaminant applied to the and natural sand. Different sources of Type I cement and reinforc-

Downloaded from ascelibrary.org by University Of Ulster AT on 06/15/15. Copyright ASCE. For personal use only; all rights reserved.

reinforcing bar: C for control 共no contaminant兲, S for concrete ing steel were used for the two test programs, but the specifica-

splatter, B for bond breaker, and F for form release agent. tions were the same for each. The reinforcing steel was Grade 60

as per ASTM A615-96A/A615M-96a 共ASTM 1997a兲. The epoxy

coating was applied by commercial coating facilities per ASTM

Test Specimens

A775-96 共ASTM 1997b兲. For the beam tests, the average rein-

The direct pullout test program followed the same procedures as forcing bar yield stress for both bar sizes was determined to be

the appropriate RILEM standard but deviated slightly from the 443 MPa 共64.2 ksi兲 and the average tensile strength was 713 MPa

provided dimensions 共RILEM 1994a兲. Fig. 1 shows the configu- 共104 ksi兲. Reinforcing bar used in the pullout test phase for both

ration of the pullout test specimens. The hatched section is a bar sizes had an average yield stress of 492 MPa 共71.3 ksi兲 and an

continuous section of reinforcing bar that ran vertically through average tensile strength of 760 MPa 共110 ksi兲. All uncoated rein-

the center of the concrete. Only the top one-half of the reinforcing forcing bar was free from any rust, unwanted contaminants, or

bar within the specimen was bonded to the concrete. The other coating damage. The bar rib configurations were somewhat dif-

one-half of the reinforcing bar was encircled by a piece of PVC ferent in the two study phases. The beam bar ribs were perpen-

pipe approximately 6.3 mm 共1/4 in.兲 larger in inside diameter than dicular to the axis of the bar, while the pullout bar ribs had a 60°

the reinforcing bar 关32 mm 共1 1/4 in.兲 and 19 mm 共3/4 in.兲 for the included angle. The rib height-to-spacing ratio for the pullout

22 mm 共#7兲 and 22 mm 共#4 bars兲, respectively兴. The total length phase bars was 0.10 and was 0.08 for the beam bars.

of the concrete specimen was 15 times the diameter 共db兲 of the The bond breaker was a water-based lifting agent used in

tested reinforcing bar 共15db兲, of which 7.5db was chosen as the tilt-up construction. The form release agent was a surface consoli-

embedment length. dating water-based form release agent used in precast and site-

A previous study had shown that 10db embedment caused ex- cast concrete applications. The concrete splatter had the same

cessive bar stresses in pullout testing; however, 10db was used in mixture proportions as the mortar portion of the concrete in the

the beam portion of the present study, so a 7.5db length was specimen, simulating a multiple lift placement where this type of

chosen as a compromise between the RILEM standard 5db and contamination often occurs.

10db. The cross section of the concrete specimen is a square mea- The method of applying these contaminants was intended to

suring 222 mm 共8.75 in.兲 on each side. This resulted in a fairly simulate worst-case field conditions. The form release agent and

large cover over the bar, with cover-to-bar size ratios 共C / db兲 for bond breaker were applied using a brush 30 min prior to placing

the 13 mm 共#4兲 and 22 mm 共#7兲 bars of 8.25, and 4.07, respec- the concrete. The concrete splatter was dropped 共or splattered兲

tively. The reinforcing bar protruded 51 mm 共2 in.兲 from the top onto the bar while slowly rotating the bar to ensure complete

of the specimen and extended 305 mm 共12 in.兲 from the reaction coverage. The concrete splatter was applied approximately 18 h

end. The specimens were cast on their sides in three even layers before placement of concrete. From a series of trial batches in

of concrete. The specimens were cured for 24 h under plastic, which the setting time was varied, 18 h was chosen as the worst-

then until the 28th day in a moist room at 100% relative humidity case situation because at this point the splatter has hardened suf-

and 20⫾ 2 ° C. Finally, the specimens were brought out to the ficiently to resist being knocked off but is not yet mature enough

RILEM-recommended ambient room temperature and relative hu- to achieve a good chemical bond to the steel.

midity prior to testing 共approximately 20° C and 60% humidity兲.

The time interval in the laboratory environment ranged from 14 to

Test Setup and Procedure

80 days.

The beam test specimens used in this study were fabricated The beam tests were conducted using a 500 kN 共110 kip兲

using the RILEM standard as a guideline, as shown in Fig. 2. servovalve-controlled machine. All loads were applied using ram

Each specimen was a flexural beam separated in the middle with stroke displacement control to better observe the failure and post-

the reinforcing bar crossing the gap. The two rectangular prisms failure behavior of the specimen. The free-end slip was measured

were joined together with a steel hinge in the compression zone using LVDTs placed on each end of the reinforcing bar. The

and the reinforcing bar in the tension zone. The reinforcing bar RILEM procedure does not require elastic rebar elongation cor-

was embedded into the cross-sectional center of each prism for a rection because of the positioning of the LVDT relative to the

length of 10 times its diameter 共10db兲, as specified by RILEM. unbonded portion of the bar at the LVDT end of the beam. The

PVC tubing was provided outside the 10db length to prevent the only movement measured is the end of the unstressed portion of

concrete from bonding to the steel along the nonembedded por- the bar, and the only movement occurring is the bar being drawn

tion of the reinforcing bar. The cover over the bar was 50 mm 共2 into 共and through兲 the beam. There is no stress in the unbonded

in.兲, which is commonly seen in practice. This level of cover gave bar length at the LVDT beam end, thus no elastic deformation is

a C / db for the 13 mm 共#4兲 and 22 mm 共#7兲 bars of 4.0 and 2.29, being measured and no correction is necessary. Both halves of the

208 / JOURNAL OF PERFORMANCE OF CONSTRUCTED FACILITIES © ASCE / MAY/JUNE 2010

J. Perform. Constr. Facil. 2010.24:206-214.

beams were tested under a symmetric four-point loading per the the lugs was occurring. The amount of slip associated with split-

RILEM specification. The LVDTs were attached securely to the ting failure is considerably less than observed in a shearing fail-

beam, assuring that only relative slip between the reinforcing bar ure.

and concrete was measured. As one side of the beam failed, a The results of the beam tests are summarized in Fig. 4 and in

restraint device was placed 共not shown in Fig. 2兲 on that end of Table 1. The bond strengths shown in Figs. 4 and 5 have been

the reinforcing bar to prevent further slip and to allow the other normalized by dividing bond stress by the square root of com-

one-half to reach failure. In this manner, two replicates were ob- pressive strength. It should be noted that the main differences in

tained from one beam. the bond strength were due to differences in C / db, which dictated

Most of the pullout specimens were tested using a servovalve- failure models 共splitting versus shearing兲. Also, from Fig. 4, it is

controlled loading machine. A LVDT was placed on top of the evident that 13 mm 共#4兲 bars show higher bond strengths com-

specimen to measure movement of the reinforcing bar relative to pared to that of 22 mm 共#7兲 bars. Both 13 mm 共#4兲 and 22 mm

the top surface of the concrete. A second LVDT was attached to 共#7兲 bars were tested under the same embedment length ratio of

the bottom of the steel cage with the reaction end placed against 10db. The relative effect of contaminants for both 13 mm 共#4兲 and

Downloaded from ascelibrary.org by University Of Ulster AT on 06/15/15. Copyright ASCE. For personal use only; all rights reserved.

a steel plate attached to the reinforcing bar. The displacement- 22 mm 共#7兲 bars may have been seen if the failure modes were

controlled method provided smooth stress versus displacement the same. However, as tested, many of the specimens failed in

curves for the first six sets of specimens. bond splitting because the tests better simulate the case of a beam

For the last two sets of specimens 关22 mm 共#7兲 reinforcing bar, or slab in terms of moderate concrete cover than pullout tests.

48 MPa 共7,000 psi兲 concrete兴, the servovalve-controlled machine Additionally, despite a constant db / le, bar stresses were higher in

could not be used to apply the failure load due to physical limi- the 13 mm 共#4兲 tests than in the 22 mm 共#7兲 tests, causing a

tations; a universal testing machine was used to apply the load. In difference in bond stress. No direct comparison of bond strength

this case, a load-control method was used to apply loads, and the between the two bars sizes is possible due to the two failure

movement of the reinforcing bar relative to the top of the speci- modes: splitting versus shearing.

men was measured with a dial gauge. As shown in Fig. 4, bond strength results of the contaminated

13 mm 共#4兲 bar tests were all greater than 12.4 MPa 共1,800 psi兲

and 5.9 MPa 共850 psi兲 for the 13 mm 共#4兲 and 22 mm 共#7兲 bar

tests, respectively. For the conditions of the tests 共concrete com-

Test Results pressive strength, bar coating type, bar yield stress, normal weight

concrete, bottom-of-beam bar position, bar sizes, concrete cover,

Concrete Compressive Strength and assumed transverse reinforcing index conservatively assumed

as zero兲, knowing bar diameters and steel yield strength, the cor-

The compressive strength of the concrete was determined accord- responding greatest average bond stresses 共calculated from equi-

ing to ASTM C39-01 共ASTM 2002兲. Average strengths for the librium using calculated embedment lengths 共as per ACI 318-05

beam tests cast with the nominal 28 MPa 共4,000 psi兲 mixture and Eq. 12-1 of Section 12.2.3兲 were 6.2 MPa 共895 psi兲 and 4.6 MPa

for the nominal 48 MPa 共7,000 psi兲 mixture were 33 MPa 共4,780 共670 psi兲 for the 13 mm 共#4兲 and 22 mm 共#7兲 bar tests, respec-

psi兲, and 46 MPa 共6,710 psi兲, respectively. The ranges were 31.5– tively. Thus, bond strengths reported herein were greater than the

32.7 MPa and 42.9–51.1 MPa. For the pullout tests, the corre- bond stresses implied by the specified development lengths.

sponding average strengths were 33 MPa 共4,860 psi兲 and 52 MPa

共7,500 psi兲. The ranges were 30.5–39.8 and 48.1–54.0 MPa.

Direct Pullout Test Results

Beam Test Results Bond strengths for each set of direct pullout tests are summarized

in Fig. 5 and Table 2. The effects of the testing variables were

Average bond stress-slip curves were generated for each beam. more pronounced than in the beam testing program. Unlike the

The general shape of the curves depended on the type of failure. beam tests, most of the direct pullout specimens failed by a shear-

Two failure modes were observed: splitting and shearing, with the ing mechanism. A few of the 22 mm 共#7兲, 48 MPa 共7,000 psi兲

majority of failures 共76 out of 90兲 being splitting; two-thirds of specimens, and none of the 13 mm 共#4兲 specimens experienced a

the 13 mm 共#4兲 bars and all of the 22 mm 共#7兲 bars failed in this bond splitting failure mechanism. The reason for the different

manner. In Table 1, the failure mode “both” indicates that with the failure mechanism of the larger bar-stronger concrete tests may

particular set of three replicates, some specimens failed by split- have been the change from a displacement-control to a load-

ting and some by shearing. An example of each type of failure control testing method. The load-control method produced a

curve is shown in Fig. 3. The results in Table 1 were expected greater loading rate during the failure interval resulting in sudden

because cover did not scale with bar diameter: larger bars with failure and may have contributed to splitting.

small cover 共C / db = 2.29兲 typically produced failure by splitting, The stress-slip curves were plotted for every direct pullout

while specimens with smaller bars 共C / db = 4.0兲 failed by shearing specimen. An illustrative example of the shearing failure mecha-

or splitting. Splitting failure is characterized by a small amount of nism is seen in Fig. 6. The predomination of the shearing failure

slip that produces the splitting, followed by further slip, and fi- mode meant that the bond interface was being tested, probably

nally a complete loss of bond 共MacGregor 2009兲. because of the large clear cover depth 共distance to edge兲. Suffi-

Shearing only occurred in a limited number of 13 mm 共#4兲 bar cient concrete covered the bars, forcing most of the bonds to fail

tests. This failure is characterized by an increasing amount of slip instead of the clear cover failing. Additionally, bond strengths for

until the bar pulls out of the concrete and the bond stress is 22 mm 共#7兲 bars tended to be higher than for the 13 mm 共#4兲 bars

considerably reduced. It is shown in Fig. 3 that the flatness of the because of greater bar embedment lengths. As shown in Fig. 5,

average bond stress, slip curve beginning at about 5 mm 共0.2 in.兲 bond strength results of the contaminated 13 mm 共#4兲 and the 22

of slip. While no post examination was recorded, it would have mm 共#7兲 bar tests were all greater than 11.7 MPa 共1,700 psi兲.

shown that shearing at the extremity and crushing at the face of Looking at both the beam and pullout data, there is a trend of

JOURNAL OF PERFORMANCE OF CONSTRUCTED FACILITIES © ASCE / MAY/JUNE 2010 / 209

J. Perform. Constr. Facil. 2010.24:206-214.

Table 1. Beam Test Results

Significance

Bar size Concrete strength Bar stress Bond strength Strength change

Pullout id 关mm共#兲兴 共MPa兲 Surface condition Contaminant Failure mode 共MPa兲 共MPa兲 共%兲 90% 95%

C47C 13共#4兲 46.3 Epoxy Control Splitting 636 15.9 — — —

C47B 13共#4兲 46.3 Epoxy Bond breaker Both 568 14.2 ⫺10.7 Yes No

C47F 13共#4兲 46.3 Epoxy Release agent Both 564 14.1 ⫺11.4 Yes No

C47S 13共#4兲 46.3 Epoxy Splatter Splitting 612 15.3 ⫺3.8 No No

U47C 13共#4兲 51.1 Uncoated Control Both 644 16.1 — — —

U47B 13共#4兲 51.1 Uncoated Bond breaker Both 581 14.5 ⫺9.8 Yes No

U47F 13共#4兲 51.1 Uncoated Release agent Both 559 14.0 ⫺13.1 Yes Yes

U47S 13共#4兲 51.1 Uncoated Splatter Splitting 653 16.3 1.4 No No

C44C 13共#4兲 32.3 Epoxy Control Both 623 15.6 — — —

Downloaded from ascelibrary.org by University Of Ulster AT on 06/15/15. Copyright ASCE. For personal use only; all rights reserved.

C44B 13共#4兲 32.3 Epoxy Bond breaker Splitting 540 13.5 ⫺13.3 Yes Yes

C44F 13共#4兲 32.3 Epoxy Release agent Both 541 13.5 ⫺13.2 Yes Yes

C44S 13共#4兲 32.3 Epoxy Splatter Shear 628 15.7 0.8 No No

U44C 13共#4兲 32.7 Uncoated Control Splitting 563 14.1 — — —

U44B 13共#4兲 32.7 Uncoated Bond breaker Shear 500 12.5 ⫺11.3 No No

U44F 13共#4兲 32.7 Uncoated Release agent Both 547 13.7 ⫺2.9 No No

U44S 13共#4兲 32.7 Uncoated Splatter Splitting 589 14.7 4.5 No No

C77C 22共#7兲 42.9 Epoxy Control Splitting 286 7.2 — — —

C77B 22共#7兲 42.9 Epoxy Bond breaker Splitting 255 6.4 ⫺11.0 No No

C77F 22共#7兲 42.9 Epoxy Release agent Splitting 270 6.7 ⫺5.9 No No

C77S 22共#7兲 42.9 Epoxy Splatter Splitting 300 7.5 4.8 No No

U77C 22共#7兲 44.8 Uncoated Control Splitting 278 6.9 — — —

U77B 22共#7兲 44.8 Uncoated Bond breaker Splitting 271 6.8 ⫺2.5 No No

U77F 22共#7兲 44.8 Uncoated Release agent Splitting 308 7.7 ⫺11.0 No No

U77S 22共#7兲 44.8 Uncoated Splatter Splitting 312 7.8 12.2 No No

C74C 22共#7兲 31.5 Epoxy Control Splitting 256 6.4 — — —

C74B 22共#7兲 31.5 Epoxy Bond breaker Splitting 255 6.4 ⫺0.4 No No

C74F 22共#7兲 31.5 Epoxy Release agent Splitting 238 6.0 ⫺7.0 No No

C74S 22共#7兲 31.5 Epoxy Splatter Splitting 235 5.9 ⫺8.0 No No

U74C 22共#7兲 35.2 Uncoated Control Splitting 268 6.7 — — —

U74B 22共#7兲 35.2 Uncoated Bond breaker Splitting 257 6.4 ⫺3.9 No No

U74F 22共#7兲 35.2 Uncoated Release agent Splitting 252 6.3 ⫺6.0 No No

U74S 22共#7兲 35.2 Uncoated Splatter Splitting 290 7.3 8.3 No No

predominant failure types: for C / db = 8.25, all failures were of the reinforcing bar compared to epoxy coated 共22 out of 32 tests兲. In

shearing type; for C / db of about 4.0, there was a mixture of comparison, the results of the direct pullout tests reveal that the

shearing and splitting types; for C / db of 2.29, all failures were bond strength was greater for: 共1兲 22 mm 共#7兲 bars 共11 out of 14

splitting. Bond strength increased as compressive strength, C / db, tests兲; 共2兲 higher compressive strength concrete 共11 out of 12

and db / le increased. The trend for bar size as an isolated variable tests兲; 共3兲 control compared to all three contaminants 共28 out of

was conflicted by other factors. 28 tests兲; and 共4兲 plain reinforcing bar compared to epoxy coated

共10 out of 14 tests兲.

Statistical Analysis of Data The effect of form release agent on bond strength using beam

testing resulted in an overall average of 8% loss across all vari-

The statistical significance of the effects of the contaminants was

ables. Two of eight tests were significantly different at the 95%

investigated by use of Dunnett’s t test and a least-squares model.

confidence level. Strength losses were 13% in both significant

Dunnett’s t test compares a set of means against a control group

cases. Direct pullout specimen testing resulted in an overall 16%

mean. The significance levels chosen for this test were ␣ = 0.05

and 0.10. Tables 1 and 2 show the results of the Dunnett’s t test at loss across all variables. Four of eight tests were significantly

95% and 90% confidence levels for the beam and pullout tests, different at the 95% confidence level. In the four significant cases,

respectively. strength losses were 16–28%.

An inspection of the bond stress results for the beam tests The effect of bond breaker on bond strength using beam test-

shows that the bond strength was greater for: 共1兲 13 mm 共#4兲 bars ing resulted in an overall 9% loss across all variables. One of

共all 32 tests兲 as compared to 22 mm 共#7兲; 共2兲 higher compressive eight tests was significantly different at the 95% confidence level.

strength mixture 共31 out of 32 tests兲; 共3兲 control compared to In that case, strength loss was 13%. Direct pullout specimen test-

bond breaker 共eight out of eight tests兲; 共4兲 control compared to ing resulted in an overall 23% loss across all variables. Five of

form release agent 共seven out of eight tests兲; 共5兲 concrete splatter eight tests were significantly different at the 95% confidence

compared to control 共six out of eight tests兲; and 共6兲 uncoated level. Strength losses were 22–40%.

210 / JOURNAL OF PERFORMANCE OF CONSTRUCTED FACILITIES © ASCE / MAY/JUNE 2010

J. Perform. Constr. Facil. 2010.24:206-214.

Bond Slip (mm)

0 1 2 3 4 5 6

2500

Bond Splitting 16

2250

(Drop in Bond

2000 14

Strength)

1750 12

Bond Stress (MPa)

Bond Stress (psi)

1500

10

Bond

1250

Pullout 8

1000

Downloaded from ascelibrary.org by University Of Ulster AT on 06/15/15. Copyright ASCE. For personal use only; all rights reserved.

6

750

4

500

250 2

0 0

0 0.05 0.1 0.15 0.2

Bond Slip (in)

Fig. 3. Example bond stress-slip curve from the beam tests

The effect of concrete splatter on bond strength using beam four of 10 cases. Thus it appears that the effect of epoxy coating

testing resulted in an overall 2% change across all variables. None itself was relatively small and did not consistently increase or

of eight tests were significantly different at the 95% confidence decrease the bond strength.

level. Direct pullout specimen testing resulted in an overall 13% From the distribution of the beam data shown in Fig. 4, the 22

loss across all variables. Two of four tests were significantly dif- mm 共#7兲 reinforcing bars gave a lower bond stress 共average 54%兲

ferent at the 95% confidence level. Strength losses were 22–42%. than the 13 mm 共#4兲 bars, due to insufficient cover. For the direct

For the direct pullout results, an analysis of the effect of coat- pullout test program, Fig. 5 shows a small 共10%兲 increase in bond

ing of the reinforcing bar showed that for each contaminant treat- strength for the 22 mm 共#7兲 bar tests mainly due to the longer

ment, the difference in bond strength loss between coating types embedment length provided for larger bars, plus cover did not

averaged 11%. The epoxy coated tests resulted in larger losses in govern failure as in most of beam tests. In comparing the results

35

C: Coated

U: Uncoated

30 First # (4 vs. 7) = bar size

Second # (4 vs. 7) = concrete strength

Normalized Bond Strength

25

20

15

10

0

U44 C44 U47 C47 U74 C74 U77 C77

Control Release Agent Bond Breaker Concrete Splatter

Fig. 4. Bond strength test results from the beam tests

JOURNAL OF PERFORMANCE OF CONSTRUCTED FACILITIES © ASCE / MAY/JUNE 2010 / 211

J. Perform. Constr. Facil. 2010.24:206-214.

45

C: Coated

U: Uncoated

40 First # (4 vs. 7) = bar size

Second # (4 vs. 7) = concrete strength

35

Normalized Bond Strength 30

25

20

Downloaded from ascelibrary.org by University Of Ulster AT on 06/15/15. Copyright ASCE. For personal use only; all rights reserved.

15

10

0

U44 C44 U47 C47 U74 C74 U77 C77

Control Release Agent Bond Breaker Concrete Splatter

Fig. 5. Bond strength test results from the direct pullout tests

Table 2. Pullout Test Results

Significance

Bar size Concrete strength Bar stress Bond strength Strength change

Pullout id 关mm共#兲兴 共MPa兲 Surface condition Contaminant Failure mode 共MPa兲 共MPa兲 共%兲 90% 95%

C47C 13共#4兲 54.0 Epoxy Control Shear 668 22.3 — — —

C47B 13共#4兲 54.0 Epoxy Bond breaker Shear 499 16.6 ⫺25.2 Yes Yes

C47F 13共#4兲 54.0 Epoxy Release agent Shear 482 16.1 ⫺27.8 Yes Yes

C47S 13共#4兲 54.0 Epoxy Splatter Shear 592 19.7 ⫺11.5 No No

U47C 13共#4兲 53.0 Uncoated Control Shear 594 19.8 — — —

U47B 13共#4兲 53.0 Uncoated Bond breaker Shear 354 11.8 ⫺40.2 Yes Yes

U47F 13共#4兲 53.0 Uncoated Release agent Shear 540 18.0 ⫺8.8 No No

U47S 13共#4兲 53.0 Uncoated Splatter Shear 451 15.0 ⫺24.0 Yes Yes

C44C 13共#4兲 32.8 Epoxy Control Shear 449 15.0 — — —

C44B 13共#4兲 32.8 Epoxy Bond breaker Shear 379 12.6 ⫺15.7 Yes No

C44F 13共#4兲 32.8 Epoxy Release agent Shear 354 11.8 ⫺21.5 Yes Yes

U44C 13共#4兲 31.2 Uncoated Control Shear 497 16.6 — — —

U44B 13共#4兲 31.2 Uncoated Bond breaker Shear 387 12.9 ⫺22.5 Yes Yes

U44F 13共#4兲 31.2 Uncoated Release agent Shear 362 12.1 ⫺27.3 Yes Yes

C77C 22共#7兲 48.1 Epoxy Control Splitting 691 23.0 — — —

C77B 22共#7兲 48.1 Epoxy Bond breaker Splitting 540 18.0 ⫺21.8 Yes Yes

C77F 22共#7兲 48.1 Epoxy Release agent Both 614 20.5 ⫺11.2 No No

C77S 22共#7兲 48.1 Epoxy Splatter Shear 401 13.4 ⫺42.1 Yes Yes

U77C 22共#7兲 51.2 Uncoated Control Splitting 677 22.6 — — —

U77B 22共#7兲 51.2 Uncoated Bond breaker Both 577 19.2 ⫺14.6 No No

U77F 22共#7兲 51.2 Uncoated Release agent Both 641 21.4 ⫺5.1 No No

U77S 22共#7兲 51.2 Uncoated Splatter Both 550 18.3 ⫺18.7 No No

C74C 22共#7兲 30.5 Epoxy Control Shear 422 14.1 — — ——

C74B 22共#7兲 30.5 Epoxy Bond breaker Shear 364 12.1 ⫺13.6 Yes No

C74F 22共#7兲 30.5 Epoxy Release agent Shear 354 11.8 ⫺15.9 Yes Yes

U74C 22共#7兲 39.8 Uncoated Control Shear 575 19.2 — — —

U74B 22共#7兲 39.8 Uncoated Bond breaker Shear 414 13.8 ⫺27.9 Yes Yes

U74F 22共#7兲 39.8 Uncoated Release agent Shear 476 15.9 ⫺17.5 Yes No

212 / JOURNAL OF PERFORMANCE OF CONSTRUCTED FACILITIES © ASCE / MAY/JUNE 2010

J. Perform. Constr. Facil. 2010.24:206-214.

Bond Slip (mm)

1 2 3 4 5 6 7

2250 6

2000 14

Ultimate Bond Strength (Mpa)

1750 12

1500

10

Bond Stress (psi)

1250 8

1000

6

750

Bond

Pullout 4

Downloaded from ascelibrary.org by University Of Ulster AT on 06/15/15. Copyright ASCE. For personal use only; all rights reserved.

500

2

250

0

0.00 0.05 0.10 0.15 0.20 0.25 0.30

Bond Slip ( In.)

Fig. 6. Illustrative bond stress-slip curve in a direct pullout test

of all control tests, the effect of greater concrete compressive 1. All of the beams with 22 mm 共#7兲 bars and approximately

strength resulted in an 8% increase in bond strength in the beam two-thirds of the beams with 13 mm 共#4兲 bars failed by

study. In the direct pullout study, the increase was 37%. splitting. The amount of slip associated with this failure is

A comparison of the means of the control specimens in the considerably less than observed in a shearing failure. Shear-

beam tests using Dunnett’s t test showed that the following were ing failure occurred in about one-half of the 13 mm 共#4兲 bar

significantly different at the ␣ = 0.05 level: bar size 共uncoated兲 and beam specimens;

bar size 共coated兲. The Dunnett’s t test comparison of the means of 2. The direct pullout tests tended to fail in the shearing failure

the control specimens of the direct pullout tests showed that the mode. The thick clear cover around the reinforcing bar pre-

effect of concrete strength was significant at the ␣ = 0.05 level. vented splitting failures;

Least-squares model analysis verified the significance of these 3. The C / db influenced the type of failure mechanism, which

variables. impacted whether the contaminants were seen to be detri-

In Table 1, the significantly different beam treatment combi- mental. The difference between the mechanisms is that in the

nations are the 13 mm 共#4兲 bar, epoxy coated, 28 MPa 共4,000 psi兲 direct pullout test, forces are applied parallel to the bond.

concrete strength contaminated with bond breaker or form release The beam tests have forces as seen by a flexural beam or slab

agent, and 13 mm 共#4兲 bar, uncoated, 48 MPa 共7,000 psi兲 con- that are more typical in practice than in the pullout test. Fail-

crete strength contaminated with form release agent. This trend ures by splitting in a beam test showed a much smaller bond

shows a possible interaction of the form release agent or bond strength reduction than a comparable test in a direct bond

breaker contaminants with the smaller bar size, weaker concrete, pullout method;

and epoxy bar coating. A least-squares model verified the signifi- 4. For the beam tests, bond strength was greater for the follow-

cance of that interaction. ing:

In Table 2, the direct pullout tests had a large number of sig- a. 13 mm 共#4兲 bars;

nificantly different tests so a least-squares model was used to find b. Higher compressive strength mixture;

possible interactions. The interactions of all three contaminants, c. Control compared to bond breaker;

the bar size, and the concrete strength were significant when try- d. Control compared to form release agent;

ing to predict bond strength at a significance level of 0.05. e. Concrete splatter compared to control; and

With the significance level of ␣ = 0.10, Table 1 shows three f. Plain reinforcing bar compared to epoxy coated.

additional beam tests identified as significantly different, for a 5. In the results of the pullout tests, bond strength was greater

total of six. All were for 13 mm 共#4兲 bars. For the direct pullout for the following:

case, three additional tests were found to be significantly different a. 22 mm 共#7兲 bars;

resulting in a total of 14 out of 20 significantly different tests. b. Higher compressive strength concrete;

c. Control compared to all three contaminants; and

d. Plain reinforcing bar compared to epoxy coated.

Conclusions 6. The beam tests exhibited an average loss in bond strength of

8% due to the presence of form release agents or bond

An examination was made of the effects of three common con- breaker contaminants. However, in 13 out of 16 contamina-

taminants 共water-based bond breaker, water-based release agent, tion tests, a comparison of the means analysis showed that

concrete splatter兲 on bond strength of reinforced concrete for two the bond strength was not significantly affected by the form

bar sizes, two levels of concrete strength, and for plain and epoxy release agents or bond breaker contaminants. None of the

coated conditions. The following conclusions are drawn from the beam results were significantly affected by the concrete

experimental and statistical studies of this investigation: splatter. However, as the data indicates, as bar size and con-

JOURNAL OF PERFORMANCE OF CONSTRUCTED FACILITIES © ASCE / MAY/JUNE 2010 / 213

J. Perform. Constr. Facil. 2010.24:206-214.

crete strength decrease and the bar surface is epoxy coated, Technology, McCarthy Construction, Associated General Con-

the reinforced concrete may be more susceptible to a loss of tractors, Site Advancement Foundation, Industry Advancement

bond strength caused by bond breaker and form release agent Fund, Southern Illinois Construction Advancement Program, St.

contaminants, regardless of the failure mode observed: split- Louis Construction Training and Advancement Foundation, and

ting versus shearing; the Erectors and Riggers Association of St. Louis.

7. The direct pullout tests exhibited an average loss in bond

strength of 21% due to all three contaminants. Nine of the 16

pullout tests performed with the form release agent or bond References

breaker were significantly affected by the contaminant. Two

of the four concrete splatter sets were also significantly af- American Concrete Institute 共ACI兲. 共1966兲. “Bond stress-the state of the

art.” American Concrete Institute (ACI) Journal Proceedings, 63共11兲,

fected;

1161–1190.

8. A comparison of the means of the control specimens showed American Concrete Institute 共ACI兲. 共2005兲. “Standard specifications for

that: structural concrete.” 301-05, Farmington Hills, Mich.

Downloaded from ascelibrary.org by University Of Ulster AT on 06/15/15. Copyright ASCE. For personal use only; all rights reserved.

a. For beam tests, the effect of bar size 共coated and un- American Concrete Institute 共ACI兲. 共2007兲. “ACI manual of concrete

coated兲 was significant; and inspection.” SP-2(07), Farmington Hills, Mich.

b. For pullout tests, the effect of concrete strength was American Concrete Institute 共ACI兲. 共2008兲. “Building code requirements

significantly different. for structural concrete 共ACI 318-08兲 and commentary.” 318-08, Farm-

9. The interaction of the form release agent contaminant with ington Hills, Mich.

bar size, concrete strength level, and coating condition was ASTM. 共1997a兲. “Standard specification for deformed and plain billet-

significant. For the direct pullout tests, the interaction of all steel bars for concrete reinforcement.” A615/A 615M-96a, West Con-

shohocken, Pa., 301–305.

three contaminants, the bar size, and the concrete strength

ASTM. 共1997b兲. “Standard specification for epoxy-coated steel reinforc-

were significant when trying to predict bond strength; ing bar.” 775-96, West Conshohocken, Pa., 301–305.

10. The pullout tests showed that contaminants can decrease ASTM. 共2002兲. “Standard test method for compressive strength of cylin-

bond strength significantly. The beam tests showed that at drical concrete specimens.” C39-01, West Conshohocken, Pa., 21–25.

commonly used levels of cover, the concrete member may Bazant, Z. P., and Sener, S. 共1988兲. “Size effect of pullout tests.” ACI

fail before the effect of the contaminants can assert them- Mater. J., 85共5兲, 347–351.

selves. Additionally, contaminants were applied to all the Castro, P. 共1996兲. “Influence of coatings on bar-concrete bond.” J. Mater.

bars with 100% coverage. This would be considered the Civ. Eng., 8共4兲, 212–214.

worst-case scenario. Whether this much contamination Darwin, D., Hadje-Ghaffari, H., Choi, O., and McCabe, S. 共1994兲. “Bond

would occur under actual field conditions is considered un- of epoxy-coated reinforcement: Cover, casting position, slump, and

consolidation.” ACI Struct. J., 91共1兲, 59–68.

likely. Even with 100% coverage, contaminants were ineffec-

Fu, X., and Chung, D. 共1998兲. “Effects of water-cement ratio, curing age,

tive in certain conditions; and silica fume, polymer admixtures, steel surface treatments, and corro-

11. A universal statement cannot be made about bond contami- sion on bond between concrete and steel reinforcing bars.” ACI Mater.

nants for every scenario at this time. Although certain con- J., 95共6兲, 725–734.

taminants lowered bond strength significantly, in the case of Goto, Y. 共1974兲. “Cracks formed in concrete around deformed tension

the beam specimens the bond strengths were still greater than bars.” ACI J., 68共4兲, 244–251.

that required by ACI 318-08. However, it is recommended Johnston, B., and Cox, K. 共1940兲. “The bond strength of rusted deformed

that specifications for cleaning of contaminants should not be bars.” ACI J., 37, 57–72.

relaxed until further research and analysis is performed. Kemp, E., Brezny, F. and Unterspan, J. 共1968兲. “Effect of rust and scale

on the bond characteristics of deformed reinforcing bars.” ACI J.,

65共9兲, 743–756.

MacGregor, J. 共2009兲. Reinforced concrete-mechanics and design, 3rd

Recommendations for Future Research

Ed., Prentice-Hall, Upper Saddle River, N.J.

Mo, Y., and Chan, J. 共1996兲. “Bond and slip of plain rebars in concrete.”

One purpose of this research was to provide a credible basis for J. Mater. Civ. Eng., 8共4兲, 208–211.

future research to be performed. The goal is to eventually gather Orangun, C. O., Jirsa, J. O., and Breen, J. E. 共1977兲. “A reevaluation of

enough data for the possible development of appropriate recom- test data on development length and splices.” American Concrete In-

mendations that consider altering the current requirements of stitute (ACI) Journal Proceedings, 74共3兲, 114–122.

cleaning contaminated steel reinforcing bar prior to placement of Park, R., and Paulay, T. 共1975兲. “Chapter 9: Bond and anchorage.” Rein-

concrete. Studies that focus on other types of contaminants, set- forced concrete structures, Wiley, New York, 392–425.

ting times, amount of contaminant coverage, reliability studies, RILEM. 共1994a兲. “RC5: Bond test for reinforcing steel. 1. Beam test.”

concrete admixtures, embedment lengths, factors of safety, and a RILEM technical recommendations for the testing and use of con-

comparison of code-required bond strength for a variety of sce- struction materials, 7-II-28 D, E & FN Spon, London, 96–101.

narios should be undertaken. RILEM. 共1994b兲. “RC6: Bond test for reinforcing steel. 1. Pull-out test.”

RILEM technical recommendations for the testing and use of con-

struction materials, 7-II-128, E & FN Spon, London, 102–105.

Setareh, M., and Darvas, R. 共2007兲. “Chapter 3: Special topics in flex-

Acknowledgments ure.” Concrete structures, Pearson Education, Inc., Upper Saddle

River, N.J., 194–195.

For their help with funding, the writers thank the University Suprenant, B., and Malisch, W. 共1998兲. “How clean must rebar be?”

Transportation Center at Missouri University of Science and Conc. Constr., 43共6兲, 517–523.

214 / JOURNAL OF PERFORMANCE OF CONSTRUCTED FACILITIES © ASCE / MAY/JUNE 2010

J. Perform. Constr. Facil. 2010.24:206-214.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Important Electrical Properties of CRGO & Hi - B CRGO GradesDokument6 SeitenImportant Electrical Properties of CRGO & Hi - B CRGO GradesaaaaNoch keine Bewertungen

- Shed Ga FoundationDokument5 SeitenShed Ga FoundationDarshit VyasNoch keine Bewertungen

- Guru Gobind Singh Indraprastha University, Delhi: Design of Light Weight Fire ExtinguisherDokument28 SeitenGuru Gobind Singh Indraprastha University, Delhi: Design of Light Weight Fire ExtinguisherVishal JhaNoch keine Bewertungen

- Cera DampproofDokument2 SeitenCera DampproofAnwar HussainNoch keine Bewertungen

- SPAB Technical Advice Note-Caring For Old FloorsDokument20 SeitenSPAB Technical Advice Note-Caring For Old FloorsPaul Ionescu IINoch keine Bewertungen

- Section - 4 General Damage Mechanisms - 475deg C EmbrittlementDokument3 SeitenSection - 4 General Damage Mechanisms - 475deg C EmbrittlementlokelooksNoch keine Bewertungen

- Pentas 2: Specifications Site PlanDokument2 SeitenPentas 2: Specifications Site Planhafis820% (1)

- Tolerances FitsDokument25 SeitenTolerances FitsAnonymous E2oSW7Noch keine Bewertungen

- Submital & Method Statement - Loading BracketsDokument1 SeiteSubmital & Method Statement - Loading BracketsvtalexNoch keine Bewertungen

- BohlerDokument2 SeitenBohlerjupiter zNoch keine Bewertungen

- Metal CastingDokument12 SeitenMetal CastingChinmay Das100% (4)

- Copper Piping Checklist VRVDokument1 SeiteCopper Piping Checklist VRVSkill IndiaNoch keine Bewertungen

- Ground Anchor SystemsDokument60 SeitenGround Anchor SystemsDoby Kamburova100% (1)

- Grade Library NITONDokument2 SeitenGrade Library NITONKande RameshNoch keine Bewertungen

- Lec-3 Building EstimatesDokument16 SeitenLec-3 Building Estimatesshahzeb khanNoch keine Bewertungen

- BLDG TECH Juson Assignment Lecture 1Dokument23 SeitenBLDG TECH Juson Assignment Lecture 1Ma. Janelle GoNoch keine Bewertungen

- Shear Strengthening of RC Beams With NSM FRP Strips Concept and Behaviour of Novel FRP AnchorsDokument7 SeitenShear Strengthening of RC Beams With NSM FRP Strips Concept and Behaviour of Novel FRP AnchorsEngr. RaihanNoch keine Bewertungen

- Concrete Pavers Vendors, Suppliers & Wholesalers in KarachiDokument4 SeitenConcrete Pavers Vendors, Suppliers & Wholesalers in KarachiAdeel100% (2)

- Casting DeffectsDokument35 SeitenCasting DeffectsJaswinder SinghNoch keine Bewertungen

- Surface Box On Field or Verges Surface Box On Paved Roads Plan ViewDokument1 SeiteSurface Box On Field or Verges Surface Box On Paved Roads Plan ViewAbdelmoneimNoch keine Bewertungen

- Zinc Cold GalvanizeDokument1 SeiteZinc Cold GalvanizeVăn Trường LêNoch keine Bewertungen

- Steel ConnectionsDokument69 SeitenSteel Connectionsmaomontes75% (4)

- (Concrete) Material Consumption ReportDokument34 Seiten(Concrete) Material Consumption Reportmeerut nazibabad projectNoch keine Bewertungen

- 2009 CatalogueDokument53 Seiten2009 CataloguehapidzNoch keine Bewertungen

- Eurocode 6 Part1.1 (ENG) - prEN 1996-1-1 (2001 Out) PDFDokument123 SeitenEurocode 6 Part1.1 (ENG) - prEN 1996-1-1 (2001 Out) PDFmarineugenNoch keine Bewertungen

- Equivalencia Moldes Erico y CadwellDokument58 SeitenEquivalencia Moldes Erico y CadwellCarlo Rocha ZapanaNoch keine Bewertungen

- Gravitex Plus: Technical Data Sheet & Process GuideDokument3 SeitenGravitex Plus: Technical Data Sheet & Process GuideOluwaseun TaiwoNoch keine Bewertungen

- Metal Partion WallDokument28 SeitenMetal Partion WallTanishq RathodNoch keine Bewertungen

- Quezon Iii District Engineering Office: Department of Public Works and HighwaysDokument1 SeiteQuezon Iii District Engineering Office: Department of Public Works and HighwaysVenus PunzalanNoch keine Bewertungen

- Check Valves: Swing Check Valve Class 300Dokument1 SeiteCheck Valves: Swing Check Valve Class 300Tania Milagros Mego JimenezNoch keine Bewertungen