Beruflich Dokumente

Kultur Dokumente

316 LVM

Hochgeladen von

Metehan Agaca0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

65 Ansichten1 Seite316LVM is an austenitic stainless steel that is initially electric arc melted and then vacuum arc remelted to improve purity and homogeneity. It has been used for permanent medical implants for many years due to its good corrosion resistance and ductility when annealed or cold worked. Applications include suture wire, orthopedic cables, and other small machined medical parts. The document provides details on the typical chemistry, mechanical properties, physical properties, thermal treatment, and surface finish of 316LVM stainless steel.

Originalbeschreibung:

Originaltitel

316lvm

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument melden316LVM is an austenitic stainless steel that is initially electric arc melted and then vacuum arc remelted to improve purity and homogeneity. It has been used for permanent medical implants for many years due to its good corrosion resistance and ductility when annealed or cold worked. Applications include suture wire, orthopedic cables, and other small machined medical parts. The document provides details on the typical chemistry, mechanical properties, physical properties, thermal treatment, and surface finish of 316LVM stainless steel.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

65 Ansichten1 Seite316 LVM

Hochgeladen von

Metehan Agaca316LVM is an austenitic stainless steel that is initially electric arc melted and then vacuum arc remelted to improve purity and homogeneity. It has been used for permanent medical implants for many years due to its good corrosion resistance and ductility when annealed or cold worked. Applications include suture wire, orthopedic cables, and other small machined medical parts. The document provides details on the typical chemistry, mechanical properties, physical properties, thermal treatment, and surface finish of 316LVM stainless steel.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

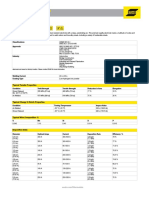

F O R T WAY N E M E T A L S RESEARCH PRODUCTS CORP.

316LVM

Melt Practice Applications

This austenitic stainless steel is initially electric-arc melted. 316LVM material has been used for permanent implants

Then as a refinement to the purity and homogeneity of the metal, for many years. The corrosion resistance in the annealed

316LVM is Vacuum Arc Remelted (VAR). This process yields a condition is good. Many studies for new alloys use

more uniform chemistry with minimal voids and contaminants. 316LVM as a reference. This stainless steel has good

316LVM is unique nomenclature for Fort Wayne Metals. ductility in the cold worked condition. Applications

This alloy meets the requirements of 316LS. include: suture wire, orthopaedic cables, skin closure

staples, catheters, stylets, bone pins and many small

machined parts.

Typical Chemistry

FWM Avg. Wt. % ASTM F138

Mechanical Properties

Carbon .023 .03

% Elongation

Manganese 1.84 2.00 % CW Y.S. (psi) U.T.S. (psi) (10" gage length)

Silicon .37 .75 0% 45,000 91,000 42%

Phosphorus .014 .025 20% 110,000 123,000 8%

Sulphur .001 .01 37% 145,000 160,000 2.5%

Chromium 17.57 17-19 50% 161,000 176,000 2.2%

Nickel 14.68 13-15.0 60% 170,000 191,000 2.1%

Molybdenum 2.79 2.25-3 68% 176,000 203,000 2.5%

Copper .03 .5 75% 191,000 218,000 2.6%

Nitrogen .03 .1 80% 186,000 217,000 2.6%

Iron Balance Balance 84% 202,000 227,000 2.6%

90% 205,000 238,000 2.6%

FWM chemistry is for reference only, and is not to be used for specification purposes.

93% 212,000 239,000 2.6%

95% 213,000 246,000 2.8%

Physical Properties

0.287 lbs/in3

Values are typical and may not represent all diameters. Test method will affect results.

Density

Modulus of Elasticity 27.9 psi x 106

Electrical Resistivity 740 µohms-mm Surface Conditions

Thermal Conductivity 16.3 W/m K (100°C) Stainless steels develop a highly polished appearance as

they are drawn to fine diameters. Surface roughness can

be less than 5 RMS when processed using SCND* dies

Thermal Treatment and measured with a profilometer. Diameters over .040"

A reducing atmosphere is preferred for thermal treatment, but are finished with polycrystalline dies and exhibit a

inert gas can be used. 316LVM will fully anneal at 1010-1121°C rougher surface than natural diamond dies. Diameters

in just a few minutes. The precipitation of carbides that decreases over .100" have an even rougher surface because they are

corrosion resistance in other 300 series alloys is controlled by a drawn with carbide dies. Additional finish treatments can

reduced carbon content in 316LVM. enhance the surface of the wire.

* SCND means single crystal natural diamond.

www.fwmetals.com

1.4

Das könnte Ihnen auch gefallen

- Chemical Composition: ASTM B103Dokument1 SeiteChemical Composition: ASTM B103MarcoAntonioNoch keine Bewertungen

- Aluminum 5182-H34: Metal Nonferrous Metal Aluminum Alloy 5000 Series Aluminum AlloyDokument2 SeitenAluminum 5182-H34: Metal Nonferrous Metal Aluminum Alloy 5000 Series Aluminum AlloyLuis BadoffNoch keine Bewertungen

- 303-Cruicible SteelDokument2 Seiten303-Cruicible SteelARUNKANNANNoch keine Bewertungen

- Sureweld 6010: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesDokument1 SeiteSureweld 6010: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesGibbs PerNoch keine Bewertungen

- Aluminio 3105 H16Dokument2 SeitenAluminio 3105 H16Cesar Zarate100% (1)

- Aluminum 380.0-F Die Casting AlloyDokument2 SeitenAluminum 380.0-F Die Casting AlloyLuis BadoffNoch keine Bewertungen

- Conductor TAIHAN Size ChartsDokument40 SeitenConductor TAIHAN Size ChartsUdomkarn SmtNoch keine Bewertungen

- E16 8 2Dokument4 SeitenE16 8 2Branko FerenčakNoch keine Bewertungen

- ASTM A36 Steel, Plate: Metal Ferrous Metal ASTM Steel Carbon Steel Low Carbon SteelDokument1 SeiteASTM A36 Steel, Plate: Metal Ferrous Metal ASTM Steel Carbon Steel Low Carbon SteelStan HonNoch keine Bewertungen

- Glaistytieji Elektrodai (Smaw) Žemos Vandenilio Jonų Koncentracijos ElektrodaiDokument2 SeitenGlaistytieji Elektrodai (Smaw) Žemos Vandenilio Jonų Koncentracijos ElektrodaiKiranNoch keine Bewertungen

- ASTM A36 Steel, PlateDokument1 SeiteASTM A36 Steel, PlateI-SignNoch keine Bewertungen

- Aluminum 6082-T4: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloyDokument1 SeiteAluminum 6082-T4: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloydeepscubNoch keine Bewertungen

- S 45 CDokument1 SeiteS 45 CFahmi IrmanshahNoch keine Bewertungen

- Dual Shield 710X: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresDokument3 SeitenDual Shield 710X: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresPhilippe TrudelNoch keine Bewertungen

- Aluminum 5052Dokument6 SeitenAluminum 5052lalfredoperezNoch keine Bewertungen

- CSF-71T Technical Report EN - V2Dokument7 SeitenCSF-71T Technical Report EN - V2Miroslav ThôngNoch keine Bewertungen

- Special Metals UDIMET® Alloy 250 Maraging SteelDokument1 SeiteSpecial Metals UDIMET® Alloy 250 Maraging SteelshubhamNoch keine Bewertungen

- Superalloy C276 PlateDokument1 SeiteSuperalloy C276 PlateJitendra AmbaselkarNoch keine Bewertungen

- Aluminum 6351-T6, Aluminium DatasheetDokument2 SeitenAluminum 6351-T6, Aluminium DatasheetvikrantNoch keine Bewertungen

- FICHADokument2 SeitenFICHAadmisecoinperuNoch keine Bewertungen

- Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDokument2 SeitenCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodesdarmawan listyonoNoch keine Bewertungen

- JIS S45C Steel, TemperedDokument2 SeitenJIS S45C Steel, TemperedAnonymous kAday2100% (2)

- Covered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesDokument1 SeiteCovered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesKannan MurugesanNoch keine Bewertungen

- Atom Arc 7018: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDokument2 SeitenAtom Arc 7018: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesKrishna VachaNoch keine Bewertungen

- Aluminum 3004-H112: Metal Nonferrous Metal Aluminum Alloy 3000 Series Aluminum Alloy Click HereDokument2 SeitenAluminum 3004-H112: Metal Nonferrous Metal Aluminum Alloy 3000 Series Aluminum Alloy Click HereksichalosNoch keine Bewertungen

- 316L SS CrucibleDokument2 Seiten316L SS CrucibleARUNKANNANNoch keine Bewertungen

- Metalcor Cual10fe3mn2Dokument1 SeiteMetalcor Cual10fe3mn2robertjob34Noch keine Bewertungen

- 316L-SS-annealed Bar and Cold DrawnDokument2 Seiten316L-SS-annealed Bar and Cold DrawnARUNKANNANNoch keine Bewertungen

- C93200 Spec4Dokument1 SeiteC93200 Spec4Rajendra ChoudharyNoch keine Bewertungen

- 303-Stainless Steel-Annealed BarDokument2 Seiten303-Stainless Steel-Annealed BarARUNKANNANNoch keine Bewertungen

- Bronze C86300 SpecificationsDokument2 SeitenBronze C86300 SpecificationsDoss MartinNoch keine Bewertungen

- JIS S45C Steel, Normalized: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Medium Carbon SteelDokument1 SeiteJIS S45C Steel, Normalized: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Medium Carbon SteelPuji RiatnoNoch keine Bewertungen

- Specification - GL Wires - MESPL May 2021Dokument2 SeitenSpecification - GL Wires - MESPL May 2021M. I. BhadiNoch keine Bewertungen

- ESM Inert Support BallsDokument1 SeiteESM Inert Support BallsBamrung SungnoenNoch keine Bewertungen

- Amorkast 80al C - AdtechDokument2 SeitenAmorkast 80al C - AdtechFaisal YaniNoch keine Bewertungen

- 316L-SS-annealed BarDokument2 Seiten316L-SS-annealed BarARUNKANNANNoch keine Bewertungen

- Nominal Composition Standard Inventory SpecificationsDokument3 SeitenNominal Composition Standard Inventory Specificationssafat parNoch keine Bewertungen

- A286 (Ficha Tecnica)Dokument3 SeitenA286 (Ficha Tecnica)Alex Zambrana RodríguezNoch keine Bewertungen

- OK Weartrode 30: Covered (Stick) Electrodes (Smaw) Hardfacing ElectrodesDokument1 SeiteOK Weartrode 30: Covered (Stick) Electrodes (Smaw) Hardfacing Electrodesraghubhaimantra4136Noch keine Bewertungen

- Material - S45C NormalizedDokument1 SeiteMaterial - S45C NormalizedhanazahrNoch keine Bewertungen

- Aluminum 1050-H14 (Soportes)Dokument2 SeitenAluminum 1050-H14 (Soportes)Carlos Andres Garcia MuñozNoch keine Bewertungen

- 316 PDFDokument1 Seite316 PDFViswanathan SrkNoch keine Bewertungen

- MaterialData 7754Dokument2 SeitenMaterialData 7754Joko TriwardonoNoch keine Bewertungen

- 316 Stainless Steel, Annealed SheetDokument2 Seiten316 Stainless Steel, Annealed SheetZASSNoch keine Bewertungen

- 316-SS-annealed Bar and Cold DrawnDokument2 Seiten316-SS-annealed Bar and Cold DrawnARUNKANNANNoch keine Bewertungen

- ASMEDokument1 SeiteASMEdeyanshu7Noch keine Bewertungen

- Merit RM-56: Lincoln Electric China Gmaw Solid WireDokument2 SeitenMerit RM-56: Lincoln Electric China Gmaw Solid WirejuanchepeinNoch keine Bewertungen

- ESB 321M116700 SpecSheetDokument2 SeitenESB 321M116700 SpecSheetArthanari VaidyanathanNoch keine Bewertungen

- ESB 321M116700 SpecSheetDokument2 SeitenESB 321M116700 SpecSheetCitra Adelina SitorusNoch keine Bewertungen

- ASTM A36 Steel, Bar: To View All Available Suppliers For This MaterialDokument1 SeiteASTM A36 Steel, Bar: To View All Available Suppliers For This Materialapepglory8Noch keine Bewertungen

- (Discontinued ) : ASTM A202 Low Alloy Steel, Grade BDokument1 Seite(Discontinued ) : ASTM A202 Low Alloy Steel, Grade BDhanyajaNoch keine Bewertungen

- 6061 T6 MaterialDokument2 Seiten6061 T6 Materialtravis8zimmermannNoch keine Bewertungen

- Aluminum 6061-T6 6061-T651: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloyDokument3 SeitenAluminum 6061-T6 6061-T651: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloySaad SaudNoch keine Bewertungen

- Alloy 276 Spec SheetDokument3 SeitenAlloy 276 Spec SheetJAYA BHARATHA REDDYNoch keine Bewertungen

- Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesDokument1 SeiteCovered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile Propertiescorsini999Noch keine Bewertungen

- CLC 18-12-4LN: A 3%mo Austenitic Stainless Steel With Nitrogen Addition (317LN Grade)Dokument4 SeitenCLC 18-12-4LN: A 3%mo Austenitic Stainless Steel With Nitrogen Addition (317LN Grade)PeterWayNoch keine Bewertungen

- Aluminium A380Dokument1 SeiteAluminium A380Ashokkumar VelloreNoch keine Bewertungen

- Newnes Circuit Calculations Pocket Book: with Computer ProgramsVon EverandNewnes Circuit Calculations Pocket Book: with Computer ProgramsNoch keine Bewertungen

- Inerwood Mobel ReportDokument23 SeitenInerwood Mobel ReportJalil AhmadNoch keine Bewertungen

- EE C245 - ME C218 Introduction To MEMS Design Fall 2008 Fall 2008Dokument41 SeitenEE C245 - ME C218 Introduction To MEMS Design Fall 2008 Fall 2008Luis ClarkNoch keine Bewertungen

- Wire Rope Technical Manual: Choose QualityDokument62 SeitenWire Rope Technical Manual: Choose QualityMelchorRdzNoch keine Bewertungen

- ISCC 205 Greenhouse Gas EmissionsDokument43 SeitenISCC 205 Greenhouse Gas Emissionskkjayasurya100% (1)

- Metode Pemasangan Pipa HDPEDokument13 SeitenMetode Pemasangan Pipa HDPEBudi SantonyNoch keine Bewertungen

- PDP 434PE DatasheetDokument108 SeitenPDP 434PE DatasheetGabriela Diana MaximovaNoch keine Bewertungen

- Cec 110p PDFDokument20 SeitenCec 110p PDFJoifry DonnaNoch keine Bewertungen

- Penguin Windows BrochureDokument16 SeitenPenguin Windows BrochurePenguin Windows100% (2)

- Heating System Design (Student)Dokument25 SeitenHeating System Design (Student)markbrennan1Noch keine Bewertungen

- 8-1 Technical+Specification+for+Refrigerating+Units PDFDokument94 Seiten8-1 Technical+Specification+for+Refrigerating+Units PDFRyan WongNoch keine Bewertungen

- Royalty Line Catalog 2016Dokument88 SeitenRoyalty Line Catalog 2016Инна БутенкоNoch keine Bewertungen

- Process Compressor Siemens PDFDokument8 SeitenProcess Compressor Siemens PDFTabiquera Guadalupe Victoria Texcoco De MoraNoch keine Bewertungen

- Teco SRL - Catalogo 2015 - ItaDokument66 SeitenTeco SRL - Catalogo 2015 - ItaDaniel AchovskiNoch keine Bewertungen

- CFSEI Tech Note X Bracing L001-09Dokument8 SeitenCFSEI Tech Note X Bracing L001-09Jane EyreNoch keine Bewertungen

- Exhibitors List - Malaysia Gifts Fair 2019 - GiftsDokument4 SeitenExhibitors List - Malaysia Gifts Fair 2019 - GiftsMimpi GraphicsNoch keine Bewertungen

- Bell & Gosset PumpDokument8 SeitenBell & Gosset Pumprogel_ganaNoch keine Bewertungen

- P 340 SDokument190 SeitenP 340 SPera PericNoch keine Bewertungen

- Pressure Vessel & Process Equipment Design & EngineeringDokument9 SeitenPressure Vessel & Process Equipment Design & EngineeringTree TaweeNoch keine Bewertungen

- KPC-Core Logging ManualDokument44 SeitenKPC-Core Logging ManualSupriyanto Drs0% (1)

- Telegarten Coaxial Bulk CablesDokument4 SeitenTelegarten Coaxial Bulk CablesFirmansyah PanduNoch keine Bewertungen

- BySmart Fiber (New) Datasheet Eng OriginalDokument2 SeitenBySmart Fiber (New) Datasheet Eng Originalaaa a sadNoch keine Bewertungen

- Department: Mechanical Engineering Programme: HND I School: Centre For Continuing Education (PH) DATE: MAY, 2013Dokument8 SeitenDepartment: Mechanical Engineering Programme: HND I School: Centre For Continuing Education (PH) DATE: MAY, 2013taridanNoch keine Bewertungen

- Tools StatusDokument10 SeitenTools StatusMachinery ClubNoch keine Bewertungen

- 6000722B CH10 Electrosurgical PrintDokument12 Seiten6000722B CH10 Electrosurgical PrintAland BravoNoch keine Bewertungen

- Strategies For Operations of Vertical Shaft Kilns PDFDokument7 SeitenStrategies For Operations of Vertical Shaft Kilns PDFKalai SelvanNoch keine Bewertungen

- EP-1 Manual 21851 en V1.6-WebDokument48 SeitenEP-1 Manual 21851 en V1.6-WebFirda Ratna Safitri100% (1)

- Block PistonDokument5 SeitenBlock Pistonbikash_88Noch keine Bewertungen

- Solas A and B PackDokument4 SeitenSolas A and B PackBatak LegendsNoch keine Bewertungen

- Quality PricingDokument22 SeitenQuality PricingNathan BukoskiNoch keine Bewertungen

- 6DS BFA A19 CombineDokument3 Seiten6DS BFA A19 CombineAdnan GeeNoch keine Bewertungen