Beruflich Dokumente

Kultur Dokumente

Article - Multi-Channel Vibration Measurements - CTSS PDF

Hochgeladen von

kwakwa4Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Article - Multi-Channel Vibration Measurements - CTSS PDF

Hochgeladen von

kwakwa4Copyright:

Verfügbare Formate

TECH CORNER

MULTI-CHANNEL VIBRATION MEASUREMENTS

Multi-channel vibration

measurements allow efficient

station-wide assessment

Ensuring pulsations

don’t result in excessive

vibration is objective.

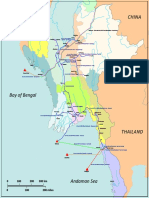

FIGURE 1

By Wally Bratek A typical natural gas compressor station.

D

ue to changing pipeline flow Piping changes in the station will create

requirements and flow reversal different acoustic resonances. Each of these

trends in the natural gas industry, factors can cause a station that has run

it is often necessary to modify the smoothly for decades to suddenly develop

AUTHORS CORNER

WALLY BRATEK is a principal compressor

c stations feeding the vibration problems.

consultant in Wood’s vibration, pipelines.

p Sometimes, different operating To prevent potential vibration problems

dynamics and noise group. His pressures

pr or additional load steps are when changing operating conditions, a

more than 20 years’ design and field required. In other cases, new compression,

req pulsation simulation study is recommended.

experience include acoustical (pulsation) and meter stations or coolers may be added. However, options to control pulsation are

mechanical vibration analysis, field testing and These changes can inadvertently create limited, as existing pulsation bottles cannot

troubleshooting, and lateral rotordynamics. pulsation and vibration problems in the be reconfigured to new conditions. As a

Wally has presented multiple papers at industry station. result, many stations end up experiencing

conferences, is a member of the GMRC Gas As shown in Figure 2, changing pulsation exceeding API 618 allowable

Machinery Conference Planning Committee, and compressor load steps or pressures will amplitudes. The best way to ensure that

is an active member of the API 618 6th Edition alter the flow from each unit as required, but these pulsations do not result in excessive

task force for pulsation analysis. Contact him at: this will also modify the pulsation source vibration and fatigue failures is to measure

wally.bratek@woodplc.com amplitudes originating at the compressors, vibration levels within the station, so that

both on the suction and discharge systems. problem areas can be mitigated. >

www.CTSSnet.net 2019 | COMPRESSORTECH2 SOURCING SUPPLEMENT | 219

TECH CORNER

MULTI-CHANNEL VIBRATION MEASUREMENTS

Challenges with vibration data compressor speeds, and the multi-channel collect all the data. The multi-channel

collection analyzer will record how the station reacts approach is much more efficient.

Measuring and analyzing vibration in terms of pulsation and vibration. These The multi-channel approach also provides

adequately throughout a station can be tests can usually be completed in one greater insight, as the data can be easily

challenging. This is because most stations day, but more complex troubleshooting plotted and compared to process parameters

do not operate at a single, steady-state cases may require up to three days of data such as pressure or flow. This is done by

operating condition. Each compressor has collection. importing historical process data into the

multiple load steps to control capacity, and vibration post-processing database.

some compressors shut down under certain Advantages of multi-channel Further, the multi-channel approach

operating scenarios. Each compressor vibration analyzers allows capturing of transient events

also has an operating speed range that One advantage of the multi-channel throughout a station while changing

will determine the excitation frequencies. approach is that disruption to operations between different load-steps or bringing

Combined with changing pipeline pressures, is minimized. If a measurement campaign different units online, which can be critical for

the number of possible operating scenarios was to be undertaken with a 2- or 4-channel ensuring high station reliability.

becomes overwhelming. analyzer, operations would be forced to

The most efficient way to measure set up for one operating scenario, and Advanced post-processing tools

vibration on a complex piping system with then hold it for as long as it takes to move turn vast amounts of data into

multiple operating conditions is to utilize a sensors and collect data throughout the actionable insights

multi-channel vibration analyzer as shown in station. If compressor speed sweeps are While there is great value in obtaining such

Figure 3. required, then the sweep would have to comprehensive data on pulsation and

A typical station may require 56 to as be repeated multiple times to capture the

many as 240 channels of simultaneous effect throughout the station. Completing

vibration and pulsation measurements. the measurement process with a 2- to FIGURE 3 Multi-channel analyzer setup.

Vibration specialists typically spend a 4-channel analyzer could easily take weeks

day setting up transducers and mapping to complete, while severely limiting station

channels before they are ready to press availability. This is not only inconvenient for

the record button. Operators can then cycle operations, but also expensive considering

the station through various scenarios and the number of person-hours required to

1600 150

1500

130

1400

1300

110

HORSEPOWER

1200

FLOW (MMSCF/D)

1100 90

1000

70

900

800

50

700

600 30

400 420 440 460 480 500 520 540 560 580 600 620 640

SUCTION PRESSURE (PSIG)

FIGURE 2

Reciprocating compressor loading curve.

220 | COMPRESSORTECH2 SOURCING SUPPLEMENT | 2019 www.CTSSnet.net

TECH CORNER

MULTI-CHANNEL VIBRATION MEASUREMENTS

FIGURE4

PostPro data

processing results.

vibration in a compressor station, the volume

of data can be difficult to process and

analyze. To overcome this challenge, Wood

has developed an advanced post-processing

software tool. Data on vibration, pulsation,

revolutions per minute (RPM) and process

conditions is compiled into an aggregated

database. The software then creates

anomaly reports, listing the measurements

and their values relative to applicable

guidelines.

The tool also flags RPMs with high

vibration amplitudes in a “speeds to avoid”

chart, which allows operators to run

equipment at safe speeds until corrective

action is implemented in the field. Individual

spectrum and waterfall plots are also

produced, as shown in Figure 4.

Conclusion

The ability to collect, process, analyze and

present hundreds of gigabytes of vibration

test data in a short amount of time provides

valuable advantages for facility owners. The

summarized overview of key information

helps vibration analysts and operators make

meaningful and timely conclusions and

determine appropriate actions to ensure

a station’s safe operation and optimize its

long-term reliability. CT2

www.CTSSnet.net 2019 | COMPRESSORTECH2 SOURCING SUPPLEMENT | 221

Das könnte Ihnen auch gefallen

- Fire Hydrant System Design Installation Commisioning and TestingDokument5 SeitenFire Hydrant System Design Installation Commisioning and Testingjaianit89Noch keine Bewertungen

- DNV 2-7-1Dokument60 SeitenDNV 2-7-1Apostolie Iulian100% (1)

- DNV 2-7-1Dokument60 SeitenDNV 2-7-1Apostolie Iulian100% (1)

- PTS Index To PTSDokument47 SeitenPTS Index To PTSDandy Harris FirdiandaNoch keine Bewertungen

- Roots Blower Operating ManualDokument15 SeitenRoots Blower Operating Manualanup_nairNoch keine Bewertungen

- Vibration Analysis For Reciprocating Compressors Part 1 1681772666Dokument8 SeitenVibration Analysis For Reciprocating Compressors Part 1 1681772666Mohamed F. OmarNoch keine Bewertungen

- Ceidp DWGDokument4 SeitenCeidp DWGyahyaupsefNoch keine Bewertungen

- SPE 77655 Downhole Fiber-Optic Multiphase Flowmeter: Design, Operating Principle, and TestingDokument7 SeitenSPE 77655 Downhole Fiber-Optic Multiphase Flowmeter: Design, Operating Principle, and TestingTheNourEldenNoch keine Bewertungen

- Dynamic Data Analysis of Compressor Rotating StallDokument12 SeitenDynamic Data Analysis of Compressor Rotating Stalljessika woodNoch keine Bewertungen

- 03 Combustor Dynamics Monitoring (CDM)Dokument9 Seiten03 Combustor Dynamics Monitoring (CDM)Luis Alonso Dipaz ZeaNoch keine Bewertungen

- Optical VibrationDokument6 SeitenOptical VibrationKarthick VelayuthamNoch keine Bewertungen

- Suppression of Drill-String Stick-Slip VibrationDokument5 SeitenSuppression of Drill-String Stick-Slip VibrationYan Nazareth SimõesNoch keine Bewertungen

- Article Overall Vibration Values For Reliable Wind Turbines PDFDokument4 SeitenArticle Overall Vibration Values For Reliable Wind Turbines PDFrrNoch keine Bewertungen

- Meter Selection For Various Load RequirementsDokument6 SeitenMeter Selection For Various Load RequirementsjnmanivannanmechNoch keine Bewertungen

- Ban0016en12 Ms Fin FansDokument5 SeitenBan0016en12 Ms Fin FansHash LalaNoch keine Bewertungen

- The K FactorDokument11 SeitenThe K FactorSOURAV PRASADNoch keine Bewertungen

- Acoustic Pressure Transient Testing CIM 2008Dokument16 SeitenAcoustic Pressure Transient Testing CIM 2008sameer bakshiNoch keine Bewertungen

- Artikel Specifying Magnetic Bearings PDFDokument2 SeitenArtikel Specifying Magnetic Bearings PDFAgustin A.100% (1)

- Current Instrument Transformer Error CalculationsDokument4 SeitenCurrent Instrument Transformer Error CalculationsAli YıldırımNoch keine Bewertungen

- Programing: Vehicle TestingDokument7 SeitenPrograming: Vehicle TestingwerNoch keine Bewertungen

- Bulletin: New Swivel Base Compatible Smart Triaxial Orthoshear Accelerometer Now Available With TedsDokument1 SeiteBulletin: New Swivel Base Compatible Smart Triaxial Orthoshear Accelerometer Now Available With TedsBrianna Daniela VARGAS MERMANoch keine Bewertungen

- Colibrys Paper Ieee Plans 16Dokument7 SeitenColibrys Paper Ieee Plans 16Jayasuryaa G RNoch keine Bewertungen

- Field Experiences With V - Cone Technology: High LowDokument12 SeitenField Experiences With V - Cone Technology: High LowEdisonCorderoNoch keine Bewertungen

- The Effect of Change in Ow Rate On The Vibration of Double-Suction Centrifugal PumpsDokument12 SeitenThe Effect of Change in Ow Rate On The Vibration of Double-Suction Centrifugal PumpsGhassan ABO ALINoch keine Bewertungen

- N-16-13 - A Rule of Thumb For Vibration (Velocity) Limits For Plant Piping SystemsDokument2 SeitenN-16-13 - A Rule of Thumb For Vibration (Velocity) Limits For Plant Piping SystemsHamid Hasan100% (1)

- Downhole Broadband Solutions Brochure PDFDokument6 SeitenDownhole Broadband Solutions Brochure PDFA-selam IbraNoch keine Bewertungen

- Jet Pump Response ExtractDokument1 SeiteJet Pump Response ExtractAfonso MatondoNoch keine Bewertungen

- 2013 - The Monitoring of The Two Phase Flow-Annular Flow Type Regime Using Microwave Sensor TechniqueDokument7 Seiten2013 - The Monitoring of The Two Phase Flow-Annular Flow Type Regime Using Microwave Sensor Techniqueh3r0n3duNoch keine Bewertungen

- New Methods For Switchgear - Test and AnalysisDokument3 SeitenNew Methods For Switchgear - Test and AnalysisJNoch keine Bewertungen

- Automated Drilling Algorithms ImplementationDokument11 SeitenAutomated Drilling Algorithms ImplementationnanlingjigongNoch keine Bewertungen

- Machinery Vibration Limits and Dynamic Structural ResponseDokument28 SeitenMachinery Vibration Limits and Dynamic Structural ResponseteguhfujyardiNoch keine Bewertungen

- Vibration System For GT GeneratorDokument5 SeitenVibration System For GT GeneratorMayurNoch keine Bewertungen

- Brochure Echometer Well AnalyzerDokument3 SeitenBrochure Echometer Well AnalyzermiguelNoch keine Bewertungen

- 9.1 Definition of Indexes of Performance For Servo DrivesDokument16 Seiten9.1 Definition of Indexes of Performance For Servo DrivesChinh Hoang QuangNoch keine Bewertungen

- Monitoring Strategy of LNG Reciprocating CompressorsDokument4 SeitenMonitoring Strategy of LNG Reciprocating Compressorsalhumaid28Noch keine Bewertungen

- BVMS WriteupDokument3 SeitenBVMS Writeupmunna777Noch keine Bewertungen

- A4 SPEC Pumping Systems 201507 PDFDokument5 SeitenA4 SPEC Pumping Systems 201507 PDFJose BijoyNoch keine Bewertungen

- Flow Scanner North Sea CsDokument2 SeitenFlow Scanner North Sea Cshamed1725Noch keine Bewertungen

- Beckhoff Energy MeasurementDokument28 SeitenBeckhoff Energy MeasurementAdito JunandaNoch keine Bewertungen

- Condition Monitoring System For Hydro TurbinesDokument4 SeitenCondition Monitoring System For Hydro TurbinesEng Bagaragaza RomualdNoch keine Bewertungen

- TI Slva882Dokument19 SeitenTI Slva882alprovieNoch keine Bewertungen

- Static Check Synchronisers: MeasurementsDokument6 SeitenStatic Check Synchronisers: MeasurementssravankotlasNoch keine Bewertungen

- Vibration Measuring InstrumentsDokument8 SeitenVibration Measuring InstrumentsSardar Wasif Ashraf KhanNoch keine Bewertungen

- Gas Pulsation Study For Reciprocating Compressors in Chemical PlantsDokument11 SeitenGas Pulsation Study For Reciprocating Compressors in Chemical PlantsLTORRESMNoch keine Bewertungen

- Unlocking Hydraulic Limits in A RevampDokument7 SeitenUnlocking Hydraulic Limits in A RevampBramJanssen76Noch keine Bewertungen

- MeterRunDesign BestPracticesDokument8 SeitenMeterRunDesign BestPracticesjohnzrwNoch keine Bewertungen

- Fachartikel Mobile-Mining Newman 27-01-2016 enDokument7 SeitenFachartikel Mobile-Mining Newman 27-01-2016 enhrstgaNoch keine Bewertungen

- Ijertv12n7 01Dokument7 SeitenIjertv12n7 01IgorNoch keine Bewertungen

- SPE-173759-MS Scale Modeling in ReservoirsDokument10 SeitenSPE-173759-MS Scale Modeling in ReservoirsLawNoch keine Bewertungen

- Applying SystemDokument1 SeiteApplying SystemTan NguyenNoch keine Bewertungen

- Q3 07 PDFDokument16 SeitenQ3 07 PDFChakravarthy BharathNoch keine Bewertungen

- Manara: Production and Reservoir Management SystemDokument2 SeitenManara: Production and Reservoir Management SystemabdouNoch keine Bewertungen

- Modern Management of Artificial Lift Wells: A.L. PodioDokument11 SeitenModern Management of Artificial Lift Wells: A.L. Podiojaccucv2150Noch keine Bewertungen

- Reducing Pump Vibration: The Service Magazine of The PRÜFTECHNIK GroupDokument8 SeitenReducing Pump Vibration: The Service Magazine of The PRÜFTECHNIK Groupduy ngo thanhNoch keine Bewertungen

- Of Steam Turbine-Generators: I Method For Predicting The PerformanceDokument40 SeitenOf Steam Turbine-Generators: I Method For Predicting The PerformancenckpourlasNoch keine Bewertungen

- 13 Venting RequirementsDokument3 Seiten13 Venting RequirementsMuhammad Adil KhanNoch keine Bewertungen

- Invariant Coordinate Systems For Compressor ControlDokument16 SeitenInvariant Coordinate Systems For Compressor ControlReyes SanchezNoch keine Bewertungen

- TD Actuator 001 en ADokument24 SeitenTD Actuator 001 en AhermanNoch keine Bewertungen

- Demand Side Check 1Dokument4 SeitenDemand Side Check 1Mauro TognocchiNoch keine Bewertungen

- OTC 15194 Deepwater Bop Control Systems - A Look at Reliability IssuesDokument10 SeitenOTC 15194 Deepwater Bop Control Systems - A Look at Reliability IssuesRajeev ThomasNoch keine Bewertungen

- DC Link Measurements Based Sensorless Induction Motor Variable-Speed DriveDokument14 SeitenDC Link Measurements Based Sensorless Induction Motor Variable-Speed DriveNationalinstituteDsnrNoch keine Bewertungen

- Application Notes Bearing Monitoring Equipment For Gear Driven Paper Machines Bo0072Dokument4 SeitenApplication Notes Bearing Monitoring Equipment For Gear Driven Paper Machines Bo0072AndysNoch keine Bewertungen

- MonitorRotMachine Part1Dokument14 SeitenMonitorRotMachine Part1SEBINNoch keine Bewertungen

- SymbolsDokument1 SeiteSymbolskwakwa4Noch keine Bewertungen

- Tritech Knowledge Base Profiling SonarsDokument2 SeitenTritech Knowledge Base Profiling Sonarskwakwa4Noch keine Bewertungen

- SymbolsDokument1 SeiteSymbolskwakwa4Noch keine Bewertungen

- MPS Day1 World Class Reliability PerformanceDokument142 SeitenMPS Day1 World Class Reliability Performancemelator100% (1)

- ETAP Electrical StrategyDokument5 SeitenETAP Electrical Strategykwakwa4Noch keine Bewertungen

- EENG 223 Final Exam S08-09 SolnDokument7 SeitenEENG 223 Final Exam S08-09 Solnkwakwa4Noch keine Bewertungen

- Vibration, Dynamics and NoiseDokument6 SeitenVibration, Dynamics and NoiseMauricio R MoralesNoch keine Bewertungen

- BPS91 08Dokument38 SeitenBPS91 08kwakwa4Noch keine Bewertungen

- Veridian iDAC - Data Acquisition DeviceDokument2 SeitenVeridian iDAC - Data Acquisition Devicekwakwa4Noch keine Bewertungen

- Risk Check Sheet: Vibration, Fatigue, Reliability and NoiseDokument3 SeitenRisk Check Sheet: Vibration, Fatigue, Reliability and NoiseMauricio R MoralesNoch keine Bewertungen

- Vibration, Dynamics and NoiseDokument6 SeitenVibration, Dynamics and NoiseMauricio R MoralesNoch keine Bewertungen

- Article - Multi-Channel Vibration Measurements - CTSS PDFDokument3 SeitenArticle - Multi-Channel Vibration Measurements - CTSS PDFkwakwa4Noch keine Bewertungen

- WHO - Indoor Air PollutionDokument484 SeitenWHO - Indoor Air PollutionCosmo Deus100% (2)

- Psrs550 en Om c1Dokument142 SeitenPsrs550 en Om c1Andrei Ieremciuc100% (1)

- HvacDokument376 SeitenHvacJERIN JOHNSON100% (1)

- What Is Acceptable Oil Consumption in Diesel EnginesDokument1 SeiteWhat Is Acceptable Oil Consumption in Diesel Engineskwakwa4Noch keine Bewertungen

- Pipeline Map 20140402 - HJS - Cropped (Units in KM)Dokument1 SeitePipeline Map 20140402 - HJS - Cropped (Units in KM)kwakwa4Noch keine Bewertungen

- Sulzer Vertical Pump TroubleshootingDokument20 SeitenSulzer Vertical Pump TroubleshootingNguyễn Thanh SơnNoch keine Bewertungen

- TOEIC 870 QuestionsDokument6 SeitenTOEIC 870 Questionskwakwa4Noch keine Bewertungen

- Check Your English Vocabulary For TOEICDokument81 SeitenCheck Your English Vocabulary For TOEICRobby100% (27)

- CAP437Dokument164 SeitenCAP437universidaddistritalNoch keine Bewertungen

- Thu Kyon Ma Khan B PDFDokument173 SeitenThu Kyon Ma Khan B PDFkwakwa4Noch keine Bewertungen

- ကုရ္အာန္ဘာသာျပန္Dokument1.130 Seitenကုရ္အာန္ဘာသာျပန္Aung Kyaw MoeNoch keine Bewertungen

- MPS Day1 World Class Reliability PerformanceDokument142 SeitenMPS Day1 World Class Reliability Performancemelator100% (1)

- RCA Mini Guide PDFDokument15 SeitenRCA Mini Guide PDFIldzamar Haifa WardhaniNoch keine Bewertungen

- Operations and Maintenance GuideDokument321 SeitenOperations and Maintenance GuideNatrajiNoch keine Bewertungen

- Terrain and Geohazard Challenges Facing Onshore Oil and Gas PipelinesDokument741 SeitenTerrain and Geohazard Challenges Facing Onshore Oil and Gas Pipelinesargentino_ar01100% (1)

- Moisture MeasurementDokument8 SeitenMoisture MeasurementnimasinaNoch keine Bewertungen

- Pipeline Construction Stages With PDFDokument11 SeitenPipeline Construction Stages With PDFBrijesh Katariya VCSNoch keine Bewertungen

- Cold WorkDokument2 SeitenCold WorkGiorgi KandelakiNoch keine Bewertungen

- Standing Committee On Natural Resources (Canada) 02-01-2011Dokument22 SeitenStanding Committee On Natural Resources (Canada) 02-01-2011permaculturistNoch keine Bewertungen

- EC201 (Rev) Tcm92 22934kompressDokument12 SeitenEC201 (Rev) Tcm92 22934kompressJoe GoparNoch keine Bewertungen

- 11-6005 CS Process FinalDokument2 Seiten11-6005 CS Process FinalChung ChuanNoch keine Bewertungen

- Oim CBSDDokument30 SeitenOim CBSDHendi Hendriansyah100% (1)

- A81936-3 Trans Mountain Appendix A Part 2 of 7 Condition 26 - A5J1X3Dokument352 SeitenA81936-3 Trans Mountain Appendix A Part 2 of 7 Condition 26 - A5J1X3suphissNoch keine Bewertungen

- Corrosion Brochure 2022Dokument12 SeitenCorrosion Brochure 2022Shiraz AlamNoch keine Bewertungen

- YET-AGRU-EXE-MEB-000-PCMM-PRC-0002-0 General Testing Pre-Commissioning and Commissioning Procedure - Amended-signed-Code-3Dokument11 SeitenYET-AGRU-EXE-MEB-000-PCMM-PRC-0002-0 General Testing Pre-Commissioning and Commissioning Procedure - Amended-signed-Code-3mohsin moin100% (1)

- 17Dokument15 Seiten17entindanNoch keine Bewertungen

- Standard Practice For Operation and Maintenance of Integrated Natural Gas Pipelines and Optical Fiber SystemsDokument5 SeitenStandard Practice For Operation and Maintenance of Integrated Natural Gas Pipelines and Optical Fiber Systemssebastian novoaNoch keine Bewertungen

- Code of Practice For The Installation of Pressure Sensing Devices On Dry Gaseous and Liquid Chlorine ApplicationsDokument12 SeitenCode of Practice For The Installation of Pressure Sensing Devices On Dry Gaseous and Liquid Chlorine ApplicationsKimberly ConleyNoch keine Bewertungen

- OLGA Sample CasesDokument134 SeitenOLGA Sample CasesRoberto Caceres0% (1)

- Gas Pipeline Risk Assessment by Internet ApplicationDokument4 SeitenGas Pipeline Risk Assessment by Internet Applicationjhuerta888100% (1)

- Pipeline Engineer Cover Letter SampleDokument4 SeitenPipeline Engineer Cover Letter SampleUKNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 15-Dec-09 MechDokument3 SeitenSaudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 15-Dec-09 MechEagle SpiritNoch keine Bewertungen

- Tugas Review PaperDokument5 SeitenTugas Review PaperKetut Vera Budi LesmanaNoch keine Bewertungen

- M40 Rev1 Eng-2019Dokument2 SeitenM40 Rev1 Eng-2019Aleksandar StankovicNoch keine Bewertungen

- EPT GL PRO 0001 Facility Line SizingDokument46 SeitenEPT GL PRO 0001 Facility Line Sizingnasiruddin276Noch keine Bewertungen

- Report Thrust BlockDokument73 SeitenReport Thrust BlockTarek AbulailNoch keine Bewertungen

- Crude Oil Processing On Offshore Facilities PDFDokument14 SeitenCrude Oil Processing On Offshore Facilities PDFmohit4821Noch keine Bewertungen

- PCVL Pigging Procedure (RB-B To RB-A)Dokument9 SeitenPCVL Pigging Procedure (RB-B To RB-A)hai dang maiNoch keine Bewertungen

- Awwa C218 2008Dokument36 SeitenAwwa C218 2008Moito Carvalho100% (1)

- Specifying Surge Relief Valves in Liquid PipelinesDokument6 SeitenSpecifying Surge Relief Valves in Liquid Pipelinesmatteo2009Noch keine Bewertungen

- Pipeline Design Calculations PDFDokument21 SeitenPipeline Design Calculations PDFjimallen21281% (21)

- 0031R 50 D PR 004 Hydrotest Pre Commissioning Procedure Rev. 0Dokument45 Seiten0031R 50 D PR 004 Hydrotest Pre Commissioning Procedure Rev. 0bonnico100% (1)