Beruflich Dokumente

Kultur Dokumente

Renderoc SXtra

Hochgeladen von

Mansoor AliCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Renderoc SXtra

Hochgeladen von

Mansoor AliCopyright:

Verfügbare Formate

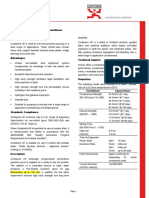

Fosroc Renderoc SXtra constructive solutions

Shrinkage controlled, polymer modified, structural grade

cementitious repair mortar system

Uses Properties

Renderoc SXtra is suitable for hand application to repairs The following typical results were obtained at a water to

where significant load bearing is required. Typical applica- powder ratio of 0.15.

tions would include, but not be limited to, the following :

Test method Typical result

Vertical and overhead repairs Drying shrinkage to ASTM C 157-93

7 days : < 300 microstrain

Patch repairs to concrete floor slabs 28 days : < 500 microstrain

Permeability : < 10 mm

Patch repairs to stairs, steps and other areas subject to

(DIN 1048 Part 5)

repeated, heavy trafficking Flexural strength : > 7 N/mm2 at 28 days

Arris repairs to joint edges (BS 6319 Pt.3)

Tensile strength : > 3.5 N/mm2 at 28 days

General structural repairs where formwork cannot be (BS 6319 Pt.7)

easily erected Compressive strength : Tolerance (±10%)

(BS 1881 Pt.1161) : 35 N/mm2 at 3 days

Advantages 45 N/mm2 at 7 days

55 N/mm2 at 28 days

Renderoc SXtra features Dimensional Stability Technolo- Water absorption : < 2%

gy - a new materials technology which controls the rate of (BS 1881 Pt.122)

drying shrinkage such that, when used correctly : Note1: 50mm cubes, air cured @ 250C

i. the dimensions of the repair remain stable; and thus

Design criteria

ii. eliminating failure, due to shrinkage cracking.

Dimensional Stability Technology is a major step forward

This in turn leads to a series of associated benefits : in the general compatibility of repair mortar systems with the

host substrate, and the control of drying shrinkage in particu-

Cost effective - shrinkage control enables repairs to be lar.

completed ‘right first time’ Attention to the basic design criteria given below should

ensure that the full benefits of this technology are gained in

Enhanced durability - works in tandem with extremely

use :

low permeability to prolong effective working life

(i) Recommended limits for a single application are:

Compatibility - aligns performance closer than ever

before, to that of host concrete Minimum applied thickness : 5 mm

Overhead sections : up to 25 mm thick

User friendly - specifically developed to provide an Vertical sections : up to 35 mm thick

easy-to-apply product, suitable for local conditions Small pockets or horizontal : up to 100 mm thick

Definable performance - positive benefits are easily Maximum length : up to 3 m

demonstrated via a single, simple measurement

NOTE : If the repair area exceeds 2.5 m2, consideration

should be given to the use of mass fill by means

Description of either Renderoc SPXtra* spray applied mortar

Renderoc SXtra is supplied as a ready to use blend of dry or Renderoc LAXtra* microconcrete.

powders, which requires only the addition of clean water to (ii) In situations where a substrate/repair barrier is required,

produce a highly consistent repair mortar suitable for most or enhanced bond strength/working time is required, or

structural and load bearing repairs. where the substrate is likely to be damp (e.g. seawalls,

quays etc.), Nitobond EP epoxy bonding agent should be

used.

(iii) Water addition = 3.75 litres per 25kg bag

Renderoc SXtra

Under no circumstances should part bags be used or

additional water be employed. Either of these two actions

will adversely affect material performance, automatically

invalidating Fosroc’s standard product guarantee.

Fosroc Renderoc SXtra

Instructions for use Precautions

Renderoc SXtra should be mixed and applied in strict accord- Health and safety

ance with the Product Method Statement, a copy of which

Renderoc SXtra contains cement powders which, when

may be obtained from your nearest Fosroc office.

mixed with water or upon becoming damp, release alkalis

which can be harmful to the skin.

Estimating

During use, avoid inhalation of the dust and contact with the

Supply

skin or eyes. Wear suitable protective clothing - eye protec-

Renderoc SXtra : 25 kg bags tion, gloves and respiratory equipment (particularly in

confined spaces).

Yield

The use of barrier creams to provide additional skin protec-

Renderoc SXtra : 12.5 litres per 25 kg bag

tion is also advised. In case of contact with the skin, rinse

with plenty of clean water, then cleanse thoroughly with soap

Limitations

and water.

- Renderoc SXtra should not be used when the ambient

In case of contact with eyes, rinse immediately with plenty of

temperature is below 50C and falling.

clean water and seek medical advice. If swallowed seek

- Renderoc SXtra should not be part mixed, nor part bags medical attention immediately - do not induce vomiting.

used.

Fire

- Renderoc SXtra should not be exposed to running water

Renderoc SXtra, is non-flammable and presents no fire

either during application or prior to final set.

hazard.

- Water ponding is not recommended for curing.

For further information, please refer to the respective

Product Material Safety Data Sheet for Renderoc SXtra.

Storage

Shelf life

Renderoc SXtra has a shelf life of 12 months; if kept in a dry

environment, in its original, unopened packing. If stored in †

See separate data sheet

conditions of high humidity and/or temperature, the shelf life

may be reduced to as little as 4 months.

Standards compliance

Renderoc SXtra repair mortar system complies with the

following international standards :

ASTM C157-93 : Test for drying shrinkage

DIN 1048 Part 5 : Test for permeability

BS 1881 Pt.121 : Test for water absorption

Important note

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard Conditions for the Supply of

Goods and Service. All Fosroc datasheets are updated on a regular basis. It is the user’s responsibility to obtain the latest version.

Head Office

telephone: (+9714) 2039699 fax: (+9714) 2859649 email: agf@fosroc.com

Al Gurg Fosroc LLC

Regional offices

Post Box 657, Dubai Abu Dhabi, Al Gurg Fosroc telephone: 673 1779 fax: 673 1449 email: abudhabi@fosroc.com

Bahrain, YBA Kanoo telephone: 17738200 fax: 17732828 email: bahrain@fosroc.com

United Arab Emirates Kuwait, Boodai telephone: 4817618 fax: 4832124 email: kuwait@fosroc.com

Oman, Al Amana telephone: 24815080 fax: 24817554 email: oman@fosroc.com

www.fosroc.com

UAE/0252/18/J

Das könnte Ihnen auch gefallen

- Let's DanceDokument6 SeitenLet's DancethierrysteNoch keine Bewertungen

- KWPL07 RankinDokument28 SeitenKWPL07 RankinBoogy GrimNoch keine Bewertungen

- Impact of Government Policy and Regulations in BankingDokument65 SeitenImpact of Government Policy and Regulations in BankingNiraj ThapaNoch keine Bewertungen

- Ygg 07Dokument44 SeitenYgg 07JemGirlNoch keine Bewertungen

- METCON 6 Quickstart Action PlanDokument9 SeitenMETCON 6 Quickstart Action PlanVictorNoch keine Bewertungen

- Rheumatoid ArthritisDokument15 SeitenRheumatoid ArthritisPJHG100% (2)

- Ad3na0ab (COMBI NACCO-ing)Dokument30 SeitenAd3na0ab (COMBI NACCO-ing)Kaique MelloNoch keine Bewertungen

- TDS Conbextra GP3 IndiaDokument4 SeitenTDS Conbextra GP3 IndiaashishroshanNoch keine Bewertungen

- Success Criteria For Change InitiativesDokument6 SeitenSuccess Criteria For Change Initiativesgimmeanearful100% (1)

- Asphalt Defect, Causes and RemediesDokument5 SeitenAsphalt Defect, Causes and RemediesMansoor AliNoch keine Bewertungen

- Modbus PDFDokument70 SeitenModbus PDFAbhishek ChatterjeeNoch keine Bewertungen

- Soal Latihan Bahasa Inggris Asking and Giving OpinionDokument2 SeitenSoal Latihan Bahasa Inggris Asking and Giving OpinionAndy Luth100% (3)

- Fosroc Renderoc Sxtra: Constructive SolutionsDokument2 SeitenFosroc Renderoc Sxtra: Constructive SolutionsVincent JavateNoch keine Bewertungen

- Renderoc TGXTRADokument2 SeitenRenderoc TGXTRAMansoor AliNoch keine Bewertungen

- Renderoc HSXtraDokument2 SeitenRenderoc HSXtraMansoor AliNoch keine Bewertungen

- Renderoc TgxtraDokument2 SeitenRenderoc TgxtratalatzahoorNoch keine Bewertungen

- Renderoc LAXtraDokument2 SeitenRenderoc LAXtraMansoor Ali100% (1)

- Renderoc LA Xtra: Shrinkage Controlled, Fluid Micro-Concrete For Structural Repairs of All TypesDokument2 SeitenRenderoc LA Xtra: Shrinkage Controlled, Fluid Micro-Concrete For Structural Repairs of All TypesBassam ElsayedNoch keine Bewertungen

- TDS Renderoc HSXtra IndiaDokument2 SeitenTDS Renderoc HSXtra IndiaZulfikar A. SheriNoch keine Bewertungen

- Fosroc Renderoc Hsxtra: Constructive SolutionsDokument2 SeitenFosroc Renderoc Hsxtra: Constructive Solutionsanon_550534553Noch keine Bewertungen

- Renderoc SPXtraDokument2 SeitenRenderoc SPXtraMansoor AliNoch keine Bewertungen

- Fosroc Renderoc Tgxtra: Constructive SolutionsDokument2 SeitenFosroc Renderoc Tgxtra: Constructive SolutionsVincent JavateNoch keine Bewertungen

- Fosroc Renderoc Spxtra: Constructive SolutionsDokument2 SeitenFosroc Renderoc Spxtra: Constructive SolutionsVincent JavateNoch keine Bewertungen

- Civil Engineering Standard Data - 2Dokument2 SeitenCivil Engineering Standard Data - 2talatzahoorNoch keine Bewertungen

- Fosroc Renderoc Laxtra: Constructive SolutionsDokument2 SeitenFosroc Renderoc Laxtra: Constructive SolutionsVincent JavateNoch keine Bewertungen

- TDS-Renderoc-SPXtra-Saudi-Arabia-Shrinkage Controlled, Cementitious Repair Mortar, Specifically Designed For SprayingDokument2 SeitenTDS-Renderoc-SPXtra-Saudi-Arabia-Shrinkage Controlled, Cementitious Repair Mortar, Specifically Designed For SprayingSHAIK ASIMUDDINNoch keine Bewertungen

- RENDEROC HSXtraDokument2 SeitenRENDEROC HSXtratalatzahoorNoch keine Bewertungen

- Renderoc HS Xtra: Fibre Reinforced, Shrinkage Controlled, Cementitious Repair Mortar SystemDokument2 SeitenRenderoc HS Xtra: Fibre Reinforced, Shrinkage Controlled, Cementitious Repair Mortar SystemSHAIK ASIMUDDIN0% (1)

- Renderoc LAXtra PlusDokument2 SeitenRenderoc LAXtra PlusMansoor AliNoch keine Bewertungen

- RENDEROC SPxtraDokument2 SeitenRENDEROC SPxtraIrshad Ali DurraniNoch keine Bewertungen

- Fosroc Renderoc Laxtra Plus: Constructive SolutionsDokument2 SeitenFosroc Renderoc Laxtra Plus: Constructive SolutionsVincent Javate0% (1)

- TDS Renderoc LAXtra India3Dokument2 SeitenTDS Renderoc LAXtra India3ARCHANA GUPTANoch keine Bewertungen

- TDS Renderoc LAXtra IndiaDokument2 SeitenTDS Renderoc LAXtra IndiaSHAIK ASIMUDDINNoch keine Bewertungen

- RENDEROC HSXtraDokument48 SeitenRENDEROC HSXtraRehan HasanNoch keine Bewertungen

- Expanmortar SP PDFDokument2 SeitenExpanmortar SP PDFIrfan AkhtarNoch keine Bewertungen

- Renderoc HSXtraDokument2 SeitenRenderoc HSXtraPremNoch keine Bewertungen

- TEC-030100.2-MET-DoR-002-Fosroc1B-Renderoc HS (High Strenght) (Shrinkage Compensated, Polymer Modified, FibreDokument2 SeitenTEC-030100.2-MET-DoR-002-Fosroc1B-Renderoc HS (High Strenght) (Shrinkage Compensated, Polymer Modified, FibreEli MatucadNoch keine Bewertungen

- Renderoc TGDokument2 SeitenRenderoc TGMansoor Ali50% (2)

- Emortar FC200Dokument2 SeitenEmortar FC200m.elsanee.cubicNoch keine Bewertungen

- Renderoc RSXtraDokument4 SeitenRenderoc RSXtraMansoor AliNoch keine Bewertungen

- Nito or SL2000: Flow Applied, 2mm Thick Epoxy Resin Based Oor ToppingDokument4 SeitenNito or SL2000: Flow Applied, 2mm Thick Epoxy Resin Based Oor Toppingkartick adhikaryNoch keine Bewertungen

- Fosroc Renderoc TG: Constructive SolutionsDokument2 SeitenFosroc Renderoc TG: Constructive SolutionsVincent JavateNoch keine Bewertungen

- TDS Renderoc TG Saudi ArabiaDokument4 SeitenTDS Renderoc TG Saudi Arabiaumn_mlkNoch keine Bewertungen

- TDS Conbextra 621 Saudi ArabiaDokument4 SeitenTDS Conbextra 621 Saudi ArabiaMichael MazoNoch keine Bewertungen

- TDS Renderoc RGM IndiaDokument4 SeitenTDS Renderoc RGM IndiaKishore Nayak kNoch keine Bewertungen

- Conbextra GP3: High Performance Cementitious GroutDokument4 SeitenConbextra GP3: High Performance Cementitious GroutAarish KhanNoch keine Bewertungen

- Renderoc SP40: Constructive SolutionsDokument2 SeitenRenderoc SP40: Constructive SolutionsChandan MirajkarNoch keine Bewertungen

- RENDEROC-S - Merged SDSDokument11 SeitenRENDEROC-S - Merged SDSKannan Sasidharan PillaiNoch keine Bewertungen

- Fosroc Cemtop 400SD: Constructive SolutionsDokument4 SeitenFosroc Cemtop 400SD: Constructive SolutionsVincent JavateNoch keine Bewertungen

- Renderoc RGDokument3 SeitenRenderoc RGR.ThangarajNoch keine Bewertungen

- Datasheet File Conbextra - HFDokument4 SeitenDatasheet File Conbextra - HFandikaNoch keine Bewertungen

- Renderoc HB40 TDS.2018Dokument5 SeitenRenderoc HB40 TDS.2018Joan FosterNoch keine Bewertungen

- Conbextra EP75: High Strength, Epoxy Resin GroutDokument4 SeitenConbextra EP75: High Strength, Epoxy Resin GroutVikas Singh ChandelNoch keine Bewertungen

- Conbextra EP75: High Strength, Epoxy Resin GroutDokument4 SeitenConbextra EP75: High Strength, Epoxy Resin GroutHamkarNoch keine Bewertungen

- Conbextra ATDokument4 SeitenConbextra ATRyan Joseph QuebrarNoch keine Bewertungen

- Fosroc Renderoc RsxtraDokument4 SeitenFosroc Renderoc RsxtraVincent JavateNoch keine Bewertungen

- TDS Renderoc RG SPL IndiaDokument3 SeitenTDS Renderoc RG SPL IndiaKumar SundaramNoch keine Bewertungen

- TDS Renderoc RG India PDFDokument3 SeitenTDS Renderoc RG India PDFrajiv_quantumNoch keine Bewertungen

- TDS Renderoc RG IndiaDokument3 SeitenTDS Renderoc RG IndiaBijaya RaulaNoch keine Bewertungen

- Conbextra EP75 PlusDokument4 SeitenConbextra EP75 Plusm.elsanee.cubicNoch keine Bewertungen

- Renderoc HS PDFDokument2 SeitenRenderoc HS PDFMuhammed KunnappillyNoch keine Bewertungen

- TDS Renderoc RG SPL IndiaDokument3 SeitenTDS Renderoc RG SPL IndialavekushNoch keine Bewertungen

- Conbextra HFDokument4 SeitenConbextra HFabhay_joshi2002Noch keine Bewertungen

- TDS Renderoc UW India3Dokument3 SeitenTDS Renderoc UW India3ARCHANA GUPTANoch keine Bewertungen

- Conbextra HF - Grout For Tank Gaps PDFDokument4 SeitenConbextra HF - Grout For Tank Gaps PDFEngr.Mohammed KhaledNoch keine Bewertungen

- Conbextra GP PremixDokument3 SeitenConbextra GP Premixtabah sentosaNoch keine Bewertungen

- Renderoc S: Constructive SolutionsDokument2 SeitenRenderoc S: Constructive SolutionsMuhammad.FaisalNoch keine Bewertungen

- DR - Fixit Micro ConcreteDokument3 SeitenDR - Fixit Micro ConcreteKiran KumarNoch keine Bewertungen

- Fosroc Nitoflor FC550: Constructive SolutionsDokument4 SeitenFosroc Nitoflor FC550: Constructive SolutionsVincent JavateNoch keine Bewertungen

- TDS Renderoc RG IndiaDokument3 SeitenTDS Renderoc RG IndiaPrad RNoch keine Bewertungen

- Flexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsVon EverandFlexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsSean M. GarnerNoch keine Bewertungen

- 07Dokument8 Seiten07Mansoor Ali0% (1)

- Interview Preparation UAEDokument136 SeitenInterview Preparation UAEMansoor AliNoch keine Bewertungen

- 02 (2) Dubai-Traffic Control Device ManualDokument7 Seiten02 (2) Dubai-Traffic Control Device ManualMansoor AliNoch keine Bewertungen

- 01 (2) Dubai-Traffic Control Device ManualDokument3 Seiten01 (2) Dubai-Traffic Control Device ManualMansoor AliNoch keine Bewertungen

- Dubai-Traffic Control Device ManualDokument3 SeitenDubai-Traffic Control Device ManualMansoor Ali50% (2)

- Bridge SpecificationDokument56 SeitenBridge SpecificationMansoor AliNoch keine Bewertungen

- Renderoc PlugDokument2 SeitenRenderoc PlugMansoor AliNoch keine Bewertungen

- Renderoc LADokument2 SeitenRenderoc LAMansoor AliNoch keine Bewertungen

- Renderoc SPXtraDokument2 SeitenRenderoc SPXtraMansoor AliNoch keine Bewertungen

- Renderoc SDokument2 SeitenRenderoc SMansoor AliNoch keine Bewertungen

- Renderoc RSXtraDokument4 SeitenRenderoc RSXtraMansoor AliNoch keine Bewertungen

- Renderoc TGDokument2 SeitenRenderoc TGMansoor Ali50% (2)

- Renderoc LAXtra PlusDokument2 SeitenRenderoc LAXtra PlusMansoor AliNoch keine Bewertungen

- Renderoc PuttyDokument2 SeitenRenderoc PuttyMansoor AliNoch keine Bewertungen

- Renderoc La80Dokument2 SeitenRenderoc La80Mansoor Ali0% (1)

- Renderoc BF2Dokument2 SeitenRenderoc BF2MOHAMED.NOUSAR100% (1)

- Renderoc FCXtraDokument4 SeitenRenderoc FCXtraMansoor AliNoch keine Bewertungen

- Renderoc HSDokument2 SeitenRenderoc HSMansoor AliNoch keine Bewertungen

- Renderoc LA55Dokument2 SeitenRenderoc LA55Mansoor AliNoch keine Bewertungen

- Nitowrap FRCDokument2 SeitenNitowrap FRCMansoor AliNoch keine Bewertungen

- Nitoplate CP - Formerly Known Nitoplate CP StripsDokument3 SeitenNitoplate CP - Formerly Known Nitoplate CP StripsMansoor AliNoch keine Bewertungen

- Renderoc FCDokument4 SeitenRenderoc FCMansoor AliNoch keine Bewertungen

- Renderoc BFDokument2 SeitenRenderoc BFMansoor AliNoch keine Bewertungen

- Nitomortar TSDokument2 SeitenNitomortar TSMansoor AliNoch keine Bewertungen

- Nitomortar SDokument4 SeitenNitomortar SMansoor AliNoch keine Bewertungen

- SUMMATIVE Entrep Q1Dokument2 SeitenSUMMATIVE Entrep Q1ocsapwaketsNoch keine Bewertungen

- Lesson 2 - Pure Substances and MixturesDokument41 SeitenLesson 2 - Pure Substances and Mixturescecil tayagNoch keine Bewertungen

- Java Programming - Module2021Dokument10 SeitenJava Programming - Module2021steven hernandezNoch keine Bewertungen

- Canada's Top 50 FinTech CompaniesDokument16 SeitenCanada's Top 50 FinTech CompaniesTina SmithNoch keine Bewertungen

- Wavelets and Signal ProcessingDokument193 SeitenWavelets and Signal ProcessingAlbeno Saleh AhmadNoch keine Bewertungen

- Moses MendelssohnDokument2 SeitenMoses Mendelssohncoolio_94Noch keine Bewertungen

- Nano Technology Oil RefiningDokument19 SeitenNano Technology Oil RefiningNikunj Agrawal100% (1)

- Risk Management NotesDokument27 SeitenRisk Management NoteskomalNoch keine Bewertungen

- Frederick Douglass EssayDokument4 SeitenFrederick Douglass Essayapi-452857710Noch keine Bewertungen

- Chitosan 55910823Dokument4 SeitenChitosan 55910823sharemwNoch keine Bewertungen

- Technipfmc Corporate Brochure en 2018Dokument7 SeitenTechnipfmc Corporate Brochure en 2018Sivaji RajinikanthNoch keine Bewertungen

- Splitting of Moon Into Two Pieces by Prophet Muhammad (Pbuh)Dokument9 SeitenSplitting of Moon Into Two Pieces by Prophet Muhammad (Pbuh)Esha AimenNoch keine Bewertungen

- Bank TaglineDokument2 SeitenBank TaglineSathish BabuNoch keine Bewertungen

- ! Warning: Servomotor TestDokument1 Seite! Warning: Servomotor Testjoku jokunenNoch keine Bewertungen

- Metcert Information: National Laboratory AssociationDokument8 SeitenMetcert Information: National Laboratory AssociationM Jawad AliNoch keine Bewertungen

- Erinnerungsmotive in Wagner's Der Ring Des NibelungenDokument14 SeitenErinnerungsmotive in Wagner's Der Ring Des NibelungenLaur MatysNoch keine Bewertungen

- HFY-GEN-CP-SPC-0001 - D Specification For Piping and Pipeline Coating Code-ADokument37 SeitenHFY-GEN-CP-SPC-0001 - D Specification For Piping and Pipeline Coating Code-ATahir FadhilNoch keine Bewertungen

- Narrations - Direct and Indirect SpeehesDokument6 SeitenNarrations - Direct and Indirect Speehesskitteringkite100% (1)

- DerivativeDokument29 SeitenDerivativeMohit AggarwalNoch keine Bewertungen

- Prepositioncombinations PDFDokument14 SeitenPrepositioncombinations PDFMichalisBenedictusNoch keine Bewertungen