Beruflich Dokumente

Kultur Dokumente

300 5ST Sheet 10 - 10 Rev 0 PDF

Hochgeladen von

Anwar SadatOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

300 5ST Sheet 10 - 10 Rev 0 PDF

Hochgeladen von

Anwar SadatCopyright:

Verfügbare Formate

10 / 10 0

48 48

NOTES :

1 - USE DOUBLE BLOCK FOR ANY CLASS 900 LINES OR HIGHER AND FOR H2

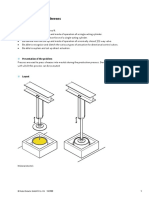

47 TYPE L TYPE M TYPE N 47

OR H2S SERVICES.

SAMPLING DEVICE FOR VERY HAZARDOUS MATERIAL HIGH PRESSURE LIQUID / VAPOR SAMPLE OILY CATALYST SAMPLING 2 - THE COOLING BOX SHALL BE INTERNALLY COVERED WITH "EPOXY"

THE COIL SHALL BE TUBING SPECIFICATION OR SS.

5ST

46 46

3 - ALL SAMPLING BOMBS SHOWN ON THIS PID SHOULD BE EQUIPED WITH

BLOCK VALVES ON EACH SIDE.

45 45

0

44 44

43 43

04653

42 42

04653_0_5ST_10.pid

BLOWDOWN

41 41

2"

1-1/2"x2"

HORIZONTAL CONNECTION 3/4"

MOUNTING FRAME OR PLATE FOR EASY CARRYIN

40 40

2500#SS

FRAME TO HAVE A CARRYING HANDLE

STRAMMAM OR EQUAL RAM-TYPE

39

1 39

2500#SS SAMPLING VALVE 300 RF

PROCESS LINE

38

HIGHER PRESSURE CONNECTION 2" SC 38

1-1/2"

FLOW

CS

37 DIRECTION SAMPLING 37

SUPPLY LINE

PIPING

2 3/4"x1/2" 3/4"x1/2" BASKET WITH 0.4 mm MAXIMUM

2500# SS

36 NOTE 1 36

OPEN SPACES

3/4"

1/2"

POSITION FOR SAMPLE PG

100 DIAM 150 LONG JOHNSON SCREEN

INST.

35 35

COOLER WHERE REQUIRED I FLEXIBLE ARMOURED TUBING

NOTE 2

34 34

"SNAP-ON" COUPLINGS 6 COOLING WATER RETURN OIL COLLECTOR

33 O 4"x700 33

(ONE ON SAMPLE DEVICE,

ONE ON FLEXIBLE TUBING)

32 COOLING WATER SUPPLY 32

SELECTOR LG

3/4"

VALVE (S.V.) 1

2 4

31 LOW PRESSURE STEAM WASHING OIL 31

3 TG

3/4"

30 30

29

A B 29

SAMPLE BOMB EVACUATION BOMB

3/4"

SIZE: SIZE:

28 300 OR 500 CC 300 OR 500 CC 28

NOTE 3 NOTE 3

FLUSHING

27 OIL SUPPLY 27

26 SELECTOR 26

VALVE (S.V.)

CS 2500# SS

25 3 25

2 4 3 4 5

1

"SNAP-ON" COUPLINGS

2500# SS

24

(ONE ON SAMPLE DEVICE, 24

ONE ON FLEXIBLE TUBING)

QUICK CONNECT

23 23

FITTING FOR SAMPLING

TYPE P

22 22

CATALYST SAMPLING

2500# SS

FLEXIBLE ARMOURED TUBING

SAMPLE RETURN LINE

This document is the property of Axens and shall not be reproduced or divulged without Axens consent

INST.

21 21

20 20

PIPING

PROCESS LINE SLOPS OILY WATER SEWER

19

LOWER PRESSURE CONNECTION SAMPLING PROCEDURE 19

1 - Check that all valves in the sampling system are closed.

18 18

2 - Open the cooling water line to the sample cooler wide open.

17 OPERATING SEQUENCE 17

3 - Possibly adjust the temperature using steam if too cold.

- NEEDLE VALVES CLOSED.

16 16

- CONNECT "SNAP-ON" COUPLINGS. 4 - Check that the pressure indicator shows no pressure. If a pressure is reported, this is an indication of leaking upstream valves.

- S.V.S. POSITION 1: OFF. Open valve 2 from the top of the sample pot to blowdown to vent off any pressure. Then close valve 2.

15 - ANGLE VALVES OPEN. 15

- S.V.S. POSITION 2: 5 - With caution, slowly open valve 1 from the reactor effluent line to the sample pot. Check that the pressure indicator is reading

14 FLOW THROUGH BOMB "A" TO RETURN LINE FOR SAMPLE. close to the reactor pressure. Liquid in the sample line will drop into the sample pot. STRAMMAM OR EQUAL RAM-TYPE 14

- S.V.S. POSITION 3: SAMPLING VALVE 300 RF

SAMPLING COMPLETE SAMPLE IN BOMB "A". 6 - Close valve 1 to block in the sample pot. Then crack open valve 3 from the bottom of the pot to allow the liquid to pressure out to

13

blowdown. Keep the valve open until the pot has depressured to about 7 bar. Then close valve 3. 2" SC 13

- ANGLE VALVES CLOSED.

- S.V.S. POSITION 4:

12 EVACUATION OF TUBING UP TO THE ANGLE VALVES BACK TO BOMB "B". 7 - With caution, slowly open valve 1. Crack open valve 2 from the top of the pot to vent to blowdown. Fresh sample will flow through 12

- DISCONNECT "SNAP-ON" COUPLINGS. the cooler into the sample pot. The sample should be drawn slowly enough that the sample pot does not get hot (over about

11

50 °C). The object is to draw 1-2 liters of liquid into the sample pot. This typically takes about 30 seconds. Caution : 11

This step is critical since the high pressure system is open directly to blowdown. The valves to blowdown must be operated

100 DIAM 150 LONG BASKET

cautiously and never left without shutting them. 0 01/06/11 PROCESS BOOK ISSUE LWT DPH

10 10

DRAWN CHECKED

ISS. DATE ISSUES DESCRIPTIONS

BY BY

8 - Block off the sample by closing valve 1 from the effluent line. Permit the sample pot to depressure to blowdown through valve 2

CONTRACTOR :

9 from the top of the pot until the pressure is about 3 bar. Then close valve 2. 9

9 - Open valve 5. Then cautiously open valve 4 to the sample outlet point and withdraw enough liquid in a bottle to clear any old

8 8 This document is the property of Axens

sample or flushing oil from the line. Discard this material. IFP Group Technologies

and shall not be reproduced or divulged

Process Licensing without Axens consent

P.T. ISTANA KARANG LAUT

7 10- With a new bottle, withdraw the sample necessary from the lab. Caution : 7 CLIENT PROJECT NUMBER CLIENT DWG NUMBER

C-209

01/06/2011 16:03:28 Deliverable Print

If all liquid is withdrawn, close the sample line immediately.

6 6

PT ISTANA KARANG LAUT

11- Close valves 4 and 5. Then crack open valve 3 at the bottom of the pot to pressure the rest of the sample to blowdown. Then

CONDENSATE FRACTIONATION PLANT PROJECT

close all valves.

5 5 MONGLA, BANGLADESH

12- Shut off the cooling water and steam, whenever used.

4 4 STANDARD

13- Flush the sample system with flushing oil. This is done to remove heavy material that could cool and plug the lines in the system.

Axens Standards Drawings And Specifications

3

Open valve 6 to bring flushing oil into the sample pot. Flush any heavy oil from the sample outlet line by opening valves 4 and 5. 3

Then close valve 6 and open valve 3 to pressure the flushing oil to blowdown.

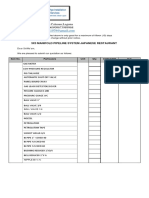

SAMPLE CONNECTIONS 3/3

2 2

14- The sample collected will contain H2S and ammonia.

The ammonia must be removed before the sample is analysed for total organic nitrogen.

JOB NUMBER UNIT TYPE SHEET ISS.

1 The sample should be water washed twice in the laboratory before analysing. 1

04653 0 5ST 10 / 10 0

BE SPPID_GEN_5PD_10.pid_Rev_0_10/02/11 04653_0_5ST_10.pid

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- 8th Edition Cengel-Thermodynamics-An-Engineering-Approach PDFDokument177 Seiten8th Edition Cengel-Thermodynamics-An-Engineering-Approach PDFyash0% (2)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Kimia Dasar Bab 5 GasDokument42 SeitenKimia Dasar Bab 5 GasRiko KedikNoch keine Bewertungen

- What Refiners Need To Know About Diesel Cetane - RefinerLinkDokument9 SeitenWhat Refiners Need To Know About Diesel Cetane - RefinerLinkAnwar SadatNoch keine Bewertungen

- W Series Multi-Round: Bag Filter HousingsDokument16 SeitenW Series Multi-Round: Bag Filter HousingsAnwar SadatNoch keine Bewertungen

- HF Series: Cartridge Filter HousingsDokument2 SeitenHF Series: Cartridge Filter HousingsAnwar SadatNoch keine Bewertungen

- HydrocarbonFiltration ProductsDokument24 SeitenHydrocarbonFiltration Productsio1_roNoch keine Bewertungen

- Why Must We Maintain Distillation of Diesel 95Dokument1 SeiteWhy Must We Maintain Distillation of Diesel 95Anwar SadatNoch keine Bewertungen

- PR 900 PDFDokument26 SeitenPR 900 PDFsanjay ukalkarNoch keine Bewertungen

- 209-P-DS-215 Rev C Process Data Sheet For Stripper Bottom Pumps P-203ABDokument5 Seiten209-P-DS-215 Rev C Process Data Sheet For Stripper Bottom Pumps P-203ABAnwar SadatNoch keine Bewertungen

- Name Plate Drawing 1200-E-4006: Document TitleDokument2 SeitenName Plate Drawing 1200-E-4006: Document TitleAnwar SadatNoch keine Bewertungen

- The Cetane Index Is A Figure Which Denotes The Quality of A Diesel FuelDokument4 SeitenThe Cetane Index Is A Figure Which Denotes The Quality of A Diesel FuelAnwar SadatNoch keine Bewertungen

- Tube Bundle Detail Drawing 1200-E-4006: Document TitleDokument2 SeitenTube Bundle Detail Drawing 1200-E-4006: Document TitleAnwar SadatNoch keine Bewertungen

- Part Detail Drawing 1200-E-4006: Document TitleDokument4 SeitenPart Detail Drawing 1200-E-4006: Document TitleAnwar SadatNoch keine Bewertungen

- Filters: CCR Platforming Process UnitDokument3 SeitenFilters: CCR Platforming Process UnitAnwar SadatNoch keine Bewertungen

- Gasket SpecificationDokument5 SeitenGasket SpecificationAnwar SadatNoch keine Bewertungen

- General Arrangement Drawing 1200-E-4006: Document TitleDokument2 SeitenGeneral Arrangement Drawing 1200-E-4006: Document TitleAnwar SadatNoch keine Bewertungen

- Md. Hasmat Ali S.H. Plaza, 9091 Nazimuddin Road, 4 Floor F-2 Dhaka: 1100 Career AspirationDokument3 SeitenMd. Hasmat Ali S.H. Plaza, 9091 Nazimuddin Road, 4 Floor F-2 Dhaka: 1100 Career AspirationAnwar SadatNoch keine Bewertungen

- Piping Work Contractor Bill-1Dokument21 SeitenPiping Work Contractor Bill-1Anwar SadatNoch keine Bewertungen

- Materials RequisitionDokument3 SeitenMaterials RequisitionAnwar SadatNoch keine Bewertungen

- Prime DDokument2 SeitenPrime DAnwar SadatNoch keine Bewertungen

- 1Dokument1 Seite1Anwar SadatNoch keine Bewertungen

- Forwarded MessageDokument2 SeitenForwarded Messageanwar sadatNoch keine Bewertungen

- Work PlanningDokument7 SeitenWork Planninganwar sadatNoch keine Bewertungen

- Outline of Diesel Hydrotreating Unit (DHT Unit)Dokument4 SeitenOutline of Diesel Hydrotreating Unit (DHT Unit)Anwar SadatNoch keine Bewertungen

- Outline of Diesel Hydrotreating Unit (DHT Unit)Dokument4 SeitenOutline of Diesel Hydrotreating Unit (DHT Unit)Anwar SadatNoch keine Bewertungen

- UzairsahmedDokument1 SeiteUzairsahmedAnwar SadatNoch keine Bewertungen

- Air CoolerDokument5 SeitenAir CoolerAnwar SadatNoch keine Bewertungen

- PCF Series Pleated CartridgesDokument1 SeitePCF Series Pleated CartridgesAnwar SadatNoch keine Bewertungen

- Program - 15 Round 30inchs Stainless Steel Filter HousingDokument6 SeitenProgram - 15 Round 30inchs Stainless Steel Filter HousingAnwar SadatNoch keine Bewertungen

- Name Deposit Meals. Meals Rate Total Cost Balance (+)Dokument3 SeitenName Deposit Meals. Meals Rate Total Cost Balance (+)Anwar SadatNoch keine Bewertungen

- Avanti Process Pte LTDDokument3 SeitenAvanti Process Pte LTDAnwar SadatNoch keine Bewertungen

- What Is Magnetic FiltrationDokument2 SeitenWhat Is Magnetic FiltrationAnwar SadatNoch keine Bewertungen

- Data Sheet of High Pressure PumpDokument2 SeitenData Sheet of High Pressure Pumpsajeesh5113699Noch keine Bewertungen

- Boilers: Steam PropertiesDokument12 SeitenBoilers: Steam PropertiesJAY PARIKHNoch keine Bewertungen

- Https - WWW - Johncrane.com - Media - J - Johncrane - Com - Files - Products - Specification Sheets - S-28SCDokument4 SeitenHttps - WWW - Johncrane.com - Media - J - Johncrane - Com - Files - Products - Specification Sheets - S-28SCsalamrefighNoch keine Bewertungen

- The Curtis Turbine & The Parson Turbine: Options For Economically Viable SpeedsDokument23 SeitenThe Curtis Turbine & The Parson Turbine: Options For Economically Viable SpeedsVivek Kumar GuptaNoch keine Bewertungen

- Exercise 1: Pressing Cheeses: Cheese ProductionDokument8 SeitenExercise 1: Pressing Cheeses: Cheese ProductionAhmed HusseinNoch keine Bewertungen

- DGA Comparison Between Ester and Mineral Oils: C. Perrier, M. Marugan, M. Saravolac A. BeroualDokument4 SeitenDGA Comparison Between Ester and Mineral Oils: C. Perrier, M. Marugan, M. Saravolac A. BeroualJhon Fredy Vallejo GiraldoNoch keine Bewertungen

- Air Vacuum PumpDokument2 SeitenAir Vacuum Pumplkumar4454Noch keine Bewertungen

- Quotation - Japanese RestaurantDokument2 SeitenQuotation - Japanese RestaurantMark Angelo “Gelo” RoxasNoch keine Bewertungen

- Shielding Gases Selection Chart 2013Dokument1 SeiteShielding Gases Selection Chart 2013Lachie TaylorNoch keine Bewertungen

- Downhole Hydraulic IDokument67 SeitenDownhole Hydraulic ImouradbzNoch keine Bewertungen

- 045 Mikropor Deoxo Nitrogen Brosur 070720Dokument8 Seiten045 Mikropor Deoxo Nitrogen Brosur 070720AyahKenzieNoch keine Bewertungen

- Turbine Meter Data SheetDokument24 SeitenTurbine Meter Data SheetehsanelahimirzaNoch keine Bewertungen

- 32 Samss 013 PDFDokument17 Seiten32 Samss 013 PDFragulNoch keine Bewertungen

- Pump DataDokument534 SeitenPump Datahiteshguptaiocl100% (4)

- Pneumatic Tools and EquipmentsDokument15 SeitenPneumatic Tools and EquipmentsJoshua HicksNoch keine Bewertungen

- B08401000 Discharge Regulator - 027630016aDokument1 SeiteB08401000 Discharge Regulator - 027630016aLeandro MagriNoch keine Bewertungen

- 623-09 - Compressor Airflow ControlDokument36 Seiten623-09 - Compressor Airflow ControlA ENGENHARIA DAS COISASNoch keine Bewertungen

- Gas LawsDokument2 SeitenGas LawsRaleen GenerNoch keine Bewertungen

- Norgren LubricatorsDokument1 SeiteNorgren LubricatorsSetyohdWNoch keine Bewertungen

- C.P Training Module Levl.2 HydraulicDokument56 SeitenC.P Training Module Levl.2 HydraulicEslam Mansour100% (1)

- Operating Instructions Linear Flow Control LFC: DK S N P GR D GB F NL I E TR CZ PL RUS HDokument4 SeitenOperating Instructions Linear Flow Control LFC: DK S N P GR D GB F NL I E TR CZ PL RUS HmohamedwalyNoch keine Bewertungen

- SkinDokument8 SeitenSkinYamal E Askoul TNoch keine Bewertungen

- Pressure Drop Evaluation Along PipelinesDokument23 SeitenPressure Drop Evaluation Along PipelinespeweajeNoch keine Bewertungen

- Pulsation Design ReqsDokument2 SeitenPulsation Design ReqsdigecaNoch keine Bewertungen

- Requestn About Power Plant Project (Included Technical & Commercial For Informatio Part)Dokument6 SeitenRequestn About Power Plant Project (Included Technical & Commercial For Informatio Part)Chakravarthi NagaNoch keine Bewertungen

- (Notes On Numerical Fluid Mechanics and Multidisciplinary Design 127) Rudibert King (Eds.) - Active Flow and Combustion Control 2014-Springer International Publishing (2015) PDFDokument405 Seiten(Notes On Numerical Fluid Mechanics and Multidisciplinary Design 127) Rudibert King (Eds.) - Active Flow and Combustion Control 2014-Springer International Publishing (2015) PDFerney03Noch keine Bewertungen

- Bidirectional Flow Control Valve: Hydraulic FeaturesDokument1 SeiteBidirectional Flow Control Valve: Hydraulic Featuresraj jangidNoch keine Bewertungen

- PRESSURISEDDokument17 SeitenPRESSURISEDrahigi8656Noch keine Bewertungen