Beruflich Dokumente

Kultur Dokumente

Value Stream Management For Lean Office-A Case Stu

Hochgeladen von

alejandra toscanoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Value Stream Management For Lean Office-A Case Stu

Hochgeladen von

alejandra toscanoCopyright:

Verfügbare Formate

American Journal of Industrial and Business Management, 2012, 2, 17-29 17

doi:10.4236/ajibm.2012.22004 Published Online April 2012 (http://www.SciRP.org/journal/ajibm)

Value Stream Management for Lean Office—A Case Study

Joseph C. Chen1, Ronald A. Cox2

1

Department of Industrial and Manufacturing Engineering and Technology, Bradley University, Peoria, USA; 2College of Engineering,

Iowa State University, Ames, USA.

Email: jchen@bradley.edu, rcox@isstate.edu

Received November 22nd, 2011; revised January 6th, 2012; accepted January 16th, 2012

ABSTRACT

This paper presents a look at the concept of Lean Manufacturing as applied to the office environment. Lean Manufac-

turing, which is often referred to as Lean, is a philosophy of manufacturing process improvement through the elimina-

tion of waste. As Lean developed since its origins in the automobile industry, it has been extended to apply to various

enterprises and organizations, and has achieved a renowned reputation for reducing waste while adding value to prod-

ucts and services. Lean has also been applied in the office environment; however, participants in the implementation of

Lean Office face more difficulties because of higher variation in office processes, less foundation information for par-

ticipants, and lack of references in literature. This paper addresses these issues by proposing, a systematic procedure for

conducting Lean Office techniques, along with a case study at a local company. The case study demonstrates a step by

step procedure to help more participants in Lean Office understand its benefits and how to get started.

Keywords: Lean Manufacturing; Lean Office; Value Stream Mapping; Kaizen; Kanban

1. Introduction streamline a process. By classifying the steps of a proc-

esses into two categories, value added and non-value

Although Lean was initially introduced by the automo-

added, it is possible to initiate actions to improve the

bile industry, its principles have more recently spread

former and eliminate the latter by reducing wastes in

into other industries. There are a variety of companies

that have experienced the advantages of applying Lean in both of them. In his book, Toyota Production System,

their manufacturing area. For instance, Lean was applied Taiichi Ohno lays out the main foundations of Lean

by Boeing to eliminate waste and make its products more Manufacturing, and describes seven wastes existing in

cost-competitive. After implementing Lean, Boeing suc- manufacturing [4]. These wastes are transportation, in-

cessfully cuts its defect costs by 75 percent, which re- ventory, waiting, defects, over-processing, excessive mo-

sulted in a cost savings of about $655,000 per aircraft [1]. tion, and over-production. To identify areas in a system

Moreover, after applying Lean in its manufacturing sys- where improvement is needed, the seven wastes needs to

tem the inventory level of DELL dropped by 50% and be identified and then measured. While most of these

the time required to produce a PC was reduced, and as a wastes are visible and easily quantifiable in a manufac-

result, DELL can guarantee that customers will receive turing environment, they are more difficult to be distin-

their products one week after they order them [2]. These guished and measured in an office environment.

enterprises are major producers of tangible products and Transportation waste in manufacturing, for example,

the results of their improvements can be measured by can be measured by estimating the time consumed while

comparing the product cost before and after implementa- moving work in process (WIP) from one workstation to

tion. In order to obtain such benefits in the office settings next workstation. On the other hand, in an office envi-

of the manufacturing industry, Lean princeples are now ronment, most of the tasks are translated via email or fax,

being applied in office-based functional areas such as causing more variation in time consumption, and correct

research and development, administration, and customer arrive and departure times are difficult to determine. In-

service. ventory waste in manufacturing can be classified by cal-

“Lean is a systematic approach for identifying and culating the WIP level in the workstation or finished

eliminating waste through continuous improvement by goods in the warehouse, but it is hard to identify the

‘flowing’ the product at the pull of the customer in pur- amount of pending items in each office job. Moreover,

suit of perfection” [3]. One of the key phases in Lean is time waste due to waiting can be evaluated by accumu-

the identification of non-value added steps in order to lating the total idle time of machines or operators; whereas,

Copyright © 2012 SciRes. AJIBM

18 Value Stream Management for Lean Office—A Case Study

the idle time in the office is difficult to judge because of this event or targeted department which is considered

some tasks require confirmation by a supervisor or cus- as a bottleneck in the company. The basic rule for se-

tomer. This makes it difficult to assess the problem due lecting members is to find major processes that are re-

to lack of definition of office workers’ idle time. Fur- lated to this Lean event and separate these into individual

thermore, the defect rate can be measured by calculating process. Then, determine the owner of each process re-

the amount of finished product and WIP that fail inspec- lated to this event for providing necessary information;

tion divided by the amount of parts that pass inspection, moreover, fundamental training of team members is nec-

but it is hard to establish a measurement in an office en- essary to create a common language among the team

vironment to distinguish whether the task is failed or not members and to help sustain the Lean event in the com-

because there are many variables in these tasks. pany.

Not only are office wastes difficult to define, lack of Several professional organizations and companies ex-

references about conducting Lean in an office environ- ist today that provide training for new-Lean-participant

ment leave participants struggling in how to get started. companies. They normally provide the introduction of

Although some Lean Office projects have been docu- basic concepts about Lean Manufacturing to help team

mented [5-7], a systematic procedure for creating a Lean members understand the benefits. According to a par-

Office has not been universal. It is also the authors’ be- ticipant workbook of a Lean training organization [8],

lief that more documented successful case studies of im- Lean is a systematic approach to identify and eliminate

plementation of Lean Office, including a proposed sys- waste through continuous improvement, focusing on

tematic approach, would help many companies with such flowing the product at the pull of the customer. Lean

a project. Implementing lean office helps reducing their philosophies are also described as a building with com-

idle time and makes each department organized. The ponent blocks, which is shown in Figure 1. As seen in

purpose of this paper is to demonstrate a successful Lean this figure, there are several Lean principles that can be

project in a local small manufacturer for two major pur- used to eliminate waste from the system. Descriptions of

poses. First, this study will provide a systematic proce- these Lean principles are listed in Table 1.

dure which will help managers or engineers that are at- Once the basic Lean concepts have been introduced to

tempting to implement Lean in their office. Second, a team members, they will have a better sense about how

case study will be presented by following the proposed to use these principles to eliminate waste and add value

systematic procedures at this company and demonstrate to the product. In the Figure 1, it can be seen the impor-

that Lean can be implemented in an office environment tant step to lead the team into the rest of the Lean build-

of the manufacturing industry. ing blocks is Value Stream Mapping (VSM). VSM is one

of the most powerful Lean tools available [9]. It com-

bines material production flows with information flows

2. Proposed Systematic Procedures for

of company in a map; moreover, it forms the basis of an

Creating Lean Office implementation plan for company to start its Lean jour-

At this time, Lean principles have been applied in several ney [10]. By mapping the whole processes, team mem-

enterprises as a means of providing products and services bers are able to visualize more than the single-process

that creates value for customers with a minimum amount level and realize the connection between information flow

of waste and a maximum degree of quality. Still, it can and material flow. The four steps that follow summarize

be more difficult to bring the concept of Lean into the the process for creating an office value steam map.

office environment than a manufacturing area because of

a lack of understanding, a lack of cooperation between

departments, and a lack of directive from the top [6]. The

proposed procedures for providing a systematic approach

for implementing Lean in an office environment consist

of the following six steps.

Step 1. Form a Lean event team and provide Lean

training to team members

Before conducting a Lean event, some preparations

should be made, and a Lean event team must be formed.

Show the office administrators some typical cases of how

lean is successfully implemented in a manufacturing en-

vironment. Describe the blueprint after implementing

lean office to convince the office managers it is cost-

effective. Selecting team members depends on the goal Figure 1. Lean building blocks.

Copyright © 2012 SciRes. AJIBM

Value Stream Management for Lean Office—A Case Study 19

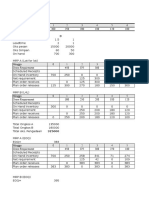

Table 1. Basic Lean principles and descriptions.

Lean principles Description

Standardized Work: Reducing the amount of variation in both the process and output with work instructions.

The product or information which will be passed to the next station should be confirmed as acceptable quality. Templates

Quality at Source:

and samples can be used as tools to efficiently perform the inspection.

An organized work place helps workers perform their task efficiently and provides a specific location for everything

required. These 5S’ are described in the following:

1) Sort: What is not needed should be sorted out from the working place.

5S or Workplace

2) Set-in-order: Make what must be kept, visible and easily distinguishable.

Organization:

3) Shine: The work place and equipment should be cleaned periodically.

4) Standardize: Make a standard for above three S’s”.

5) Sustain: These rules should be followed by every worker in the station.

Point of Use Storage Raw material is stored at the work station where it is used. Visual tools such as cards and record boards can be used as a

(POUS): tool to simplify inventory tracking, storage, and handling.

Simple signals such as cards, lights, color-coded tools, and lines delineating work are used as tools to provide

Visual Control:

immediate information in the working place.

Lean philosophy values teamwork; therefore, any improvement suggestion in the company should be discussed among

Team:

team members and provided to supervisory level manager.

By reducing the batch size, the lead time of completing a service or production will be reduced and quickly satisfying the

Batch Size Reduction:

customer demand also help company to have a better cash flow.

A pull system is a flexible and simple method of controlling and balancing the flow of resources. Production and service

Pull System:

is based on customer demand rather than forecasting.

Creating a cellular design rather than in a traditional straight line that will provide a better utilization of people and

Work Cells:

communication.

Step 2. Selecting a product/service family for con- team members with as much detail as possible. The third

ducting VSM tip is that members should start at the customer end and

“Your customers care about their specific products, work upstream because services or products should be

not all of your products” [10]. Therefore, it is important driven by customer demand. Therefore, the process that

to identify and focus on a single family of products from is linked most directly to the customer should be consid-

the customer end of the value stream. It is only necessary ered as the beginning and the pace for other processes

to map things that are relevant to this product or service, further upstream. The fourth tip is following the icon

as selected by the team leader, because drawing every- scheme which is shown in Figure 2. There are estab-

thing that happens in the plant on one map would make lished standard icons for value stream maps so that

the map too complicated [10]. Products or services which members can create a VSM which is able to be under-

involve similar customers and similar supplier inputs stood by other people. Following these tips, members can

should be put together as a target product family and bring a stopwatch, paper and pencil and then start to

drawn on one VSM. That makes the VSM easier to visu- draw the current map. Typically, it takes five steps for

alize and understand. drawing an office value stream map [10]:

Step 3. Drawing the current-state map 1) Document customer information and needs;

A current-state map value stream map is a tool that 2) Perform a value stream walk-through for identifying

helps teams see and understand the present flow of mate- processes, filling data boxes, and calculating WIP num-

rial and information. There are several tips for drawing a bers;

current-state map [10]. The first tip is that the map 3) Show the linkage of information flow and material

should be drawn by hand in pencil; drawing by hand can flow in the office;

be done without delay and helps members focus on the 4) Calculate lead time and process times;

flow rather than how to use computer software. The sec- 5) Complete the current-state map with lead time bars

ond tip is to collect current-state information while and data.

“walking through” the actual pathway of the material and Although the mapping process might be labor inten-

information flow. Remember, mapping cannot be done in sive, it takes the team to a deeper level of understanding

a conference room; members should physically go see of what is actually happening and makes the case for

and understand how each task is really done. Further- change more compelling. Additionally, the current-state

more, the process owners can provide any information to map provides foundational information for the future

Copyright © 2012 SciRes. AJIBM

20 Value Stream Management for Lean Office—A Case Study

Figure 2. The common VSM icons.

state. After creating the current map all of the team mem- future state become a reality as soon as possible.

bers are able understand the entire process, and to have Step 5. Proposing a value stream plan to reach the

more information for brainstorming the future state of the future stage of VSM

company. Future value stream maps demonstrate an ideal state

Step 4. Brainstorming and developing a future-state for companies. It is essential to make a plan for achieving

map the future state; otherwise the future value stream map

The future state should be a chain of processes, where will become worthless. A yearly value stream plan should

individual process are linked to their internal and exter- be created. A value stream plan includes the implementa-

nal customers, streamlined so that each process should tion plan from the current state to the proposed future

only produce what its customer needs, when they need it state. This plan consists of several loops separated from

[10]. In this step, team members should go through the entire office processes, such as research and development,

following seven questions and mark the future state ideas finance, and customer service [10]. In most cases it will

directly on the current-state map based on the answers to not be possible to achieve the future state all at once be-

these questions [11]. cause the proposed future value stream map demonstrates

1) What/When does the customer need? the entire flow through the office. Therefore, dividing the

2) How often will we check our performance to cus- proposed future state map into several loops and im-

tomer needs? proving individual loops is easier for team members to

3) Which steps create value and which are wastes? implement [10]. The four steps that are used when im-

4) How can we flow work with fewer interruptions? proving an individual loop are:

5) How do we control work between interruptions? 1) Develop a streamlined process that operates based

How will work be prioritized? on customer demand;

6) Is there an opportunity to balance the workload and/ 2) Establish a pull system to control production;

or different activities? 3) Apply leveling;

7) What process improvements will be necessary? 4) Practice Kaizen to continually eliminate waste and

Once the team has brainstormed ideas for the future extend the range of streamlined processes.

state as described above, a future value stream map can There are several points that should be indicated in the

be drawn. Rother & Shook described the purpose of value-stream plan, such as what will be implemented in

VSM as: “to highlight sources of waste and eliminate an individual loop, how to do that and when, measurable

them by implementation of a future state value stream goals, a clear check point with real deadlines, and an

that can become a reality within a short period of time”. assigned reviewer. A detailed “one year value-stream

After proposing a future value stream map, the team plan sheet” example is provided in the case study in S’s

members should start to think about how to make the next section.

Copyright © 2012 SciRes. AJIBM

Value Stream Management for Lean Office—A Case Study 21

Step 6. Conducting kaizen events for distinguishing of the design department, thereby increasing customer

and eliminating wastes satisfaction.

Kaizen is a Japanese word that translates to “continu-

ous improvement”. In the office environment, Kaizen 3.2. Lean Event Based on the Proposed

focuses primarily on the improvement of an individual Procedure

loop through the efforts of process owners by using their

experience [12]. Normally, there are three steps to per- Step 1. Form a Lean event team and provide Lean

form the Kaizen activity which are: training to team members

1) Utilize the 5 why’s method to find the root cause of This Lean event is focused on improving the non-

wastes [13], using the following guidelines: manufacturing area in Company X. Several employees

a) Writing down the problem helps you formalize the were selected from the Purchasing, Electrical Design,

problem and describe it completely. It also helps a team and Structural Design departments to participate in this

focus on the same problem. event. The PM was the leader of this Lean event team for

b) Ask why the problem happens and write the answer supervising the progress of this event and making the

down below the problem. improvement decisions. After forming the team, a basic

c) If the provided answer doesn’t identify the root Lean principles training was provided to team members;

cause of the problem that you wrote in step 1, ask why moreover, team members also learned about steps and

again and write that answer down. tips of creating a VSM.

d) Repeat above steps until the team is in agreement Step 2. Selecting a product/service family for con-

that the problem’s root cause has been identified. ducting VSM

2) Brainstorm and develop the resolution to meet the The blue book was chosen as the target of this Lean

goal. project because it is the major product of the non-manu-

3) Implement resolution and sustain. facturing area. Creating a blue book involves three de-

Based on the procedures of the Lean Office event, a partments in the company: Purchasing, Electrical Design,

team consisting of several employees was formed to im- and Structural Design. The Lean event team focused on

plement Lean in a local electrical company. This team the processes which were involved in creating a blue

focused on assisting the company in dealing with com- book.

plicated non-manufacturing departments such as Pur- Step 3. Drawing the current-state map

chasing, Electrical and Structural Design, and Projects. It Initially, the PM provided the information about cus-

is the authors’ hope that the case study serves as a step- tomer demand. According to the passive orders, the

by-step procedure in helping other companies achieve company receives about 180 orders annually. Performing

their own Lean office environment. a walkthrough and collecting the data which represents

the current status in each department is the second step of

3. Case Study of Creating Lean Office creating a current value stream map. By consulting proc-

ess owners, team members obtained and recorded most

3.1. Company and Product Introduction

of the necessary information, such as process time, num-

The company is a small electrical manufacturer located in bers of workers, and pending work in each station. After

the Midwest. They have a wide variety of customers lo- the first walkthrough, team members became familiar

cated all over the world, in industries ranging from gen- with the current flow and sequence of creating a blue

eral contractors, to industrial facilities, to large comer- book and also roughly drew the current-state map by

cial power grids. The major products of this company are following the icon scheme shown in Figure 2.

industrial switchgears and switchboards, and all of these In the second round, team members focus on the com-

products are made to their customers’ exact specifica- munication in each department. Operation owners de-

tions. The company has been applying Lean in their scribed the sequence of their jobs, and how they commu-

manufacturing area for several years. The Project Man- nicate with upstream and downstream processes. That

ager (PM) told us the lead time of the manufacturing area helps the team draw linkages of information and material

is one week, but the lead time of the previous process, flow on the current-state map. In the third round, the

creating a blue book is about 4 weeks. A blue book con- team focused on the time consumptions of each process

sists of engineering drawings, BOM, and manufacturing and pending job. Team members checked the process

process plan for a given customer order. Customer satis- time and lead time with operation owners; moreover, in

faction was highly impacted by the long lead times, this walkthrough team members verified uncertain in-

which kept customers waiting for their order. Therefore, formation collected in the previous walkthroughs. After

they wanted to transform their office processes by ap- collecting this data and re-checking with the process

plying a Lean strategy in order to increase the efficiency owners, the Lean project team created the current value

Copyright © 2012 SciRes. AJIBM

22 Value Stream Management for Lean Office—A Case Study

stream map as shown in Figure 3. process. The map of the Structural Design process is

Once the customer sends the order to Purchasing, this shown in Figure 5 while the Electrical Design process is

department creates a quote and a rough Bill of Materials shown in Figure 6.

(BOM). They notify the president that they received the Since a blue book is made by several departments, the

quote and then the president generates the order that tells Lean event team created a VSM for each department. In

the PM to create the BOM. Additionally, the PM is in the purchasing sub-process (Figure 4), most of the trans-

charge of customer communication and reviewing any portation of information was made via email. Following

design corrections. Therefore, every change in the blue the customer’s specification, the purchaser creates the

book must go through PM. purchase order (PO) and sends a copy to each the sup-

After creating the BOM, the PM sends it to the cus- plier to ensure that the company can make the custom-

tomer via email, and waits for the customer to review it. ized product. The POs are sent back to the purchaser

The customer review takes about 10 working days, which once the suppliers have checked their copy and corrected

greatly increases the lead time of the non-manufacturing any incorrect item numbers. The PM checks the item

area. After the customer is finished reviewing the BOM, numbers in the blue book again, makes the changes as

it is sent back to the PM who reviews the BOM once necessary to the PO, and then sends it back to the pur-

again. After the PM is finished with this review, the chaser for any necessary review/corrections by the sup-

BOM is sent to Purchasing so that they can check the raw plier. The PM told the Lean even team that the purchas-

material item numbers and ensure that the customized ing correction loop is usually repeated 2 times per task.

product can be made based on raw material availability. There are four designers involved in Electrical Design

The map of the Purchasing sub process is shown in Fig- and all of their work must be checked by the PM before

ure 4. the designs are sent to the customers or the production

While Purchasing performs this review, the BOM is area. After the PM finalizes any corrections the electrical

also sent to the customer for another review and correc- design of the blue book will be sent to Support Cycle for

tion. Once the customer reviews and approves the layout a point-to-point check of the electrical design and so la-

and the purchaser verifies the items, the information is bels can be made for each point and wire. After observ-

sent back to the PM. Once the PM approves everything, ing this and the Structural Design process, the Lean event

structural Design and Electrical Design stats the design team members determined that the correction process

Figure 3. Current VSM overview.

Copyright © 2012 SciRes. AJIBM

Value Stream Management for Lean Office—A Case Study 23

Figure 4. VSM of Purchasing sub process.

Figure 5. VSM of Electrical Design sub process.

was repeated at least 3 times. This greatly increased the Step 4. Brainstorming and developing a future-

lead time of these sub processes. Furthermore, while all state map

of the design information that is transported from the PM After three walkthroughs, the Lean event team mem-

to the customers is done via email, the information trans- bers determined there were some needed improvements

ported between the PM and Electrical Design or Struc- in the current state. Based on the information from the

tural Design is done by physically delivering the blue current value stream map, the team began brainstorming

book. a future ideal state for the company. Following the pro-

Copyright © 2012 SciRes. AJIBM

24 Value Stream Management for Lean Office—A Case Study

posed procedure, the team addressed the following seven changed.

questions to define a future VSM: 3) Which steps create value and which are wastes?

1) What/When does the customer need? According to the current-state map in Figure 3, the to-

In this case study, blue books are required for cus- tal value-added time, such as creating BOM and creating

tomer orders, and it is the need of the customers that re- the electrical and structural designs, is only about 37.18

ceive the product that they have specified, with as short a hours, but the non-value added time is more than 400

lead time as possible. According to a review of past or- hours. By reviewing the current-state map and discussing

ders, the company receives 180 orders per year. The it with the process owners, the Lean event team found

working time of the company is 8 hours per day, 250 that there are several existing non-value-added activities

days per year. The Takt time of each task, according to and waste. These non-value-added activities are described

Equation 1, is about 11.1 hours. in the Table 2.

2) How often will we check our performance to the 4) How can we increase the flow of work with fewer

customer’s needs? interruptions?

The PM will review the customized blue book, and it Due to lack of control of task sequence and time con-

will also be reviewed by customers whenever it is sumption, it is not easy to track all of the tasks in the

Figure 6. VSM of Structural Design sub process.

Table 2. Identified non-value added activity.

Definition Description

In Figure 3, it can be seen that only the PM can directly communicate with the customer during the creation of the blue book,

Transportation and the communication is done via email; whereas, in the sub-processes (Figures 4-6), the internal communication, such as

delivery of blue books from the designers to the PM, is done via manual delivery.

According to Figures 4-6, it can be seen that there are several repeated corrections in the purchasing and electrical sub

Defect

processes, especially in the electrical design sub process. This increases the lead time of sub processes.

Inventory According to the team’s observations, each process has an average of 3 blue books waiting to be worked on.

Since there is a large variation in the time consumed waiting for the customer corrections, the staff group recorded the average

Waiting waiting time, which is about 40 hours. It can be seen that there are two customer correction processes in the current state which

increase the total lead time to 465.5 hours.

Over-processing In the purchasing sub process the purchase order is created and then sent to the supplier for revisions by the purchasing agent.

The material ordered arrives months behind the creation of the layout, electrical, and structural designs. The designs remain

Over production

unused for months until the desired material arrives. This results in numerous designs that are created and not used right away.

Copyright © 2012 SciRes. AJIBM

Value Stream Management for Lean Office—A Case Study 25

company. The Lean event team suggested that the com- check their email frequently; therefore, there is no effi-

pany apply a Kanban system. This will efficiently sched- cient standard tracking system for task sequence. To

ule tasks to real time demand as well as optimize and solve this problem the Lean project team suggested that a

control the pending work. Interruptions can be decreased Kanban system be implemented as well as using software

by applying software applications in some sub processes. features to remind PM and purchasers to follow up with

5) How do we control work between interruptions? customers’ and suppliers’ corrections. This would allow

How will work be prioritized? the company to reduce the total lead time. The Lean pro-

According to observations, every process in the com- ject team also recommended that an online order entry

pany is done using a push system, there is no rule to con- should be developed for the purchasing sub process as

trol the task priority, and all of the information on cus- well as the creation of a database so that available item

tomer demand is managed by the PM. Therefore, the numbers can be recorded.

Lean project team suggested that a pull system be im- A clear future state of the company was envisioned by

plemented where the priority of the tasks are controlled the team members upon answering the seven questions

by Kanban system managed by the PM. listed above. The team then proposed a future map for

6) Is there an opportunity to balance the work load the company’s non-manufacturing area, which is shown

and/or different activities? in Figure 7. The light burst areas designate the areas that

The team suggested that the PM follow-up with the will be improved by conducting Kaizen activity. In the

customer’s corrections frequently to reduce the time proposed future state, the team members streamlined the

consumption of reviewing the BOM and design layout. If office processes and suggested that the production of

the lead time of the customer correction is able to be re- every process should be triggered by its customers de-

duced, the total lead time to create the blue books would mand.

be relatively decreased. The future VSM serves as a guide for further improve-

7) What process improvements will be necessary? ment of the Lean event. After the future state map is

The team found that the PM and purchasers did not proposed, the team members start brainstorming on how

Figure 7. Future VSM with light bursts of Kaizen events.

Copyright © 2012 SciRes. AJIBM

26 Value Stream Management for Lean Office—A Case Study

to make it become a reality, and the leader of the team in what loop is provided by the value stream plan (Fig-

creates the value stream plan. ure 8). The light bursts in the future-state map shown in

Step 5. Proposing a Value stream plan to reach fu- Figure 7, which are matched to the value stream object-

ture ideal state of company tives in the value stream plan, represent a change that

In order to reach the future state within a short period needs to be made in order to make the current system

of time, the leader of the Lean event team needs to create look more like the future state map. To achieve the goals

a “yearly value stream plan” sheet. Each sub process is in the value stream plan, the team members conducted

considered a loop for improvement. Since the lead time several Kaizen events where they used the 5 why’s

of the electrical design process is higher than the pur- method to determine the root cause of a problem. Once

chasing and structural design processes, this is consid- the root cause was identified the team then brainstormed

ered as the first target to improve. There is a measurable solutions for each problem. The following paragraphs

goal for each loop, and the leader assigns a person to be summarize these Kaizen events.

in charge of the improvement of each of the loops. The Kaizen Event 1: Reduce the defect rate in the elec-

proposed value stream plan is shown in Figure 8. trical design process

Step 6. Conducting Kaizen events to reach the fu- The defect rate in the electrical design process is about

ture state VSM 100%. The three effects of this high defect rate are:

While brainstorming the future VSM, team members 1) The overall lead time is increased;

identified where the non-value added activities and wastes 2) The amount of WIP inventory increases;

existed in the current process (Table 2). The goal of the 3) The Company labor costs increase due to rework.

Lean Office event is to continuously reduce waste in office Root cause identification:

processes and to add value in products or services. A In order to eliminate this problem, the Lean event team

clear direction about what the team needs to implement used the 5 why’s method to determine the root cause, as

Figure 8. Proposed value stream plan.

Copyright © 2012 SciRes. AJIBM

Value Stream Management for Lean Office—A Case Study 27

summarized in Figure 9. After measuring the distances, the Lean event team found

Proposed resolution: that one critical problem in the design process is the

The Lean event team suggested that the company ask repetition of identical transports. The total manual trans-

the electrical designers to cross check each other’s de- portation per job is approximately 3018 ft, which equals

signs for accuracy. In addition, the purchasing process to that $1334 in labor costs wasted by transporting blue

should be completed before the design phase begins. books or documents.

Therefore, by waiting for a final BOM and cross-check- Root cause identification:

ing each others work, the Electrical Design team can help In order to reduce the transportation problem, the team

ensure that the PM is simply approving the final design, members use the “5 whys” to find the root cause which is

rather than perpetuating a continuous cycle of correc- shown in Figure 11.

tions. Proposed resolution:

Kaizen Event 2: Reducing waiting time in the pur- The Lean event team proposed a Kanban post and

chasing process Kanban card for the company, which is shown in Figure

There is a repeated cycle that happens when Purchas- 12. This Kanban post visually shows the PM and design-

ing is forced to call the supplier for clarification. Waiting ers each task and which department it is in. To track the

waste takes place when the supplier has to send the order tasks efficiently, each task is accompanied by a Kanban

back because they don’t recognize the part number indi- card. Once a process is completed, a slip is torn off the

cated on the bill of materials. Kanban card and then placed on the board. The PM can

Root cause identification:

By asking the 5 why’s, the team members are able to Problem statement: There is too much delay in the purchasing

find out the root cause, as seen in Figure 10. process.

Proposed resolution: 1) Why is there too much delay in the purchasing process?

Due to the constant correction cycle between the ma- Because there are constant-correction cycles in the purchasing

terial supplier and Purchasing, the Lean event team pro- process.

posed another cell in which purchasing and quoting are 2) Why are there constant correction cycles in the purchasing

combined into one process to eliminate waste. If pur- process?

chasing and quoting are combined into one process, the Because the PM is involved with purchasing and quoting.

BOM will be finalized and material ordered before the 3) Why is the PM involved in purchasing and quoting?

PM starts a design and corrections will no longer need to Because purchasing is done after the design process has begun.

be passed to the PM. Consequently, the company can 4) Why is purchasing done after the design process has

save approximately 20 hours of labor per job and the begun?

company can save $340 per job, for an annual labor sav- Because it reduces the amount of delay before the design can

begin.

ings of $61,200.

5) Why does it reduce the amount of delay before the design

Kaizen Event 3: Reducing transportation in the de- can begin?

sign process Because the PM can begin the design without a purchase order.

During the design creation process, unnecessary steps

are executed that require manual transportation of design Figure 10. 5 why’s for waiting waste.

documents to several areas in the office. To deal with this

problem, the team members measured the distance from

Problem Statement: There is 3018 ft of travel required during the

each particular office and found where and when the design process.

transportation occurs, which is summarized in Table 3. 1) Why is there 3018 ft of travel required during the design

process?

Problem statement: The wiring diagram has to be double checked, Because the operations are repeated again and again.

in many cases two times, by the PM. 2) Why does an operation repeat?

1) Why do the diagrams have to be double check by the PM? Because corrections need multiple verifications.

Because errors are made in the wiring diagram. 3) Why do the corrections need multiple verifications?

2) Why are errors made in the wiring diagram? Because the support staff sometimes creates errors.

Because the incoming data is not checked. 4) Why does the support staff create errors?

3) Why is the incoming data not checked? Because the support staff is not involved in job creation.

Because mistakes and errors are repeated. 5) Why is the support staff not involved in job creation?

4) Why are the mistakes and errors repeated? Because in this company, only the PM can communicate with the

There is no internal correction procedure. customers and create jobs.

Figure 9. 5 why’s for defect waste. Figure 11. “5 whys” for transportation.

Copyright © 2012 SciRes. AJIBM

28 Value Stream Management for Lean Office—A Case Study

Table 3. Transportation distances.

Process From - To Distance Repetition Total Distance

Scheduling President to PM 119.7 Feet

PM to Structural 58.25 Feet 4 233 Feet

Structural Design Creation

PM to Production 346.9 Feet

PM to Electrical 69.3 Feet 6 415.8 Feet

Electrical Design Creation

PM to Production 346.9 Feet

Figure 12. Proposed Kanban post and card.

then sign off on the Kanban slips. During the purchasing into a Lean office that has customer-triggered working

or design process, any corrections are written on the slip, processes, faster and systematic task tracking, and re-

which is then returned to the responsible team member. duced costs due to a reduction of non-value added active-

ties.

4. Conclusion

This paper presents a systematic procedure which could REFERENCES

be used by Lean practitioners to conduct Lean events in [1] M. Jenkins, “Across the Enterprise Boeing Is Attacking

their office environment. The proposed procedure incur- Waste and Streamlining Process. The Goal? Cost Com-

porates the knowledge of several articles, books and suc- petitiveness,” 2002.

cessful Lean events. It also includes a case study which http://www.boeing.com/news/frontiers/archive/2002/augu

follows the proposed procedures and is provided as a st/cover.html

reference for creating a Lean office. The application of [2] M. Poppendieck, “The Principles of Lean Thinking,” ITC,

Lean principles in a manufacturing area means identi- Winnipeg, 2002, pp. 1-7.

fying the value added and non-value added activities in [3] IMEP, “Principle of Lean Manufacturing,” 2000.

manufacturing processes and then eliminating the non- [4] T. Ohno, “Toyota Production System: Beyond Large-

value added activities while improving the value added scale Production,” Productivity Press, New York, 1988.

activities. The systematic procedure proposed here ex- [5] M. Corrie, “Lean Success in an Administartion Envrion-

tends this concept to transform an office environment ment,” Waukesha Bearings Ltd., Northwood Hills, 2004.

Copyright © 2012 SciRes. AJIBM

Value Stream Management for Lean Office—A Case Study 29

[6] L. A. Tonkin, “Lear Office: Mapping Your Way to Chan- [10] M. Rother and J. Shook, “Learning to See,” Lean Enter-

ge,” Target, Minneapolis, 2004. prise Institute, Cambridge, 2003.

[7] E. P. Ev Dale, “Lean Enterprise: Minnesota Showcase,” [11] IMEP, “Office Value Stream Mapping. Iowa Manufac-

Target, Vol. 18, No. 1, 2002, pp. 50-53. turing Extension Partnership,” 2008.

[8] IMEP, “Principles of Lean Manufacturing with Live Simu- [12] W. Lareau, “Office Kaizen: Transforming Office Opera-

lation (Participant Workbook),” 2003. tions into a Strategic Competitive,” American Society for

[9] H.-D. Wan and F.-F. Chen, “Leanness Score of Value Quality, Milwaukee, 2002.

Stream Maps,” Proceedings of the 2007 Industrial engi- [13] J. Womack and D. Jones, “Lean Thinking: Banish Waste

neering research conference, Nashville, 20-23 May 2007, and Create Wealth in Your Corporation,” Simon and

p. 1515. Schuster, New York, 2003.

Copyright © 2012 SciRes. AJIBM

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Kaizen - The Key To Japan's Competitive SuccesDokument8 SeitenKaizen - The Key To Japan's Competitive SuccesHans Siregar67% (3)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- ISO 9001 in Plain EnglishDokument34 SeitenISO 9001 in Plain Englishjoshua_sx1100% (21)

- The Future of Lean Procurement: Oracle - JD Edwards Enterprise ONEDokument17 SeitenThe Future of Lean Procurement: Oracle - JD Edwards Enterprise ONErahuljy2000Noch keine Bewertungen

- W. W. Grainger, Inc., Is A Leading Supplier of Maintenance, Repair, and Operating (MRO) Products To Businesses and Institutions in The UnitedDokument3 SeitenW. W. Grainger, Inc., Is A Leading Supplier of Maintenance, Repair, and Operating (MRO) Products To Businesses and Institutions in The UnitedJalaj GuptaNoch keine Bewertungen

- Materi KapitaDokument11 SeitenMateri Kapitasyaibani dita ardellaNoch keine Bewertungen

- Intro To Adv PPCDokument16 SeitenIntro To Adv PPCRaraNoch keine Bewertungen

- MGMT 339 CH 13Dokument11 SeitenMGMT 339 CH 13mic100% (1)

- Efficient Integration of Suppliers, Factories, Warehouses and StoresDokument16 SeitenEfficient Integration of Suppliers, Factories, Warehouses and StoresMark John Paul CablingNoch keine Bewertungen

- Rampachodavaram Rajahmundry Bo11505124022 14.6.1979 1.10.19 1.10.19 CH - Surya Narayana, SposDokument14 SeitenRampachodavaram Rajahmundry Bo11505124022 14.6.1979 1.10.19 1.10.19 CH - Surya Narayana, SposPrashantNoch keine Bewertungen

- Applying Lean Principles to Software DevelopmentDokument53 SeitenApplying Lean Principles to Software DevelopmentAnonymous IcptMgwZlNoch keine Bewertungen

- Jawaban UAS 2016-2017Dokument4 SeitenJawaban UAS 2016-2017Zulfadin HanaNoch keine Bewertungen

- Designing Distribution NetwrokDokument45 SeitenDesigning Distribution NetwrokMayank PrakashNoch keine Bewertungen

- C9 (MC) - Cost Accounting by Carter (Part1)Dokument2 SeitenC9 (MC) - Cost Accounting by Carter (Part1)AkiNoch keine Bewertungen

- Spare Parts Management with SAP - Key StrategiesDokument47 SeitenSpare Parts Management with SAP - Key Strategiesamerican7404Noch keine Bewertungen

- The Definition of ProcurementDokument8 SeitenThe Definition of ProcurementTaufikHidayatNoch keine Bewertungen

- Supply Chain Management of Amul and Wal-MartDokument10 SeitenSupply Chain Management of Amul and Wal-Martmukkannickal100% (4)

- SilicaSandPh Intertek Lab Test Silica Quartz (SQSM)Dokument11 SeitenSilicaSandPh Intertek Lab Test Silica Quartz (SQSM)SilicaSandPhNoch keine Bewertungen

- Logistics Execution in SAP Business SuiteDokument26 SeitenLogistics Execution in SAP Business SuitemayurNoch keine Bewertungen

- Sap MMDokument20 SeitenSap MMNandhakumar TNoch keine Bewertungen

- Customer Supplier RelationshipDokument9 SeitenCustomer Supplier RelationshipBenNoch keine Bewertungen

- Differentiating Supply Chain Strategies - The Case of Light Vehicle Manufacturers in South Africa, by Intaher Marcus AmbeDokument12 SeitenDifferentiating Supply Chain Strategies - The Case of Light Vehicle Manufacturers in South Africa, by Intaher Marcus AmbemohdkhidirNoch keine Bewertungen

- Chapter 1 Introduction To Supply ChainDokument28 SeitenChapter 1 Introduction To Supply Chainaireen clores0% (1)

- Logistics Engineering & Supply Chain Design HomeworkDokument7 SeitenLogistics Engineering & Supply Chain Design HomeworkQuynh Chau TranNoch keine Bewertungen

- Place and Development of Channel SystemsDokument60 SeitenPlace and Development of Channel SystemsErjonaNoch keine Bewertungen

- Oracle University Approvals GuideDokument43 SeitenOracle University Approvals GuideAbhiram JayaramNoch keine Bewertungen

- ACCG3001 Organisational Planning and Control - Foleo Fones Case Study AnalysisDokument6 SeitenACCG3001 Organisational Planning and Control - Foleo Fones Case Study Analysisdwkwhdq dwdNoch keine Bewertungen

- Lanci Snabdevanja - Definisanje I Per For ManseDokument29 SeitenLanci Snabdevanja - Definisanje I Per For MansePredragNoch keine Bewertungen

- Seminar Topics - SCM - B.TechDokument2 SeitenSeminar Topics - SCM - B.TechJeromeNoch keine Bewertungen

- NHAI appoints safety consultants for Punjab highway projectDokument2 SeitenNHAI appoints safety consultants for Punjab highway projectAkshay PendurkarNoch keine Bewertungen

- Fundamentals of Warehouse OperationsDokument9 SeitenFundamentals of Warehouse OperationsAliff IqmalNoch keine Bewertungen