Beruflich Dokumente

Kultur Dokumente

Sucker Rod Elevators (25-Ton)

Hochgeladen von

CESAR SEGURAOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sucker Rod Elevators (25-Ton)

Hochgeladen von

CESAR SEGURACopyright:

Verfügbare Formate

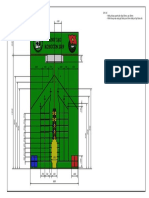

W ELL S E R V I C I N G TOO L S

553-575-500

2 553-548-500 4

2 553-548-900 4

2 553-549-010 4

2 553-551-000 4

4 553-551-400 8

2 553-551-500 4

2 553-551-800 4

2 553-766-100 4

4 553-554-000

4 553-554-000A 8

2 .

553-550-000

553-550-200

553-550-700

553-550-800

553-575-200

553-575-300

553-575-600

553-579-600

Elevator Introduction

The Trico Heavy Lift sucker rod elevator was

designed, tested, and documented to ensure

compliance with European Standard EN

1677-1, a certification that exceeds API-8C

specifications.

The Trico Heavy Lift product is manufactured

by Topco Oilsite Products following a strict

Quality Control program for overhead lifting

equipment.

This elevator has been engineered to

eliminate sharp edges or protrusions which

could cause accidents or malfunctions du

operation. It's material specifications

permit use during winter conditions, in

temperatures as low as -50F. It has been

proof tested and fatigue rated to 1.5 times

maximum load at 20,000 continuous cycles

without failure. It has also been tested to

destruction at a breaking force of 4 times

the maximum rated load of 50,000 pounds,

making this elevator a leader in the industry.

The Trico Heavy Lift with sized plates may

be used with 5/8",3/4", 7/8", 1", and 1 1/4"

sucker rods. It is also available in solid body

style for 1 1/4" polish rods, 1 1/8" and 1 1/4" 553-551-500

steel rods. @

6 LATCH FRONT (4 REQ)

..

WARNING

Loads may disengage from elevator if proper procedures are not followed. A falling load may cause serious injury or death I~~I

.Never use elevator unless levers and latches are fully closed and locked. Use only genuine Trico parts as replacements

Read and understand these instructions before using elevators.

CALGARY . EDMONTON . CLAIRMONT . RED DEER

Das könnte Ihnen auch gefallen

- Sucker Rod Elevators (17.5-Ton)Dokument1 SeiteSucker Rod Elevators (17.5-Ton)CESAR SEGURANoch keine Bewertungen

- Heavy Lift 25 Ton Rod Elevator Operators Manual: ContentDokument6 SeitenHeavy Lift 25 Ton Rod Elevator Operators Manual: ContentAngel BermudezNoch keine Bewertungen

- 6.7L DieselDokument94 Seiten6.7L DieselBrendan Brodie100% (15)

- Fiche Technique DOOSAN B15R-7Dokument2 SeitenFiche Technique DOOSAN B15R-7M2E AUTOMATIONNoch keine Bewertungen

- DrawingDokument5 SeitenDrawingMohammedNoch keine Bewertungen

- Welding Cable AmpacitiesDokument1 SeiteWelding Cable AmpacitiesDaudkandi Laboratory High SchoolNoch keine Bewertungen

- 544 KG 1 M/s T.S. 520 MMDokument2 Seiten544 KG 1 M/s T.S. 520 MMHarsh YouTubeNoch keine Bewertungen

- Falltech Harness Instruction ManualDokument24 SeitenFalltech Harness Instruction ManualEfrain HernandezNoch keine Bewertungen

- Chart Title: Grados Factores 500 5 725 4 500 3 500 2 275 1Dokument3 SeitenChart Title: Grados Factores 500 5 725 4 500 3 500 2 275 1ANGIE BRIGGITE GARCIA TIPENoch keine Bewertungen

- Puretech WFI Stills BrochureDokument6 SeitenPuretech WFI Stills Brochureoussara1979Noch keine Bewertungen

- Two Bedroom +one Bedroom AprtDokument1 SeiteTwo Bedroom +one Bedroom AprtAnorld WalkerNoch keine Bewertungen

- Link - SE EL TALADRO To VIRGEN-MANARE - Installation - ReportDokument7 SeitenLink - SE EL TALADRO To VIRGEN-MANARE - Installation - ReportLeonardo Miranda BustosNoch keine Bewertungen

- Frequency Ranges: H5: 518.000-542.000 MHZDokument5 SeitenFrequency Ranges: H5: 518.000-542.000 MHZJNoch keine Bewertungen

- Advansys Cross Reference LoadersDokument1 SeiteAdvansys Cross Reference LoadersLucas Moreira100% (1)

- Schematic Diagram: Panda River Panda River Panda River Panda RiverDokument1 SeiteSchematic Diagram: Panda River Panda River Panda River Panda RiverAŋĸɩt SɩŋʛʜNoch keine Bewertungen

- A. DAILY INCOME & EXPENSES L DECEMBER 2 0 2 1 AAADokument24 SeitenA. DAILY INCOME & EXPENSES L DECEMBER 2 0 2 1 AAAJam PabloNoch keine Bewertungen

- Woolcock Peak Flow Chart UpdatedDokument2 SeitenWoolcock Peak Flow Chart UpdatedpatriceNoch keine Bewertungen

- Ban GheDokument1 SeiteBan GheKien Nguyen TrungNoch keine Bewertungen

- ShvcrossDokument5 SeitenShvcrossEprom ServisNoch keine Bewertungen

- Frequency Distribution TableDokument2 SeitenFrequency Distribution TableJudy Grace AbdonNoch keine Bewertungen

- Tugas PPIC 2 Achmad Feri (NIM 16612045) B SoreDokument6 SeitenTugas PPIC 2 Achmad Feri (NIM 16612045) B SoreAchmad FeriNoch keine Bewertungen

- Nec AmpacitiesDokument2 SeitenNec AmpacitiesmicrajacutNoch keine Bewertungen

- Rotating Unions: Operating ManualDokument18 SeitenRotating Unions: Operating ManualFernando Aurelio de CastroNoch keine Bewertungen

- Shaft KeyDokument1 SeiteShaft KeySamuel OphoffNoch keine Bewertungen

- User Manual Book: Built-In OvenDokument51 SeitenUser Manual Book: Built-In OvenRicky TentacleNoch keine Bewertungen

- Mikrokator MDokument4 SeitenMikrokator Mciber_aristosNoch keine Bewertungen

- Data Sheet - K1500 - Cerro Verde PDFDokument3 SeitenData Sheet - K1500 - Cerro Verde PDFAntony Armando Huaylla QuispeNoch keine Bewertungen

- Bagging ScaleDokument2 SeitenBagging ScaleAli HusseiniNoch keine Bewertungen

- Ryobi.: 4-Color Offset PressDokument234 SeitenRyobi.: 4-Color Offset PressLe Duy PhuocNoch keine Bewertungen

- Hino SpecificationsDokument5 SeitenHino SpecificationsSouth Coast TechnologiesNoch keine Bewertungen

- Aleksandar Ristovic E70 III 02.09Dokument2 SeitenAleksandar Ristovic E70 III 02.09Slobodan VujaklijaNoch keine Bewertungen

- 5103R ManualDokument80 Seiten5103R Manualdan.gutulescuNoch keine Bewertungen

- The Ashplant (Reel) On The SessionDokument2 SeitenThe Ashplant (Reel) On The SessionSakura2709Noch keine Bewertungen

- 5600 FichaTecnicaDokument3 Seiten5600 FichaTecnicaJhan Carlos HuamaniNoch keine Bewertungen

- Gco-Ecp-Frb-Ppu-Doc-Split Case - Ul Product IqDokument25 SeitenGco-Ecp-Frb-Ppu-Doc-Split Case - Ul Product IqRafael AguilarNoch keine Bewertungen

- Course Programme Cutoff Report 22Dokument6 SeitenCourse Programme Cutoff Report 22kunal uikeyNoch keine Bewertungen

- Ghi CH - PH N G Bao Quanh S N R NG 50mm, Cao 50mm. - Phnkhungmuvnggi Bngcao50mmbngvigi BaosnDokument1 SeiteGhi CH - PH N G Bao Quanh S N R NG 50mm, Cao 50mm. - Phnkhungmuvnggi Bngcao50mmbngvigi BaosnTrần BảoNoch keine Bewertungen

- Quiz 2Dokument2 SeitenQuiz 2ImjusttryingtohelpNoch keine Bewertungen

- Brand Oe. Part No. Model: Original Equipment Numbers vs. Kojen ModelDokument24 SeitenBrand Oe. Part No. Model: Original Equipment Numbers vs. Kojen ModelVelina MilevaNoch keine Bewertungen

- Heavy Lift 25 Ton Rod Hook Operators Manual: ContentDokument6 SeitenHeavy Lift 25 Ton Rod Hook Operators Manual: ContentMateo PorrasNoch keine Bewertungen

- External Gear Pumps Installation Manual: Size 0Dokument8 SeitenExternal Gear Pumps Installation Manual: Size 0Edward SalasNoch keine Bewertungen

- Z-5 Running Tool1Dokument1 SeiteZ-5 Running Tool1Mohamed MamdouhNoch keine Bewertungen

- g4015z PLDokument15 Seiteng4015z PLIkhsan Nurul AkbarNoch keine Bewertungen

- WFT Composite PlugsDokument11 SeitenWFT Composite Plugsahmad haqkim muhamad malackNoch keine Bewertungen

- Turbocharger TurbochargerDokument38 SeitenTurbocharger TurbochargerFrank ChukwujiNoch keine Bewertungen

- IEC 60071-1 Page 30Dokument1 SeiteIEC 60071-1 Page 30omid fathiNoch keine Bewertungen

- SCF125-100-300 - UL Product Iq - CO NMFire CODokument2 SeitenSCF125-100-300 - UL Product Iq - CO NMFire COCamilo DazaNoch keine Bewertungen

- Model Title Quantity SKU: Pa Ge 1 of 1Dokument1 SeiteModel Title Quantity SKU: Pa Ge 1 of 1Naovalian RistandyNoch keine Bewertungen

- John Crane Type 5610/5610QDokument8 SeitenJohn Crane Type 5610/5610QRaduNoch keine Bewertungen

- Calorie Frequency 401-500 9 501-600 6 601-700 6 701-800 22 801-900 7 50Dokument5 SeitenCalorie Frequency 401-500 9 501-600 6 601-700 6 701-800 22 801-900 7 50jirongNoch keine Bewertungen

- Baseline 7 AT3 8 AT3 9 AT 3: Elementary ElementaryDokument1 SeiteBaseline 7 AT3 8 AT3 9 AT 3: Elementary ElementarySimon LawrensonNoch keine Bewertungen

- Assessmentgrid1 PDFDokument1 SeiteAssessmentgrid1 PDFSimon LawrensonNoch keine Bewertungen

- 28.03.2018.pilewind Winches - DatasheetDokument2 Seiten28.03.2018.pilewind Winches - Datasheetvinse.diesel7Noch keine Bewertungen

- Technical Manual Mecanical Bumper SubDokument6 SeitenTechnical Manual Mecanical Bumper SubYeisson Rubio100% (1)

- H800-1050HD/S SERIES Technical GuideDokument6 SeitenH800-1050HD/S SERIES Technical GuideRaduNoch keine Bewertungen

- Indian Institute of Science (Iisc) Bangalore-560012 (India) : Admissions 2023Dokument6 SeitenIndian Institute of Science (Iisc) Bangalore-560012 (India) : Admissions 2023shobhit singhNoch keine Bewertungen

- بحوث العمليات وتطبيقاتها على مستوى اتخاذ القرار الإنتا... جفعال دراسة حالة مؤسسة البثق والتغطية وتذويب الألمنيوم (eara) بالمسيلةDokument16 Seitenبحوث العمليات وتطبيقاتها على مستوى اتخاذ القرار الإنتا... جفعال دراسة حالة مؤسسة البثق والتغطية وتذويب الألمنيوم (eara) بالمسيلةasmaabdesseNoch keine Bewertungen

- ISA White CS Product Guide Cage EN L1211-2a Gj9StGzDokument16 SeitenISA White CS Product Guide Cage EN L1211-2a Gj9StGzSort ThangNoch keine Bewertungen

- Brandt Agitators GeneralDokument4 SeitenBrandt Agitators GeneralCESAR SEGURANoch keine Bewertungen

- Engineering Data Ip5-3600Dokument2 SeitenEngineering Data Ip5-3600CESAR SEGURANoch keine Bewertungen

- Dampener Hydrill Dimenciones PDFDokument2 SeitenDampener Hydrill Dimenciones PDFCESAR SEGURANoch keine Bewertungen

- FMC Swivel Joint PDFDokument22 SeitenFMC Swivel Joint PDFramudo Z100% (1)

- Certifications Ac CoilDokument2 SeitenCertifications Ac CoilCESAR SEGURANoch keine Bewertungen

- Shear Bonnet Assembly LBSBDokument4 SeitenShear Bonnet Assembly LBSBCESAR SEGURANoch keine Bewertungen

- C BOP Parts ListDokument9 SeitenC BOP Parts ListCESAR SEGURANoch keine Bewertungen

- Mazda 2 2011-2016Dokument4.855 SeitenMazda 2 2011-2016Giovanni MoralesNoch keine Bewertungen

- Spare Parts Catalog: MT-L 3095 II Material Number: 4474.053.248 Current Date: 28.04.2019Dokument38 SeitenSpare Parts Catalog: MT-L 3095 II Material Number: 4474.053.248 Current Date: 28.04.2019sffqgfeg50% (4)

- Tabla de Ajustes Fast Fin - PDFDokument8 SeitenTabla de Ajustes Fast Fin - PDFLuis GuerraNoch keine Bewertungen

- P.I.no.1209 Goodeng GD-320-LS ManualDokument1 SeiteP.I.no.1209 Goodeng GD-320-LS Manualishfaqtabu25Noch keine Bewertungen

- WF150P R6105BZLDSDokument3 SeitenWF150P R6105BZLDSChiquitita ArionaNoch keine Bewertungen

- The Expected Role of Railways in The Economic Development of Saudi ArabiaDokument11 SeitenThe Expected Role of Railways in The Economic Development of Saudi ArabiaDwijendra ChanumoluNoch keine Bewertungen

- Flexible - Pavement - Design - Tool AASHTO 1993Dokument12 SeitenFlexible - Pavement - Design - Tool AASHTO 1993Awang DarmawangsaNoch keine Bewertungen

- C4C S4P - Stage 2 - Workshop 2Dokument61 SeitenC4C S4P - Stage 2 - Workshop 2ITDP IndiaNoch keine Bewertungen

- Cruise Guide Caymans 2.0 Final 2015.09.20adDokument101 SeitenCruise Guide Caymans 2.0 Final 2015.09.20adGeoff100% (1)

- 200 Speedster 2008Dokument1 Seite200 Speedster 2008Dr. LeeNoch keine Bewertungen

- Pamphlet On Safety Precautions in ExcavationDokument4 SeitenPamphlet On Safety Precautions in ExcavationasdadNoch keine Bewertungen

- 719-99-09 Air Springs Catalog 4-18 PDFDokument91 Seiten719-99-09 Air Springs Catalog 4-18 PDFAndres SilvaNoch keine Bewertungen

- 03 Evs Ws Ch12 Means of Transport 02 KVDokument4 Seiten03 Evs Ws Ch12 Means of Transport 02 KVChandra BabuNoch keine Bewertungen

- Advanced Seal Delivery SystemDokument9 SeitenAdvanced Seal Delivery SystemThe Angry ManNoch keine Bewertungen

- Republic of The Philippines Old MIA Rd. Pasay City, Metro Manila 1300 Flight PlanDokument2 SeitenRepublic of The Philippines Old MIA Rd. Pasay City, Metro Manila 1300 Flight PlanJessie Dinoy100% (2)

- 2020 - VN Market Trend - Q - MeDokument15 Seiten2020 - VN Market Trend - Q - MeGame AccountNoch keine Bewertungen

- Euro-Air (Revised) : The World Airline IndustryDokument6 SeitenEuro-Air (Revised) : The World Airline IndustryHritik ShoranNoch keine Bewertungen

- Ginza 3Dokument2 SeitenGinza 3Nica CordovaNoch keine Bewertungen

- Policy February,: National Highways Authority of IndiaDokument3 SeitenPolicy February,: National Highways Authority of IndiasravanNoch keine Bewertungen

- MMD Sizing PlantDokument45 SeitenMMD Sizing PlantRisheet AgheraNoch keine Bewertungen

- 5 Đề Thi Giữa Học Kì 2 Môn Tiếng Anh 7 Ilearn Smart World Năm Học 2022-2023 (Có File Nghe)Dokument43 Seiten5 Đề Thi Giữa Học Kì 2 Môn Tiếng Anh 7 Ilearn Smart World Năm Học 2022-2023 (Có File Nghe)Dạy Kèm Quy Nhơn OfficialNoch keine Bewertungen

- Nebraska Driver's: Practice ExamDokument2 SeitenNebraska Driver's: Practice ExamAmela RamićNoch keine Bewertungen

- DREOrder Excluding DREMaryland March 52012Dokument37 SeitenDREOrder Excluding DREMaryland March 52012Paul B. KennedyNoch keine Bewertungen

- Hino 700 Rear Suspension.Dokument10 SeitenHino 700 Rear Suspension.Joki MarzukiNoch keine Bewertungen

- Owners Manual - DIO BS VIDokument120 SeitenOwners Manual - DIO BS VINPRNoch keine Bewertungen

- Chicago Pneumatic QRS 20-30 HP (2013 Brochure)Dokument6 SeitenChicago Pneumatic QRS 20-30 HP (2013 Brochure)Philip ShaverNoch keine Bewertungen

- Conveyor SafetyDokument4 SeitenConveyor SafetynathansolaiNoch keine Bewertungen

- Notes - ARFF Doc. 9137 Part 1Dokument5 SeitenNotes - ARFF Doc. 9137 Part 1Ralph Kevin CantonNoch keine Bewertungen

- Radio CodesDokument2 SeitenRadio CodesEzra Dimaano100% (4)

- Liens On CargosDokument2 SeitenLiens On CargosMaria Paula BlainNoch keine Bewertungen