Beruflich Dokumente

Kultur Dokumente

How To Select Gear Boxes

Hochgeladen von

prashantdhakateOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

How To Select Gear Boxes

Hochgeladen von

prashantdhakateCopyright:

Verfügbare Formate

White Paper

Buyers Guide on How to Specify Gearboxes

13 Points to consider so you get the gearbox you need

By the Engineering Staff of Rino Mechanical

www.rinomechanical.com

Buyers Guide on How to Specify Gearboxes

13 Points to consider so you get the gearbox you need

By the Engineering Staff of Rino Mechanical

www.rinomechanical.com

After many years of discussing gearboxes with engineers, we have developed a

questionnaire we use to ensure that we hav

efound al

lthe necessar

y det

ail

s ofone’

s

application. We use this even if the engineer specifies our standard part number. The

engineer may have picked the right gearbox for his application but:

1. Are there any lower cost alternatives to consider based on the specific application?

2. Is the gearbox appropriate for the operating environment?

3. Could a smaller gearbox be selected based on the duty cycle?

Some of these questions may seem simple but they allow us think about the application as a

complete system. The brief explanation of various gearbox sizing parameters below may help

you clarify your application before calling a gearbox manufacturer. With this information,

gearbox manufacturers can better assist you in selecting the correct gearbox for your

intended application.

1. Are you looking for standard, customized standard or complete custom?

This tells us quickly where we must focus. If you say“

Ineedast

andar

d,”t

henal

lot

her

avenues are eliminated. Some companies are willing to customize their standard

gearboxes, while others will not do any customization or even build a custom gearbox.

2. Main Specs

These are standard and need no clarification except for ratio and backlash.

a. Ratios are generally standard from 1:1 to 120:1 or higher depending upon the

gearbox. Many manufacturer’

s can supply custom ratios at initially higher prices

and when quantities are ordered they are usually priced similar to standard ratios.

Delivery will be a consideration when considering a custom ratio,

b. Most gearboxes have backlash ratings of less than 1 degree (60 arc-minutes).

.Af

Many are rated at half of a degree (30 arc-minutes) tert

hispoi

nt“

low backl

ash”

gearboxes come into play for positioning applications. Depending upon the

manufacturer and the gearbox type, low backlash can start at 10 arc-minutes and

can be 8 or 5 or even 1 arc-minute. When you get down to 1 arc-minute there may

not be many manufacturers that can supply such a high precision gearbox. This

may be a consideration.

3. Operation

a. 24 hour/day is listed but generally any 8 or 12 hours for 5 days a week is

considered full time operation. Maximum heat rise will occur well within 8 to 12

hours of operation time.

b. Duty cycle: There are many applications that have a low duty cycle which allows a

smaller gearbox to be used without degrading life or destroying gear teeth. Most

manufacturers rate the gearboxes for wear strength, giving a wide margin over

actual gear teeth ratings. So if a gearbox is used in a step and hold cycle with the

step cycle short and the hold time long (compared to the step cycle), it is possible

that a smaller gearbox or a slightly modified smaller gearbox can be used.

4. Temperature Range

Below -20 degree Celsius, special low temperature greases are required. Operating

temperature is required to ensure proper function.

5. Grease/Oil

This is related to temperature, but there may be other considerations. Gearboxes can

be supplied with vacuum rated grease, no grease at all, and oils for higher or lower

temperature operation.

6. Environment

This is one of the most important specification areas. Once we are outside the

standard factory environment every factor becomes important. Temperature is one

part of this equation. Ocean salt water applications and wash down applications can

be rated using the IP Code. IP codes specify how well sealed a gearbox is against

intrusion from foreign matter and covers particle sizes down to no dust entry allowed

(first digit 1-6) and water from drops to no water entry allowed (second digit 1-8). An

IP67 rating means no dust entry and no water entry at 1 meter submersion.

7. Input needs

These are straight forward except when a custom motor flange is required. It is very

important that you send the PDF of the motor or the direct web address of the data.

Manyt

imeswear

eunabl

etof

i

ndt

hepar

tnumberont

hemanuf

act

urer

’ssi

tef

ormany

reasons. By emailing the data you have, it saves time and allows us to get you an

answer quicker. Much time can be wasted when searching for a motor if a part number

is missing a letter or a dash.

8. Output needs

a. Bores: Basic items such as diameter, length of bore, and keyway are straight

forward, however, hex, square, D or splined bores can be done. But when it is

different than the standard bore it generally be will be more expensive in prototype

or small quantities.

b. Shafts: Usually the normal output shaft is round but can be supplied as a hex,

square, D or splined. Key slots need to be specifed.

c. Output Rotation: Most gearboxes with clockwise (CW) input give a counter-clock

wise (CCW) output rotation. This is what we call right hand rotation. A CW input

that produces a CW output rotation is called a left hand rotation gearbox. There are

also gearboxes with dual counter rotating output shafts.

9. Housing

a. If the gearbox is standard the material is known and is not in question. However if the

gearbox will be used in a wash down or a marine application, a more corrosion

resistant material such as stainless steel or aluminum with a hard anodized finish may

be required.

b. If you are looking for a customized standard gearbox, a drawing is required with

changes noted to ensure there are no misunderstandings between yourself and the

gearbox manufacturer.

c. In custom situations it is helpful to make clear any size restrictions to ensure the

manufactured gearbox fits appropriately into your system.

In most applications, conversations will be needed to clarify the specifications before a quote

is issued. Ask that all your specifications, written and verbal, be included in the formal quote

from the manufacturer(s). This will confirm that all quotes are the same so you can compare

them properly. Some manufacturers will supply a drawing or CAD.stp file for approval.

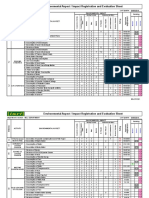

See next page for Buyers Guide on how to specify Gearboxes.

Buyers Guide on how to specify Gearboxes

Provided by Rino Mechanical Components - www.rinomechanical.com –1-888-260-7466

Are you looking for: Standard ___ Customized Standard ___Complete Custom ___

Gearbox type Right Angle __ In-line ___ Parallel ___

Bevel ___ Worm/Wheel ___ Planetary ___Other _______________________________________

Main Specs Ratio _______Input rpm _______ Output Torque _______ In-lbs (or Nm)

Backlash ___________

Operation 24 hour/ day ____ Duty cycle ____________________________________________

Temp. range _____to _____ Degrees __ C __ F Grease ___________ Oil _________________

Environment Standard Factory___ Outdoor______________________ Food grade _________

Wash down ______ Ocean commercial ______ Ocean Military ______ IP code _______

Mil Spec. __________________Other _______________________________________________

______________________________________________________________________________________

Input

Shaft: Diameter ________ Length _________ Single ___ Double ___

Bore: Diameter ________ Keyway___________________

Flange: NEMA ___________ Custom: Motor Mfg____________________________________

Motor Part Number______________________________________ or send PDF ____

Web site link for motor ___________________________________ or email link ____

___________________________________________________________________________________

Output

Shaft: Diameter _______ Length ________ Single ___ Double ___

Bore: Diameter ____ Keyway ______ Hex_____ Square_____ D___________

Spline __________

Output Rotation: RH (standard)___ LH ___ Counter Rotating ____

______________________________________________________________________________________

Housing Cast _________ Machined Alum. ________ Plastic__________Stainless ___________

Other _________________________________________________________________________

Size Restrictions________________________________________________________________

Changes from standard __________________________________________________________

Attach drawing ____ Other special needs __________________________________________

______________________________________________________________________________

Das könnte Ihnen auch gefallen

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualVon EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualBewertung: 3.5 von 5 Sternen3.5/5 (2)

- Head PortingDokument9 SeitenHead PortingJo M. Chang100% (3)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualVon EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualNoch keine Bewertungen

- DIY - Basic Cylinder Head Porting - Standard Abrasives Motor Sports PDFDokument10 SeitenDIY - Basic Cylinder Head Porting - Standard Abrasives Motor Sports PDFkristof2273Noch keine Bewertungen

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Von EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Bewertung: 5 von 5 Sternen5/5 (1)

- Engine Rebuild Block PrepDokument13 SeitenEngine Rebuild Block Prepmike9013xNoch keine Bewertungen

- Major Process Equipment Maintenance and RepairVon EverandMajor Process Equipment Maintenance and RepairBewertung: 4 von 5 Sternen4/5 (4)

- Standard Abrasives - DIY Cylinder Head Porting Guide PDFDokument14 SeitenStandard Abrasives - DIY Cylinder Head Porting Guide PDFkristof2273100% (1)

- Measuring and Marking Metals for Home Machinists: Accurate Techniques for the Small ShopVon EverandMeasuring and Marking Metals for Home Machinists: Accurate Techniques for the Small ShopBewertung: 4 von 5 Sternen4/5 (1)

- Acople Falk-WrapflexDokument16 SeitenAcople Falk-Wrapflexhenkis73Noch keine Bewertungen

- How to Rebuild & Modify Rochester Quadrajet CarburetorsVon EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsBewertung: 5 von 5 Sternen5/5 (2)

- Appraising A Used Dozer: An Earthmover & Civil Contractor Special FeatureDokument12 SeitenAppraising A Used Dozer: An Earthmover & Civil Contractor Special Featureminingnova2100% (2)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreVon EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreBewertung: 4.5 von 5 Sternen4.5/5 (11)

- Important Factors Rotary Indexer: To Consider When Choosing ADokument5 SeitenImportant Factors Rotary Indexer: To Consider When Choosing AManoj TiwariNoch keine Bewertungen

- High-Performance GM LS-Series Cylinder Head GuideVon EverandHigh-Performance GM LS-Series Cylinder Head GuideBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Feeds SpeedsDokument4 SeitenFeeds SpeedschrisNoch keine Bewertungen

- Lesson Fifteen TextDokument4 SeitenLesson Fifteen TextVignesh WaranNoch keine Bewertungen

- Engine - Blower Hardware - All 110101Dokument58 SeitenEngine - Blower Hardware - All 110101Didier Van Der LeeNoch keine Bewertungen

- Motor Quality Guide Your Questions AnsweredDokument12 SeitenMotor Quality Guide Your Questions AnsweredRyan Jay100% (1)

- 6 Centrifuge and Belt Press MaintenanceDokument21 Seiten6 Centrifuge and Belt Press MaintenanceSchwanStyNoch keine Bewertungen

- Soy Automotive Technology Midterm ExamDokument5 SeitenSoy Automotive Technology Midterm ExamJOHN STEVEN SOYNoch keine Bewertungen

- Everything You Need To Know About Flatteners and Levelers For Coil ProcessingPart 4Dokument7 SeitenEverything You Need To Know About Flatteners and Levelers For Coil ProcessingPart 4CarlosNoch keine Bewertungen

- Lovejoy CouplingDokument13 SeitenLovejoy Couplingsandulupeni100% (1)

- Details of Sugarcane Juice Machine With Prices in Rs.Dokument8 SeitenDetails of Sugarcane Juice Machine With Prices in Rs.mrmrschandoo100% (1)

- Gerotor Selection Pump DesignDokument28 SeitenGerotor Selection Pump Designkanteron6443100% (1)

- Everything You Need To Know About Flatteners and Levelers For Coil Processing-Part 4 - The FabricatorDokument7 SeitenEverything You Need To Know About Flatteners and Levelers For Coil Processing-Part 4 - The FabricatorSIMONENoch keine Bewertungen

- BSmith 356registry JetSettingDokument3 SeitenBSmith 356registry JetSettingAlvaro MontesinosNoch keine Bewertungen

- Goulds 3393 ReaderDokument12 SeitenGoulds 3393 ReaderJuan Luis RodrguezNoch keine Bewertungen

- High-Speed Milling of Hard MetalsDokument4 SeitenHigh-Speed Milling of Hard Metalsbogdangabriel1985Noch keine Bewertungen

- Falk Coupling SGDokument16 SeitenFalk Coupling SGJorge Ernesto PinzonNoch keine Bewertungen

- Seleccion y Diseño GerotorDokument28 SeitenSeleccion y Diseño GerotoremersonNoch keine Bewertungen

- Vehicle MaintenanceDokument89 SeitenVehicle Maintenancejalda srikaranNoch keine Bewertungen

- Engine Tuning Stage 1: ExhaustDokument8 SeitenEngine Tuning Stage 1: ExhaustJuan PerezNoch keine Bewertungen

- Everything You Need To Know About Flatteners and Levelers For Coil Processing - Part IVDokument7 SeitenEverything You Need To Know About Flatteners and Levelers For Coil Processing - Part IVertuokumusNoch keine Bewertungen

- Tarex Jaw Crusher Part Manual PDFDokument333 SeitenTarex Jaw Crusher Part Manual PDFKAMAL SINGH100% (3)

- Gearbox 101 EbookDokument20 SeitenGearbox 101 EbookBubai111Noch keine Bewertungen

- Pinto+Doc Med+ResDokument20 SeitenPinto+Doc Med+ResSirRD80% (5)

- Perhitungan Gearbox Part-1 PDFDokument32 SeitenPerhitungan Gearbox Part-1 PDFHermawan SuwantoNoch keine Bewertungen

- Basics of Gearbox Selection: Common Aspects of Sizing ApplicationsDokument3 SeitenBasics of Gearbox Selection: Common Aspects of Sizing ApplicationsSamik MukherjeeNoch keine Bewertungen

- Ritchinavigation ServicemanualDokument108 SeitenRitchinavigation ServicemanualAlejandro ErroNoch keine Bewertungen

- Design (II) 2Dokument49 SeitenDesign (II) 2khudhayer1970Noch keine Bewertungen

- A Beginners Guide To Progressive Cavity PumpsDokument4 SeitenA Beginners Guide To Progressive Cavity PumpsGaurav SinghNoch keine Bewertungen

- ManualDokument8 SeitenManualSanchai ProgaeewNoch keine Bewertungen

- 30 March 2023 New Engine Builders GuideDokument52 Seiten30 March 2023 New Engine Builders Guideapi-536926373100% (1)

- 0106-7 Section C-DDokument129 Seiten0106-7 Section C-DPartsGopher.comNoch keine Bewertungen

- Why Universal Motors Turn On The Appliance IndustryDokument4 SeitenWhy Universal Motors Turn On The Appliance IndustrymcelebimNoch keine Bewertungen

- Nol Cat 09060Dokument60 SeitenNol Cat 09060Lewis McPhearsonNoch keine Bewertungen

- Basic Techniques for Polishing Molds 銅作品Dokument32 SeitenBasic Techniques for Polishing Molds 銅作品DiehardNoch keine Bewertungen

- Here Is A Program and Reamer/ Cutting Fluid Recommendation That Has Saved Companies Thousands of DollarsDokument5 SeitenHere Is A Program and Reamer/ Cutting Fluid Recommendation That Has Saved Companies Thousands of DollarsDean MillerNoch keine Bewertungen

- Vallorbs Guide Cut Vs Rolled ThreadsDokument3 SeitenVallorbs Guide Cut Vs Rolled ThreadsOrlando AriasNoch keine Bewertungen

- Efr Turbo Technical BriefDokument126 SeitenEfr Turbo Technical BriefTM125Noch keine Bewertungen

- Management Guide To AlignmentDokument3 SeitenManagement Guide To Alignmentjonalthan1987Noch keine Bewertungen

- Flow Meter Fillrate 900 Series PDFDokument5 SeitenFlow Meter Fillrate 900 Series PDFSatrio Ongis NadeNoch keine Bewertungen

- Gear Torque RatingsDokument8 SeitenGear Torque RatingsMNMNoch keine Bewertungen

- Modifying Servos For Continuous RotationDokument28 SeitenModifying Servos For Continuous RotationDarko AlavanjaNoch keine Bewertungen

- 811 BroDokument20 Seiten811 BrorodolfocordovaperezNoch keine Bewertungen

- Faure Herman TurbineDokument3 SeitenFaure Herman TurbinedidikosanNoch keine Bewertungen

- Kiner GoDokument5 SeitenKiner GoJorge Rodriguez Mendivil0% (1)

- Technical Specification For Energy Efficient Pumpsets: Dakshin Haryana Bijli Vitran Nigam LimitedDokument8 SeitenTechnical Specification For Energy Efficient Pumpsets: Dakshin Haryana Bijli Vitran Nigam LimitednatanNoch keine Bewertungen

- Brake Lathe HUNTER 3937TDokument8 SeitenBrake Lathe HUNTER 3937TjifijifiNoch keine Bewertungen

- CDI T2 10 (Adv Gen) Integrated Project Police Vehicle Student Version....Dokument6 SeitenCDI T2 10 (Adv Gen) Integrated Project Police Vehicle Student Version....aboubakr soultanNoch keine Bewertungen

- 14 Lubricator SDokument26 Seiten14 Lubricator SmaocaleirlNoch keine Bewertungen

- Bendy PlywoodDokument1 SeiteBendy PlywoodKesavan DhuraiNoch keine Bewertungen

- Kluber 4 UH1 N en enDokument8 SeitenKluber 4 UH1 N en enVladimir GonzalezNoch keine Bewertungen

- The Impact of Industrialisation and Development of Modern ArchitectureDokument5 SeitenThe Impact of Industrialisation and Development of Modern ArchitectureAnusha Singh ChauhanNoch keine Bewertungen

- Analysis of Geopolymer Concrete ColumnsDokument10 SeitenAnalysis of Geopolymer Concrete ColumnsRodick AndyNoch keine Bewertungen

- Hilux Brochure PDFDokument2 SeitenHilux Brochure PDFVincent DavinchiNoch keine Bewertungen

- (Abstract) Automatic Railway Gate ControllingDokument4 Seiten(Abstract) Automatic Railway Gate ControllingNikhith ReddyNoch keine Bewertungen

- Panelboard and Switchboard PDFDokument32 SeitenPanelboard and Switchboard PDFGerardo M. James BravoNoch keine Bewertungen

- CRR40 300 ThermokingDokument53 SeitenCRR40 300 Thermokingrazvanmstancescu100% (1)

- AICTE Approved Institutes Dec 19 2012Dokument789 SeitenAICTE Approved Institutes Dec 19 2012dipakdks420Noch keine Bewertungen

- AgisDokument20 SeitenAgisFabian Andres Blanco GNoch keine Bewertungen

- TasksDokument2 SeitenTasksParag PatilNoch keine Bewertungen

- FAII Biogas Flare - ENDokument2 SeitenFAII Biogas Flare - ENMariusCapraNoch keine Bewertungen

- Expansion Joints DataDokument52 SeitenExpansion Joints DatamehdiNoch keine Bewertungen

- ECSCADA Presentation NRB 120816Dokument36 SeitenECSCADA Presentation NRB 120816Mohit Sharma100% (1)

- Best Practices in Capital Equipment CommissioningDokument8 SeitenBest Practices in Capital Equipment CommissioningBramJanssen76Noch keine Bewertungen

- Under Water WeldingDokument16 SeitenUnder Water Weldingsyed nadheemNoch keine Bewertungen

- Environmental Aspect / Impact Registration and Evaluation SheetDokument3 SeitenEnvironmental Aspect / Impact Registration and Evaluation SheetrewrtegamingNoch keine Bewertungen

- List of PlatesDokument13 SeitenList of PlatesPSGNoch keine Bewertungen

- Veetagrout V71 Instruction Manual - New Format V 2Dokument3 SeitenVeetagrout V71 Instruction Manual - New Format V 2Alirio Ramirez VelasquezNoch keine Bewertungen

- 3 Engine FundamentalsDokument2 Seiten3 Engine FundamentalsAkshay PatelNoch keine Bewertungen

- Catalogo XMDokument42 SeitenCatalogo XMAlejandro Saco HerreraNoch keine Bewertungen

- Clyde Bergemann Presentation MD PUMPDokument37 SeitenClyde Bergemann Presentation MD PUMPTan Nguyen Huu100% (1)

- Exhibition Material - Smart Energy ICT Solution Cases - V3.0Dokument7 SeitenExhibition Material - Smart Energy ICT Solution Cases - V3.0Ahmed HadhoudNoch keine Bewertungen

- ARCH THESIS (Chapter 1)Dokument10 SeitenARCH THESIS (Chapter 1)Clifford Jan Tabada AtigNoch keine Bewertungen

- Fur An Flex 6 PP BrochureDokument2 SeitenFur An Flex 6 PP Brochureseptimiu89Noch keine Bewertungen

- Cycle Time of Transit Mixer: DateDokument3 SeitenCycle Time of Transit Mixer: DateAtulJainNoch keine Bewertungen

- Sitex CP Series enDokument2 SeitenSitex CP Series enAlftigre TovarNoch keine Bewertungen

- MUSEUM MICROCLIMATES Trends in Microclimate Control of Museum Display CasesDokument10 SeitenMUSEUM MICROCLIMATES Trends in Microclimate Control of Museum Display CasesManenMidoryNoch keine Bewertungen

- Beginning AutoCAD® 2022 Exercise Workbook: For Windows®Von EverandBeginning AutoCAD® 2022 Exercise Workbook: For Windows®Noch keine Bewertungen

- Autodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)Von EverandAutodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)Bewertung: 5 von 5 Sternen5/5 (2)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchVon EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchBewertung: 4 von 5 Sternen4/5 (10)

- From Vision to Version - Step by step guide for crafting and aligning your product vision, strategy and roadmap: Strategy Framework for Digital Product Management RockstarsVon EverandFrom Vision to Version - Step by step guide for crafting and aligning your product vision, strategy and roadmap: Strategy Framework for Digital Product Management RockstarsNoch keine Bewertungen

- AutoCAD 2010 Tutorial Series: Drawing Dimensions, Elevations and SectionsVon EverandAutoCAD 2010 Tutorial Series: Drawing Dimensions, Elevations and SectionsNoch keine Bewertungen

- SolidWorks 2015 Learn by doing-Part 1Von EverandSolidWorks 2015 Learn by doing-Part 1Bewertung: 4.5 von 5 Sternen4.5/5 (11)