Beruflich Dokumente

Kultur Dokumente

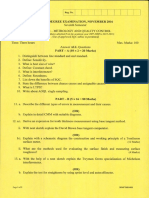

ME1037 - 7 - SEM Nov 2016

Hochgeladen von

Deepak MisraOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ME1037 - 7 - SEM Nov 2016

Hochgeladen von

Deepak MisraCopyright:

Verfügbare Formate

'

Reg. No.

b. Write short note on following

(i) Work volume and precision of robot B.Tech. DEGREE EXAMINATION, NOVEMBER 2016

(ii) Weight carrying capacity of robot Seventh Semester

(iii) Types of drive systems in robot

ME I 037 _ COMPUTER AIDED MANUFACTURING

32. a. Explain the inputs to the Material Requirement Planning (MRP) and how MRP works in (For the candidates admined during the academic year 2013 2014 and 201a -2015)

detail and benefits of MRP. Note:

(i) Part - A should be answered in OMR sheet within first 45 minutes and OMR sheet should be handed

(oR) over to hall invigilator at the end of 45s minute.

b. Explain the concept of and with the case study in (Just in Time) JIT and its benefits of (ii) Part - B and Part - C should be answered in answer booklet.

implementation of IIT in a companies.

Time: Three Hours Ma:<. Marks: 100

*rt:lri* PART-A(20x 1=20Marks)

Answer ALL Questions

l. A manufactwing system organized to meet the specific customer requirement is called

(A) Job order production @) Batch production

(C) Flow production (D) Mass production

2. Group technolory brings together and organises

(A) Pafis and simulation analysis (B) Documentation and analysis

(C) Automation and tool production (D) Common parts, problem and tasks

3. CIM technolory is a ultimate automated manufacturing methodolory, which is fully

automated as to achieve

product

(A) Faster and cheaper (B) Greater coordination among departments

(C) lnformation process bottom to top (D) Design analysis and testing

and top to bottom

4. Machining centre is a

(A) Automatic tool changing unit (B) Group of automatic machine tools

(C) Next logical steps beyond NC (D) NC machine tool

(numeric al controlled machine)

5. CNC contouring is an example of

(A) Continuous path positioning (B) Point to point positioning

(C) Absolutepositioning (D) Incremental positioning

6. Which of the following is the position feedback device on NC machine?

(A) Shaftencoder (B) Strain gauge

(C) Revolver (D) Light dependent resistor

7. Recirculating bull screw are used

(A) Reduce the friction and accuracy (B) Increase the load

(C) lmprove the desigr (D) Replace the lead screw

8. Advantage of automatic tool change

(A) Increase accuracy (B) knprove the repeatability

(C) Simultaneous operations (D) Improve the speed and torque

Page 4 of4 I5NA7ME1037 Page I of ,l rSNATMEla)37

20. Principle (or) philosophy of IIT is

9. Automation is need for (B) Zero inventory and less set up cost

(A) Reduce the workload (B) Improve the production and reduce lead (A) More lead time

(D) Fixed product

(C) gign productivity and more in work @) Setup cost is more

(C) Loss of customer satisfaction in process inventory

10. Automated assemblY is helPful

(A) Replace the manual loading (B) Improve the delivery and customer

(C) Implement the FMS system (D) To improve the quantity PART-B(5x4=20Marks)

Aaswer ANY FM Questions

11. production Flow Anatysis (PFA) is a method of identifying part families that uses data from f[m.

(A) Engineering drawings (B) Route sheets 21. Draw a information processing cycle in a typical manufacturing

(C) Production schedule and bill of (D) From past forecasting

materials ZZ. Explain the types of layout configurations commonly found in flexible manufacturing

systems.

12. Design criteria for automated assembly

(A) Simplification (B) Non Poka-yoke 23. Explain the various CNC control features with neat sketch and advantages of CNC'

(C) Non modular products design (D) Simplify desigrr and reduce the number of

part 24. Explain the any five automation strategies to improve to productivity.

,< Explain the important categories of automated storage and retieval system.

13. The material handling function is to

(A) Supply tool and scheduling (B) To move raw materials and work in process

(C) (D) Shop floor control 26. Draw the neat sketch ofany five physical configuration ofRobot'

Replace the human labour

)'l List out the types and benefits of computer aided production planning.

14. Function of vehicle guidance and routing

(A) Remote scanning (B) Traffic control and safety

(C) Central process control (D) Zone blocking PART C (5 x 12 :60 Marks)

-

Answer ALL Questions

15. Robots are specified by

(A) Grip pressure (B) Most flexible in all asPects 28. a. What is GT? Explain any one part classification and coding system in detail'

(C) Pay load and axis of movement (D) Overall dimension

(oR)

16. Robot motion b. With a neat diagram, explain the CIM wheel and also list out benefits of CIM its principle.

(A) lmitate human motion (B) Is same for all robots

(C) Depend on drives used in robot (D) In not dependent on robot structure 29. a. Differentiate between DNC and adaptive control. Explain any one type of adaptive control

system with neat sketch.

17. Benefits of computer aided production planning is to

(A) Improve the labour involvement (B) Routing and costing ofjob (oR)

(D) Reduce inventory and improve b. Write short note on following (any one with neat sketch)

iCi Foiecasting and expeditinC the

(i) Recirculating ball screw

productivitY

(ii) Spindle and feed drive

18. Kanban is Japanese term indicating (iii) Feedback devices

(A) A method of line balancing (B) Information for production and with&awal (iv) Automatic tool changer

(C) Prioritydispatching (D) Line time emploYment

30. a. Explain need of automation and levels of automation and benefits of automation in detail-

19. In an MRP system, component depend is

(A) Forecasted (B) Established by the master production (oR)

schedule b. With neat sketch, explain the elements of the parts delivery system in detail.

(C) Calculated by the MRP system from (D) Ignored

31. a. Explain the types of automated guided vehicle system and their application in detail.

the master production schedule

(oR)

1SNA7ME1037

l5NA7MEr037 Page 3 ofd

Pagc 2 of4

Das könnte Ihnen auch gefallen

- Of (I) (Ii) : Bills. For MAYDokument2 SeitenOf (I) (Ii) : Bills. For MAYJerry SinghNoch keine Bewertungen

- Intermediate Examination: Suggested Answers To QuestionsDokument10 SeitenIntermediate Examination: Suggested Answers To Questionskapilg0510Noch keine Bewertungen

- Intermediate Examination: Suggested Answers To QuestionsDokument15 SeitenIntermediate Examination: Suggested Answers To QuestionsKirthika GunasekaranNoch keine Bewertungen

- Please Check Whether You Have Got The Right Question Paper.Dokument2 SeitenPlease Check Whether You Have Got The Right Question Paper.Rajvardhan ShindeNoch keine Bewertungen

- Mechanical Engineering Department December 2019 Djf5042 - Industrial Robotics (End of Chapter 1)Dokument3 SeitenMechanical Engineering Department December 2019 Djf5042 - Industrial Robotics (End of Chapter 1)YING AEISYAHNoch keine Bewertungen

- 15it342e 5 Sem PDFDokument2 Seiten15it342e 5 Sem PDFAshutosh SahooNoch keine Bewertungen

- Btech Me 5 Sem Industrial Engineering Kme503 2023Dokument3 SeitenBtech Me 5 Sem Industrial Engineering Kme503 2023vikashgupta4093Noch keine Bewertungen

- Paper9 Set2 AnsDokument17 SeitenPaper9 Set2 Ansbatmam7589Noch keine Bewertungen

- BCA 5th Sem Dec 2017Dokument7 SeitenBCA 5th Sem Dec 2017lolol lololNoch keine Bewertungen

- II B. Tech II Semester Regular Examinations, April - 2018 Software EngineeringDokument4 SeitenII B. Tech II Semester Regular Examinations, April - 2018 Software EngineeringPAVANNoch keine Bewertungen

- WWW - Manaresults.Co - In: III B. Tech II Semester Regular and Supplementary Examinations, April - 2018 Software EngineeringDokument4 SeitenWWW - Manaresults.Co - In: III B. Tech II Semester Regular and Supplementary Examinations, April - 2018 Software EngineeringAnandKumarNoch keine Bewertungen

- WWW - Manaresults.co - In: Software EngineeringDokument1 SeiteWWW - Manaresults.co - In: Software EngineeringVignesh DhevNoch keine Bewertungen

- WWW - Manaresults.Co - In: Set No. 1Dokument1 SeiteWWW - Manaresults.Co - In: Set No. 1Natarajan NatarajNoch keine Bewertungen

- Software Engineering May18Dokument2 SeitenSoftware Engineering May18Tanisha PoojariNoch keine Bewertungen

- WWW Manaresults Co inDokument4 SeitenWWW Manaresults Co insriniefsNoch keine Bewertungen

- WWW Manaresults Co inDokument4 SeitenWWW Manaresults Co insriniefsNoch keine Bewertungen

- Imp Topics & Pre Q Papers - CAD CAMDokument21 SeitenImp Topics & Pre Q Papers - CAD CAMramsicon1Noch keine Bewertungen

- Paper 13 Operations and Project Management & Control June 2003Dokument4 SeitenPaper 13 Operations and Project Management & Control June 2003api-19931402Noch keine Bewertungen

- Technology, Tbengal: Maulana Abul Kalam Azad University OFDokument7 SeitenTechnology, Tbengal: Maulana Abul Kalam Azad University OFBikash ChoudhuriNoch keine Bewertungen

- Paper 1Dokument4 SeitenPaper 1guna gouthamNoch keine Bewertungen

- Dec - 2006Dokument7 SeitenDec - 2006api-19931402Noch keine Bewertungen

- Cad Cam Previous Paper JntukDokument4 SeitenCad Cam Previous Paper JntukMD KHALEELNoch keine Bewertungen

- Model Test Paper - 1 CMA Inter Group-II Paper - 9 Operations Management & Strategic Management Section - A (Operations Management) 1Dokument17 SeitenModel Test Paper - 1 CMA Inter Group-II Paper - 9 Operations Management & Strategic Management Section - A (Operations Management) 1Rajesh ShuklaNoch keine Bewertungen

- 5th Sem Mid B.B.A. 2018Dokument19 Seiten5th Sem Mid B.B.A. 2018Jayant JawlaNoch keine Bewertungen

- BTM3514 Computer Integrated Manufac S1 0119 PDFDokument10 SeitenBTM3514 Computer Integrated Manufac S1 0119 PDFKhairul AnamNoch keine Bewertungen

- Osm June 19Dokument19 SeitenOsm June 19Sannu VijayeendraNoch keine Bewertungen

- Automation Objective QuestionsDokument10 SeitenAutomation Objective QuestionsSrinivasaReddyM100% (2)

- 117BD112018Dokument2 Seiten117BD112018skumarNoch keine Bewertungen

- Term II Test 29 October 2013Dokument3 SeitenTerm II Test 29 October 2013PETERNoch keine Bewertungen

- 2 Bft-Vi - Appc - QPDokument5 Seiten2 Bft-Vi - Appc - QPYuvraj PahujaNoch keine Bewertungen

- 223 TOP Industrial Engineering - Mechanical Engineering Multiple Choice Questions and Answers - MCQs Preparation For Engineering Competitive ExamsDokument20 Seiten223 TOP Industrial Engineering - Mechanical Engineering Multiple Choice Questions and Answers - MCQs Preparation For Engineering Competitive ExamsSivasutha007Noch keine Bewertungen

- Nov Dec 2016 PPC Question Paper PDFDokument21 SeitenNov Dec 2016 PPC Question Paper PDFrajNoch keine Bewertungen

- University of Mauritius Faculty of EngineeringDokument5 SeitenUniversity of Mauritius Faculty of Engineeringmy pcNoch keine Bewertungen

- Illlllllllllilllllllllllllllll (Pages 2) 7586Dokument2 SeitenIlllllllllllilllllllllllllllll (Pages 2) 7586tamilmani2020Noch keine Bewertungen

- SAP S4HANA DTS Practice QuestionsDokument11 SeitenSAP S4HANA DTS Practice QuestionsCédric SinclairNoch keine Bewertungen

- IE UNIVERSITY MCQ MergedDokument16 SeitenIE UNIVERSITY MCQ MergedChota ChatriNoch keine Bewertungen

- Revisionary Test Paper: Group IiDokument38 SeitenRevisionary Test Paper: Group Iianto.a.fNoch keine Bewertungen

- Fourth Semester Examination - 2010 System ProgrammingDokument7 SeitenFourth Semester Examination - 2010 System ProgrammingCasper IvanovitNoch keine Bewertungen

- CIMDokument8 SeitenCIMSree Ranjani GovardhanNoch keine Bewertungen

- CAM Question Paper AktuDokument2 SeitenCAM Question Paper AktuAshutosh KumarNoch keine Bewertungen

- Project? Key Project. (8,8) : Unit-IDokument11 SeitenProject? Key Project. (8,8) : Unit-ImohitNoch keine Bewertungen

- MPMC Previous QP 2018Dokument4 SeitenMPMC Previous QP 2018PrasannaKumar KaraNamNoch keine Bewertungen

- WWW - Manaresults.Co - in WWW - Manaresults.Co - In: II B. Tech II Semester Model Question Paper, March - 2018 Java ProgrammingDokument4 SeitenWWW - Manaresults.Co - in WWW - Manaresults.Co - In: II B. Tech II Semester Model Question Paper, March - 2018 Java ProgrammingSivaramakrishna Markandeya GuptaNoch keine Bewertungen

- T.E (2008-2012 Pattern)Dokument298 SeitenT.E (2008-2012 Pattern)Sai Tejesh Reddy GurijalaNoch keine Bewertungen

- CADCAM Question Paper 1Dokument2 SeitenCADCAM Question Paper 1RameshNoch keine Bewertungen

- I TestDokument2 SeitenI TestEllur AnandNoch keine Bewertungen

- Cim Model QBDokument3 SeitenCim Model QBSoorya NarayananNoch keine Bewertungen

- Answer The Following Any TWO Questions: I. Choose The Correct AlternativeDokument2 SeitenAnswer The Following Any TWO Questions: I. Choose The Correct Alternativemba trritNoch keine Bewertungen

- Computer Aided Manufacturing (19PME103: National Institute of Technologyandhra PradeshDokument2 SeitenComputer Aided Manufacturing (19PME103: National Institute of Technologyandhra PradeshBabuRaoThellaNoch keine Bewertungen

- Chadalawada Ramanamma Engineering College: Time: 3 Hours Max Marks: 70Dokument2 SeitenChadalawada Ramanamma Engineering College: Time: 3 Hours Max Marks: 70BADAS POOJANoch keine Bewertungen

- CAM - Minor 1Dokument2 SeitenCAM - Minor 1BabuRaoThellaNoch keine Bewertungen

- B.Tech. EXAMINATION, May 2017: No. of Printed Pages: 03 Roll No. ......................Dokument2 SeitenB.Tech. EXAMINATION, May 2017: No. of Printed Pages: 03 Roll No. ......................Neil DahiyaNoch keine Bewertungen

- 2018 CXC Indust Techn Core-3 PDFDokument10 Seiten2018 CXC Indust Techn Core-3 PDFDonald SanicharaNoch keine Bewertungen

- (M19CAD1102) I M. Tech I Semester (R19) Regular ExaminationsDokument2 Seiten(M19CAD1102) I M. Tech I Semester (R19) Regular Examinationsraja raoNoch keine Bewertungen

- Management Programme Term-End Examination June, 2OO8Dokument8 SeitenManagement Programme Term-End Examination June, 2OO8DipeshNoch keine Bewertungen

- Nov Dec 2016 PPC Question PaperDokument21 SeitenNov Dec 2016 PPC Question PapersathyadallyNoch keine Bewertungen

- E-1885 D.C.A. (II Sem) (New Course) Gui-Programming in Visual Basic (Dca-105)Dokument1 SeiteE-1885 D.C.A. (II Sem) (New Course) Gui-Programming in Visual Basic (Dca-105)sdfosdofiojfNoch keine Bewertungen

- Se Mid Question PaperDokument3 SeitenSe Mid Question Papervarsha reddyNoch keine Bewertungen

- Cad Cam QBDokument10 SeitenCad Cam QBhari0118Noch keine Bewertungen

- Mechanical Solar Tracker - BOMDokument7 SeitenMechanical Solar Tracker - BOMDeepak MisraNoch keine Bewertungen

- Safety Considerations in RoboticsDokument12 SeitenSafety Considerations in RoboticsDeepak Misra0% (1)

- 17PME328E: Process Planning and Cost EstimationDokument48 Seiten17PME328E: Process Planning and Cost EstimationDeepak MisraNoch keine Bewertungen

- 5.et Unit 1Dokument20 Seiten5.et Unit 1Deepak MisraNoch keine Bewertungen

- Transforms and PdeDokument143 SeitenTransforms and PdeDeepak MisraNoch keine Bewertungen

- 17PME328E: Process Planning and Cost EstimationDokument127 Seiten17PME328E: Process Planning and Cost EstimationDeepak MisraNoch keine Bewertungen

- MICROBOTDokument8 SeitenMICROBOTDeepak MisraNoch keine Bewertungen

- Stanly Senivasagam (Pa1711002010018), Gowri Shankar (PA1711002010022) ", Who Carried Out The Project Work and We Go HomeDokument1 SeiteStanly Senivasagam (Pa1711002010018), Gowri Shankar (PA1711002010022) ", Who Carried Out The Project Work and We Go HomeDeepak MisraNoch keine Bewertungen

- Stanly Senivasagam (Pa1711002010018), Gowri Shankar (PA1711002010022) ", Who Carried Out The Project WorkDokument1 SeiteStanly Senivasagam (Pa1711002010018), Gowri Shankar (PA1711002010022) ", Who Carried Out The Project WorkDeepak MisraNoch keine Bewertungen

- DFMEADokument2 SeitenDFMEADeepak MisraNoch keine Bewertungen

- Ex No 9Dokument4 SeitenEx No 9Deepak MisraNoch keine Bewertungen

- CMM Notes For ParttimeDokument3 SeitenCMM Notes For ParttimeDeepak MisraNoch keine Bewertungen

- Ex. No.: Date: Identification of Light Metal AlloysDokument7 SeitenEx. No.: Date: Identification of Light Metal AlloysDeepak MisraNoch keine Bewertungen

- Ex. No.: Date: Identification of Copper AlloysDokument7 SeitenEx. No.: Date: Identification of Copper AlloysDeepak MisraNoch keine Bewertungen

- Unit 2 Screw Thread - Gear Elements - Surface FinishDokument53 SeitenUnit 2 Screw Thread - Gear Elements - Surface FinishDeepak MisraNoch keine Bewertungen

- Tuesday, November 7, 2017 6:21 PM: BUS Page 1Dokument2 SeitenTuesday, November 7, 2017 6:21 PM: BUS Page 1Deepak MisraNoch keine Bewertungen

- Unit 2 MFTDokument43 SeitenUnit 2 MFTDeepak MisraNoch keine Bewertungen

- Metrology and Quality ControlDokument13 SeitenMetrology and Quality ControlDeepak MisraNoch keine Bewertungen

- 17Pme202L - Manufacturing Process Laboratory: Semester: IDokument3 Seiten17Pme202L - Manufacturing Process Laboratory: Semester: IDeepak MisraNoch keine Bewertungen

- Of In::150 (PT) Degree Examination, MayDokument2 SeitenOf In::150 (PT) Degree Examination, MayDeepak MisraNoch keine Bewertungen

- PME403 6 Sem2018Dokument1 SeitePME403 6 Sem2018Deepak MisraNoch keine Bewertungen

- Coordinate Measuring Machine-6840Dokument7 SeitenCoordinate Measuring Machine-6840Deepak MisraNoch keine Bewertungen

- (Or) o Offive.: Examination, MayDokument2 Seiten(Or) o Offive.: Examination, MayDeepak MisraNoch keine Bewertungen

- ME1035 - 6 - Sem (1) 2018RDokument2 SeitenME1035 - 6 - Sem (1) 2018RDeepak MisraNoch keine Bewertungen

- PME304 - 5 - SEM Dec 2016Dokument1 SeitePME304 - 5 - SEM Dec 2016Deepak MisraNoch keine Bewertungen

- Examination,: Degree NoyemberDokument2 SeitenExamination,: Degree NoyemberDeepak MisraNoch keine Bewertungen

- (I) MR (Ii) Of: N (, TheDokument2 Seiten(I) MR (Ii) Of: N (, TheDeepak MisraNoch keine Bewertungen

- Unit 4 Jet Propulsion PDFDokument34 SeitenUnit 4 Jet Propulsion PDFDeepak MisraNoch keine Bewertungen

- (I) (Ii) (Iii) (R) (Ii) : KLKGK, MayDokument2 Seiten(I) (Ii) (Iii) (R) (Ii) : KLKGK, MayDeepak MisraNoch keine Bewertungen

- PME304 - 5 - Sem June 2017 PDFDokument1 SeitePME304 - 5 - Sem June 2017 PDFDeepak MisraNoch keine Bewertungen

- Production Operation Management SCDL AssignmentDokument26 SeitenProduction Operation Management SCDL Assignmentsaurabh303100% (3)

- OM Lecture 4 (MRP)Dokument83 SeitenOM Lecture 4 (MRP)kalineczka.rausNoch keine Bewertungen

- Chapter 23Dokument33 SeitenChapter 23Yashvardhan SinghNoch keine Bewertungen

- MRP V4 PDFDokument32 SeitenMRP V4 PDFRx DentviewNoch keine Bewertungen

- Total Sap ReportsDokument313 SeitenTotal Sap ReportsRickNoch keine Bewertungen

- Variables and QuestionnaireDokument7 SeitenVariables and QuestionnaireMadiha KhanNoch keine Bewertungen

- 1.the MRP II HierarchyDokument17 Seiten1.the MRP II HierarchyPrasath KmkNoch keine Bewertungen

- Batch Determination For Sales Order DeliveryDokument25 SeitenBatch Determination For Sales Order DeliveryKrishnavel R100% (2)

- Assignment Case Study SGHE5013Dokument27 SeitenAssignment Case Study SGHE5013ctkhadeejaNoch keine Bewertungen

- Operations Management - Problems & SolutionsDokument3 SeitenOperations Management - Problems & SolutionsMaidhily Govind82% (11)

- EPRDokument62 SeitenEPRrkrawczysribedNoch keine Bewertungen

- ERP - Past Present and FutureDokument17 SeitenERP - Past Present and Futurekrati12Noch keine Bewertungen

- Inventory Management 2016 UpdatedDokument91 SeitenInventory Management 2016 UpdatedAnonymous u0OHlnzNoch keine Bewertungen

- Computer Integrated Manufacturing: Computerized Manufacturing Planning SystemsDokument40 SeitenComputer Integrated Manufacturing: Computerized Manufacturing Planning SystemsMuhd Sabry AnwarNoch keine Bewertungen

- BYD of ChinaDokument20 SeitenBYD of ChinapthavNoch keine Bewertungen

- 2008 CPIM Exam Content ManualDokument58 Seiten2008 CPIM Exam Content ManualelmozzNoch keine Bewertungen

- E - 20230914 MRP Fields Simplification in S4 HANADokument3 SeitenE - 20230914 MRP Fields Simplification in S4 HANAPOORNA SOMAYAJULANoch keine Bewertungen

- SAP Repetitive Manufacturing With Reporting Point BackflushDokument12 SeitenSAP Repetitive Manufacturing With Reporting Point BackflushDevidas Karad100% (1)

- Information Systems: Dr. Sobhan SarkarDokument23 SeitenInformation Systems: Dr. Sobhan SarkarcbssNoch keine Bewertungen

- Chapter 1 - Operations and ProductivityDokument2 SeitenChapter 1 - Operations and ProductivitykaboomkapowNoch keine Bewertungen

- Interchangeability in SAP PDFDokument40 SeitenInterchangeability in SAP PDFmohameds1988Noch keine Bewertungen

- Sap MRP 2 ViewDokument13 SeitenSap MRP 2 ViewLannie PFNoch keine Bewertungen

- ProdPlan OverviewDokument40 SeitenProdPlan OverviewDaut PoloNoch keine Bewertungen

- Material Requirement PlanningDokument14 SeitenMaterial Requirement PlanningPaul Tello RojasNoch keine Bewertungen

- MAPICS TrainingMLMDokument3 SeitenMAPICS TrainingMLMVenkatasubramanian SivagnanasundaramNoch keine Bewertungen

- MRPDokument134 SeitenMRPpersonalmail_20011078Noch keine Bewertungen

- Man QB2Dokument50 SeitenMan QB2Madhavi SonawaneNoch keine Bewertungen

- SAP PP MRP Manual For Newbies PDFDokument97 SeitenSAP PP MRP Manual For Newbies PDFmehrezNoch keine Bewertungen

- Advanced Operations ManagementDokument2 SeitenAdvanced Operations ManagementF JNoch keine Bewertungen