Beruflich Dokumente

Kultur Dokumente

WC-477 - Gas Metal Arc Welding (GMAW) Modes of Transfer PDF

Hochgeladen von

NathanLaertePiaiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

WC-477 - Gas Metal Arc Welding (GMAW) Modes of Transfer PDF

Hochgeladen von

NathanLaertePiaiCopyright:

Verfügbare Formate

Gas Metal Arc Welding (GMAW)

MODES OF TRANSFER

SHORT CIRCUIT TRANSFER GLOBULAR TRANSFER

Operating Range for Steel Shielding Gases Used Operating Range for Steel Shielding Gases Used

3/8 to 1/2 in.

»» Low Voltages and (16V to 22V) »» 100% CO2 »» High Voltages and (25V to 35V) »» 100% CO2 (most common)

»» Low Amperages (30A to 200A) »» 75% Ar 25% CO2 Gas Mix »» High Amperages (200A to 500A) »» 75% Ar 25% CO2 Gas Mix

Wire Electrode Size Wire Electrode Size

»» Smaller Diameters »» Larger Diameters

(0.025 - 0.045 in.) (0.035 in. and Larger)

(0.60 - 1.10 mm) (0.89 mm and Larger)

GMAW Advantages

»» A wide range of materials can be welded

»» Faster than SMAW welding

»» Relatively inexpensive for home use

3/8 to 1/2 in. 1/2 to 1 in.

»» No slag

»» Good for poor fit-up and gaps

PULSED SPRAY TRANSFER SPRAY TRANSFER GMAW Mode of

Operating Range for Steel

»» High Voltages and (25V to 35V)

Shielding Gases Used

»» Gas mixtures with over 80% Argon

Operating Range for Steel

»» High Voltages and (25V to 35V)

Shielding Gases Used

»» Gas mixtures with over 80% Argon

Transfer Selector

3/8 to 1/2 in. 3/8 to 1/2 in.

»» Two Amperage Levels - peak »» 90% Ar with 10% CO2 »» High Amperages (200A to 500A) »» 90% Ar with 10% CO2

and background (200A to 500A) Wire Electrode Size

1/2 to 1 in.

Wire Electrode Size »» Smaller Diameters

»» Smaller Diameters (0.035 in. and Larger)

(0.035 in. and Larger) (0.89 mm and Larger)

(0.89 mm and Larger)

1/2 to 1 in. 1/2 to 1 in.

WC-477 08/15 ©Lincoln Global, Inc. All Rights Reserved.

Das könnte Ihnen auch gefallen

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceVon EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceNoch keine Bewertungen

- WC-477 - Gas Metal Arc Welding (GMAW) Modes of Transfer PDFDokument1 SeiteWC-477 - Gas Metal Arc Welding (GMAW) Modes of Transfer PDFNathanLaertePiaiNoch keine Bewertungen

- WPS 작성 (영)Dokument24 SeitenWPS 작성 (영)hunghoanglongNoch keine Bewertungen

- Convexity Aws PDFDokument4 SeitenConvexity Aws PDFHJ SJNoch keine Bewertungen

- Index AwsDokument1 SeiteIndex AwsRaul2307Noch keine Bewertungen

- Effect of Heat Input On Microstructure and Mechanical Properties of The TIG Welded Joints of AISI 304Dokument10 SeitenEffect of Heat Input On Microstructure and Mechanical Properties of The TIG Welded Joints of AISI 304Kaushik SenguptaNoch keine Bewertungen

- Application Notes Welding (English)Dokument8 SeitenApplication Notes Welding (English)metallurgist100% (6)

- Weld AbilityDokument34 SeitenWeld AbilityGauthamSarangNoch keine Bewertungen

- Metric Practices for Welding InspectionDokument39 SeitenMetric Practices for Welding InspectionNDTInstructor100% (1)

- Murex Oxy Welding Poster 2008 PDFDokument1 SeiteMurex Oxy Welding Poster 2008 PDFPCNoch keine Bewertungen

- WC-482 - Parts of A Weld PDFDokument1 SeiteWC-482 - Parts of A Weld PDFNathanLaertePiaiNoch keine Bewertungen

- CMT Welding Research PaperDokument23 SeitenCMT Welding Research PaperUpendra93Noch keine Bewertungen

- Welding Processes GuideDokument27 SeitenWelding Processes Guidesuri345Noch keine Bewertungen

- Introduction To GMAWDokument63 SeitenIntroduction To GMAWRumman Ul AhsanNoch keine Bewertungen

- Miller - Joint Design and Weld TypeDokument8 SeitenMiller - Joint Design and Weld Typed_beachboyzNoch keine Bewertungen

- TIG Welding Process GuideDokument20 SeitenTIG Welding Process GuideEnache DaniNoch keine Bewertungen

- Gen - Importance of Welding in L & T PDFDokument30 SeitenGen - Importance of Welding in L & T PDFSivaNoch keine Bewertungen

- CWB Acboa April 2008Dokument29 SeitenCWB Acboa April 2008bountymaniNoch keine Bewertungen

- Visual inspection of welds essential first stepDokument1 SeiteVisual inspection of welds essential first stepfallalovaldes100% (1)

- Strips and Fluxes for Electroslag and Submerged Arc WeldingDokument0 SeitenStrips and Fluxes for Electroslag and Submerged Arc WeldingCarlos Bermejo AlvarezNoch keine Bewertungen

- Guidelines for Optimal Tube Expansion in BoilersDokument1 SeiteGuidelines for Optimal Tube Expansion in Boilersmicheld1964Noch keine Bewertungen

- 03-Symbols Mock ExamDokument5 Seiten03-Symbols Mock ExamCRISTIAN SILVIU IANUC100% (1)

- Aws Cwi BrochureDokument16 SeitenAws Cwi BrochureMS SIVAKUMARNoch keine Bewertungen

- In-Situ MetallographyDokument7 SeitenIn-Situ Metallographyhatem jafouraNoch keine Bewertungen

- Effect of Different Metalurgical Phases On The Welding Residual Stresses of Base MetalDokument71 SeitenEffect of Different Metalurgical Phases On The Welding Residual Stresses of Base Metalsalmanzafar_37304938Noch keine Bewertungen

- Welding Consumable GuideDokument26 SeitenWelding Consumable Guidebrianpham007100% (1)

- Welding SymbolsDokument78 SeitenWelding Symbolsuttamtm100% (1)

- Module 12 - Design & Construction - Rev 5 - May 15Dokument107 SeitenModule 12 - Design & Construction - Rev 5 - May 15sskiitb100% (1)

- Projection Welding Guide for Materials & DesignDokument20 SeitenProjection Welding Guide for Materials & DesignCebrac ItatibaNoch keine Bewertungen

- CWB CredentialsDokument14 SeitenCWB Credentialsranjith_022Noch keine Bewertungen

- WC-475 - Weld Joints, Sections, Symbols PDFDokument1 SeiteWC-475 - Weld Joints, Sections, Symbols PDFNathanLaertePiaiNoch keine Bewertungen

- Module 1Dokument30 SeitenModule 1mahmoud aliNoch keine Bewertungen

- Course: Materials TechnologyDokument60 SeitenCourse: Materials TechnologyelvisNoch keine Bewertungen

- API 1104 welding defect criteriaDokument1 SeiteAPI 1104 welding defect criteriaravigurajapuNoch keine Bewertungen

- Weld Cladding Overlay - Topics by ScienceDokument73 SeitenWeld Cladding Overlay - Topics by ScienceMichael TayactacNoch keine Bewertungen

- ASME 9 Multi Process Welding Procedures QW200Dokument2 SeitenASME 9 Multi Process Welding Procedures QW200Teodor EzaruNoch keine Bewertungen

- WIS5 Mechanical Testing - 03Dokument57 SeitenWIS5 Mechanical Testing - 03Sầu ĐờiNoch keine Bewertungen

- Welding Inspection Technology Module 3Dokument8 SeitenWelding Inspection Technology Module 3Shaheed MohammedNoch keine Bewertungen

- Weld Defects 2Dokument122 SeitenWeld Defects 2Pradeep Kumar Raju B100% (1)

- Twi Hardness TestingDokument8 SeitenTwi Hardness TestingchungndtNoch keine Bewertungen

- And Solutions: Welding Problems and Defects - CausesDokument1 SeiteAnd Solutions: Welding Problems and Defects - CausesAli Osman YaşarNoch keine Bewertungen

- WTDokument299 SeitenWTrsarunprasathNoch keine Bewertungen

- Weldability of Steel PDFDokument5 SeitenWeldability of Steel PDFVC100% (3)

- ASTM Welding Tips A410 To A643Dokument20 SeitenASTM Welding Tips A410 To A643MARIO HUAMANNoch keine Bewertungen

- Design - Part 4 - Job Knowledge 93Dokument4 SeitenDesign - Part 4 - Job Knowledge 93Billy TanNoch keine Bewertungen

- Failure Analysis of Friction Weld (FRW) in Truck Axle ApplicationDokument4 SeitenFailure Analysis of Friction Weld (FRW) in Truck Axle ApplicationVivekintenseCmNoch keine Bewertungen

- 25 Macro Micro ExaminationDokument14 Seiten25 Macro Micro ExaminationAdhanom G.100% (1)

- CSWIP 3.1-2010 The Welding Inspection of SteelDokument317 SeitenCSWIP 3.1-2010 The Welding Inspection of Steelapply19842371100% (1)

- GMAW Transfer Modes GuideDokument1 SeiteGMAW Transfer Modes GuideNathanLaertePiai100% (1)

- WC477Dokument1 SeiteWC477RodrigoNoch keine Bewertungen

- Indian Institute of Welding Refresher Course Module on GMAW and FCAW ProcessesDokument47 SeitenIndian Institute of Welding Refresher Course Module on GMAW and FCAW ProcessesdayalramNoch keine Bewertungen

- Ultracore 360 M81: Conformances Key FeaturesDokument3 SeitenUltracore 360 M81: Conformances Key FeaturesDaniel Lvqve GarciaNoch keine Bewertungen

- 25 35 4CNbDokument1 Seite25 35 4CNbRomy MiftachNoch keine Bewertungen

- Lasting Connections for Demanding WeldsDokument2 SeitenLasting Connections for Demanding WeldsKara WhiteNoch keine Bewertungen

- Diamondspark Pipeline Cored Wires: FCAW and MCAW Seamless Welding Wires For Pipeline ApplicationsDokument2 SeitenDiamondspark Pipeline Cored Wires: FCAW and MCAW Seamless Welding Wires For Pipeline ApplicationsRMNoch keine Bewertungen

- WallthicknessDokument1 SeiteWallthicknessGabriela MotaNoch keine Bewertungen

- Primacore MW 71Dokument2 SeitenPrimacore MW 71rjan7peNoch keine Bewertungen

- Pipeliner 70S-G: Conformances Key FeaturesDokument2 SeitenPipeliner 70S-G: Conformances Key FeaturesZanuardi YahyaNoch keine Bewertungen

- WC-550 - Learn To Weld PDFDokument1 SeiteWC-550 - Learn To Weld PDFNathanLaertePiaiNoch keine Bewertungen

- Crack WeldDokument1 SeiteCrack WeldJanice VaflorNoch keine Bewertungen

- WC-474 - Welding Positions Groove & Fillet Welds PDFDokument1 SeiteWC-474 - Welding Positions Groove & Fillet Welds PDFNathanLaertePiaiNoch keine Bewertungen

- WC-550 - Learn To Weld PDFDokument1 SeiteWC-550 - Learn To Weld PDFNathanLaertePiaiNoch keine Bewertungen

- WC-482 - Parts of A Weld PDFDokument1 SeiteWC-482 - Parts of A Weld PDFNathanLaertePiaiNoch keine Bewertungen

- Crack WeldDokument1 SeiteCrack WeldJanice VaflorNoch keine Bewertungen

- WC-514 - Weld Discontinuities PDFDokument1 SeiteWC-514 - Weld Discontinuities PDFNathanLaertePiaiNoch keine Bewertungen

- WC-478 - Effects of Welding Variables PDFDokument1 SeiteWC-478 - Effects of Welding Variables PDFNathanLaertePiaiNoch keine Bewertungen

- WC-475 - Weld Joints, Sections, Symbols PDFDokument1 SeiteWC-475 - Weld Joints, Sections, Symbols PDFNathanLaertePiaiNoch keine Bewertungen

- GMAW Transfer Modes GuideDokument1 SeiteGMAW Transfer Modes GuideNathanLaertePiai100% (1)

- WC-473 - Welding Positions For Pipes Poster PDFDokument1 SeiteWC-473 - Welding Positions For Pipes Poster PDFNathanLaertePiaiNoch keine Bewertungen

- WC-478 - Effects of Welding Variables PDFDokument1 SeiteWC-478 - Effects of Welding Variables PDFNathanLaertePiaiNoch keine Bewertungen

- WC-514 - Weld Discontinuities PDFDokument1 SeiteWC-514 - Weld Discontinuities PDFNathanLaertePiaiNoch keine Bewertungen

- WC-474 - Welding Positions Groove & Fillet Welds PDFDokument1 SeiteWC-474 - Welding Positions Groove & Fillet Welds PDFNathanLaertePiaiNoch keine Bewertungen

- WC-475 - Weld Joints, Sections, Symbols PDFDokument1 SeiteWC-475 - Weld Joints, Sections, Symbols PDFNathanLaertePiaiNoch keine Bewertungen

- WC-473 - Welding Positions For Pipes Poster PDFDokument1 SeiteWC-473 - Welding Positions For Pipes Poster PDFNathanLaertePiai100% (3)

- WC-482 - Parts of A Weld PDFDokument1 SeiteWC-482 - Parts of A Weld PDFNathanLaertePiaiNoch keine Bewertungen

- MC-13111 - Alloy Poster PDFDokument1 SeiteMC-13111 - Alloy Poster PDFNathanLaertePiaiNoch keine Bewertungen

- MC-10146 - Automation Selection Guide Poster PDFDokument2 SeitenMC-10146 - Automation Selection Guide Poster PDFNathanLaertePiaiNoch keine Bewertungen

- MC-1267 - Are You Ready For... New GHS Guidelines PDFDokument1 SeiteMC-1267 - Are You Ready For... New GHS Guidelines PDFNathanLaertePiai100% (1)

- MC-04211 - Welding Career Path Tree PDFDokument1 SeiteMC-04211 - Welding Career Path Tree PDFNathanLaertePiaiNoch keine Bewertungen

- ARC WELDING Safely PDFDokument2 SeitenARC WELDING Safely PDFdannywdcgmailNoch keine Bewertungen

- MC-1484 - BUILT FOR THE WAY YOU WELD. Excalibur 7018 MR PDFDokument1 SeiteMC-1484 - BUILT FOR THE WAY YOU WELD. Excalibur 7018 MR PDFNathanLaertePiaiNoch keine Bewertungen

- MC-1204 - Weld Fume Control System Selection Guide PDFDokument2 SeitenMC-1204 - Weld Fume Control System Selection Guide PDFNathanLaertePiaiNoch keine Bewertungen

- Gantt ChartDokument6 SeitenGantt ChartNathanLaertePiaiNoch keine Bewertungen

- MC-1429 - Viking Welding Helmet Poster PDFDokument2 SeitenMC-1429 - Viking Welding Helmet Poster PDFNathanLaertePiaiNoch keine Bewertungen

- MC-1429 - Viking Welding Helmet Poster PDFDokument2 SeitenMC-1429 - Viking Welding Helmet Poster PDFNathanLaertePiaiNoch keine Bewertungen

- ARC WELDING Safely PDFDokument2 SeitenARC WELDING Safely PDFdannywdcgmailNoch keine Bewertungen

- Pub 83 Al Bronze Alloys For Industry PDFDokument24 SeitenPub 83 Al Bronze Alloys For Industry PDFpbanerjeeNoch keine Bewertungen

- OA Cutting and WeldingDokument24 SeitenOA Cutting and WeldingJames Hale0% (1)

- SMAW NC I Safety ModuleDokument30 SeitenSMAW NC I Safety ModuleCelso Amoto100% (1)

- EPP-360 Plasma Power Source 0558007676Dokument46 SeitenEPP-360 Plasma Power Source 0558007676martin_jaitmanNoch keine Bewertungen

- 8 Tips MIG Welding BeginnersDokument7 Seiten8 Tips MIG Welding BeginnerspeterNoch keine Bewertungen

- ISO 9692 3 2002 Joint PreparationDokument16 SeitenISO 9692 3 2002 Joint PreparationLHYT NTUANoch keine Bewertungen

- Hot-Dip Zn-5% Al Alloy-Coated Steel Sheets "Jfe Ecogal®": AbstractDokument5 SeitenHot-Dip Zn-5% Al Alloy-Coated Steel Sheets "Jfe Ecogal®": AbstractVijay SharmaNoch keine Bewertungen

- RTFI Assessment Presentation 5-23-05Dokument185 SeitenRTFI Assessment Presentation 5-23-05shaban100% (5)

- 2 Terms and Definitions SectionDokument12 Seiten2 Terms and Definitions SectionJawed AkhterNoch keine Bewertungen

- Aws Eg2.0 - 2006 Guide For Training For Welding PersonnelDokument161 SeitenAws Eg2.0 - 2006 Guide For Training For Welding PersonnelRoberto SlataperNoch keine Bewertungen

- Acceptance Creiteria Asme IiiDokument5 SeitenAcceptance Creiteria Asme Iiimostafa aliNoch keine Bewertungen

- AWS B2 1 1 004 2013 SWPS GMAW ShortDokument22 SeitenAWS B2 1 1 004 2013 SWPS GMAW Shortreza acbariNoch keine Bewertungen

- Handbook MetrodeDokument371 SeitenHandbook Metrodejf2587Noch keine Bewertungen

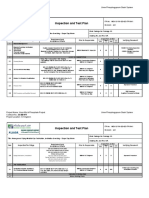

- R057-Ac-It-002 (C) - Inspection and Test Plan For Pipe SpoolDokument16 SeitenR057-Ac-It-002 (C) - Inspection and Test Plan For Pipe SpooldharwinNoch keine Bewertungen

- ITP-3041 For PipeDokument8 SeitenITP-3041 For PipeSkinhead TvNoch keine Bewertungen

- ULTERSONIC CLEANING MACHINE MANUFACTURERS-Microsupersonic Ultrasonic Cleaning MachineDokument23 SeitenULTERSONIC CLEANING MACHINE MANUFACTURERS-Microsupersonic Ultrasonic Cleaning MachineChetan GoudaNoch keine Bewertungen

- To Heat Treatment of Welded Structures and Technical Data: CooperheatDokument11 SeitenTo Heat Treatment of Welded Structures and Technical Data: Cooperheatsnipertomb100% (9)

- Handout 1Dokument11 SeitenHandout 1Adefris FikireNoch keine Bewertungen

- Astm E340 2015 PDFDokument11 SeitenAstm E340 2015 PDFnantha kumar100% (1)

- Eaton Eaton Basket Screen DataDokument2 SeitenEaton Eaton Basket Screen Dataadalcayde2514Noch keine Bewertungen

- QCF312 WPQRDokument2 SeitenQCF312 WPQRminhnnNoch keine Bewertungen

- Trafo Las, Mesin Las, Kompressor Dan SandblastingDokument10 SeitenTrafo Las, Mesin Las, Kompressor Dan SandblastingCv RONATAMA GUSLHANNoch keine Bewertungen

- Mig/Mag: Product Catalogue 3.1 / V1Dokument48 SeitenMig/Mag: Product Catalogue 3.1 / V1Matija BušićNoch keine Bewertungen

- Weld OverlayDokument4 SeitenWeld OverlayInfoNoch keine Bewertungen

- SAIC-W-2081 Receiving Inspection of Welding Consumables (EE)Dokument2 SeitenSAIC-W-2081 Receiving Inspection of Welding Consumables (EE)karioke mohaNoch keine Bewertungen

- B2.1 8 025 2001PVDokument4 SeitenB2.1 8 025 2001PVJaimeNoch keine Bewertungen

- Method Statement & Risk Assessment For Hot Works WeldingDokument4 SeitenMethod Statement & Risk Assessment For Hot Works Weldingchandanprakash30100% (1)

- Welding CalculatorDokument18 SeitenWelding CalculatorKhamdi AfandiNoch keine Bewertungen

- Steel Plates For Offshore StructuresDokument8 SeitenSteel Plates For Offshore StructuresYiengeChanYeeNoch keine Bewertungen

- Design of Structural MembersDokument153 SeitenDesign of Structural Membersquiron20100% (1)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeVon EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Stuff Matters: Exploring the Marvelous Materials That Shape Our Man-Made WorldVon EverandStuff Matters: Exploring the Marvelous Materials That Shape Our Man-Made WorldBewertung: 4 von 5 Sternen4/5 (289)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeVon EverandChemistry for Breakfast: The Amazing Science of Everyday LifeBewertung: 4.5 von 5 Sternen4.5/5 (14)

- Guidelines for Asset Integrity ManagementVon EverandGuidelines for Asset Integrity ManagementBewertung: 5 von 5 Sternen5/5 (1)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction in the Science of Everyday LifeVon EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction in the Science of Everyday LifeBewertung: 4 von 5 Sternen4/5 (9)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsVon EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsBewertung: 4 von 5 Sternen4/5 (146)

- Science Goes Viral: Captivating Accounts of Science in Everyday LifeVon EverandScience Goes Viral: Captivating Accounts of Science in Everyday LifeBewertung: 5 von 5 Sternen5/5 (1)

- Coating and Drying Defects: Troubleshooting Operating ProblemsVon EverandCoating and Drying Defects: Troubleshooting Operating ProblemsBewertung: 5 von 5 Sternen5/5 (1)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolVon EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolNoch keine Bewertungen

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksVon EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksBewertung: 5 von 5 Sternen5/5 (1)

- Guidelines for Defining Process Safety Competency RequirementsVon EverandGuidelines for Defining Process Safety Competency RequirementsBewertung: 3 von 5 Sternen3/5 (1)

- Napoleon's Buttons: 17 Molecules That Changed HistoryVon EverandNapoleon's Buttons: 17 Molecules That Changed HistoryBewertung: 4 von 5 Sternen4/5 (25)

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsVon EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsBewertung: 5 von 5 Sternen5/5 (3)

- Essential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilVon EverandEssential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilBewertung: 5 von 5 Sternen5/5 (1)

- It's Elemental: The Hidden Chemistry in EverythingVon EverandIt's Elemental: The Hidden Chemistry in EverythingBewertung: 4 von 5 Sternen4/5 (10)

- Meltdown: Nuclear disaster and the human cost of going criticalVon EverandMeltdown: Nuclear disaster and the human cost of going criticalBewertung: 5 von 5 Sternen5/5 (5)

- Chemical Elements Pocket Guide: Detailed Summary of the Periodic TableVon EverandChemical Elements Pocket Guide: Detailed Summary of the Periodic TableNoch keine Bewertungen

- Chemistry: a QuickStudy Laminated Reference GuideVon EverandChemistry: a QuickStudy Laminated Reference GuideBewertung: 5 von 5 Sternen5/5 (1)

- The Periodic Table: A Very Short IntroductionVon EverandThe Periodic Table: A Very Short IntroductionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincVon EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincBewertung: 3.5 von 5 Sternen3.5/5 (150)

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableVon EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableBewertung: 3.5 von 5 Sternen3.5/5 (22)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeVon EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeBewertung: 4 von 5 Sternen4/5 (1)